Method for preparing siloxane potassium alcoholate

A technology of potassium siloxanolate and polysiloxane, applied in the field of preparing potassium siloxanolate, can solve problems such as long reaction time, unfavorable application of potassium siloxanolate, etc., and achieve the effect of avoiding environmental pollution and the danger of operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

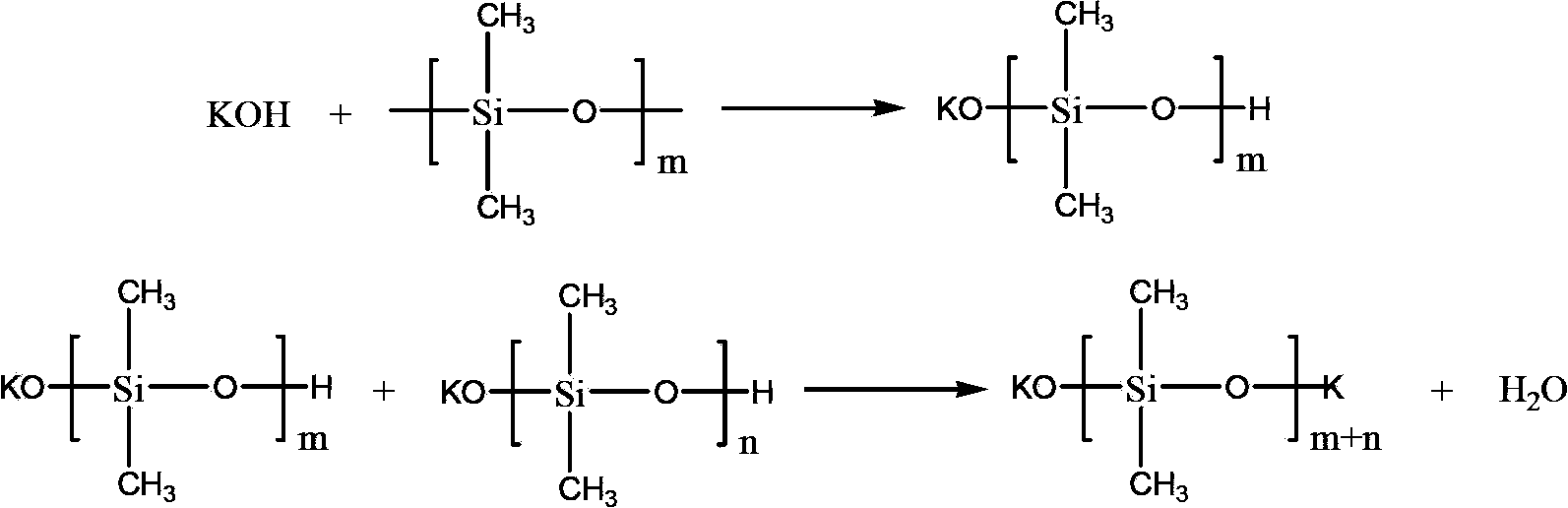

Method used

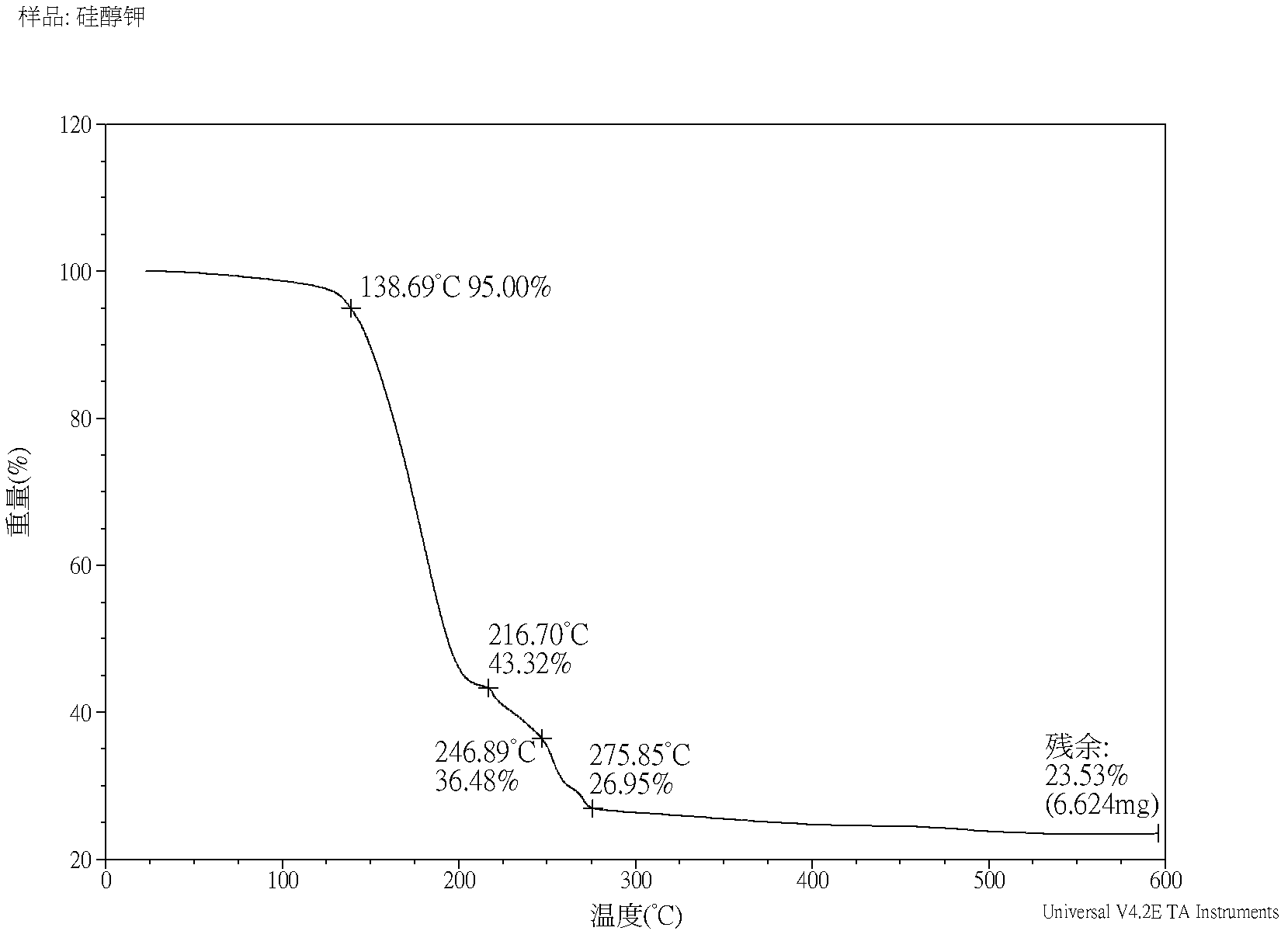

Image

Examples

Embodiment 1

[0033] The method for preparing potassium siloxanate, the steps are as follows:

[0034]Rinse the surface of the sheet-shaped potassium hydroxide quickly under the protection of nitrogen with twice-distilled water that has been boiled to remove carbon dioxide, then quickly weigh 40g of potassium hydroxide and dissolve it in 40g of secondary water that has removed carbon dioxide, and transfer it to 500ml four-port under the protection of nitrogen. Then add 360g of dimethylsiloxane mixed rings into the flask. The four-necked flask is equipped with a water separator, and the temperature is raised to 120°C under the condition of constant stirring and nitrogen, and then the vacuum is turned on to maintain dehydration at -0.04Mpa. When it is observed that the speed at which the water droplets are collected becomes slow, the vacuum degree can be gradually increased to -0.09MPa until it is found that no water droplets are collected within 10 minutes, and the reaction ends. Then it was...

Embodiment 2

[0039] The method for preparing potassium siloxanate, the steps are as follows:

[0040] Rinse the surface of the sheet-shaped potassium hydroxide quickly under the protection of nitrogen with twice-distilled water that has been boiled to remove carbon dioxide, then quickly weigh 20g of potassium hydroxide and dissolve it in 10g of secondary water that has removed carbon dioxide, and transfer it to 500ml four-port under nitrogen protection. In the flask, then add a mixture of 380g cyclic polysiloxane and hydroxyl-terminated linear polysiloxane, wherein the mass ratio of the two siloxanes is 3:7, and the viscosity is 28mpas. The four-neck flask was equipped with a water separator, and the temperature was raised to 120°C under the condition of constant stirring and nitrogen, and then the vacuum was opened to maintain dehydration at -0.05Mpa. When it is observed that the speed at which the water droplets are collected becomes slow, the vacuum degree can be gradually increased to ...

Embodiment 3

[0042] The method for preparing potassium siloxanate, the steps are as follows:

[0043] Dissolve 40g of potassium hydroxide in 15g of double-distilled water from which carbon dioxide has been removed, then add 10g of strong basic macroporous anion exchange resin, exchange and adsorb for 2 hours, quickly filter and transfer to a 500ml four-necked flask equipped with it, and then add 360 g 70 mpas of hydroxyl terminated linear polysiloxane. The four-neck flask was equipped with a water separator, and the temperature was raised to 120°C under the condition of constant stirring and nitrogen, and then the vacuum was opened to maintain dehydration at -0.05Mpa. When it is observed that the speed at which the water droplets are collected becomes slow, the vacuum degree can be gradually increased to -0.09MPa until it is found that no water droplets are collected within 10 minutes, and the reaction ends. Then it was naturally cooled to 60°C under the protection of nitrogen, transferre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flash point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com