Preparation method of chromium carbide/carbon nano composite material with mesoporous structure

A composite material and mesoporous structure technology, which is used in the production field of chromium carbide/carbon nanocomposite materials, can solve the problems of low catalytic activity, etc., and achieve the effects of high reaction activity, lower synthesis reaction temperature, and increase reaction speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

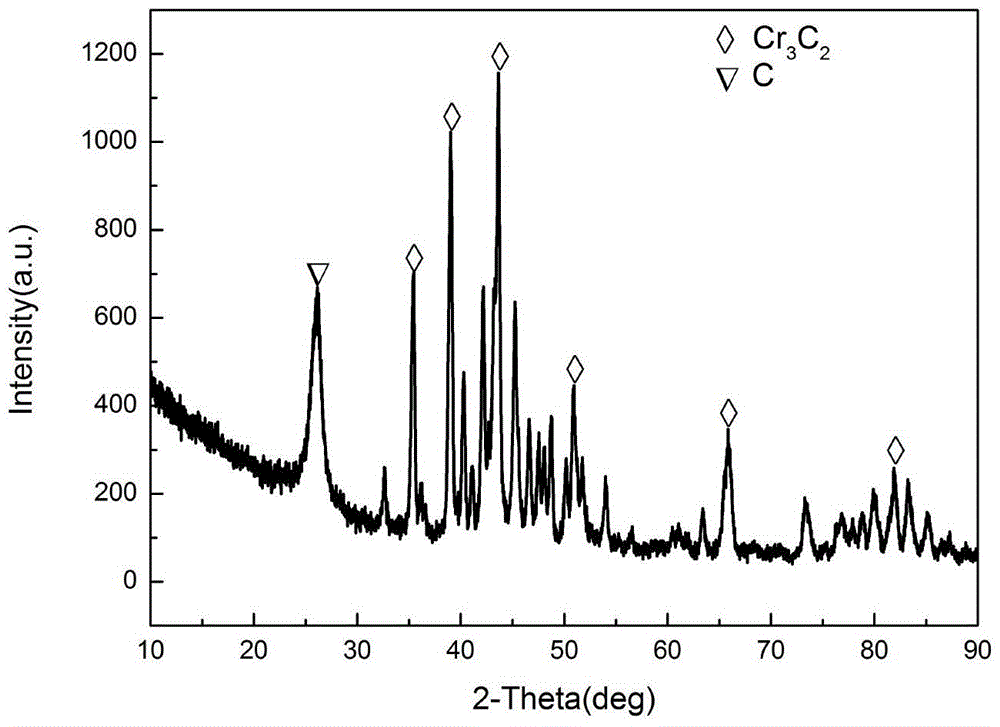

Image

Examples

Embodiment 1

[0015] Weigh 0.025 moles of chromium nitrate, 0.025 moles of glycine and 0.0375 moles of carbon source, dissolve various raw materials in deionized water to prepare a mixed solution, and place the solution on a temperature-controlled electric furnace for heating. After the solution undergoes a series of reactions such as volatilization, concentration and decomposition, a precursor powder is obtained, and the precursor powder is reacted at 900° C. under an argon atmosphere for 2 hours to obtain a chromium carbide / carbon nanocomposite material.

Embodiment 2

[0017] Weigh 0.025 moles of chromium chloride, 0.15 moles of glycine, 0.1 moles of carbon source, and 0.025 moles of ammonium nitrate, dissolve various raw materials in deionized water to prepare a mixed solution, and place the solution on a temperature-controlled electric furnace for heating. After the solution undergoes a series of reactions such as volatilization, concentration and decomposition, a precursor powder is obtained, and the precursor powder is reacted at 1000° C. under an argon atmosphere for 1 hour to obtain a chromium carbide / carbon nanocomposite material.

Embodiment 3

[0019] Weigh 0.025 moles of chromium sulfate, 0.125 moles of glycine, 0.0375 moles of carbon source, and 0.15 moles of ammonium nitrate, dissolve them in distilled water to prepare a solution, and place the solution on a temperature-controlled electric furnace for heating. The solution reacts after a series of processes such as volatilization, concentration and decomposition to obtain a precursor powder. The precursor powder is reacted in a furnace at 900° C. under a nitrogen atmosphere for 1.5 hours to obtain a chromium carbide / carbon nanocomposite material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com