A preparation method of a special auxiliary agent for improving the mechanical properties of polybutene-1 in the initial stage of molding and the application of the special auxiliary agent

A technology of polybutene and additives, which is applied in the field of polymer materials, can solve the problems of substantive integration, failure to achieve, and the advent of special additives for polybutene-1, etc., to achieve improvement Resource utilization efficiency, promoting improvement, and enhancing the effect of mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

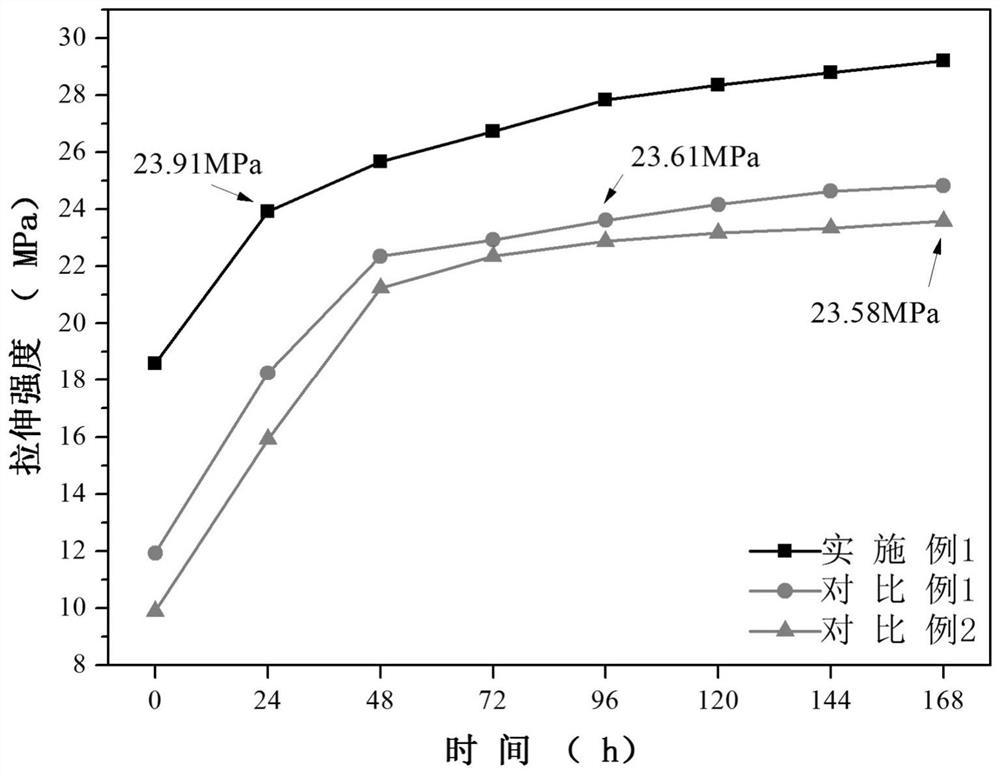

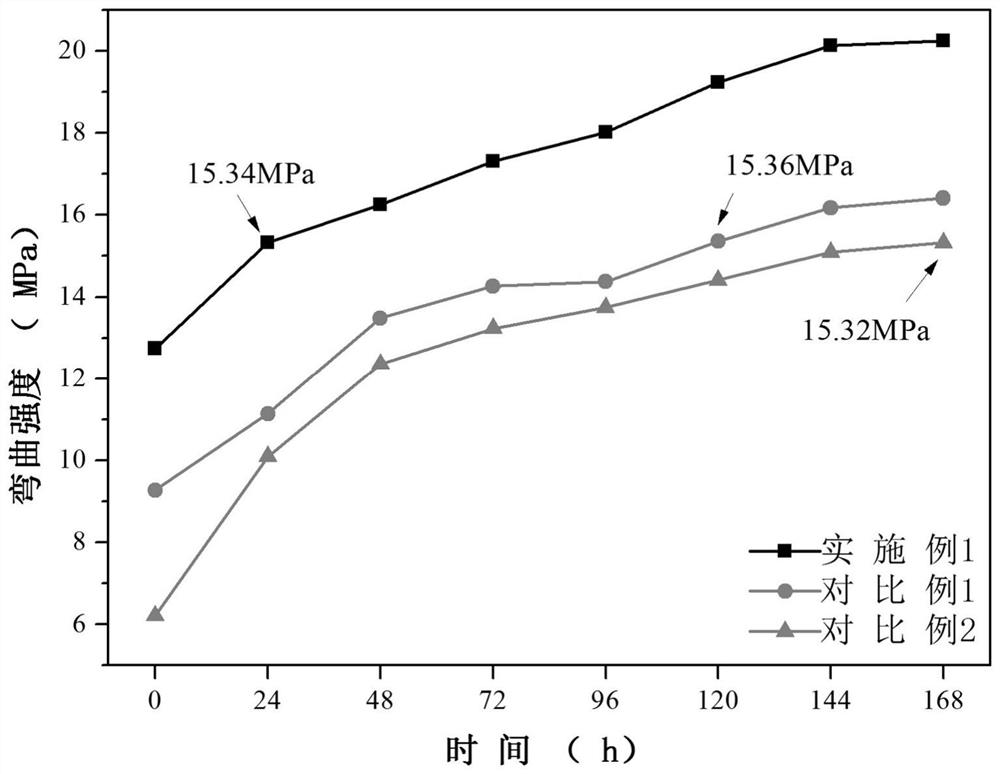

[0029] The hydroxy aryl phosphate powder 5g solid aluminum was placed 250mL N, N- dimethyl formamide and heated to 130. deg.] C, stirred for 1h dissolved completely. Then, the particle diameter of 20μm 1g bacterial cellulose powder was added to the above mixture, the mixture was slowly added dropwise 20mL succinic anhydride. After the dropwise addition, reaction was stirred for 6 hours. The mixture was suction-filtered after the completion of the reaction substance, a large amount of hot methanol and then repeatedly washed 10 times, and the resulting white powder was dried at 80 ℃. The above-described special additives and 1g 1000g polybutene-mixed in a high speed mixer, after extrusion, pelletizing, injection molding and other molding step. At 24 hour intervals, the tensile and impact properties of the material according to the method of 9341-2008 GB / T 1040-2006 and GB / T. See specific data figure 1 , figure 2 Indicated.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com