Patents

Literature

41 results about "Antimony pentafluoride" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

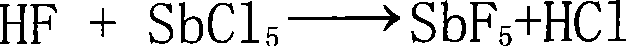

Antimony pentafluoride is the inorganic compound with the formula SbF₅. This colourless, viscous liquid is a valuable Lewis acid and a component of the superacid fluoroantimonic acid, the strongest known acid formed when mixing liquid HF with liquid SbF₅ in a 2:1 ratio. It is notable for its Lewis acidity and its ability to react with almost all known compounds.

Process for production of 1,2,2,2-tetrafluoro ethyl difluoro methyl ether

InactiveUS20060205983A1High yieldPromote conversionOrganic chemistryOrganic compound preparationHydrogen fluorideEther

A method for the preparation of 1,2,2,2-tetrafluoroethyl difluoromethyl ether (CF3CHFOCHF2, Desflurane) is provided, which comprises reacting CF3CHClOCHF2 (isoflurane) and hydrogen fluoride in the presence of antimony pentafluoride such that desflurane is formed.

Owner:FIRST NIAGARA BANK

Method for preparing graphite fluoride

The invention discloses a method for preparing graphite fluoride. The graphite fluoride is prepared from inorganic composite fluridizer and graphite as raw materials by heating and reaction in the presence of high-purity nitrogen, wherein the inorganic composite fluridizer is the mixture of potassium hexafluoromanganate and antimony pentafluoride. Due to the adoption of the method, the fluorine content of the finally obtained graphite fluoride can reach 59%, and the graphite fluoride can be used as the anode material and the solid lubricating material of lithium ion batteries; the purity of the graphite fluoride product prepared by a solid phase method is greater than 99%, and the use value is high; moreover, the invention is simple in operation and has high safety without needing external fluorine; and the properties of hexafluoromanganate and antimony pentafluoride are stable at normal temperature and therefore the safety is high.

Owner:BEIJING GENERAL RES INST OF MINING & METALLURGY

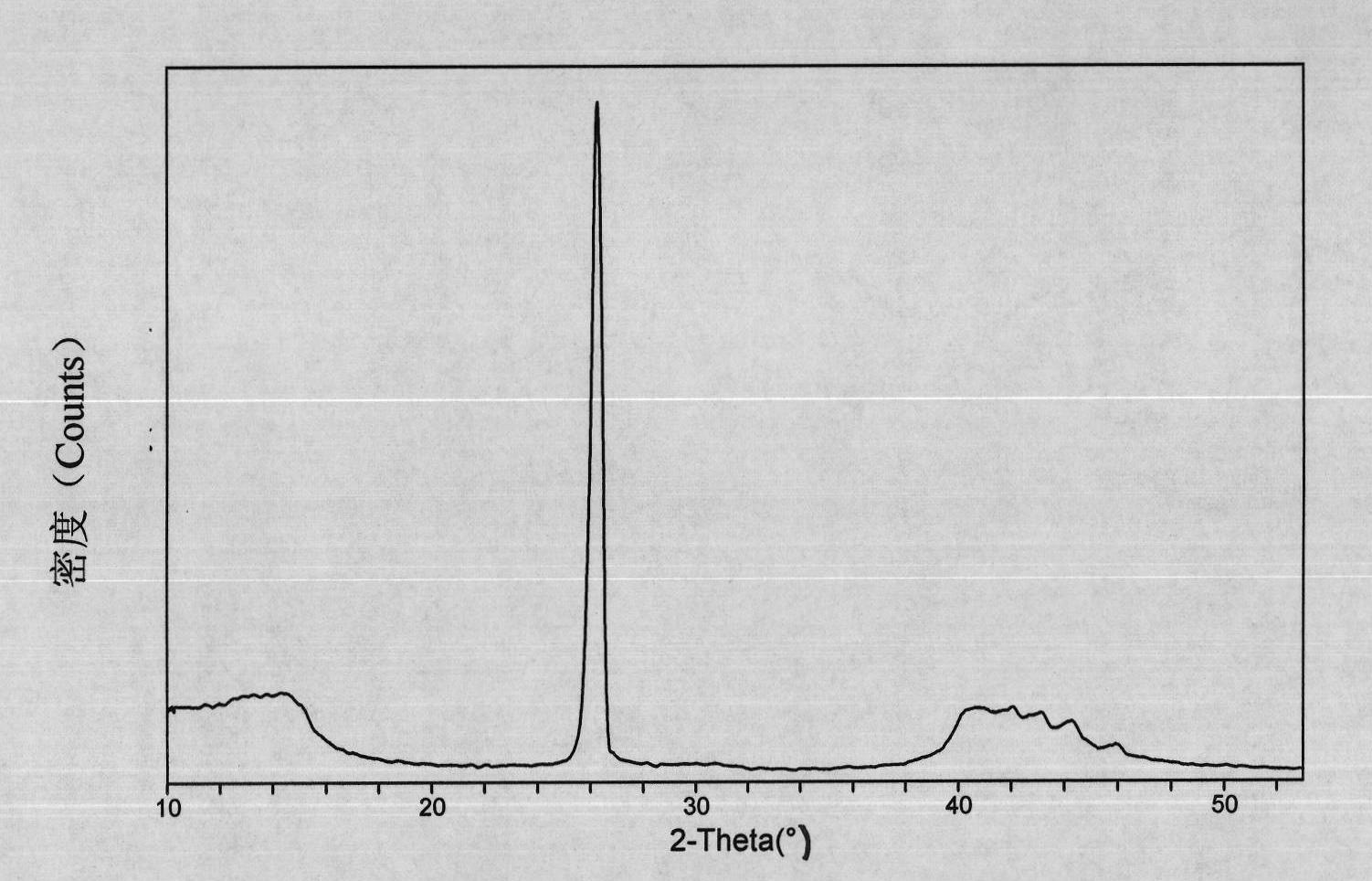

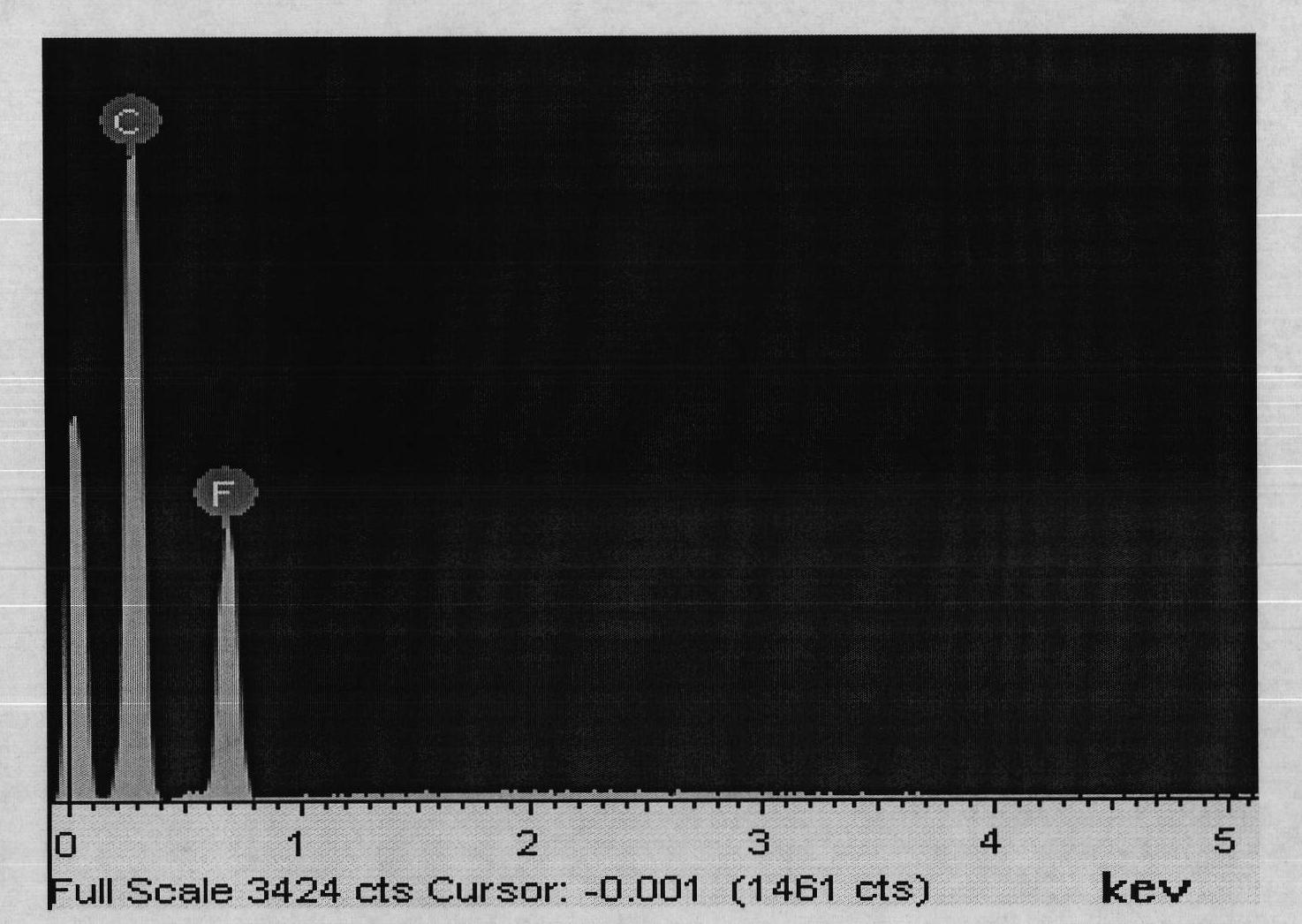

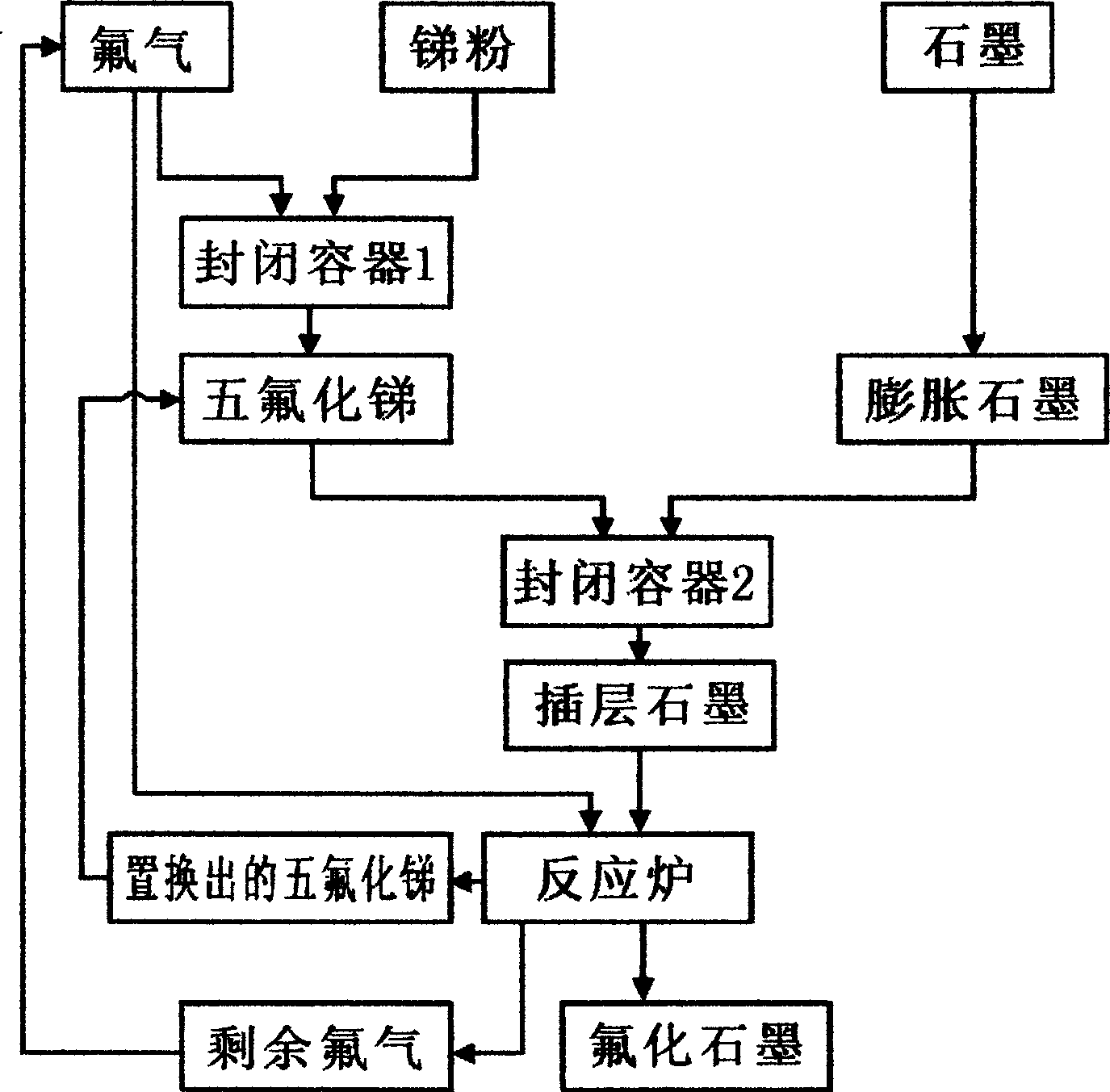

Low temperature method for producing graphite fluoride

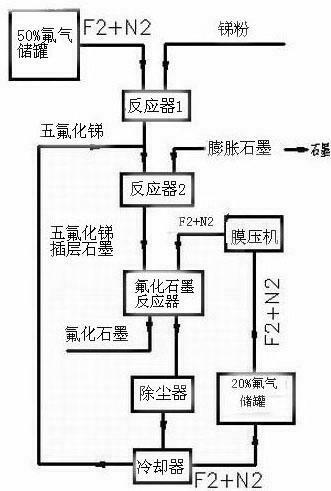

InactiveCN1544534AIncrease profitAchieve large scaleInorganic pigment treatmentAntimony pentafluorideGraphite

The invention discloses a low-temperature process for producing graphite fluoride comprising, immersing graphite with hydrochloric acid and hydroperoxide to obtain expanded graphite, reacting with fluorine gas of a finite concentration and Sb in sealed container to obtain antimony pentafluoride, placing the expanded graphite and antimony pentafluoride into sealed container to obtain intercalation graphite, placing intercalation graphite into confined reaction stove, letting in fluorine gas for reaction. The process according to the invention increases the utilization ratio of the fluorine gas.

Owner:CHENGDU XINYUAN CHEM DEV

Method for preparing graphite fluoride at low temperature

The invention discloses a method for preparing graphite fluoride at low temperature. The method comprises the following steps: using ferric fluoride as a catalyst, and performing reaction of crystalline flake graphite and bromine trifluoride at low temperature to generate a graphite intercalation compound; then, performing reaction of potassium manganese hexafluoride and antimony pentafluoride to generate fluorine; and performing reaction of the fluorine generated and the graphite intercalation compound to form the graphite fluoride with high fluorine content. Through purifying treatment by a solvent, the prepared graphite fluoride is high in purity.

Owner:东莞市致格电池科技有限公司

Detection method of purity of antimony pentafluoride products

ActiveCN102507572AEasy to operateHigh measurement accuracyMaterial analysis by observing effect on chemical indicatorAnalysis by thermal excitationHydrolysateAntimony pentafluoride

The invention discloses a detection method of purity of antimony pentafluoride products. The detection method comprises the following steps of: (i) preparing a sample, including sampling, solidifying and hydrolyzing; (ii) quantifying trivalent antimony, namely utilizing an oxidation-reduction titration method to measure the trivalent antimony; (iii) detecting total content of antimony, namely using an inductively coupled plasma emission spectrometer, selecting 206.836nm as an analytical line used for measuring, and detecting the content of total antimony elements in hydrolysate; (iv) calculating the content of pentavalent antimony, namely subtracting the content of the trivalent antimony from the total content of the antimony elements to obtain the content of the pentavalent antimony; andthrough calculating, obtaining the purity of the antimony pentafluoride products. The detection method is simple and convenient and feasible and is convenient for operation, the measurement accuracy is high, and the method is particularly suitable for detecting the purity of the antimony pentafluoride products prepared by fluoride and simple substance antimony as raw materials.

Owner:RES INST OF PHYSICAL & CHEM ENG OF NUCLEAR IND

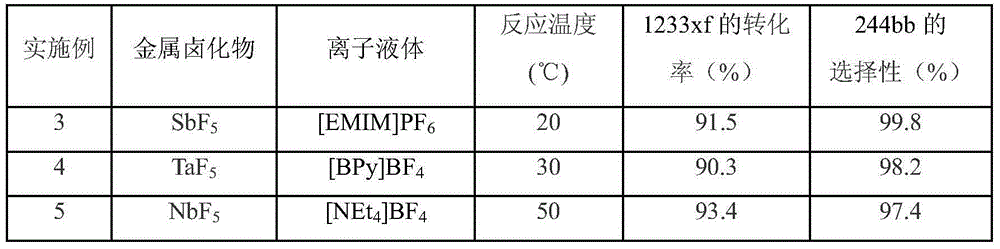

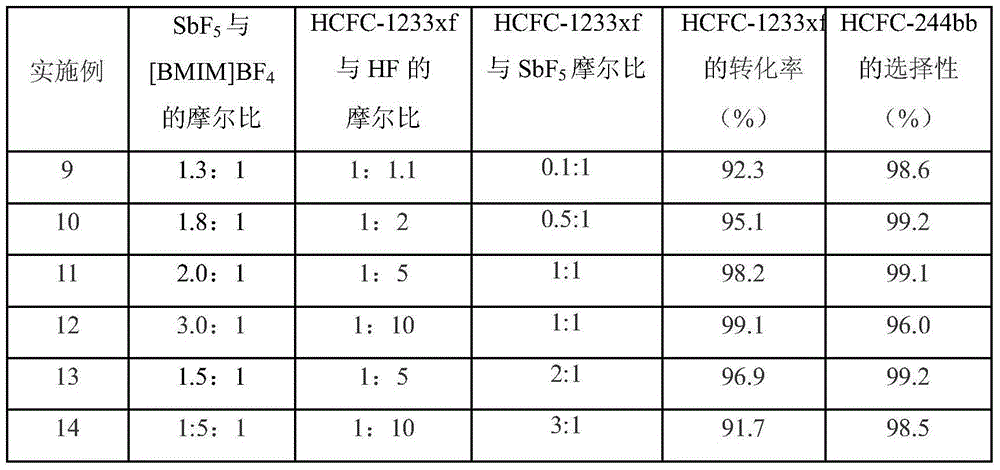

Method for preparing HCFC-244bb

InactiveCN104140354AImprove performanceLow reaction temperatureHalogenated hydrocarbon preparationReaction temperatureAntimony pentafluoride

The invention discloses a method for preparing HCFC-244bb. According to the method, 2-chloro-3, 3, 3-trifluoropropene is used as raw materials. The method comprises the following steps that, a metal halide and an ionic liquid are used as a catalyst, and fluorination is conducted on 2-chloro-3, 3, 3-trifluoropropene and a hydrogen fluoride solution, so that HCFC-244bb is prepared, wherein the metalhalide is antimony pentafluoride or antimony pentachloride or tantalum pentafluoride or tantalum pentachloride or niobium pentafluoride or niobium pentachloride, the general formula of ionic liquid is X+A-, X+ is positive ions of C1-C8 alkyl substitution type double-alkyl imidazole, pyridine and quaternary ammonium salt, A- is negative ions of tetrafluroborate negative ions or hexafluorophosphatenegative ions, the molar ratio between the metal halide and the ionic liquid is 1-3:1, the molar ratio between hydrogen fluoride and 2-chloro-3, 3, 3-trifluoropropene ranges is 1.1-10:1, and the reaction temperature ranges from 20 DEG C to 70 DEG C. The method for preparing HCFC-244bb has the advantages that the reaction temperature is low, the conversion rate is high, the selectivity is high, and chlorine is not needed in the reaction process. The method is used for preparation of HCFC-244bb.

Owner:XIAN MODERN CHEM RES INST

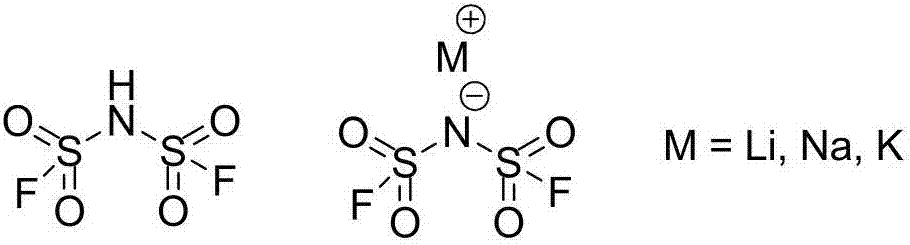

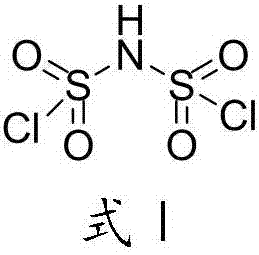

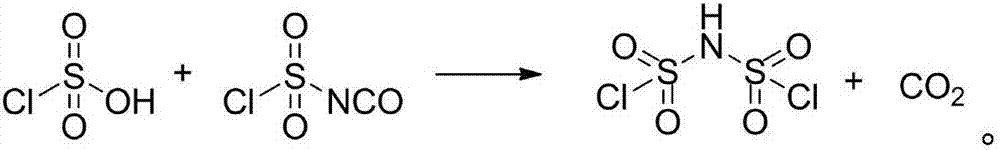

Difluoro-sulfonyl imine preparation method and method for preparing difluoro-sulfonyl imine alkali metal salt by using prepared difluoro-sulfonyl imine

InactiveCN107381522AEasy to controlHigh purityNitrosyl chlorideAmidosulfonic acidChemical industryDistillation

The invention belongs to the technical field of fluorine chemical industry, and especially relates to a difluoro-sulfonyl imine preparation method and a method for preparing difluoro-sulfonyl imine alkali metal salt by using prepared difluoro-sulfonyl imine. The difluoro-sulfonyl imine preparation method comprises the following steps: polystyrene and antimony pentalfluoride are added in a solvent and are subjected to reaction to obtain polystyrene-loaded antimony pentalfluoride, difluoro-sulfonyl imin liquid is added for a reaction, after the reaction is completed, pumping filtration and underpressure distillation are carried out to obtain the difluoro-sulfonyl imin; the method for preparing difluoro-sulfonyl imine alkali metal salt by using the prepared difluoro-sulfonyl imine comprises the following steps: adding difluoro-sulfonyl imine, an alkali metal compound and polystyrene-loaded antimony pentalfluoride in a reaction solvent, reacting the materials for 6-10 h under the reaction temperature of 0-100 DEG C, filtering the materials after the reaction is completed to obtain a difluoro-sulfonyl imine alkali metal salt crude product, and re-crystallizing the difluoro-sulfonyl imine alkali metal salt crude product to obtain a difluoro-sulfonyl imine alkali metal salt fine product. The method has the advantages of controllable reaction, safety, high efficiency, and high yield, and is suitable for industrial production.

Owner:VALIANT CO LTD

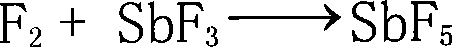

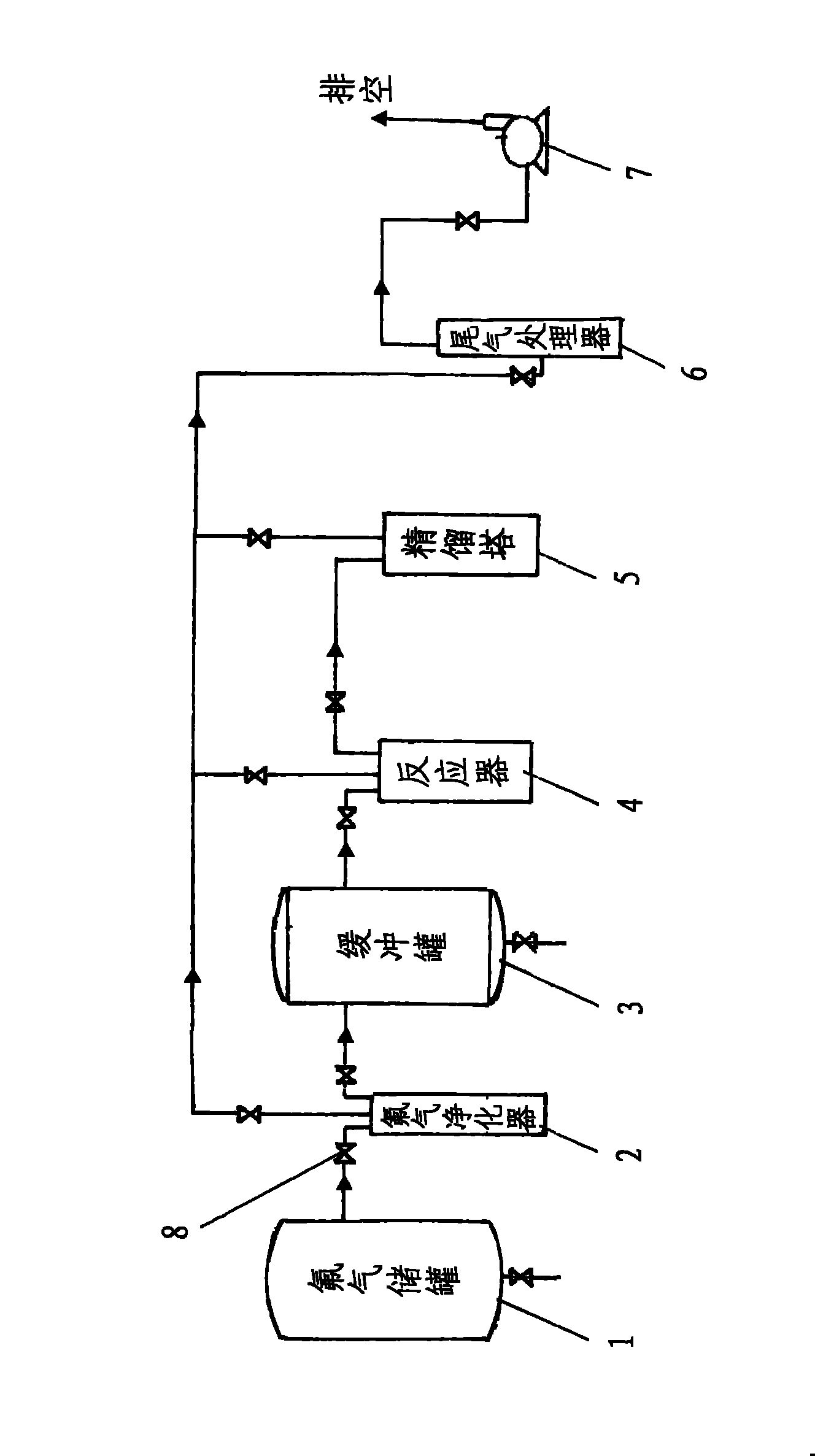

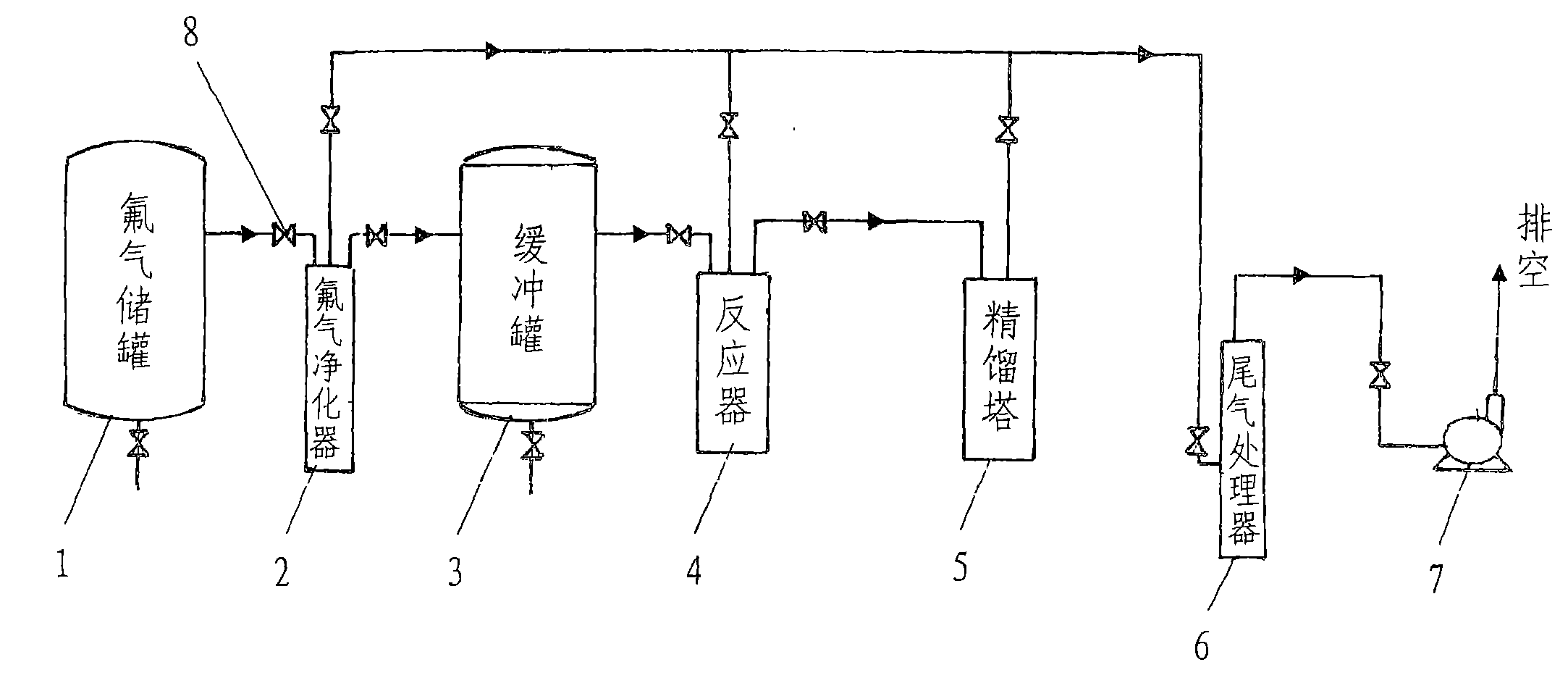

Method for preparing antimony pentafluoride

The invention discloses a method for preparing antimony pentafluoride, and the method comprises the following steps: firstly purifying raw material fluorine gas, removing high boiling point gas impurities which can not be condensed in the fluorine gas; carrying out the synthesis reaction on the fluorine gas and antimony trioxide for generating a liquid antimony pentafluoride crude product; further gasifying and condensing the liquid antimony pentafluoride crude product by the distillation process and removing the gas impurities in the crude product to obtain a high-purity liquid antimony pentafluoride product. The method has simple equipment, convenient operation, safe equipment operation, stable product quality and high purity of being greater than 98.5 percent.

Owner:RES INST OF PHYSICAL & CHEM ENG OF NUCLEAR IND

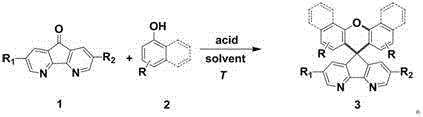

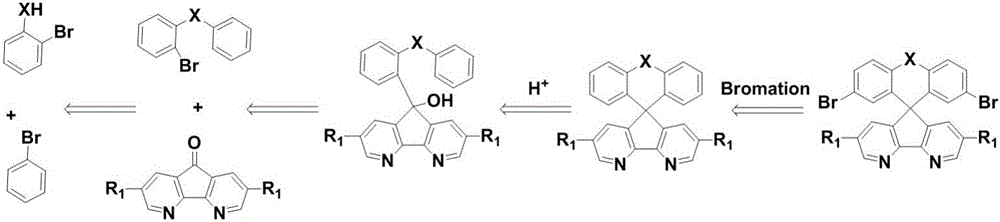

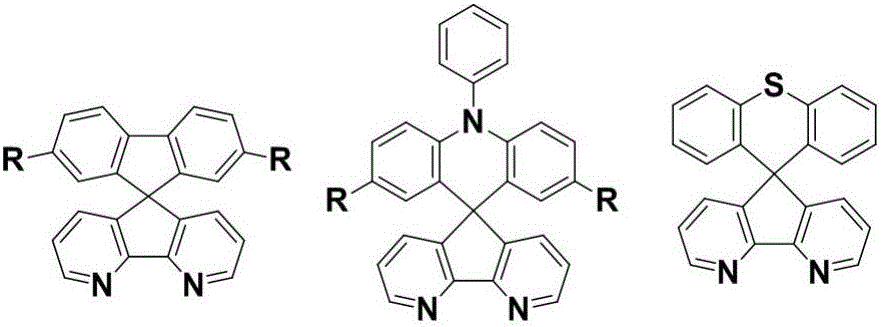

Synthesis method of azafluorene spiro aromatic hydrocarbon

ActiveCN105924450AFlexible designRaw materials are easy to getOrganic chemistrySynthesis methodsTriflic acid

The invention provides a synthesis method of azafluorene spiro aromatic hydrocarbon, and relates to the field of organic semiconductor material synthesis. According to the synthesis method, azafluorenone and a phenolic derivative are adopted as reaction substrates; a reaction is carried out for 12-16h under a temperature of 25-160 DEG C under acid catalysis; through a cationic relay tandem reaction, poly-substituted or poly-functionalized azafluorene spiro aromatic hydrocarbon is synthesized in one step with high efficiency. The acid catalysis is at least one or a combination of: acetic acid, hydrochloric acid, hydrobromic acid, periodic acid, methanesulfonic acid, concentrated sulfuric acid, trifluoromethanesulfonic acid, Eaton reagent, and trifluoroacetic acid hydrofluoric acid-antimony pentafluoride. The dosing molar ratio of the reaction substrate azafluorenone 1 to phenol 2 to the acid catalyst is 1:2-5:3-12. The method has the advantages of easy-to-obtain raw materials, simple operation, high yield, atomic economy and the like. The method is suitable for both laboratory small-scale synthesis and industrialization. The method has a good application prospect.

Owner:NANJING UNIV OF POSTS & TELECOMM

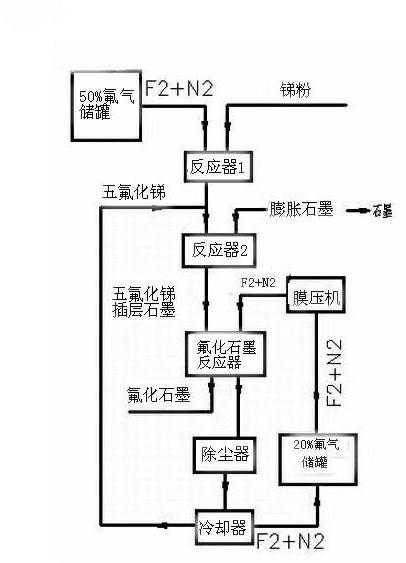

Process for producing graphite fluoride by low-temperature intercalation method

ActiveCN102491319AAvoid operational hazardsAvoid stringent requirements for tightnessGraphitePhysical chemistryAntimony pentafluoride

The invention relates to a process for producing graphite fluoride by a low-temperature intercalation method. The process comprises the following steps of: using antimony pentafluoride intercalated graphite and a fluorine-nitrogen gas mixture to produce graphite fluoride, wherein the fluorine and the nitrogen in the fluorine-nitrogen gas mixture is respectively 10% -30% and 70% - 90 % by mass percentage concentration, the reaction temperature ranges from 200 DEG C to 500 DEG C, and the pressure ranges from 100KPa (Kilopascal) to 300KPa. Then, using the fluorine-nitrogen gas mixture with fluorine and nitrogen respectively of 50% by mass percentage concentration, and antimony powder to directly react for preparing gaseous antimony pentafluoride, and adding the liquid antimony pentafluoride acquired by cooling and expanded graphite to a vacuum container in a mass ratio of 1:1.5 to1:9, controlling the temperature to be 100 DEG C to 150 DEG C, and reacting for more than 12 hours to acquire the antimony pentafluoride intercalated graphite. The graphite fluoride yield can reach 43%- 74%, and the production is safe; simultaneously, the fluorine-to-carbon ratio of the graphite fluoride can be controlled by regulating the reaction time to acquire the graphite fluoride with different fluorine-to-carbon ratios.

Owner:江西高信前沿科技有限公司

Dehydrofluorination catalyst

ActiveCN101637733AHigh selectivityHigh activityPreparation by hydrogen halide split-offCatalyst activation/preparationTitanium tetrafluorideChromium Compounds

The invention discloses a dehydrofluorination catalyst aiming at solving the problems of low activity of the catalsyt and low selectivity to Z-type fluoroolefin. The precursor of the catalyst consistsof 30-80 percent of trivalent chromium compound, 10-35 percent of metal halide and 10-35 percent of fluoride of ammonium by mass percent, wherein the trivalent chromium compound is chromic oxide or chromium hydroxide, the metal halide is stannic chloride, titanium tetrachloride, tantalum chloride, antimony pentachloride, tin tetrafluoride, titanium tetrafluoride, tantalic fluoride or antimony pentafluoride, and the fluoride of ammonium is ammonium fluoride or ammonium bifluoride. The catalyst is prepared by the following method: evenly mixing the trivalent chromium compound, the metal halideand the fluoride of ammonium by mass percent, pressing and shaping the mixture, and then baking and activating by hydrogen fluoride. The dehydrofluorination catalyst has high activity and selectivityto the Z-type fluoroolefin and is mainly used for preparing corresponding Z-type fluoroolefin by dehydrofluorination using hydrofluorocarbon as the material under the condition of gaseous phase reaction.

Owner:ZHEJIANG FLUORINE CHEM NEW MATERIAL

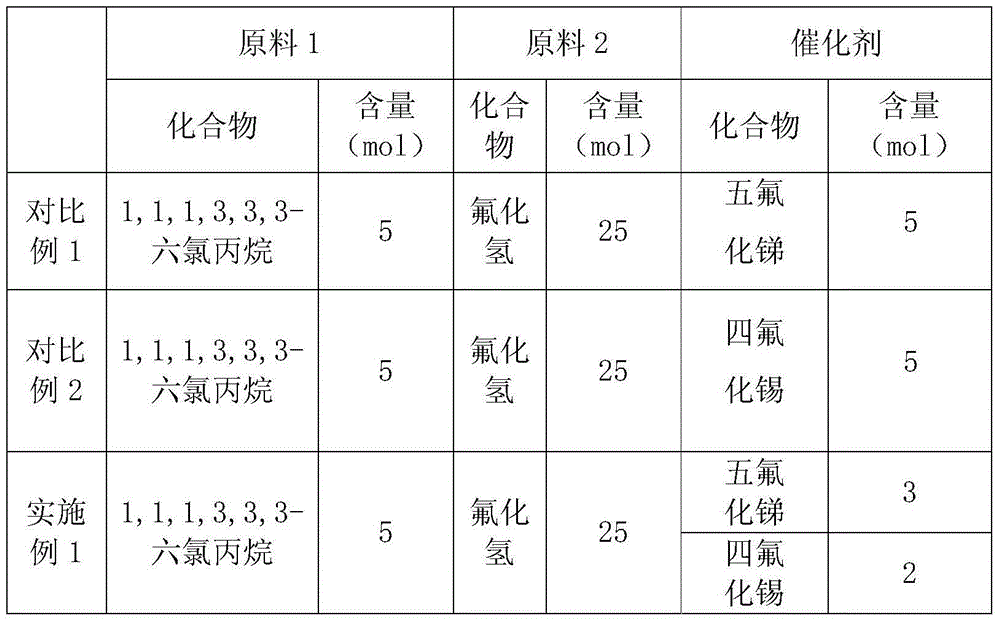

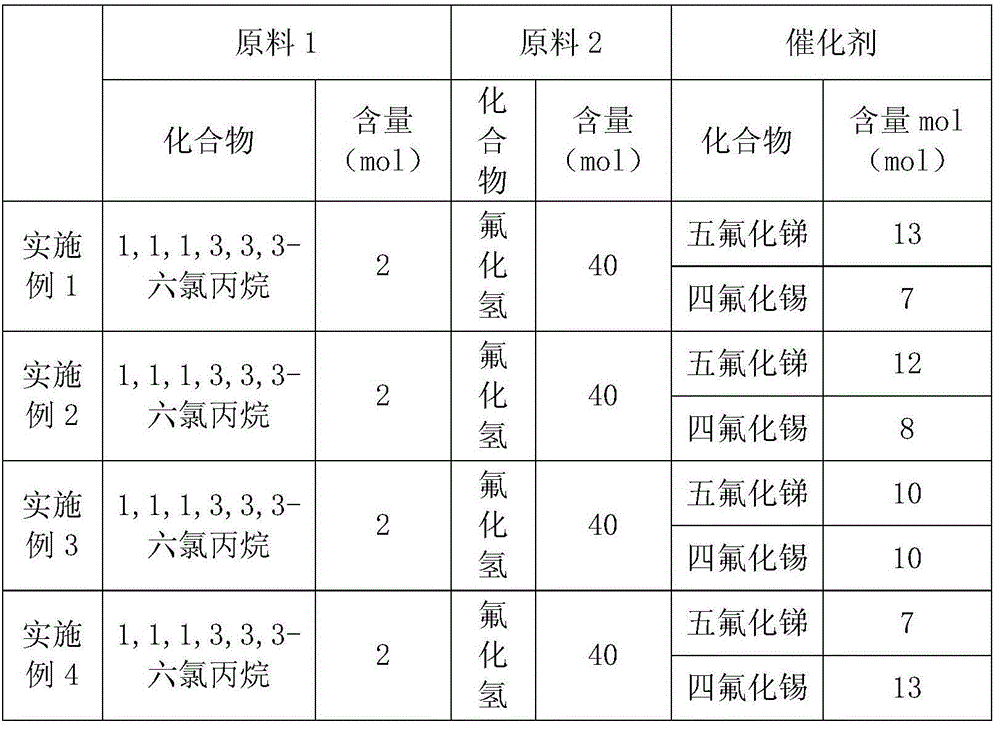

1,1,1,3,3,3-hexafluoropropane production method

InactiveCN104803824AImprove conversion rateHigh yieldHalogenated hydrocarbon preparationHydrogen fluorideHydrofluoric acid

The present invention provides a 1,1,1,3,3,3-hexafluoropropane production method, which comprises carrying out a reaction of 1,1,1,3,3,3-hexachloropropane and hydrofluoric acid under the effect of a catalyst to prepare the 1,1,1,3,3,3-hexafluoropropane, wherein the catalyst contains antimony pentafluoride and tin tetrafluoride. With the preparation method of the present invention, the 1,1,1,3,3,3-hexachloropropane conversion rate can be improved, and the prepared 1,1,1,3,3,3-hexafluoropropane of the present invention can be used as the refrigerant and the fire extinguishing agent.

Owner:上海汇友精密化学品有限公司

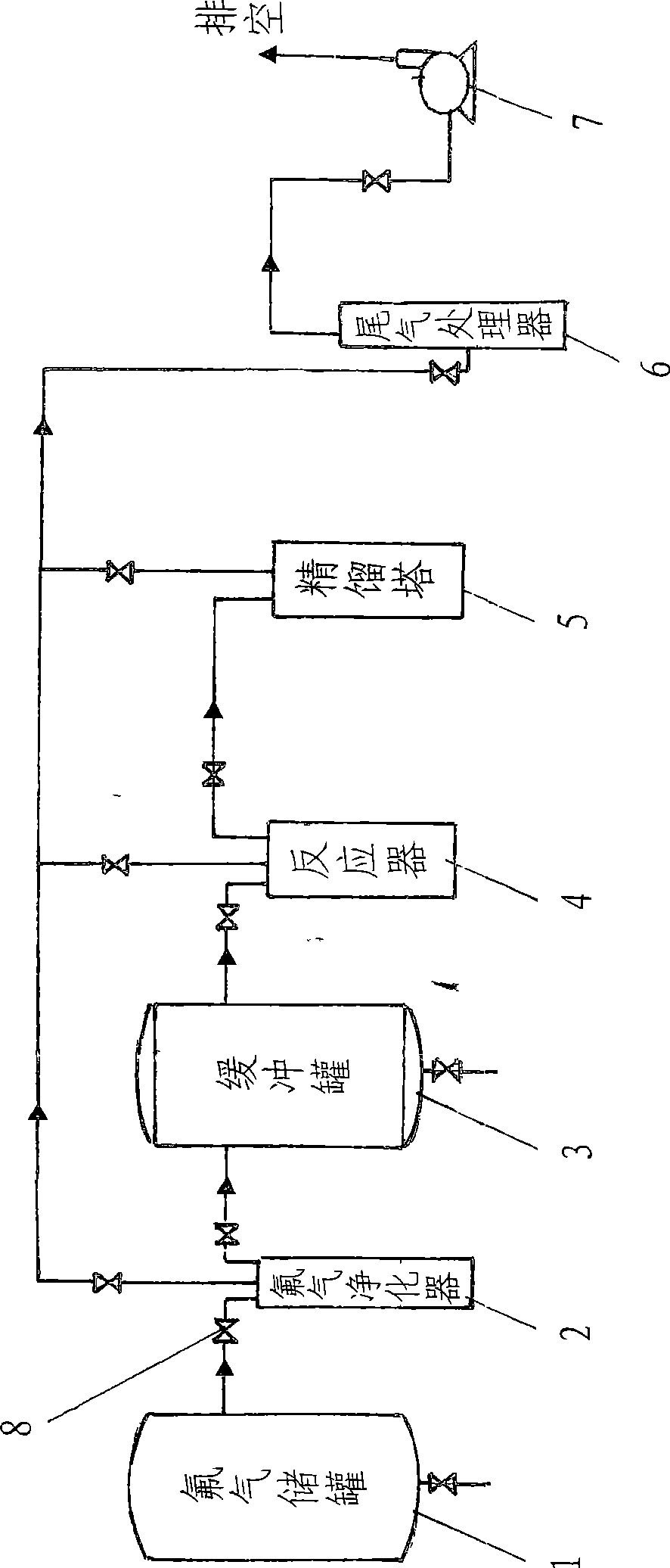

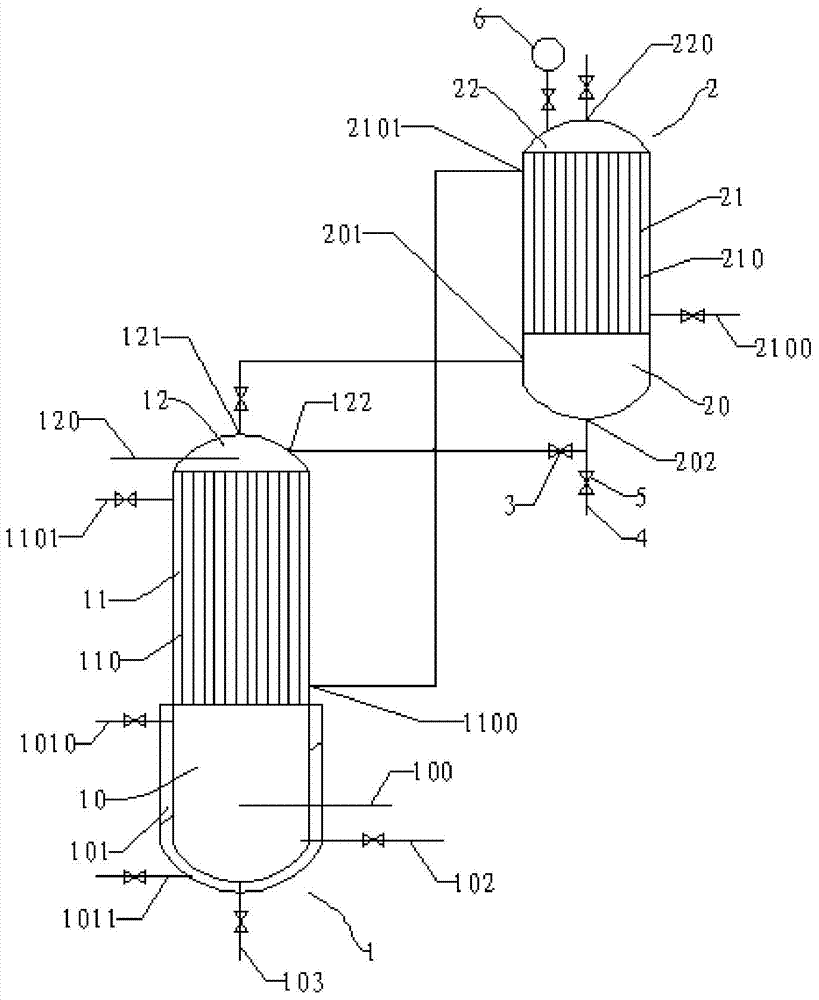

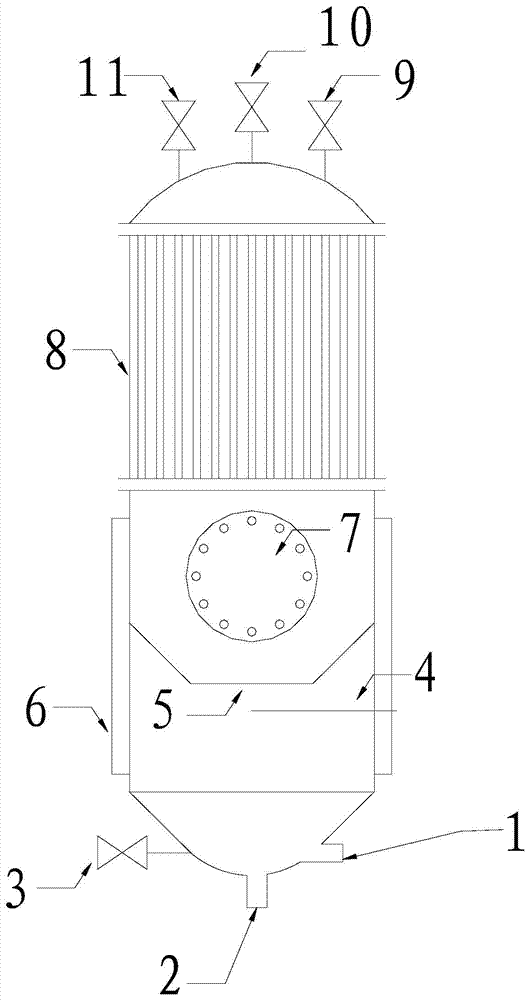

Antimony pentafluoride rectification equipment

The invention relates to antimony pentafluoride rectification equipment, which includes a distilling condenser and a recovery condenser. A liquid antimony pentafluoride crude product is subjected to heating gasification in a heating area of the distilling condenser, then undergoes at least twice condensation in a first condensation area and a second condensation area so as to form tail gas, so that the antimony pentafluoride in the gas phase can condense more fully, and the yield of the antimony pentafluoride product can be enhanced. The antimony pentafluoride primary product obtained by twice condensation in the first condensation area and the second condensation area then passes through a reflux inlet and a reflux outlet to undergo repeated cycling rectification in the distilling condenser and the recovery condenser, so that the antimony pentafluoride can be separated from other impurities more thoroughly, and the finally obtained antimony pentafluoride product can have higher purity. At the same time, the insides of the distilling condenser and the recovery condenser always maintain a negative pressure state, the temperature needed by heating gasification is lowered, and the corrosion degree of antimony pentafluoride on the rectification equipment is reduced, thereby reducing the generation of impurities and enhancing the product purity.

Owner:FUJIAN YONGJING TECH CO LTD

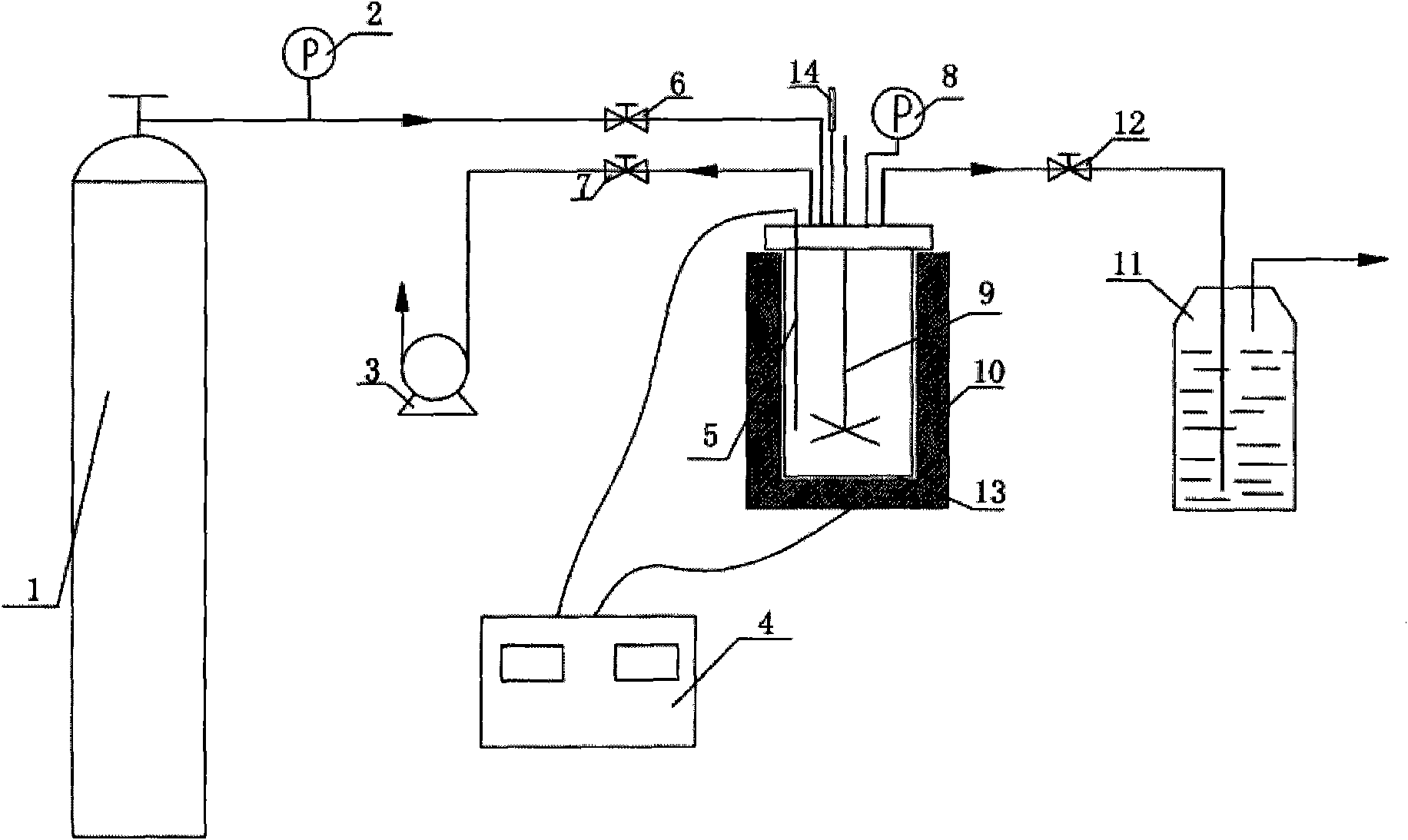

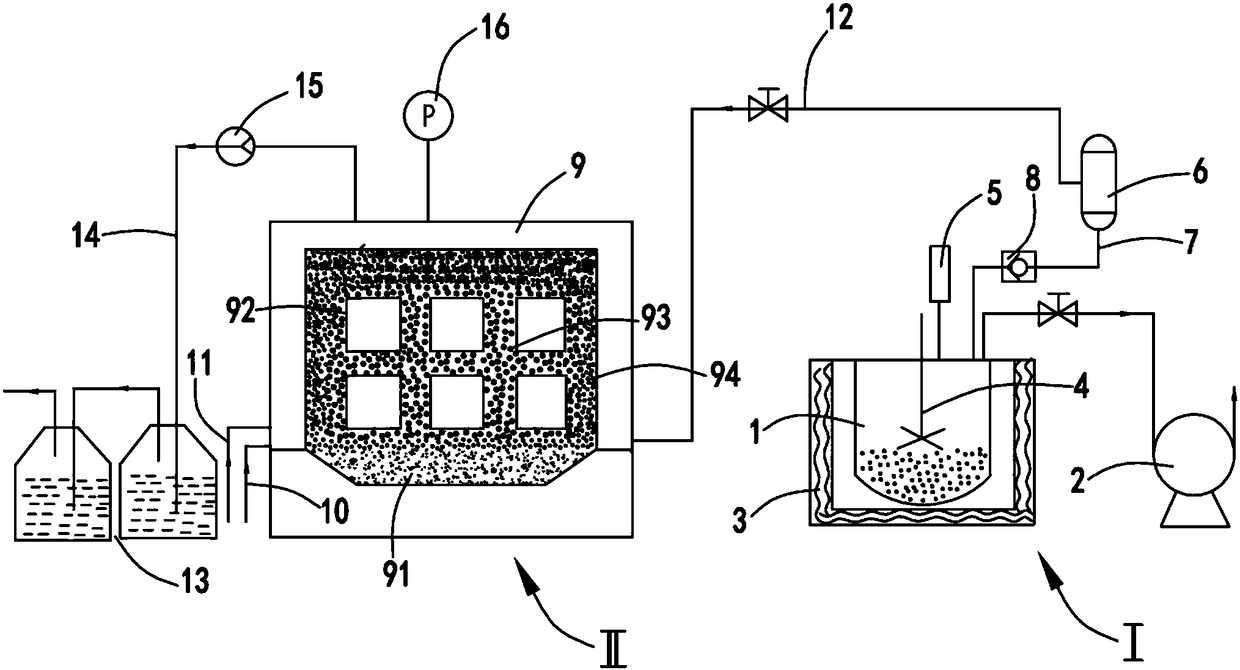

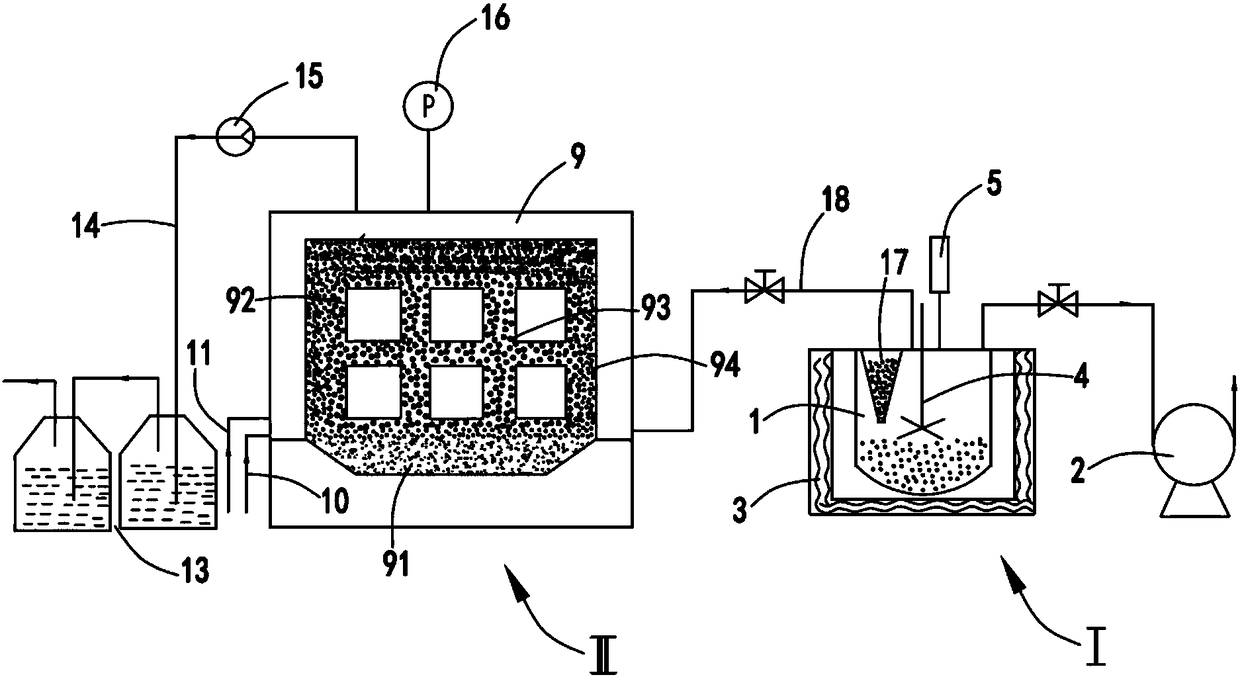

Method and reactor for preparing antimony pentafluoride

ActiveCN103613131ATemperature controlReduce chemical corrosionAntimony compoundsPressure vessels for chemical processAntimony pentafluorideNitrogen gas

The invention discloses a preparation method of antimony pentafluoride. The method comprises the following steps: 1) crushing a metallic antimony block, and adding to a reactor; 2) vacuumizing the reactor to form negative pressure, and heating to 120 DEG C to remove moisture in the reactor and a material; 3) introducing nitrogen to the reactor, so as to pressurize to constant pressure; 4) slowly introducing fluorine, reacting to generate antimony pentafluoride vapor, beginning to warm in the reaction, and emptying for a plurality of times until the pressure of a buffer tank does not ascend again; 5) preparing an antimony pentafluoride product from the antimony pentafluoride vapor in a condensation reflux mode. The invention simultaneously discloses the reactor for preparing antimony pentafluoride. In the reactor, metallic antimony directly reacts with fluorine, so as to generate antimony pentafluoride, so that the product quality is improved and the process is simplified, and the reactor is convenient to operate. Condensation reflux liquid takes away a part of reaction heat, so as to well control the internal temperature of the reactor; meanwhile, continuous reaction is also ensured; chemical corrosion inside the reactor is reduced. Thus, the service life of the reactor is prolonged.

Owner:FUJIAN YONGJING TECH CO LTD

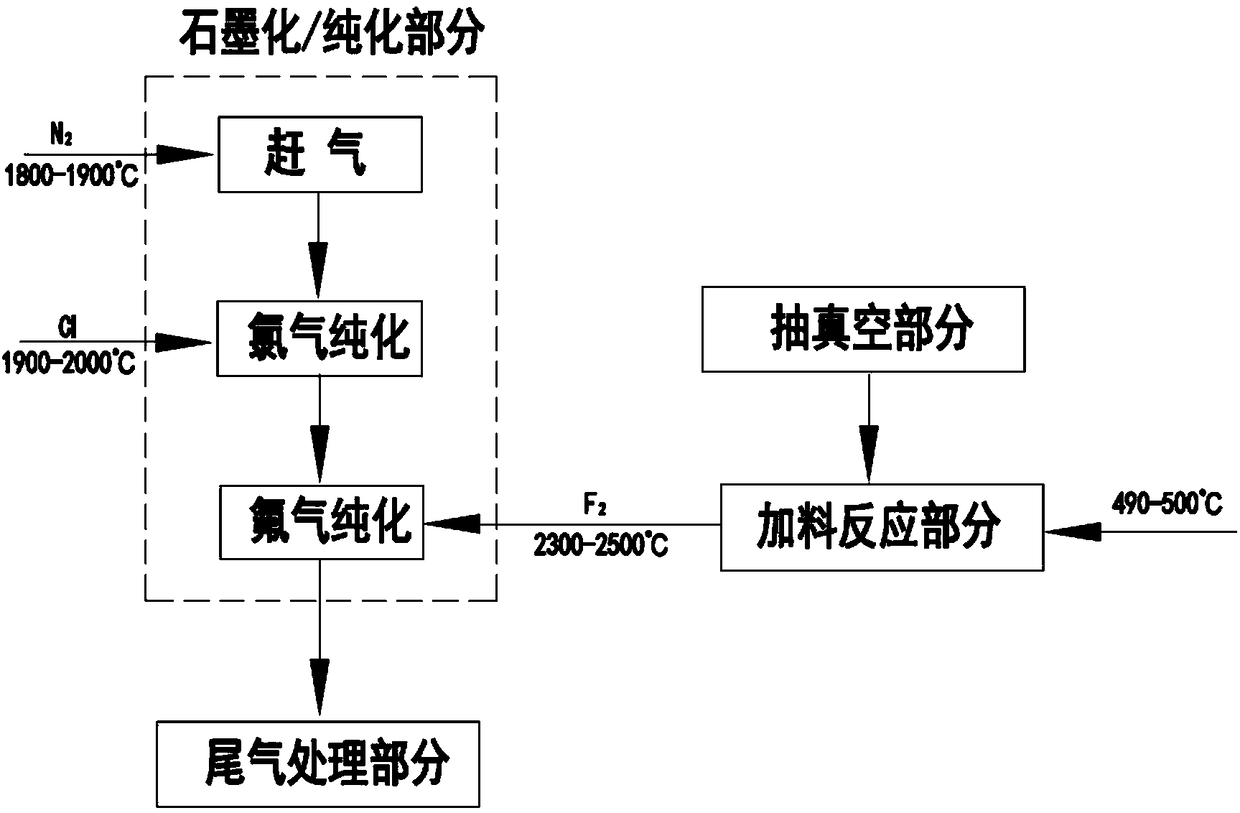

Method for purifying graphite by co-heating hexafluoromanganate and antimony pentafluoride generating fluorine gas

InactiveCN108516543AImprove the purification effectReduce adverse effectsCarbon compoundsFluorineNitrogenAntimony pentafluoride

The invention relates to a method for purifying graphite by co-heating hexafluoromanganate and antimony pentafluoride generating fluorine gas, which comprises the following steps of: vacuumizing a fluorine gas reactor, and removing air in the reactor; taking materials of antimony pentafluoride and hexafluoromanganate according to the mass ratio of 2-3:1 and adding into a reactor for reaction to generate fluorine gas; arranging a plurality of groups of graphite products in a graphitization furnace according to required spacing, sequentially filling a heat preservation material and a resistor material, heating the graphitization furnace to furnace center temperature of 1,800-1,900 DEG C after the furnace loading is finished, and introducing nitrogen into the furnace core to remove the air inthe furnace center; when the temperature is raised to 1,900-2,000 DEG C, the chlorine is stopped, and the chlorine is converted to be introduced; when the temperature is raised to 2,300-2,500 DEG C,the fluorine gas generated by the reaction is communicated into the graphitization furnace. The method for purifying graphite by co-heating hexafluoromanganate and antimony pentafluoride generating fluorine gas uses hexafluoromanganate and antimony pentafluoride to produce fluorine gas instead of freon used in the purification process in the prior art, so that the problem that the adverse effect on the environment in the use process of the freon is avoided while the purification effect is good.

Owner:SINOSTEEL NEW MATERIAL ZHEJIANG

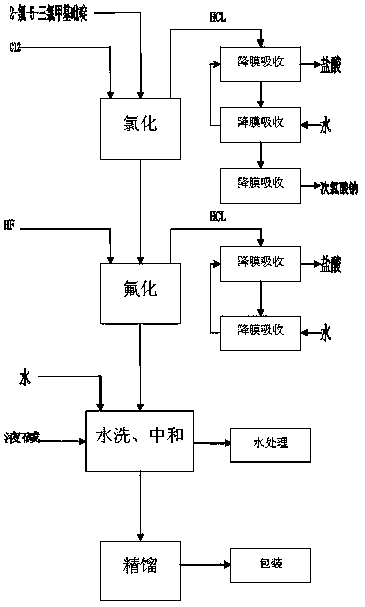

Preparation method of 2-fluorine-3-chlorine-5-trifluoromethylpyridine

InactiveCN107935920AThe market is plentiful and readily availableReliable workmanshipOrganic chemistryHydrogen fluorideChemical synthesis

The invention relates to the technical field of chemical synthesis, and in particular discloses a preparation method of 2-fluorine-3-chlorine-5-trifluoromethylpyridine. The preparation method of the 2-fluorine-3-chlorine-5-trifluoromethylpyridine is characterized by comprising the following steps: taking 2-chlorine-5-trichloromethylpyridine as a raw material, taking tungsten hexachloride as a catalyst, heating and introducing chlorine to perform chlorination reaction, thereby obtaining 2,3-dichloro-5-trichloromethylpyridine; putting the 2,3-dichloro-5-trichloromethylpyridine into a fluorination kettle, adding antimony pentafluoride and anhydrous hydrogen fluoride, stirring and heating to perform reaction, cooling after reaction, washing with water, layering, feeding to a rectification kettle, and performing reduced-pressure rectification, thereby preparing the 2-fluorine-3-chlorine-5-trifluoromethylpyridine. The process is reliable, the raw materials are sufficient in the market and easily available, and the preparation method of the 2-fluorine-3-chlorine-5-trifluoromethylpyridine is low in production cost, simple in operation, high in yield and favorable for large-scale production.

Owner:SHANDONG HUIMENG BIO TECH CO LTD

Preparation method of lithium oxalyldifluoroborate

ActiveCN111943969AEasy to separateSpeed up the reaction processGroup 3/13 element organic compoundsElectrolytic agentPentafluoride

The invention discloses a preparation method of lithium oxalyldifluoroborate, and belongs to the technical field of lithium ion battery electrolyte preparation. The preparation method comprises the following steps: 1) mixing lithium tetrafluoroborate, lithium oxalate, an organic solvent and an auxiliary agent, and carrying out a reaction on the obtained mixed solution to obtain a reaction solutioncontaining LiODFB, wherein the auxiliary agent is niobium pentachloride, niobium pentafluoride or antimony pentafluoride; 2) filtering the reaction solution containing LiODFB, and concentrating the filtrate to obtain a lithium oxalyldifluoroborate crude product; and 3) recrystallizing the lithium oxalyldifluoroborate crude product, and conducting drying to obtain lithium oxalyldifluoroborate. Thepreparation method provided by the invention has the advantages of high conversion rate, high product purity and high yield, and no corrosive gas is generated in the reaction process.

Owner:DONGYING HI TECH SPRING CHEM IND

Process for production of 1,2,2,2-tetrafluoro ethyl difluoro methyl ether

InactiveCN101068763AImprove conversion rateHigh yieldOrganic chemistryOrganic compound preparationHydrogen fluorideIsoflurane

A method for the preparation of 1,2,2,2-tetrafluoroethyl difluoromethyl ether (CF3CHFOCHF2, Deflurane) is provided, which comprises reacting CF3CHCIOCHF2 (isoflurane) and hydrogen fluoride in the presence of antimony pentafluoride such that deflurane is formed.

Owner:PIRAMAL CRITICAL CARE

Synthesis method of perfluoropolyether lubricant base oil

InactiveCN107266672AAverage relative molecular weightImprove stabilityAdditivesSynthesis methodsAntimony pentafluoride

Belonging to the field of perfluoropolyether lubricant synthesis, the invention discloses a synthesis method of perfluoropolyether lubricant base oil. The method is realized by the steps of: (1) synthesis of perfluoropolyether acyl fluoride; and (2) decarbonylation end capping for synthesis of perfluoropolyether oil. The method can endow the perfluoropolyether with a conversion rate up to 95% or above and a high average relative molecular mass, after end capping, perfluoropolyether oil with high stability, oxidation resistance and other properties can be obtained. According to the method, no diluent is added in the perfluoropolyether synthesis process, the process is relatively simple, and the cost is low. At the same time, precious transition metal halide salt or dangerous antimony pentafluoride are not used as the decarbonylation catalyst in the end capping reaction, instead a conventional nitrate is employed, and is low in cost, easy to recover, and suitable for industrial production. At the same time, compared with the conventional production process carried out at a temperature ranging from -30DEG to -60DEG C, the method is carried out at a temperature ranging from 0 to -30DEG C, under the circumstance of equal output, the production cost is significantly reduced.

Owner:上海中真润滑油有限公司

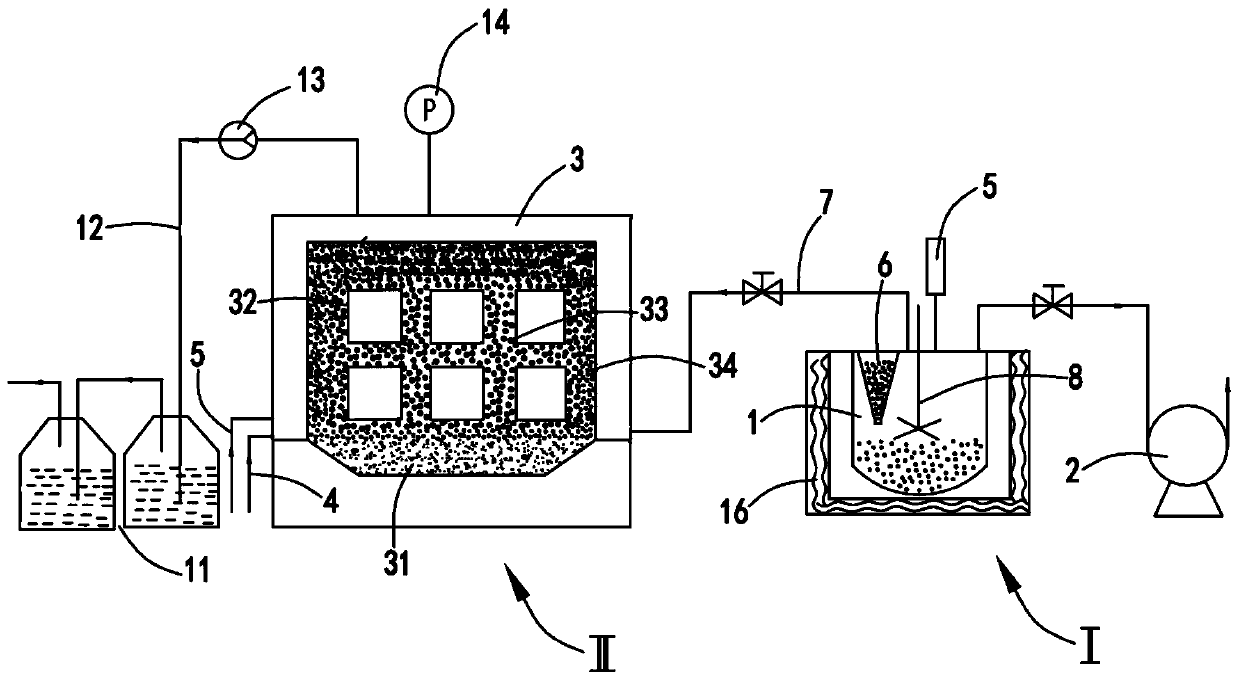

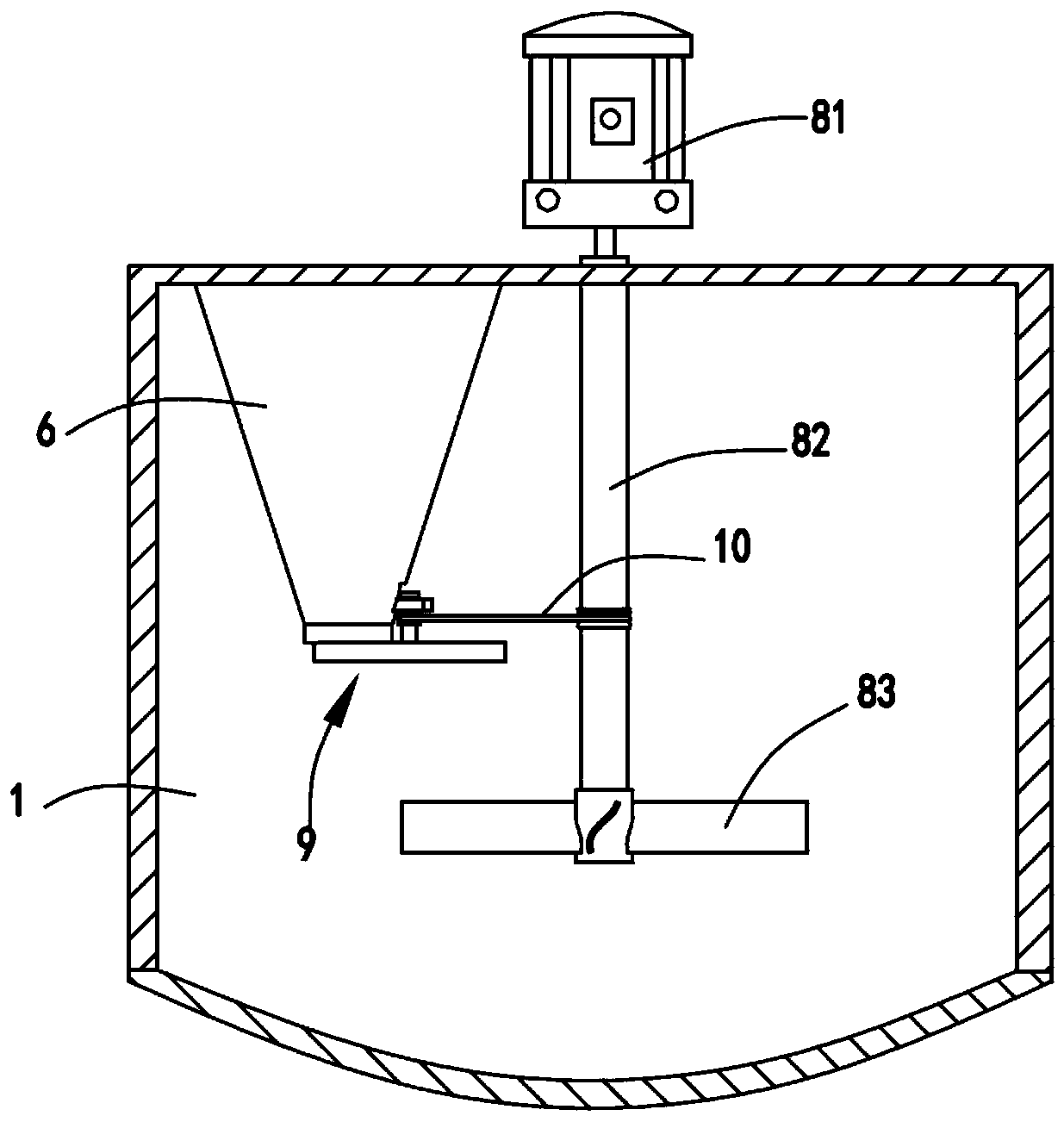

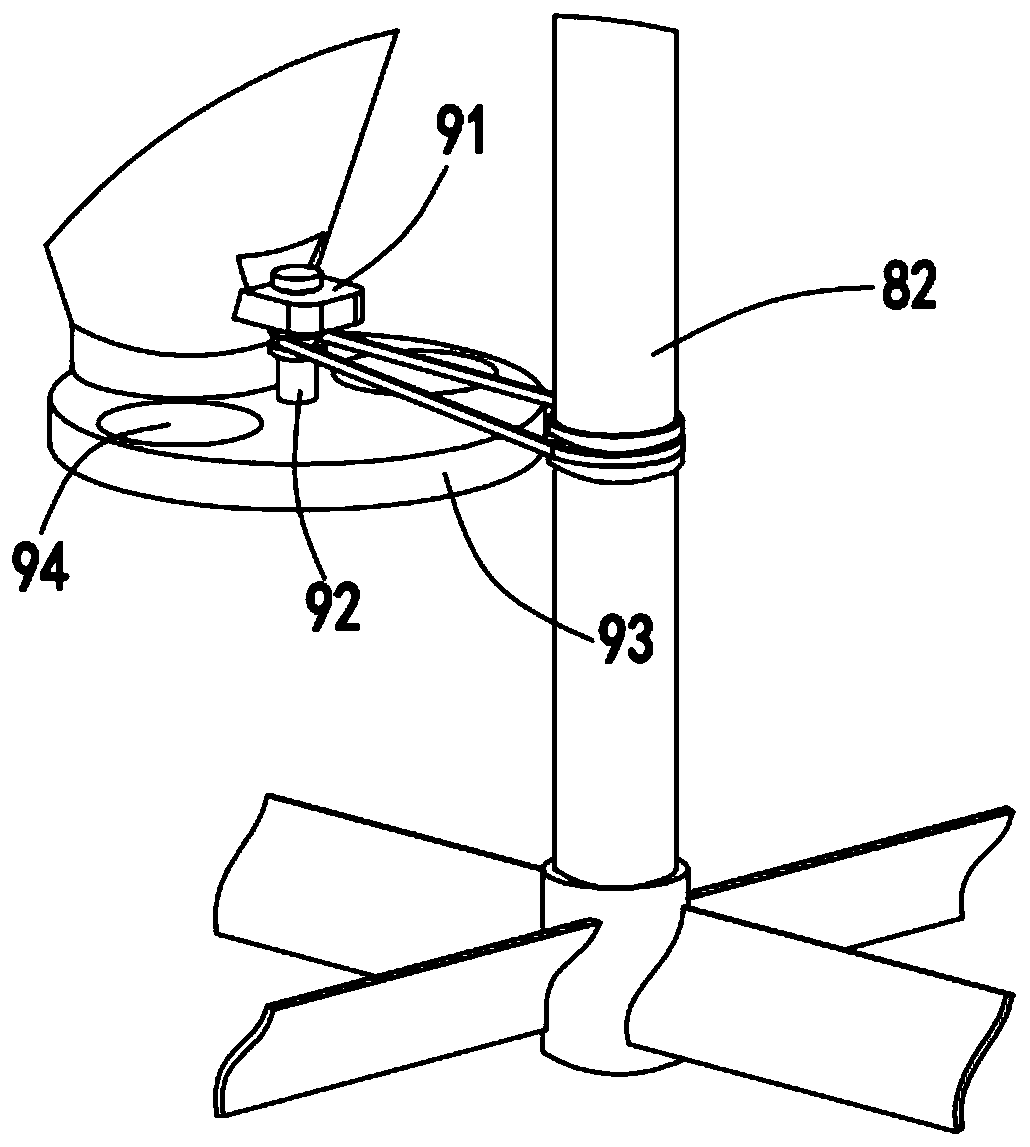

A system for co-heating potassium hexafluoromanganate and antimony pentafluoride to produce fluorine gas and purify graphite

ActiveCN108483441BImprove the purification effectReduce adverse effectsCarbon compoundsFluorineChemical reactorAntimony pentafluoride

The invention relates to a system for purifying graphite with a hexafluoro-potassium manganate and antimony pentafluoride co-heating generated fluorine gas. The system comprises a fluorine gas reaction unit I and a fluorine gas reaction unit II, wherein the fluorine gas reaction unit I comprises a reactor and a vacuum pump for vacuuming the reactor; a heater for heating the reactor is mounted outside the reactor; the fluorine gas reaction unit II comprises a furnace body; a furnace substrate is arranged at the bottom of the furnace body; a graphite product is placed beside a furnace core; a resistance material is arranged around the graphite product; a heat-preservation material is arranged outside the resistance material; a gas inlet tube a and a gas inlet tube b for introducing nitrogenand chlorine into the furnace core respectively are arranged on one side of the furnace body; the reactor is used for implementing reactions to generate a fluorine gas; the fluorine gas is introducedinto the bottom of the furnace core to remove impurity elements in the graphite product. By adopting the system, a chemical reactor is arranged on one side of a graphitization furnace, the graphite inside the graphitization furnace is purified with the hexafluoro-potassium manganate and antimony pentafluoride co-heating generated fluorine gas inside the reactor, and the problem of environment pollution caused when Freon is used can be avoided.

Owner:SINOSTEEL NEW MATERIAL ZHEJIANG

Method for preparing antimony pentafluoride

Owner:RES INST OF PHYSICAL & CHEM ENG OF NUCLEAR IND

Preparation method for graphene fluoride colloidal material

The invention discloses a preparation method for a graphene fluoride colloidal material, and is characterized in that the preparation method comprises the following steps: (1) preparing a nano graphite carbon powder, (2) carrying out a fluorination reaction, (3) preparing a graphite fluoride powder, (4) carrying out ball milling dispersion for preparing slurry, and (5) obtaining the graphene colloidal material. The preparation method solves the problems of easy agglomeration and difficult dispersion in nano graphite carbon powder preparation, potassium hexafluoromanganate and antimony pentafluoride have stable properties at the room temperature, so that the security is high, and raw materials are low in price; an organic solvent can be recycled, the production process is environmentally friendly and non-pollution, and the graphene colloidal solution has the advantages of excellent dispersity, excellent stable performance and high utilization value. The preparation method has the advantages of being simple in process method, low in production cost, suitable for industrialized production and the like.

Owner:QINGDAO WEITENG GRAPHITE

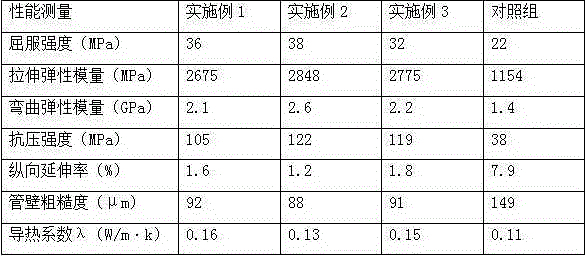

High-strength anti-aging underground communication pipe and preparation method thereof

The invention discloses a high-strength anti-aging underground communication pipe and a preparation method thereof.The high-strength anti-aging underground communication pipe is prepared from, by mass, 180-220 parts of polypropylene, 20-24 parts of corn starch, 16-20 parts of PPG-n castorate, 14-18 parts of polyvinyl alcohol, 20-24 parts of dimethyl phthalate, 16-20 parts of cobalt acetylacetonate, 14-18 parts of butyl carbitol acet, 16-20 parts of graphite fiber, 14-18 parts of paraffin oil, 20-24 parts of polymethyl acrylate, 16-20 parts of zirconium oxide, 16-20 parts of boron carbide, 14-18 parts of zinc oxide, 20-24 parts of montmorillonoid, 16-20 parts of 1,4-dyhydroxyl sulfanilic acid, 14-18 parts of antimony pentafluoride, 20-24 parts of sodium antimonite, 16-20 parts of furan resin, 14-18 parts of Pulullan, 20-24 parts of sorbitol, 14-18 parts of tetramethrin, 20-24 parts of stearoylbenzoylmethane and 16-20 parts of aluminum dihydrogen phosphate.

Owner:郭菲

Method for synthesizing halogenated alkanes

ActiveCN102140053BRaw materials are easy to getSmooth responsePreparation by halogen additionAlkaneDimethylaniline N-oxide

The invention discloses a method for synthesizing halogenated alkanes, which comprises the following steps of: adding 20 to 30 weight parts of solvent and 0.3 to 0.8 weight part of catalyst into 10 to 60 weight parts of halogens and 26 to 48 weight parts of fluorine-containing olefins, which serve as major ingredients, wherein the halogens may be a bromine simple substance or an iodine simple substance, the solvent is dimethylaniline or tetrafluoroethyl tetrafluoropropyl ether, and the catalyst is antimony pentafluoride; and reserving the pressure to between 0.05 and 0.6 MPa by using the olefins, heating to the temperature of between 150 and 230 DEG C, and reacting under the pressure of between 0.7 and 1.8 MPa for 3 to 8 hours, cooling to the temperature of between 30 and 40 DEG C, recovering unreacted raw materials, and rectifying under the reduced pressure to obtain a target product. In the method, the raw materials are readily available, and by-products are not generated; the process can be controlled, and the integral reaction process is stable and is easy and convenient to operate, so the method has the special advantage on a reaction process, and the product obtained finally has the purity of up to over 99.5 percent and yield of up to over 91 percent and can be used as the raw materials of fluorine-containing materials which are used for synthesizing fluororubber resistant to the temperature of between -50 and 260 DEG C and have stable chemical performance.

Owner:JINZHOU DPF TH CHEM CO LTD

Dehydrofluorination catalyst

ActiveCN101637733BHigh selectivityHigh activityPreparation by hydrogen halide split-offCatalyst activation/preparationTitanium tetrafluorideChromium Compounds

The invention discloses a dehydrofluorination catalyst aiming at solving the problems of low activity of the catalsyt and low selectivity to Z-type fluoroolefin. The precursor of the catalyst consists of 30-80 percent of trivalent chromium compound, 10-35 percent of metal halide and 10-35 percent of fluoride of ammonium by mass percent, wherein the trivalent chromium compound is chromic oxide or chromium hydroxide, the metal halide is stannic chloride, titanium tetrachloride, tantalum chloride, antimony pentachloride, tin tetrafluoride, titanium tetrafluoride, tantalic fluoride or antimony pentafluoride, and the fluoride of ammonium is ammonium fluoride or ammonium bifluoride. The catalyst is prepared by the following method: evenly mixing the trivalent chromium compound, the metal halideand the fluoride of ammonium by mass percent, pressing and shaping the mixture, and then baking and activating by hydrogen fluoride. The dehydrofluorination catalyst has high activity and selectivityto the Z-type fluoroolefin and is mainly used for preparing corresponding Z-type fluoroolefin by dehydrofluorination using hydrofluorocarbon as the material under the condition of gaseous phase reaction.

Owner:ZHEJIANG FLUORINE CHEM NEW MATERIAL

Hydrogen fluoride detection reagent and preparing method thereof

InactiveCN104931496AAccurate determination of hydrogen fluoride contentImprove responseMaterial analysis by observing effect on chemical indicatorAntimony pentafluorideLanthanum

The invention discloses a hydrogen fluoride detection reagent and a preparing method thereof and belongs to the technical field of gas detection. The reagent comprises, by weight, 5 to 12 parts of lanthanum trichloride, 2 to 8 parts of antimony pentafluoride, 2 to 8 parts of potassium nitrate, 3 to 6 parts of triethanolamine oleate, 2 to 7 parts of n-butyl alcohol, 3 to 8 parts of sodium sulfate, 4 to 10 parts of aluminum chloride, and 12 to 18 parts of deionized water. The preparing method includes the steps of 1, preparing premixed liquid; 2, acquiring clarified mixed liquid; and 3, allowing vacuum standing for 12 to 48 hours and performing sealing to obtain the hydrogen fluoride detection reagent. The hydrogen fluoride detection reagent is of high response speed and high accuracy, the problem that the prior art is poor in precision is effectively solved, and the content of hydrogen fluoride can be detected effectively and quickly.

Owner:SUZHOU YOUJUN ENVIRONMENTAL SCI & TECH

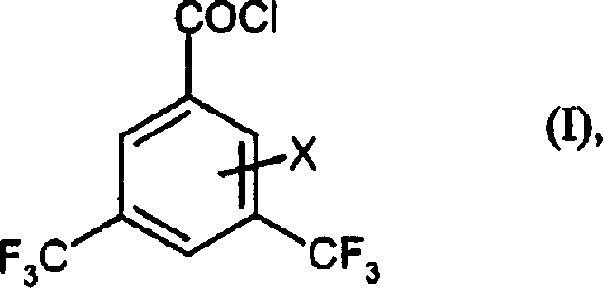

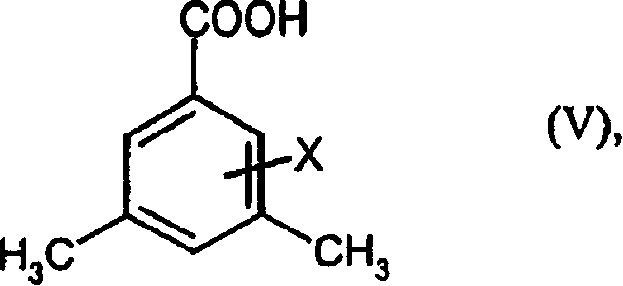

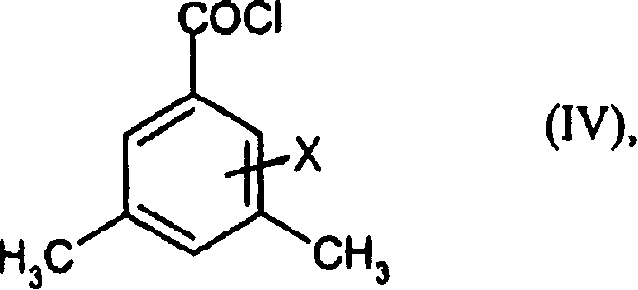

Preparation method of 3,5-di (trifluoromethyl) benzoyl chloride and new 3,5-di trihalomethyl benzoylate A and 3,5-dimethyl benzoylate A

InactiveCN1216028CHigh yieldOrganic compound preparationOrganic chemistry methodsBenzoic acidHydrogen fluoride

Preparation of 3,5-bis-(trifluoromethyl)-benzoyl chlorides (I) involves converting a 3,5-dimethyl-benzoic acid (V) into the acid chloride (IV), subjecting the side-chains to radical chlorination, fluorinating with anhydrous hydrogen fluoride and / or antimony pentafluoride to give a 3,5-bis-(trifluoromethyl)-benzoyl fluoride and reacting with silicon tetrachloride in presence of another Lewis acid. Preparation of 3,5-bis-(trifluoromethyl)-benzoyl chlorides of formula (I) involves: (1) converting a 3,5-dimethyl-benzoic acid of formula (V) into the corresponding acid chloride of formula (IV); (2) subjecting the side-chains to complete radical chlorination to give a 3,5-bis-(trichloromethyl)-benzoyl chloride of formula (III); (3) fluorinating with anhydrous hydrogen fluoride and / or antimony pentafluoride to give a 3,5-bis-(trifluoromethyl)-benzoyl fluoride of formula (II); and (4) reacting with silicon tetrachloride in presence of another Lewis acid. [Image] X : H, F or Cl. Independent claims are included for the intermediates (III; X = F or Cl) and (IV; X = F or Cl) as new compounds.

Owner:LANXESS DEUTDCHLAND GMBH

Method for preparing graphite fluoride at low temperature

The invention discloses a method for preparing graphite fluoride at low temperature. The method comprises the following steps: using ferric fluoride as a catalyst, and performing reaction of crystalline flake graphite and bromine trifluoride at low temperature to generate a graphite intercalation compound; then, performing reaction of potassium manganese hexafluoride and antimony pentafluoride to generate fluorine; and performing reaction of the fluorine generated and the graphite intercalation compound to form the graphite fluoride with high fluorine content. Through purifying treatment by a solvent, the prepared graphite fluoride is high in purity.

Owner:东莞市致格电池科技有限公司

High-strength plastic shuttle

InactiveCN104804703AFirmly connectedExtend working lifeNon-macromolecular adhesive additivesLayered productsPolysulfide rubberAdhesive

The invention discloses a high-strength plastic shuttle which comprises a plastic shuttle body; the plastic shuttle body is formed by bonding adjacent plastic plate bodies; adhesive used for bonding the plastic plate bodies is formed by linoleic acid dimerization diglycidyl ether, polysulfide rubber, wheat flour, antimony pentafluoride and butanone. The high-strength plastic shuttle is firm in connection and long in service life.

Owner:NANTONG TIANYAN TEXTILE EQUIP

PE antistatic anti-radiation mining pipe fitting

InactiveCN107793616AImprove conductivityRigid pipesElectrically-conductive paintsFuranAntimony pentafluoride

The invention discloses a PE anti-static and anti-radiation electric mine pipe fitting, which is made of a base pipe and a functional layer, and the functional layer includes the following components in terms of mass percentage: polyethylene 15‑50wt.%, corn Starch 15-50wt.%, cobalt acetylacetonate 20-55wt.%, potassium titanate whisker reinforcement 0.1-2.0wt.%, antimony pentafluoride 0.05-1.0wt.%, furan resin 0.1-1wt.%. An antistatic coating is arranged between the base pipe and the functional layer, and the antistatic coating is composed of ethyl silicate paint. The antistatic coating composed of the ethyl silicate system of the present invention has good electrical conductivity, and its effects of removing static electricity and anti-radiation are very stable and extremely good.

Owner:WUXI LONGSHUN IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com