Decompression anti-explosion device for switch cabinet

An explosion-proof device and switchgear technology, applied in the direction of switchgear, switchgear setting, electrical components, etc., can solve the problems of unsafe and reliable operation, poor standardization and versatility, poor pressure relief and explosion-proof performance, and improve pressure relief and explosion-proof High performance, high degree of versatility, avoiding the effect of dangerous operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

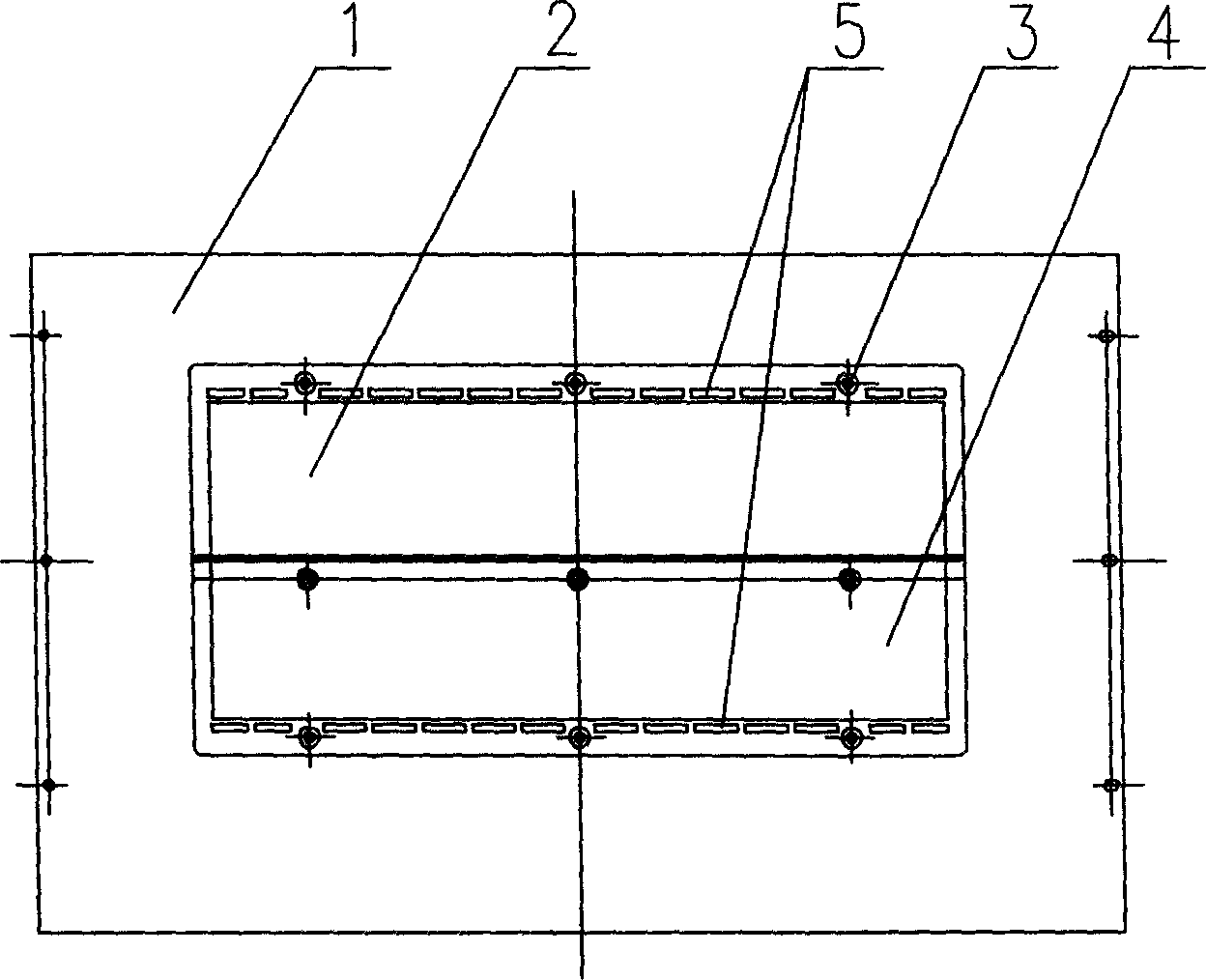

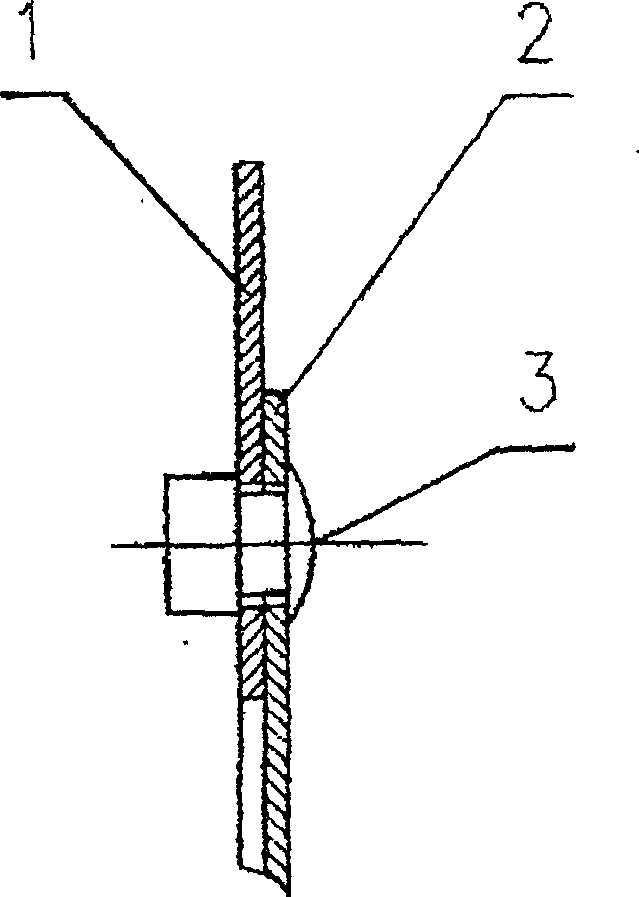

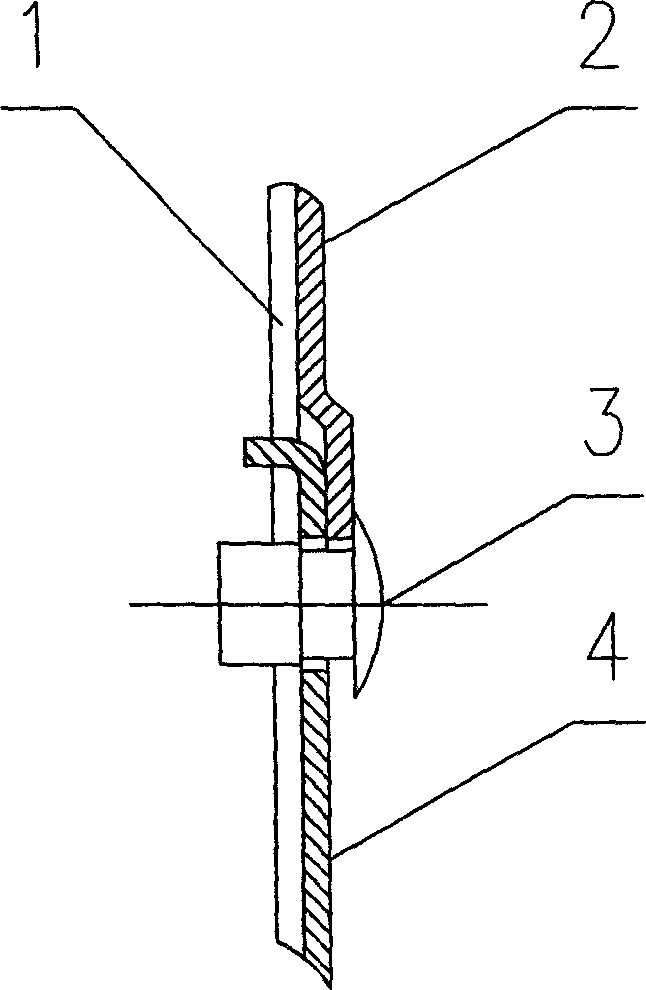

[0011] See figure 1 , Figure 2 and image 3 , The sealing plate 1 is installed on the top or side of the switch cabinet, and the middle part of the sealing plate 1 has a large rectangular hole for installing the explosion-proof plates 2 and 4. At the intersection of the explosion-proof plates 2 and 4 and the sealing plate 1, use rivets 3 to rivet the explosion-proof plates 2 and 4 and the sealing plate 1 respectively. At the middle intersection of the explosion-proof plate 2 and the explosion-proof plate 4, the bending surface of the explosion-proof plate 2 is flatly pressed on the explosion-proof plate 4, and the overlapping end of the bending surface and the explosion-proof plate 4 are riveted with rivets 3. There is no gap between the explosion-proof plate and the sealing plate like this, and rectangular grooves 5 are evenly distributed on the explosion-proof plates 2 and 4 and are processed near the riveting place with the sealing plate 1 . When an arcing fault occurs in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com