Low temperature method for producing graphite fluoride

A technology of graphite fluoride and production method, applied in chemical instruments and methods, inorganic pigment treatment, fibrous fillers, etc., can solve the problems of high temperature, difficult temperature control, unsuitable for large-scale production, etc., and achieve high utilization rate of raw materials Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

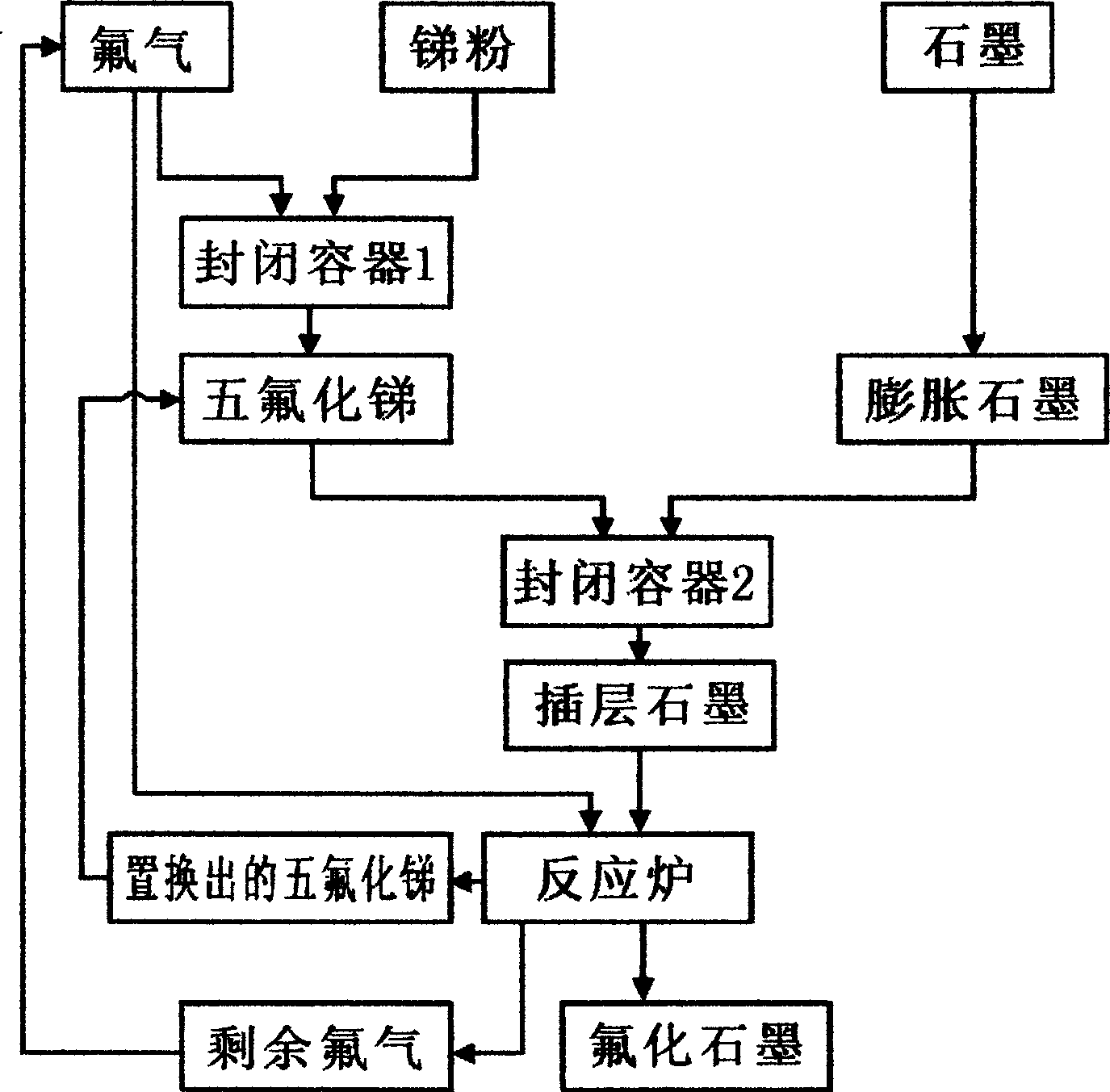

[0012] Below in conjunction with accompanying drawing, the present invention will be further described:

[0013] In the accompanying drawings, first, put the graphite in hydrochloric acid and soak it for 3-5 hours, take it out and dry it, then put it into a certain concentration of hydrogen peroxide and soak it for 3-4 hours, take it out and dry it, and then get expanded graphite; Put more than 99% of the antimony powder into the closed container 1, heat it to 150-200 degrees Celsius and keep this temperature, feed the fluorine gas with a concentration of 50-90% into the closed container 1, and let the air in the closed container 1 The pressure is kept below 0.1Mpa, so that the antimony powder in the closed container 1 reacts with fluorine gas to obtain liquid antimony pentafluoride, whose molecular formula is SbF 5 .

[0014] Then, put the above-mentioned expanded graphite into another closed container 2, vacuumize, heat to 110-150 degrees Celsius and keep a constant tempera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com