Method for keeping roundness of pressure steel pipe in concrete backfilling process

A pressure steel pipe and pressure pipeline technology, which is applied to the field of maintaining the roundness of the pressure steel pipe in the process of concrete backfilling, can solve the problems of troublesome installation and disassembly, poor rounding effect, and reduced thickness, etc., and achieves simple and convenient operation and high use stability. , to ensure the effect of roundness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

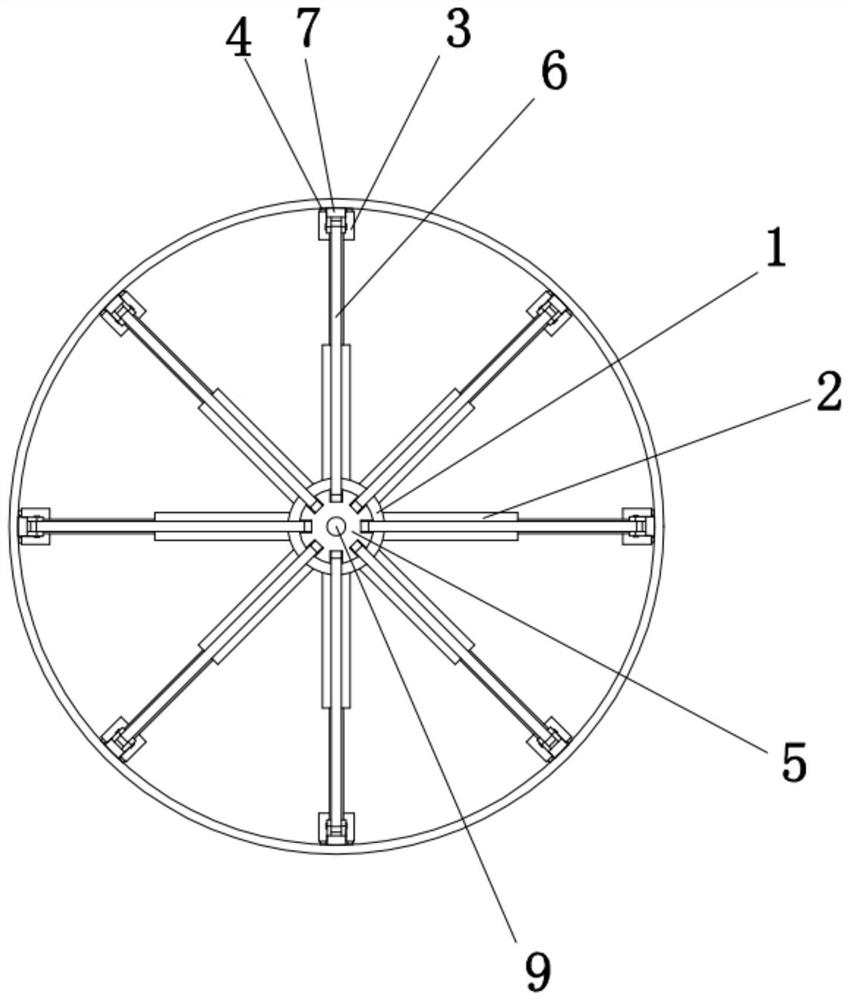

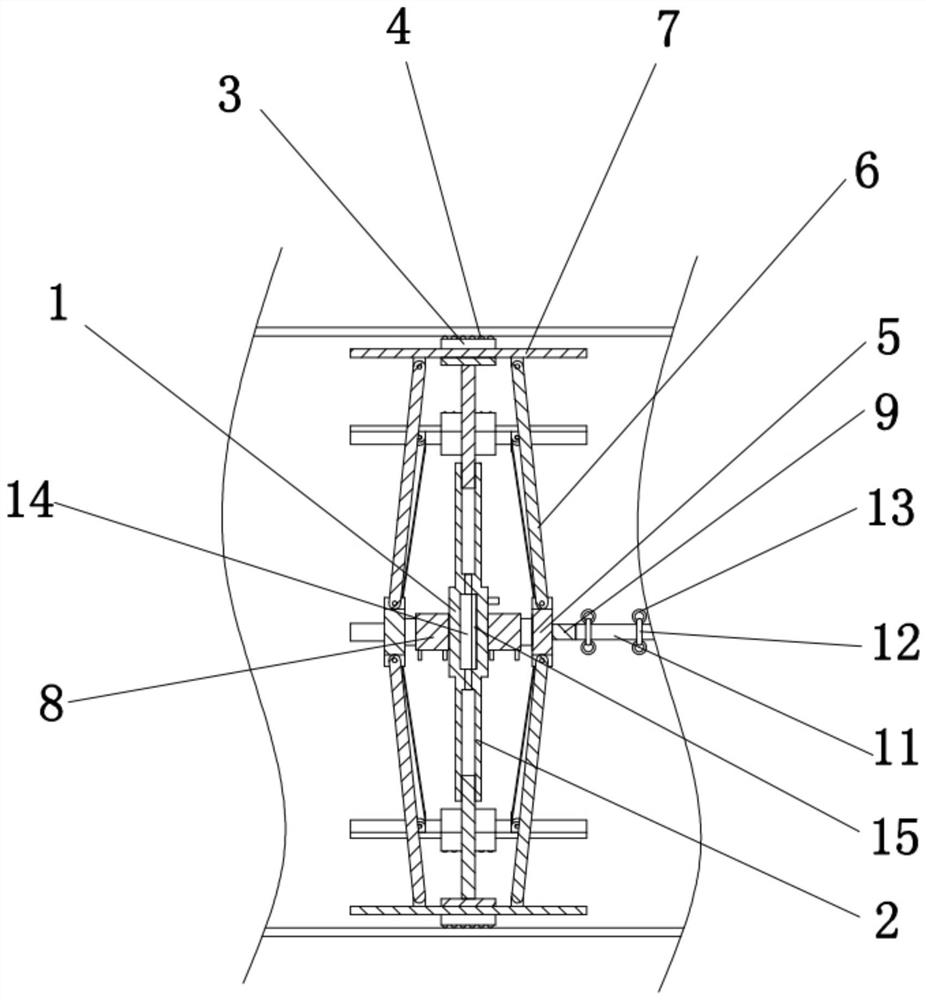

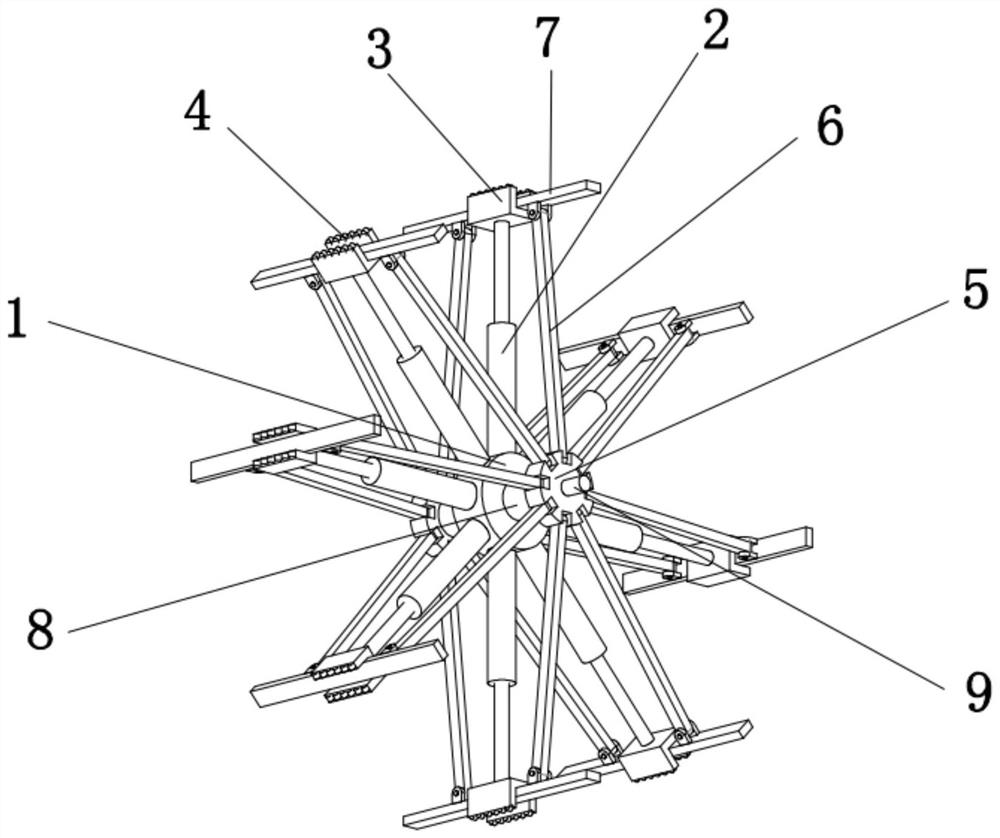

[0043] see Figure 1-5 , a method for maintaining the roundness of penstocks in the process of backfilling concrete, comprising the following steps:

[0044] S1. Put the holding device into the penstock before backfilling the concrete;

[0045] S2. The PLC control system drives the hydraulic cylinders 8 on both sides to shrink synchronously, and the hydraulic cylinders 8 drive the moving end plates 5 on both sides to approach, and the moving end plates 5 push the support plate 7 to expand outward through the diagonal tie rod 6, so that the support plate 7 and the pressure contact with the inner wall of the pipe;

[0046] S3. The PLC control system controls the outer hydraulic station to pump hydraulic oil into the oil distributor 14 in the center base 1 through the central oil delivery port 10, and the oil distributor 14 supplies hydraulic oil to the mobile support hydraulic cylinder 2 through the central oil delivery chamber 16 , so that the mobile support hydraulic cylinde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com