Process for producing cubic crystal antimony white from low-grade complex lead-antimony polymetallic ores

A polymetallic ore and cubic crystal technology, which is applied in the field of hydrometallurgy to achieve the effects of reducing waste discharge, protecting the ecological environment and improving resource utilization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

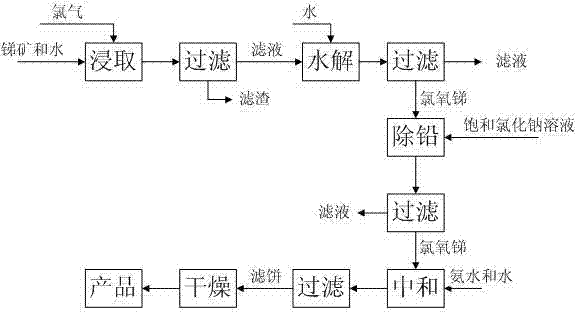

Image

Examples

example 1

[0011] Example 1: Weigh 100Kg of 150-mesh low-grade lead-antimony complex polymetallic ore powder (containing 14.56% antimony) and put it directly into the reactor, add 300kg of water to stir, and feed 19Kg of chlorine gas to the bottom of the reactor. The flow rate is first fast and then slow, and the temperature Control it above 90°C, react for 3.5 hours, lower the temperature below 50°C and filter with a plate and frame filter press, the reaction equation of the leaching process:

[0012] Sb 2 S 3 +3Cl 2 =2SbCl 3 +3S

[0013] SbCl 3 +Cl 2 =SbCl 5

[0014] 3SbCl 5 +Sb 2 S 3 =5SbCl 3 +3S

[0015] The leaching slag was treated separately, and 350L of the leaching solution was obtained and put into an enamel reaction kettle for stirring. At room temperature, 5 times the amount of water of the leaching solution was added for hydrolysis, and the hydrolysis time was 2 hours. Add 1.5 times the weight of saturated sodium chloride solution to the weight of oxyantimony, s...

example 2

[0022] Example 2. Weigh 100Kg of 200-mesh low-grade lead-antimony complex polymetallic ore powder (containing 10.58% antimony) and put it directly into the reactor, add 500kg of water to stir, and feed 14Kg of chlorine gas to the bottom of the reactor. The flow rate is first fast and then slow, and the temperature Control the temperature above 90°C, react for 4.5 hours, lower the temperature to below 50°C and filter with a plate and frame filter press, and the reaction equation of the leaching process is the same as in Example 1.

[0023] The leaching slag was treated separately, and 510L of the leaching solution was obtained, which was stirred in an enamel reaction kettle. At room temperature, 9 times the weight of the leaching solution was added for hydrolysis, and the hydrolysis time was 0.5h. Add 3 times the weight of saturated sodium chloride solution to the weight of antimony oxychloride, stir and soak for 6 hours to remove lead, separate by pressure filtration, and then ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com