Crude terephthalic acid production wastewater treatment system

A technology for producing crude terephthalic acid and waste water, applied in biological water/sewage treatment, multi-stage water treatment, natural water treatment, etc., can solve problems such as imperfect treatment process, waste of resources, difficulty in filtration, etc., and achieve resource Recycling and reuse, improving recycling efficiency and improving the effect of treatment process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The content of the present invention will be described below in conjunction with specific embodiments.

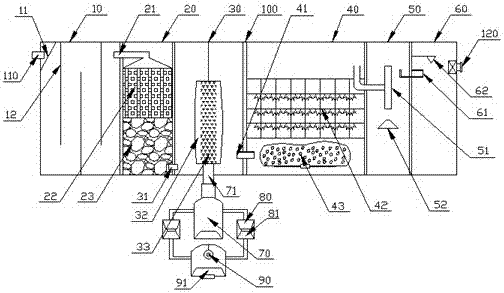

[0017] Such as figure 1 Shown is a schematic structural diagram of a crude terephthalic acid production wastewater treatment system according to the present invention.

[0018] A crude terephthalic acid production wastewater treatment system according to the present invention includes: a treatment tank body 100, a water inlet 110 and a water outlet 120 are arranged on both sides of the treatment tank body 100, and waste water enters the treatment tank body from the water inlet 110 After 100°, pass through the baffle adjustment area 10, the multi-layer filtration system 20, the adsorption area 30, the facultative anaerobic precipitation area 40, the secondary sedimentation area 50, and the water outlet area 60, and finally flow out from the water outlet 120; Distillation tower 70 is provided, and crystallization tower 80 is arranged on both sides of described distill...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com