Process for producing graphite fluoride by low-temperature intercalation method

A technology of fluorinated graphite and intercalated graphite, applied in the chemical industry, can solve the problems of difficulty in large-scale production, danger, and relatively little research on the production process of fluorinated graphite, and achieve the effect of avoiding harsh requirements and avoiding danger.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] Example 1: The synthesis of graphite fluoride has three steps:

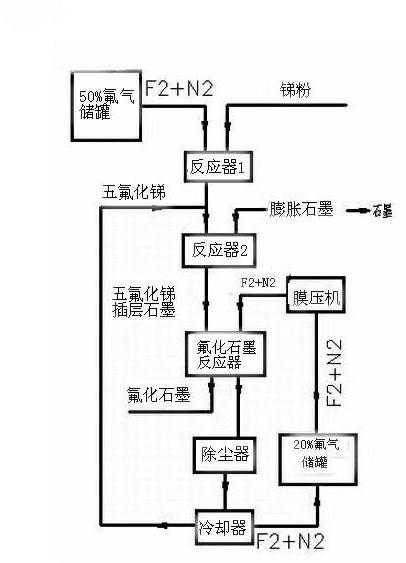

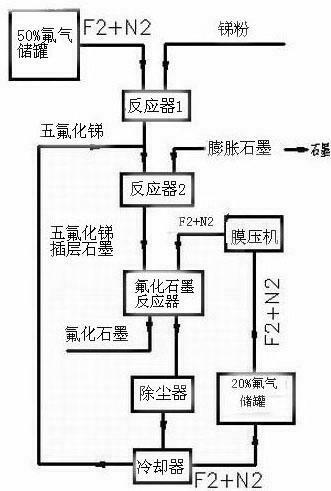

[0015] The production of graphite fluoride is divided into three steps: as figure 1 Shown:

[0016] In the first step, high-purity antimony pentafluoride is prepared by direct reaction of fluorine-nitrogen mixed gas with 50% mass percentage concentration of fluorine and nitrogen and antimony powder; the reaction equation is: 5F 2 +2Sb = 2SbF 5 .

[0017] Fluorine and nitrogen accounted for 50% of the mass percentage concentration of fluorine and nitrogen mixed gas, the flow rate is controlled by the fluorine gas flow meter, and enters the reactor from the reactor nozzle; The speed adjusts the feed amount; antimony powder and fluorine-nitrogen mixed gas directly react to generate gaseous antimony pentafluoride, and the gaseous antimony pentafluoride generated by the reaction is cooled by a cooler to obtain liquid high-purity antimony pentafluoride;

[0018] In the second step, liquid high-purity antim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com