Method and reactor for preparing antimony pentafluoride

An antimony pentafluoride and a reactor technology are applied in the field of preparation methods and reactors of antimony pentafluoride, which can solve the problems of difficult separation of impurities, low product storage, complex antimony pentafluoride, etc. Corrosion, easy operation, prolong life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to describe the technical content, structural features, achieved goals and effects of the present invention in detail, the following will be described in detail in conjunction with the embodiments and accompanying drawings.

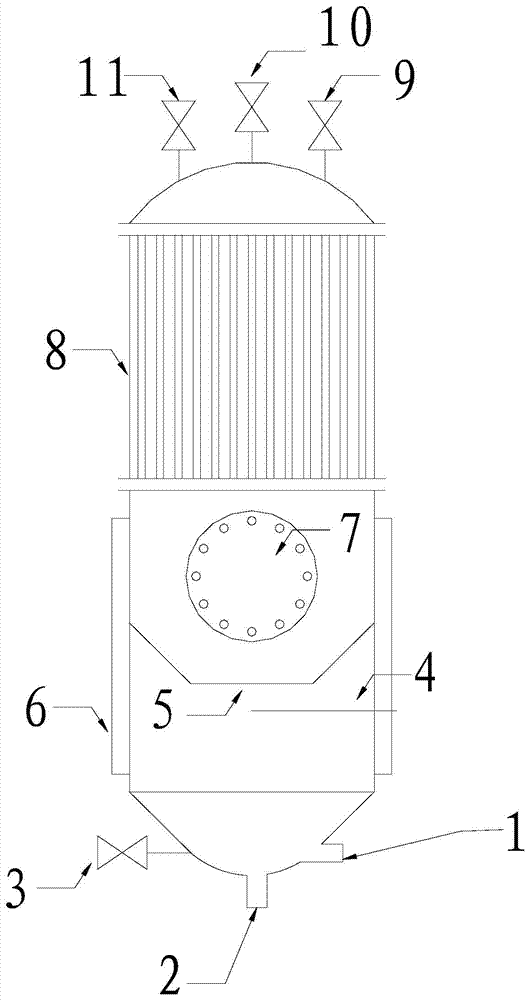

[0025] Please also refer to figure 1 , as shown in the figure, antimony tray 5 and condenser 8 are respectively arranged in the reactor of the present invention from bottom to top, and steam heating mantle 6 and feeding hole 7 are provided on the side wall of reactor and antimony tray 5 level, described The antimony tray 5 is provided with air inlet holes to make the reaction more fully; metal antimony is placed on the antimony tray 5 through the feeding hole 7, and the reactor is heated by the steam heating jacket 6, and the condenser 8 is a general steam condensation In this embodiment, a tube-and-tube condenser is used. The bottom of the reactor has a fluorine gas inlet 1 and a material outlet 2. The fluorine gas inlet 1 is connected to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com