Synthesis method for metal organic framework material MIL-53 (Al)

A technology of MIL-53 and metal organic framework, which is applied in the field of synthesis of metal organic framework material MIL-53, can solve the problems that are not suitable for industrial production and restrict large-scale industrial synthesis, and achieve the effect of improving service life and utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

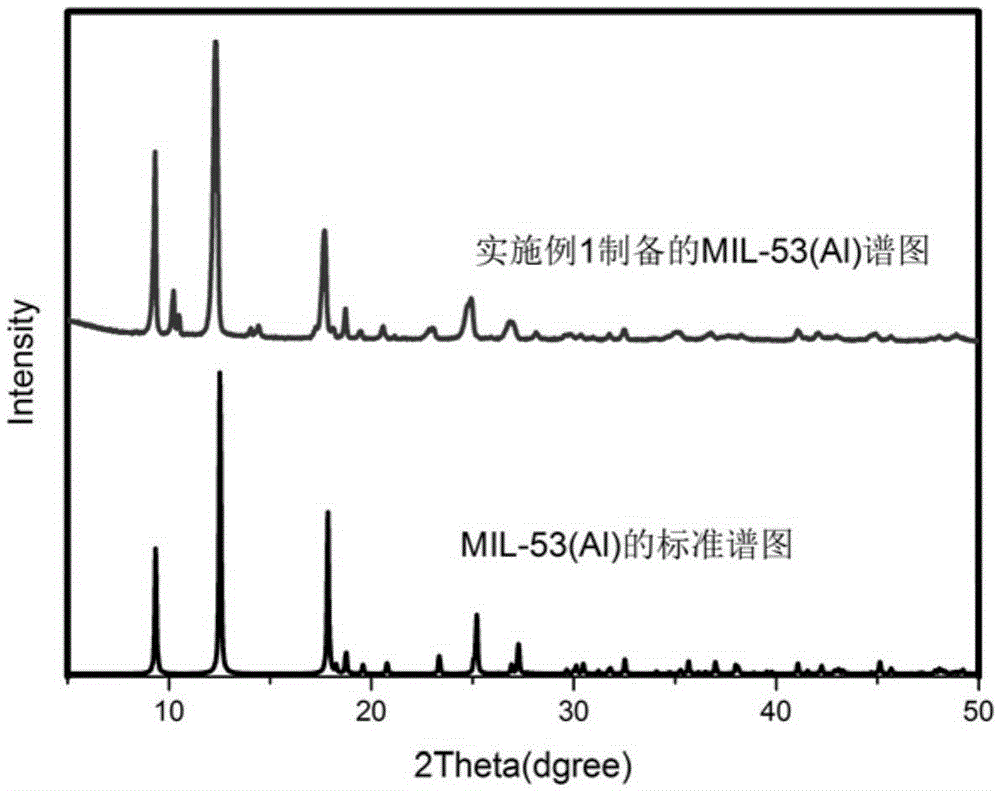

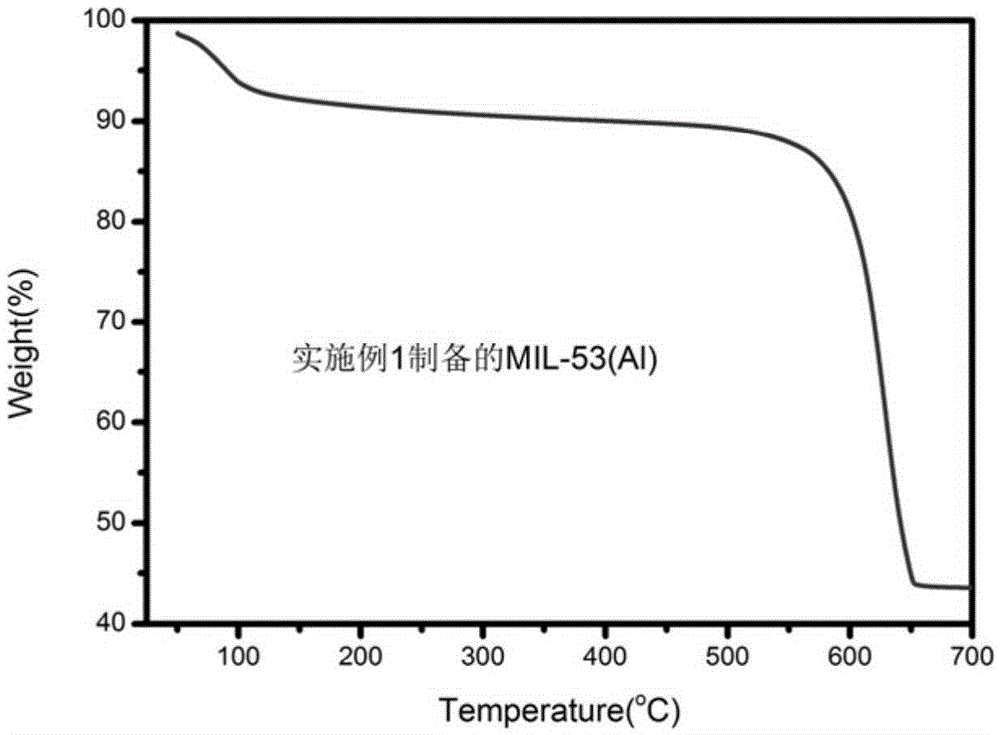

Embodiment 1

[0032] The molar ratio of aluminum hydroxide, terephthalic acid, formic acid and water used in this example is 1:1:1:160.

[0033] A kind of synthetic method of metal organic framework material MIL-53 (Al), this method comprises the steps:

[0034] (1) Mix aluminum hydroxide, terephthalic acid and water and stir thoroughly to disperse the aluminum-containing compound and organic carboxylic acid evenly in pure water; add formic acid to the above reactant solution and stir well, then move it into a stainless steel reaction kettle for Hydrothermal synthesis, the reaction temperature is 150°C, the reaction time is 72h, stop heating and cool to room temperature, and the solid obtained by solid-liquid separation is the crude product, which is placed in an oven at 80°C to dry;

[0035] (2) Put the crude product obtained in step (1) into a high-temperature furnace for calcination in an air atmosphere at a calcination temperature of 330° C. for a calcination time of 72 hours, and cool ...

Embodiment 2

[0039] The molar ratio of aluminum hydroxide, terephthalic acid, formic acid and water used in this example is 1:1:1:160.

[0040] A kind of synthetic method of metal organic framework material MIL-53 (Al), this method comprises the steps:

[0041] (1) Mix aluminum hydroxide, terephthalic acid and water and stir thoroughly to disperse the aluminum-containing compound and organic carboxylic acid evenly in pure water; add formic acid to the above reactant solution and stir well, then move it into a stainless steel reaction kettle for Hydrothermal synthesis, reaction temperature 150°C, reaction time 72h, solid-liquid separation after cooling to room temperature to obtain the crude product; the obtained crude product was activated under hydrothermal conditions at 150°C for 24 hours and then dried in an oven at 80°C;

[0042] (2) Put the product obtained in step (1) into a high-temperature furnace for calcination in an air atmosphere at a calcination temperature of 330° C. for a ca...

Embodiment 3

[0045] A synthetic method of metal-organic framework material MIL-53 (Al), which is basically the same as in Example 1, except that the molar ratio of aluminum hydroxide, terephthalic acid, formic acid and water used in this example is 0.5 :1:0.5:150. The method has simple process, moderate cost, relatively low synthesis temperature and reaction pressure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com