Process for synthesizing silicane coupling agent KII 560 at low temp.

A silane coupling agent, KH-560 technology, applied in chemical instruments and methods, compounds of group 4/14 elements of the periodic table, organic chemistry, etc., can solve the problem that the product content cannot be greatly increased, and the total yield is only 72.91 %, does not comply with clean production and other issues, and achieves the effects of reducing production costs, improving purity and yield, and improving catalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

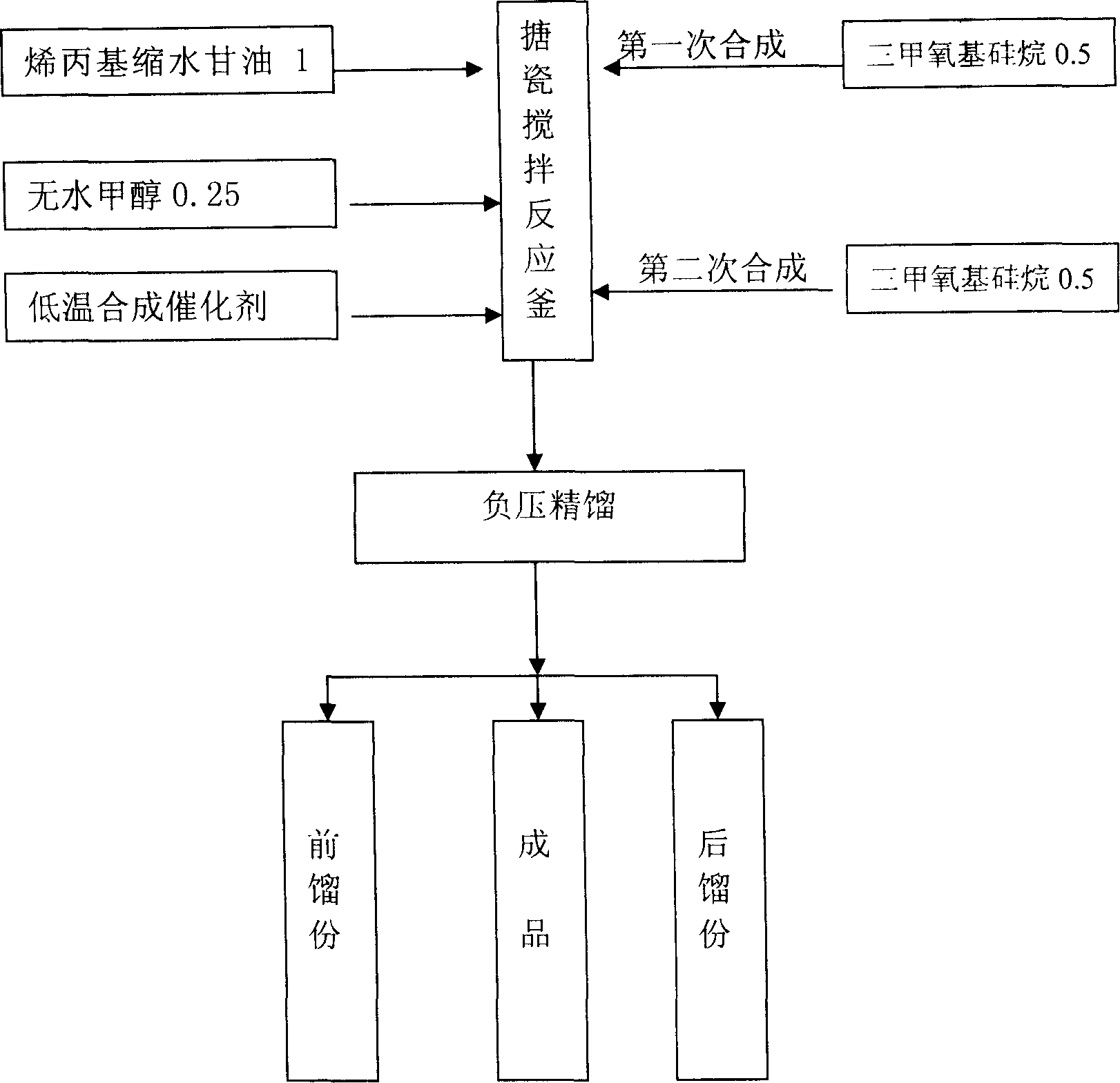

Method used

Image

Examples

specific Embodiment approach

[0009] Equipment used in the present invention: 300L polypropylene metering tank; 500L enamel stirring reactor; 3m 3 Enamel chip condenser; flushing vacuum pump; 500L stainless steel still; 4m 3 Stainless steel condenser; stainless steel receiving kettle.

[0010] Preparation of low-temperature synthesis catalyst: 1 gram of chloroplatinic acid, 60 milliliters of isopropanol, and 0.3 gram of acetylacetone were used to prepare a chloroplatinic acid alcohol solution.

[0011] Preparation and synthesis method:

[0012] The first step: add allyl glycidyl ether and anhydrous methanol to the 500L enamel stirred reactor, and the two are matched according to the weight ratio of 1:0.25, that is, add 200kg allyl glycidol to the 500L enamel stirred reactor Ether and 50kg of anhydrous methanol, and then add an appropriate amount of low-temperature synthesis catalyst chloroplatinic acid alcohol solution, when the temperature in the stirred reactor rises from 30°C to 65°C, keep it for half...

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com