Method for preparing graphite fluoride

A technology of fluorinated graphite and graphite, applied in the field of preparation of fluorinated graphite, can solve the problems of not disclosing key synthesis technologies, multiple side reactions and side reaction products, affecting the quality of fluorinated graphite, etc., and achieves stable properties and high utilization value. , the effect of promoting development

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

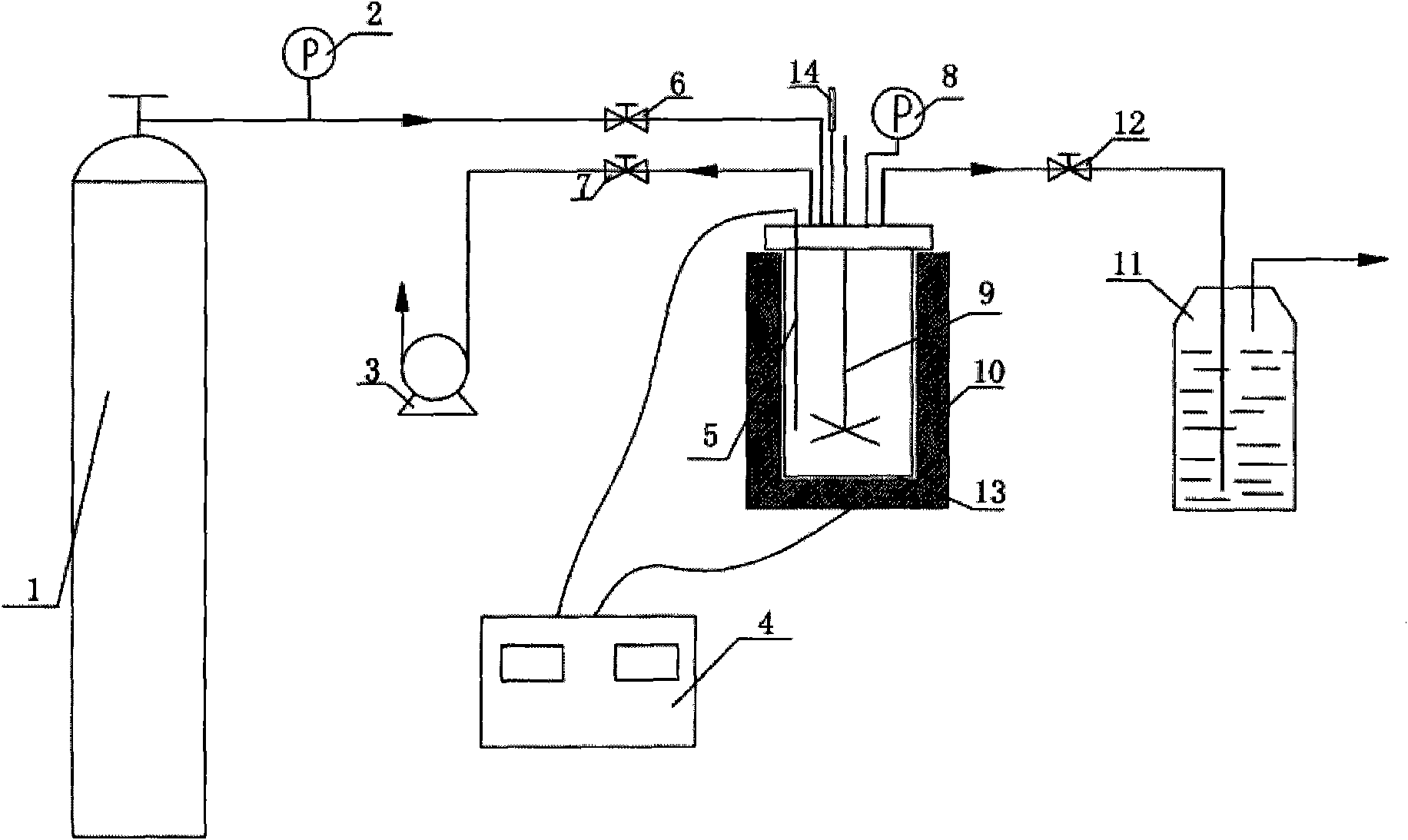

Method used

Image

Examples

Embodiment 1

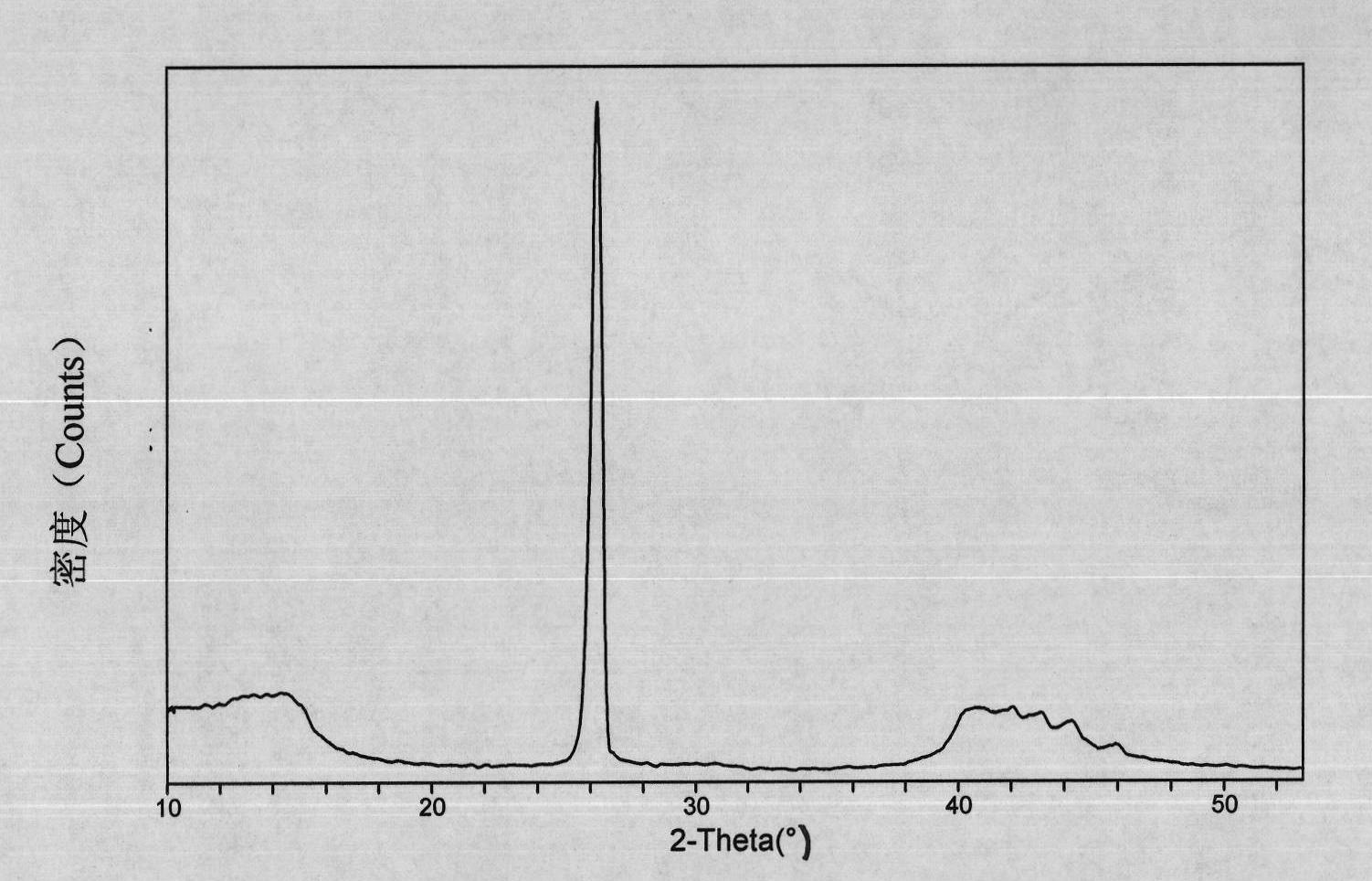

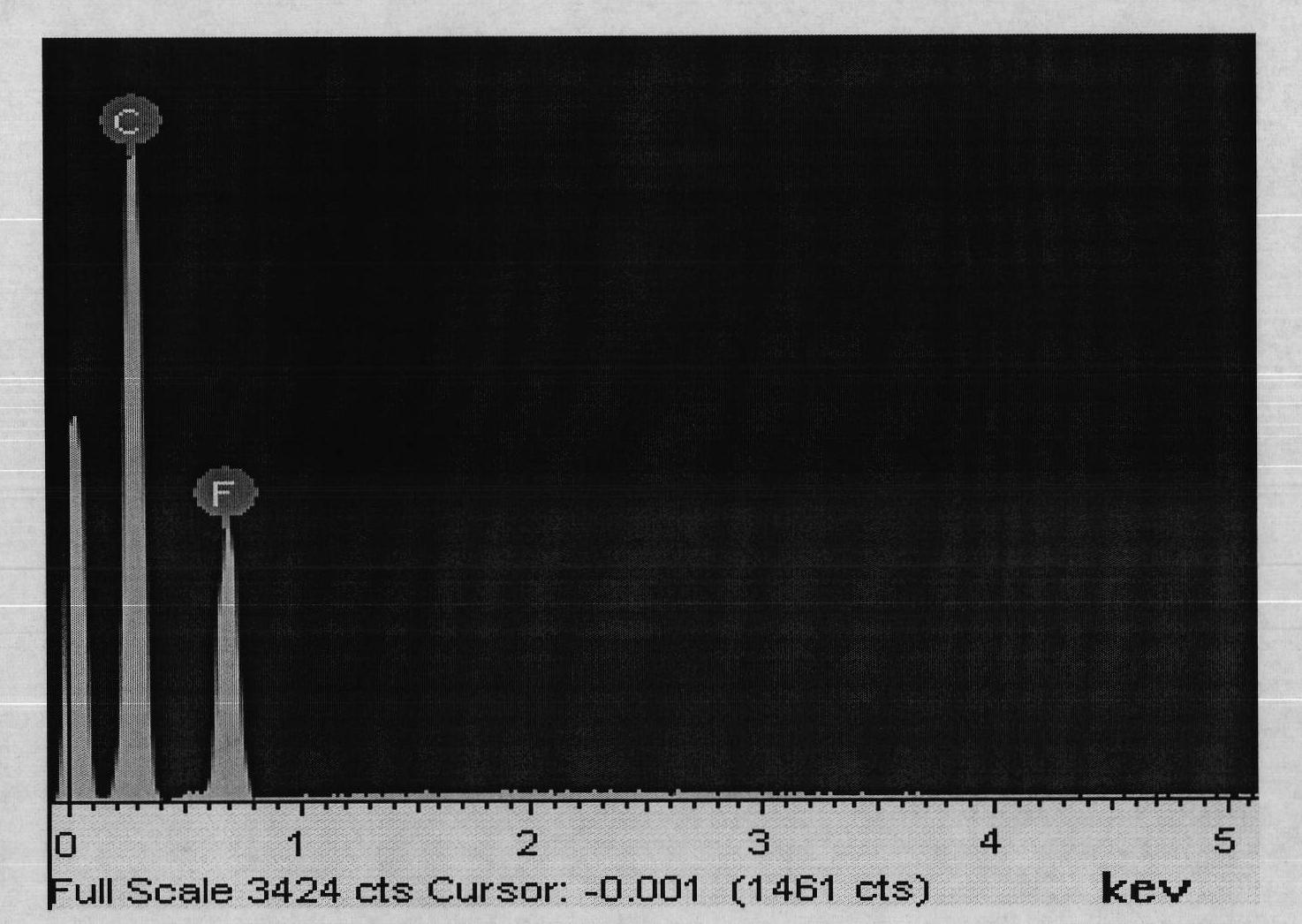

[0068] Molby K 2 MnF 6 :SbF 5 =1:2 Configure inorganic fluoride mixture, add pretreated flake graphite, the mass ratio of inorganic composite fluoride to graphite is 43:1. The mixed material was moved into the reactor, and the reactor was sealed, and finally filled with nitrogen at a pressure of 0.5Mpa. Set the heating rate of the reactor to 15°C / min, the reaction temperature to 500°C, and the time for 3 hours, heat the reactor, close the reactor after the reaction, cool to room temperature, take out the reaction product, purify and dry to obtain the product, the fluorine content of the product is 35.5 %. figure 2 with image 3 Respectively, the XRD analysis spectrum and the EDS analysis spectrum of the product obtained.

Embodiment 2

[0070] Molby K 2 MnF 6 :SbF 5 =1:2 Configure inorganic fluoride mixture, add pretreated flake graphite, the mass ratio of inorganic composite fluoride to graphite is 43:1. Move the mixed material into the reactor, seal the reactor, and finally fill the reactor with nitrogen pressure of 2.5Mpa, set the reactor heating rate to 15°C / min, and the reaction temperature to 500°C for 3 hours, heat the reactor, close the reactor after the reaction is completed, and cool to At room temperature, the reaction product was taken out, purified and dried to obtain a product with a fluorine content of 45.1%. Figure 4 with Figure 5 Respectively, the XRD analysis spectrum and the EDS analysis spectrum of the product obtained.

Embodiment 3

[0072] Molby K 2 MnF 6 :SbF 5 =1:2 Configure inorganic fluoride mixture, add pretreated flake graphite, the mass ratio of inorganic composite fluoride to graphite is 97:1. The mixed material was moved into the reactor, and the reactor was sealed, and finally filled with nitrogen at a pressure of 5Mpa. Set the heating rate of the reactor to 20°C / min, the reaction temperature to 500°C, and the reaction time to 3 hours, heat the reactor, close the reactor after the reaction, cool to room temperature, take out the reaction product, purify and dry to obtain the product, the fluorine content of the product is 59.3%. Image 6 with Figure 7 Respectively, the XRD analysis spectrum and the EDS analysis spectrum of the product obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com