Patents

Literature

83results about How to "Perfect processing technology" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

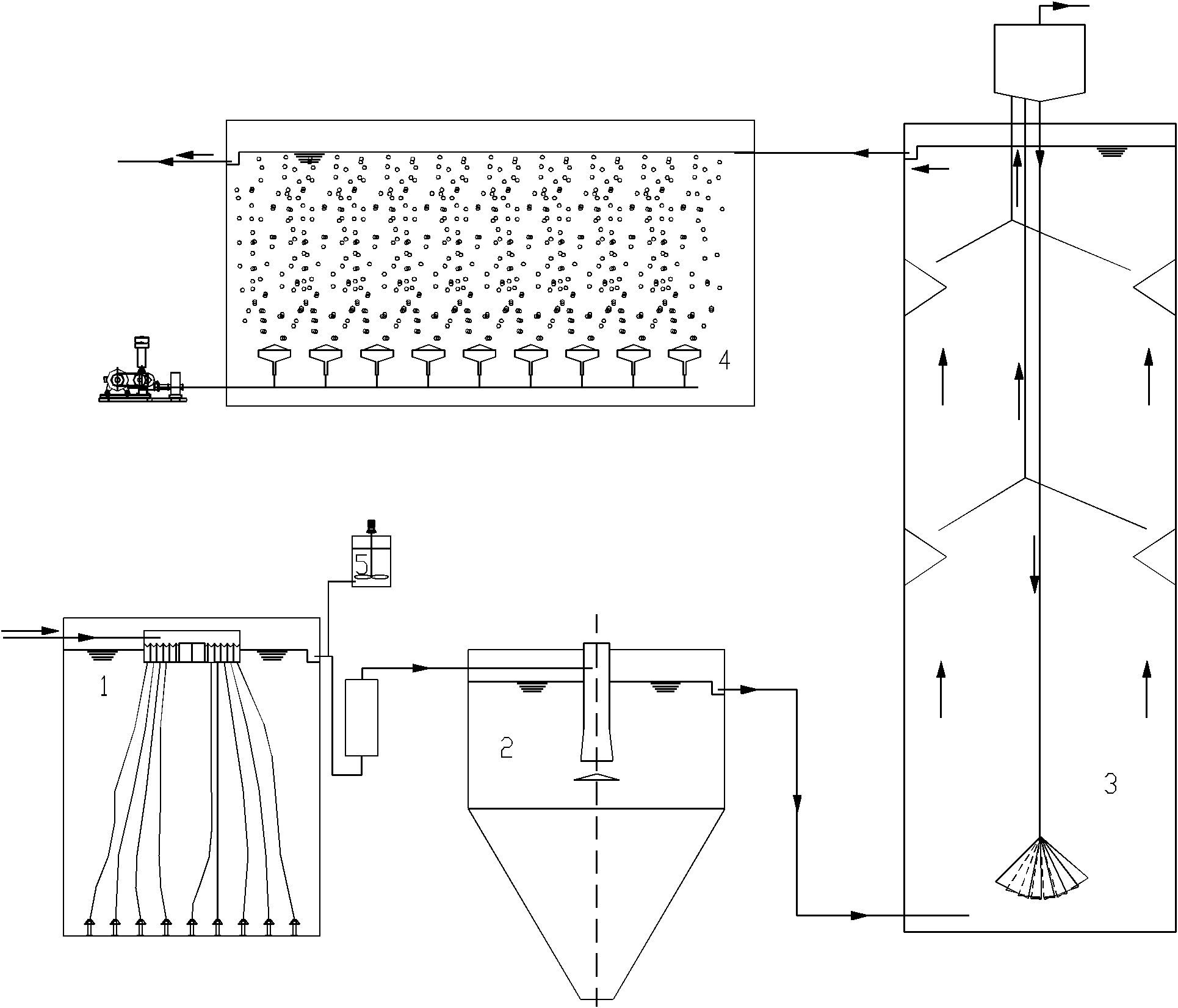

In-situ treatment system and method of black and odorous water

ActiveCN107673561AIncrease concentrationTo achieve the effect of phosphorus removalWater treatment parameter controlWater treatment compoundsWater flowWater quality

The invention provides an in-situ treatment system of black and odorous water and a method of using the system to treat black and odorous water. The in-situ treatment system of black and odorous watercomprises a pretreatment zone, an in-situ treatment zone and a separation zone; a certain section of a river channel is modified, more deflections are added to water flows, the water has longer stayin a unit zone, and the land around is scarcely used; in-situ restoration is mainly dependent on a biological method assisted by physicochemical methods, and the quality of the black and odorous wateris finally improved. In the method, the in-situ restoration of the black and odorous water is confined in a smaller area so that the concentration of microbes in the water of this area is increased,reflow can be achieved, contaminants in the water gain full time to degrade, treatment cost is lowered, and treatment is fast, efficient and free of secondary contamination.

Owner:中交生态环保投资有限公司

Water culture nutrient agent for flowers and trees and its preparation method

InactiveCN1594237AImprove absorptionPromote growthFertiliser formsFertilizer mixturesAdjuvantTrace element

The invention discloses a water culture nutrient agent for flowers and trees and its preparation method, wherein the nourishing agent includes inorganic nutrition, trace element complexing agent and a plurality of organic nourishing compositions, the slow release pelletized granule employs the same nourishing components and adjuvant, which is prepared through the steps of adsorption, embedding, granulating and dressing.

Owner:CHINA NAT RICE RES INST

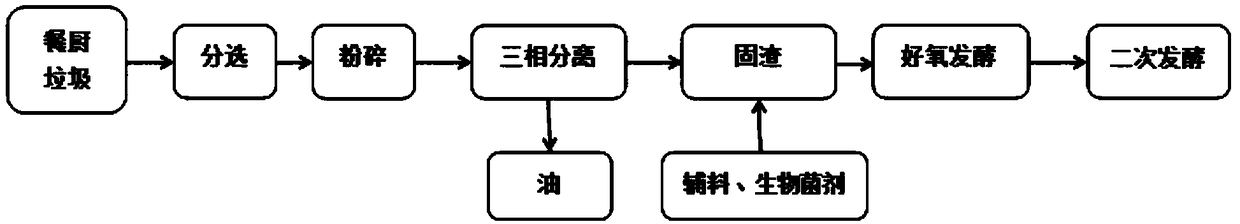

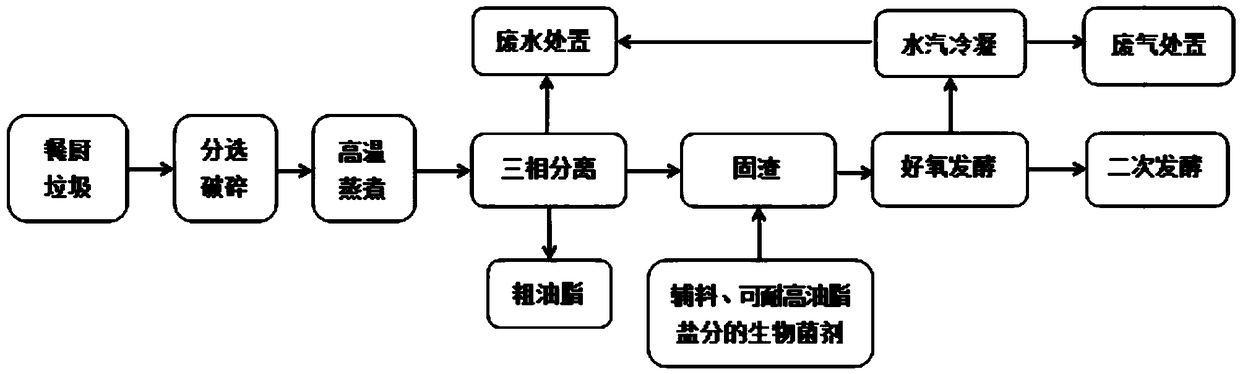

Kitchen waste resourceful treatment process

InactiveCN109467266AAccelerated precipitationImprove resource efficiencyGas treatmentTransportation and packagingOil and greaseSlag

The invention discloses a kitchen waste resourceful treatment process. The kitchen waste resourceful treatment process comprises the steps of carrying out pretreatment on collected kitchen wastes at first, wherein the pretreatment comprises sorting, crushing and cooking kitchen wastes at a high temperature; then carrying out three-phase separation on the pretreated kitchen wastes to separate out crude fat, wastewater and solid slag, and collecting the crude fat in a unified manner; adding a biological agent in the solid slag after three-phase separation, carrying out aerobic fermentation and secondary fermentation, after separating water vapor generated by fermentation, carrying out wastewater disposition and emission on a water portion and the wastewater obtained from three-phase separation, and carrying out waste gas disposition and emission on a waste gas portion. The invention provides the improved kitchen waste resourceful treatment process, the yield of the crude fat of the kitchen wastes is greatly improved, high resourceful earnings can be gained, meanwhile, an aerobic fermentation period can be shortened, the quality of compost is improved, and near zero emission of odor and wastewater is realized.

Owner:长沙工研院环保有限公司

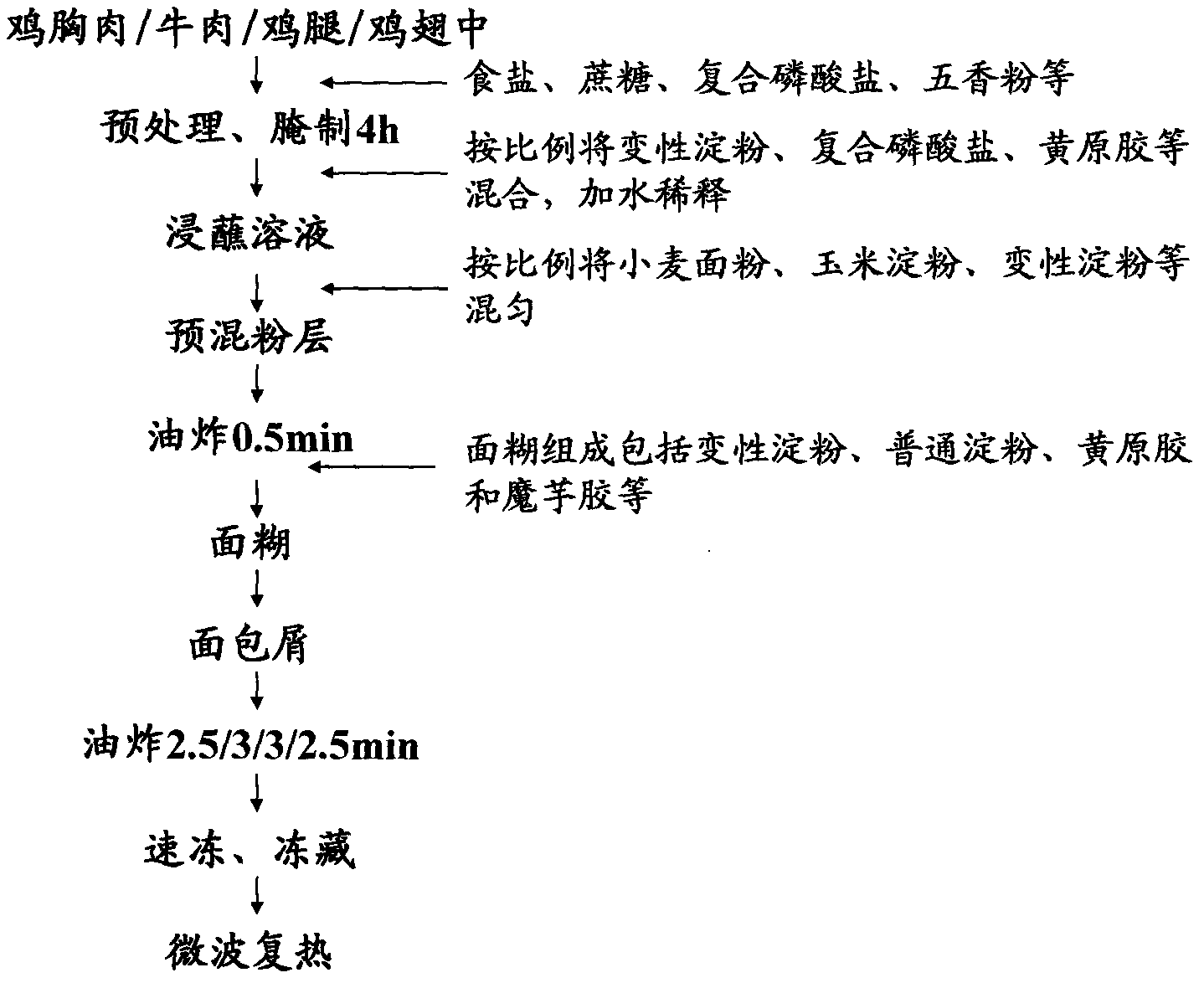

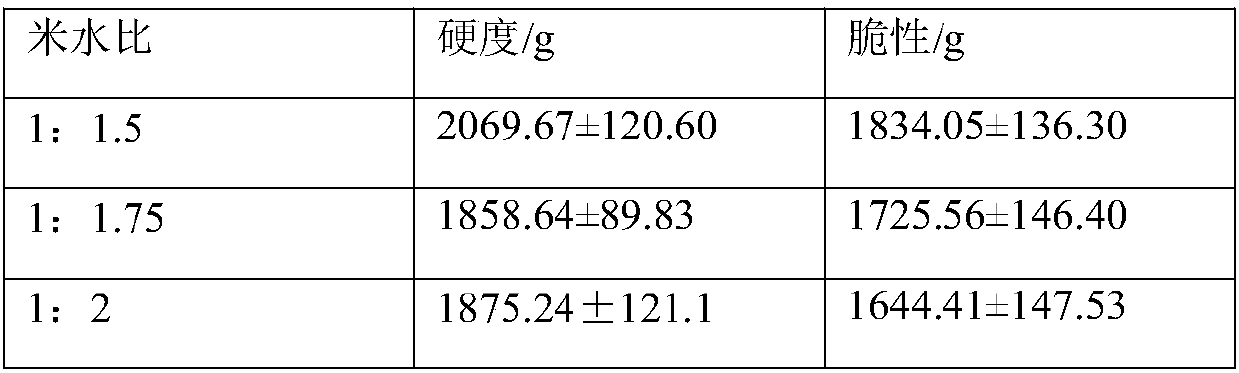

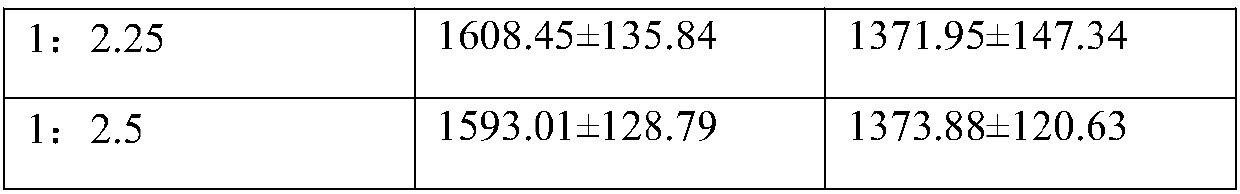

Dipping liquid for microwaveable frozen pre-fried flour-warped products and processing method of dipping liquid

The invention provides dipping liquid for microwaveable frozen pre-fried flour-warped products and a processing method of the dipping liquid, belonging to the technical field of food processing. The dipping liquid comprises the following components: 2-10% of xanthan gum, 1-10% of carrageenan, 20-40% of cassava modified starch, 10-30% of soybean protein isolate, 20-60% of warping flour, 0-10% of monoside acid and 0-10% of composite phosphate. The processing method of the dipping liquid for the microwaveable frozen pre-fried flour-warped products comprises the following steps of: 1, removing visible fat and connective tissue from a fresh meat product, dicing, and curing; 2, dipping the cured meat product in the dipping liquid; 3, evenly pasting a layer of premixing flour on the surface, and frying; and 4, evenly dipping a layer of thickener outside the fried meat product, dipping a layer of bread scraps, frying, quickly freezing, and refrigerating. Two steps of liquid dipping and pre-frying are added into an existing preparation process of a frozen flour-warped meat product, so that the frozen flour-warped meat product can be effectively guaranteed to be crispness which is as the same as a fresh fried product after being processed under microwave.

Owner:NORTHEAST AGRICULTURAL UNIVERSITY

High manganese steel and preparation method thereof

InactiveCN102534405AGuaranteed impact resistanceGuaranteed wear resistanceProcess efficiency improvementQuenching agentsHigh resistanceManganese

The invention discloses high manganese steel, which consists of the following components in percentage by weight: 0.9-1.2 % of C, 11-14 % of Mn, 0.3-0.6 % of Si, 1.5-2.5 % of Cr, less than or equal to 0.04 % of P, less than or equal to 0.04 % of S, and the balance of ferrum. A preparation method for the high manganese steel comprises the following steps of: selecting raw materials; performing smelting, namely preparing molten steel only after the components are ensured to be qualified, and controlling the temperature of the molten steel to be 1,650 DEG C for casting; performing modeling, painting after the modeling is finished, and performing mold assembly and casting; performing cleaning, namely deburring castings, and polishing and checking the castings; performing thermal treatment, namely stacking the cleaned castings in a high-temperature thermal treatment furnace, sealing a furnace door, raising the temperature to 1,100 DEG C, preserving the heat for 4 hours, quickly discharging the castings out of the furnace, and placing the castings into water for quenching; and cleaning the surfaces again, and checking and accepting, warehousing, stacking and classifying the castings. The invention has the advantages that the high manganese steel has high impact resistance and abrasion resistance; and the preparation method is simple, the production cost is low, and the market prospect is good.

Owner:TONGLING ANDONG CAST STEEL

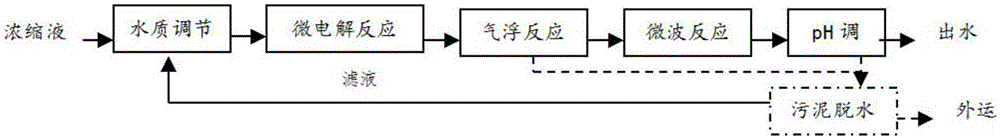

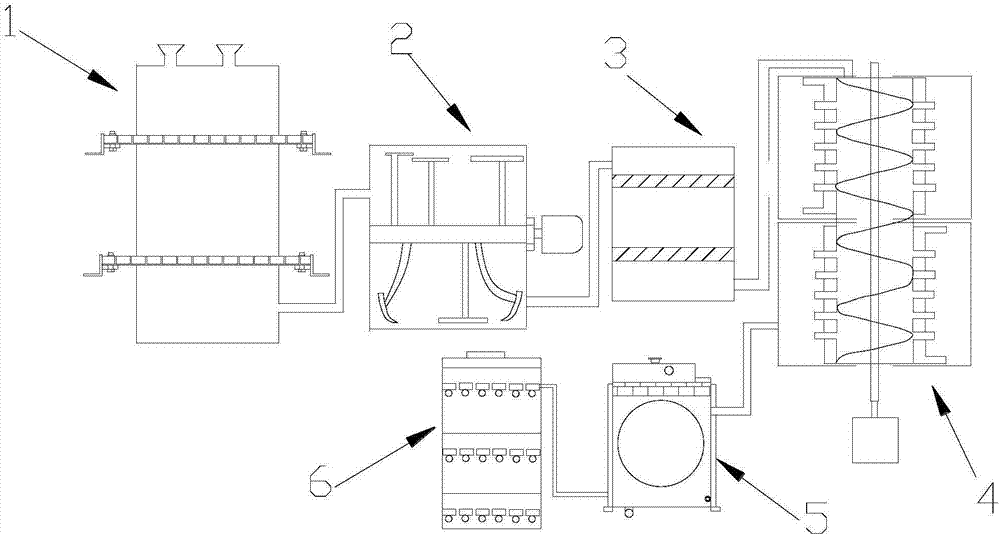

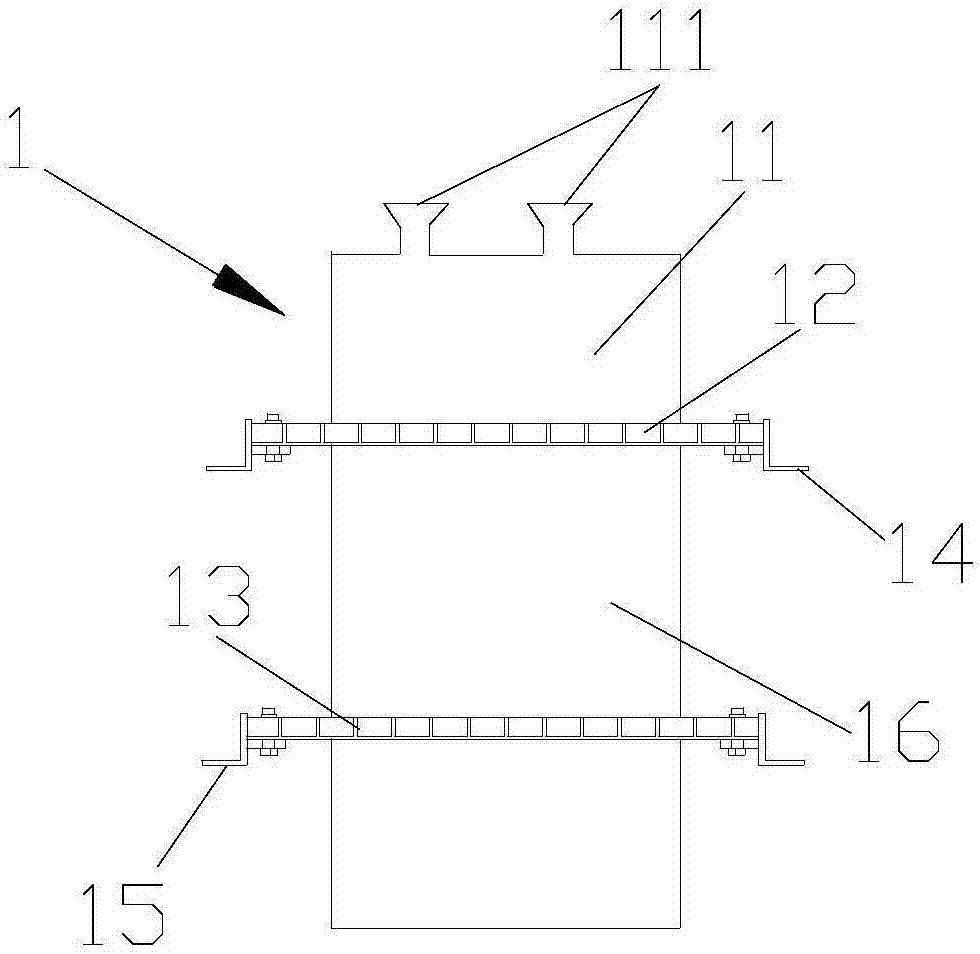

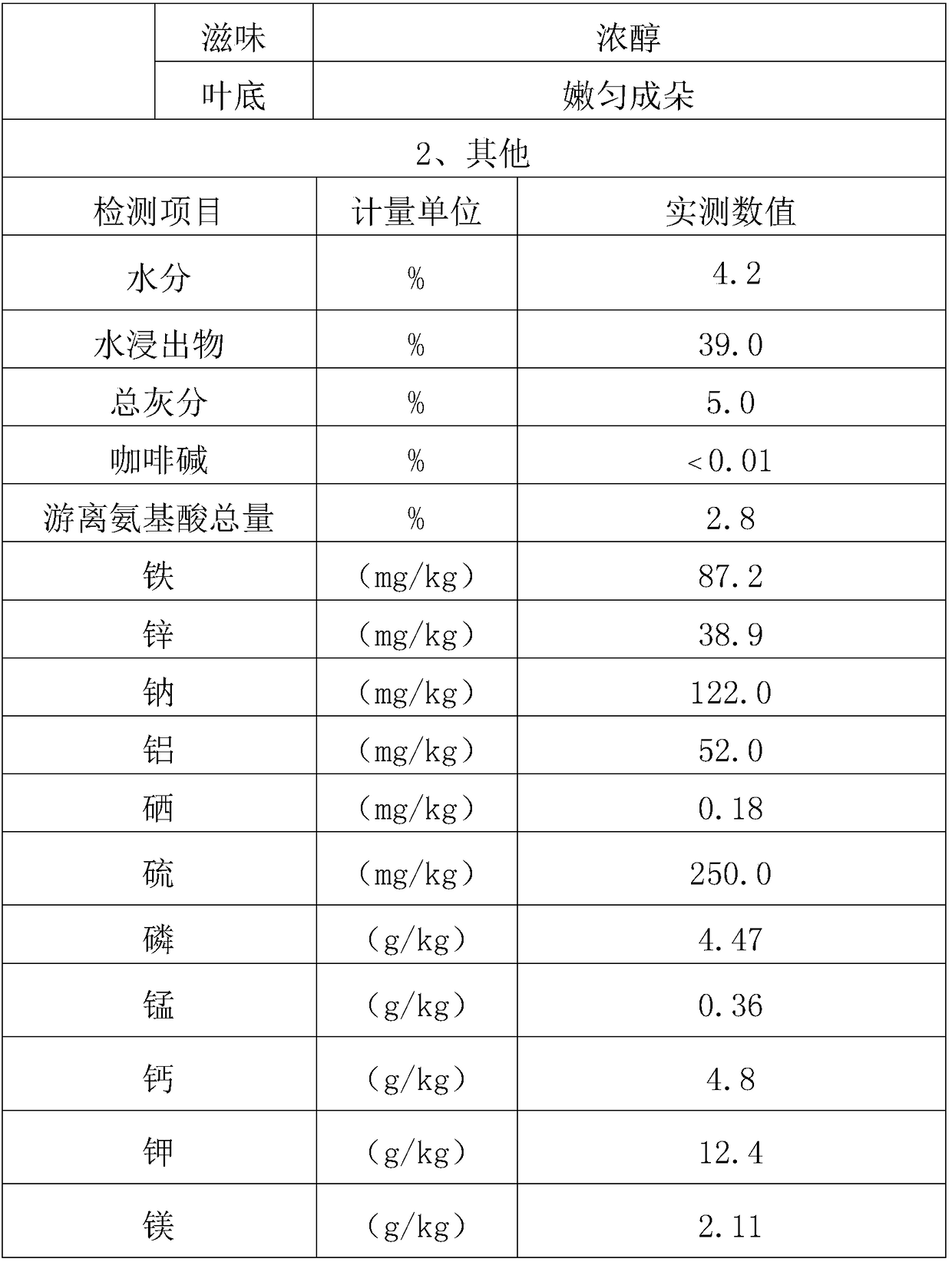

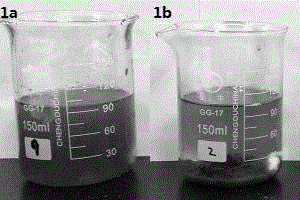

Method for treating landfill leachate nanofiltration concentrated solution through iron-carbon micro-electrolysis synergistic with microwave

InactiveCN105036434APerfect processing technologyImprove biodegradabilityMultistage water/sewage treatmentElectrolysisSludge

The invention discloses a method for treating a landfill leachate nanofiltration concentrated solution through iron-carbon micro-electrolysis synergistic with microwave. The method for treating the landfill leachate nanofiltration concentrated solution through the iron-carbon micro-electrolysis synergistic with microwave comprises the processes of water quality regulation, iron-carbon micro-electrolysis reaction, microbubble air floatation reaction, microwave reaction and pH regulation and further comprises a sludge dehydration process. The method for treating the landfill leachate nanofiltration concentrated solution through the iron-carbon micro-electrolysis synergistic with microwave has the advantages that an iron-carbon micro-electrolysis and microwave synergistic oxidation treatment process is adopted, a 'biochemical method+NF' process is used for treating a nanofiltration concentrated solution produced from landfill leachate (hereinafter referred to as a 'concentrated solution'), treatment effect is good, biochemicalization property of the concentrated solution is improved, the problem of difficulty in treatment of the concentration solution is solved, the defects of an existing landfill leachate 'biochemical method+NF' treatment process are overcome, a landfill leachate treatment technology is improved, and healthy and sustainable development of the environmental protection industry is promoted.

Owner:GUANGDONG ENG TECH INST

Processing technique of reversing valve body

The invention discloses a processing technique of a reversing valve body. The processing technique includes the following steps: (1) blanking: sawing a square billet according to the dimensions of a reversing valve; (2) forging: forging the billet through hammer forging or die forging, wherein the single-side working allowance of free forging is above 5mm and the single-side working allowance of die forging is above 2.5mm; (3) thermal treatment: annealing forge pieces and then conducting quenching and high-temperature tempering; (4) milling outline: milling the outline of a valve body, milling a big surface with a cutter and milling steps with an end mill; (5) drilling mounting holes; (6) grinding a mounting surface; (7) boring: processing through a horizontal machining center, wherein main holes are drilled by a U-shaped drill in advance and are than roughly and finely drilled; (8) tapping, burring and coating antirust agents; (9) galvanizing: galvanizing the valve body with the antirust agents to improve the antirust performance of the valve body. The processing technique of the reversing valve body is perfect; the valve body produced through the processing technique is good in quality, the integral service life of the reversing valve is prolonged, cost is reduced, and loss of enterprises is also reduced.

Owner:WUXI YANGGONG MACHINERY MFG

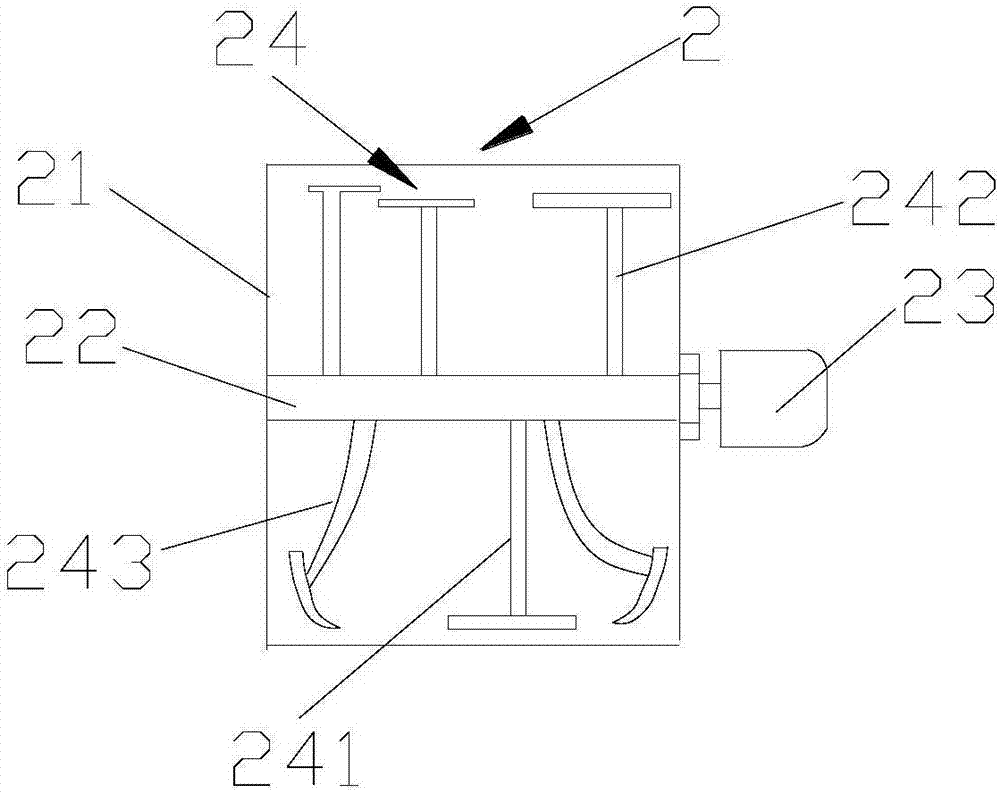

Processing equipment for lithium battery cathode material

InactiveCN107195862ARealize continuous productionReasonable structureElectrode manufacturing processesDrying gas arrangementsEngineeringMaterial storage

The invention discloses processing equipment for a lithium battery cathode material. The processing equipment can realize continuous automatic production and is good in cooling effect and high in drying efficiency. The processing equipment comprises a feeding device, a mixing device, a filter, a reaction device, a cooler and a drier, wherein the feeding device, the mixing device, the filter, the reaction device, the cooler and the drier are connected through pipelines in sequence; the cooler comprises steel channel racks and feet, the steel channel racks are arranged on two sides of the cooler, the middle part of the cooler is connected with a square boss, an inclined plane is arranged on the top of the square boss, the inclined plane is provided with a fin and a partition board, and the surface of the square boss is provided with an annular flange playing a connection role; the drier comprises a drying box, an air supplying device, a roller conveyor and a material storage box, the air supplying device is fixedly arranged on the drying box, the roller conveyor is fixedly mounted in the drying box, and the material storage box is fixedly mounted on the roller conveyor and is connected with the cooler through a pipeline. Through the structure, continuous automatic production can be realized, and the cooling effect and drying effect are good.

Owner:王映

Medium manganese steel and preparation method thereof

The invention discloses medium manganese steel. The medium manganese steel comprises the following components in percentage by weight: 0.9 to 1.1 percent of carbon (C), 6 to 8 percent of manganese (Mn), 0.3 to 0.6 percent of silicon (Si), 1.0 to 1.2 percent of chromium (Cr), 0.2 to 0.4 percent of percent (MO), less than or equal to 0.04 percent of phosphorus (P), less than or equal to 0.04 percent of sulphur (S), and the balance of Fe. A preparation method comprises the following steps of: selecting raw materials; smelting, and yielding water after ensuring that the components are qualified, wherein the water yielding temperature is controlled at 1,650 DEG C, and casting; molding, coating after molding, assembling molds and casting; removing sand: cleaning cast burrs, and performing polishing inspection; preserving the heat, stacking casts with sand cleaned in a high-temperature heat treatment furnace, sealing a furnace door, raising the temperature, preserving the heat after the temperature is raised to 1,100 DEG C, preserving the heat for 6 hours, quickly discharging the casts, and putting the casts into water for quenching; and cleaning surfaces again, and inspecting, accepting, warehousing, stacking, classifying and warehousing products. The medium manganese steel has the advantages of ensuring high impact resistance and abrasion resistance of manganese steel; having a simple production process, low production cost and a good market prospect.

Owner:TONGLING ANDONG CAST STEEL

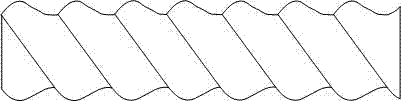

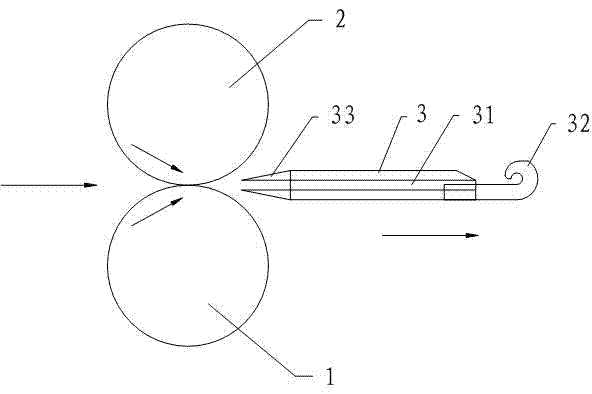

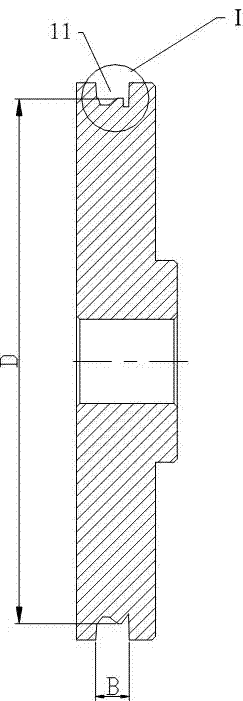

Interlocking armored forming die and process

ActiveCN103177823AMeet operational requirementsImprove securityCable/conductor manufactureMetal stripsMachining process

The invention provides an interlocking armored forming die and process. The interlocking armored forming die comprises a pair of rollers and a guide rail, wherein the rollers are divided into a fixed roller and an adjusting roller; the guide rail is arranged along with the direction of an extension line meshed with the pair of rollers; a channel is formed in the middle of the guide rail; and the end, which is far away from the rollers, of the guide rail is provided with a forming hook towards the rollers. The interlocking armored machining process comprises the following steps: pre-forming a metal strip through an active feeding roller, passing through the channel of the guide rail, and armoring the forming hook at the end of the guide rail to a cable core. Various forming angles of the rollers are adjusted, the repeated verification proves that the metal strip is naturally formed and is in smooth in transition, a good armoring effect is achieved, the requirements of impact test can be met, the product quality is guaranteed, and the difficulty in the production process is reduced.

Owner:QINGDAO CABLE

Air-dried edible meat product for pets and preparation method of same

The invention relates to an air-dried edible meat product for pets and a preparation method of the air-dried edible meat product and belongs to the technical fields of pet food and the preparation method thereof. The air-dried edible meat product for pets is characterized by comprising the following raw materials in part by weight: 100 parts of livestock and poultry meat, 0.2 to 1 part of composite phosphate, 0.005 to 0.01 part of sodium nitrite and 0.4 to 1 part of edible salt. The preparation method comprises the following steps: 1, preprocessing the raw material meat; 2, rolling and kneading; 3, sterilizing at high temperature; 4, forming; and 5, air drying at lower temperature. Compared with traditional high-temperature air-drying method, the preparation method of the air-dried ediblemeat product for pets can maintain the nutrients of the product, which are lost at high temperature, and enriches the meat processing process for the pet food. The air-dried meat product has low lossof nutrients, rich nutrients, unique flavor and high palatability, does not have any preservative and prolongs the shelf life of the product.

Owner:YANTAI CHINA PET FOODS GRP

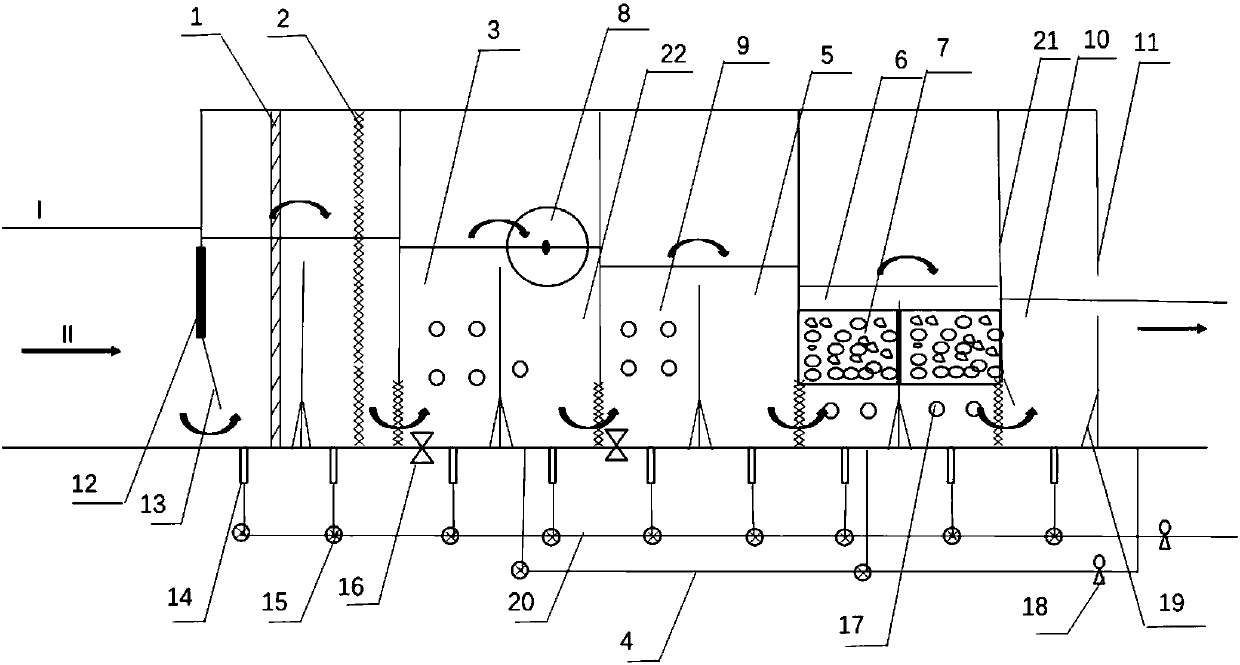

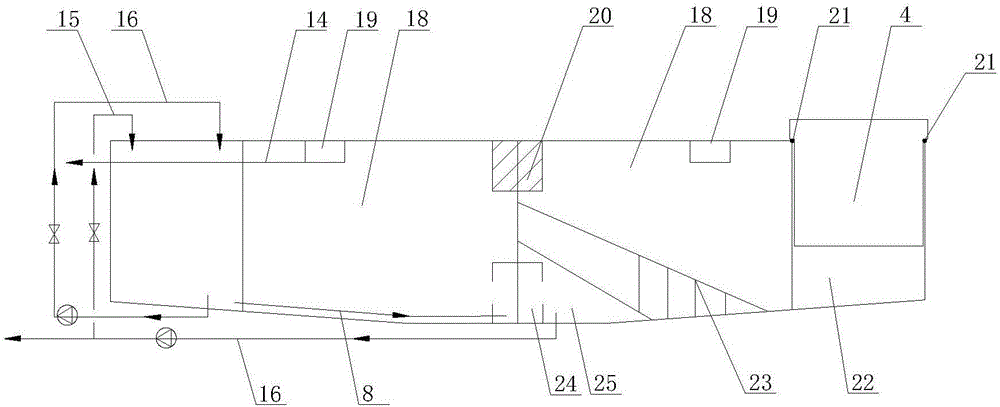

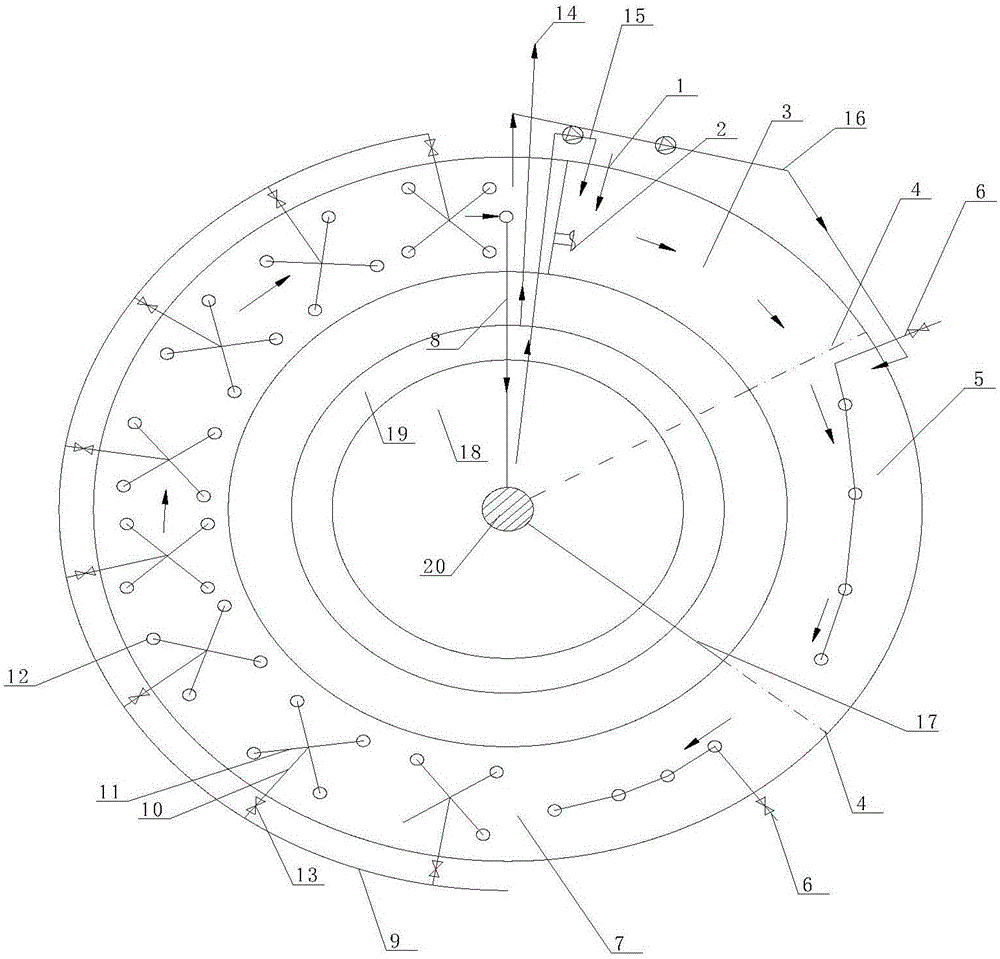

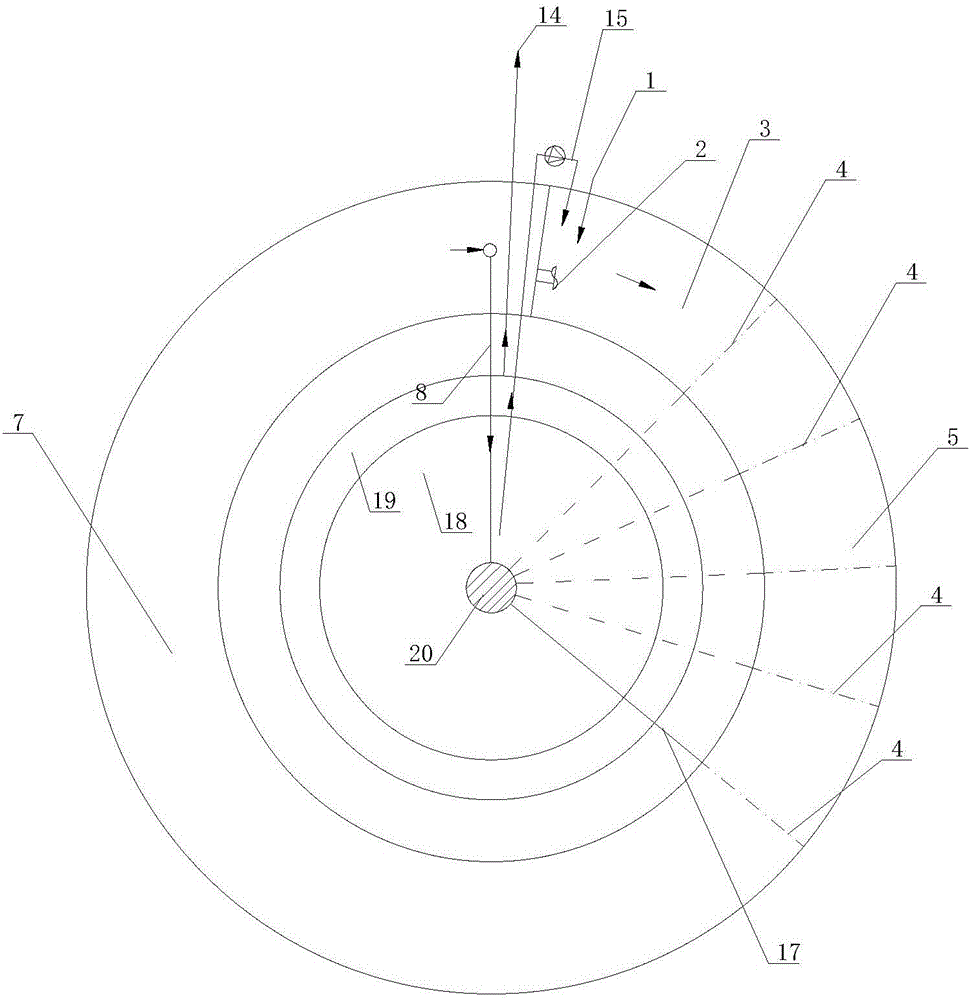

Corner adjustable type wastewater treatment biochemical reactor

PendingCN106348446AThe processing effect is stable and efficientCompact structureWater treatment parameter controlBiological treatment apparatusBiochemical engineeringWater quality

The invention discloses a corner adjustable type wastewater treatment biochemical reactor which is of annular gallery shape and comprises an anaerobic section (3), an anoxic section (5) and an aerobiotic section (7), wherein the anaerobic section (3) is connected with a water inlet pipe (1); the aerobiotic section (7) is connected with a water outlet pipe (8); a moveable separating plate (4) is arranged on the annular gallery; a slide rail (21) is arranged on an annular gallery wall; the moveable separating plate (4) is located on the slide rail (21); a driving device (20) is arranged at the center of the annular gallery; the moveable separating plate (4) is connected with the driving device (20) through a rotating arm (17); a water hole (22) is formed in the moveable separating plate (4). The corner adjustable type wastewater treatment biochemical reactor is reasonable in structure design; the relative staying time of each section can be flexibly adjusted according to the quality condition of the to-be-treated water; the microbial population is relative independent; the corresponding biochemical reaction environment is more stable; when different wastewater is treated, the efficient biochemical treatment can be kept; a settling pond is arranged at the center, so that the purifying effect is more excellent.

Owner:YANCHENG INST OF TECH

Plastic flowerpot processing technology

InactiveCN105123319AImprove yieldQuality assuranceCultivating equipmentsReceptacle cultivationPunchingUltraviolet lights

The invention discloses a plastic flowerpot processing technology. The processing technology comprises the following steps that 1, flowerpot raw materials are made of, by weight, 100 parts of polypropylene, 0.31 part of antioxygen, 0.32 part of a deoxidizing agent, 0.04 part of a stabilizing agent, and 0.13 part of an ultraviolet light absorber; 2, the flowerpot raw materials are placed in an injection molding machine, heated and molten by the injection molding machine and injected into plastic flowerpot molds with high pressure; 3, the flowerpot molds are cooled to form semi-finished flowerpots; 4, the semi-finished flowerpots are removed out of the molds, and redundant edges and corners are removed; 5, punching is carried out; 6, printing is carried out to make finished flowerpots; 7, the flowerpots passing inspection are put in storage for use. The processing technology is perfect, the processed plastic flowerpots are high in yield, the quality can be ensured, the aging resistance is high, and using requirements of consumers can be met.

Owner:WUXI HEBANG METAL PROD

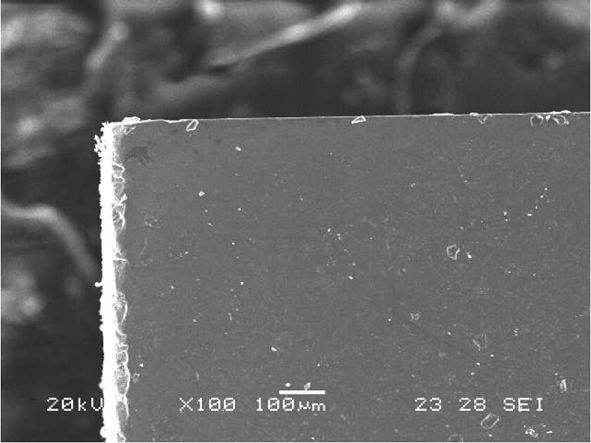

Nano-diamond cutter and preparation method and application thereof

ActiveCN112025530AAvoid Corrosion ShockGuaranteed damagePolishing machinesChemical vapor deposition coatingMetallurgyDiamond knife

The invention discloses a preparation method and application of a nano-diamond cutter. Diamond is adopted as a raw material in the method, and the method includes a cutting and shaping procedure, a polishing procedure and a cutting edge machining procedure, and further particularly comprises a pretreatment procedure carried out before the cutting and shaping procedure and a surface modification procedure carried out after the cutting edge machining procedure. The pretreatment procedure is used for eliminating defects in the diamond as much as possible; the surface modification procedure is used for forming a protective layer on the surface of a cutting edge; in the polishing procedure, firstly, a diamond cutter base material is detected to recognize the crystal face of the diamond, then the crystal face (100) or the crystal face (110) of the diamond is selected to be subjected to subsequent polishing, and the polished crystal face serves as a front cutter face; and a protective cuttergrinding method or a laser directional cleavage method is adopted in the cutting edge machining procedure. The nano-diamond cutter prepared through the method can reach the cutting edge precision of 15 nm, and is suitable for being applied to the fields of turning, nano-probes, biological sectioning and the like.

Owner:SHANGHAI ZHENGSHI TECH CO LTD

Manufacturing method of LED light source manufactured through vacuum sputtering technology

The invention discloses a manufacturing method of an LED light source manufactured through a vacuum sputtering technology, and relates to the technical field of LED light sources. The upper part of the a base material is fixedly connected with an LED support through a base material filled rubber material; an avoiding device is arranged at the middle part of the upper part of the LED support; a chip is mounted above the avoiding device; the chip is welded with a gold thread; and fluorescence rubber is packaged inside the chip and the upper part of the gold thread. The main body of the base material is selected from an aluminum material, through the vacuum sputtering technology, the material such as copper, silver, tin, nickel or zinc is deposited at the upper part of the specific base material to form an easily welded interface, and an LED packaging support aluminum material is manufactured, so that the technology protects the surface of the material from being vulcanized, brominated and oxidized, and the reflectivity and glossiness of the base material are improved. Titanium oxide on the surface and the thicknesses of titanium oxide and silver layers are controlled, routing and positive and negative tin soldering functions on the substrate surface of the special LED support can be realized, and the forming processing technology of the special LED support is varied.

Owner:SHENZHEN SMALITE OPTOELECTRONICS CO LTD

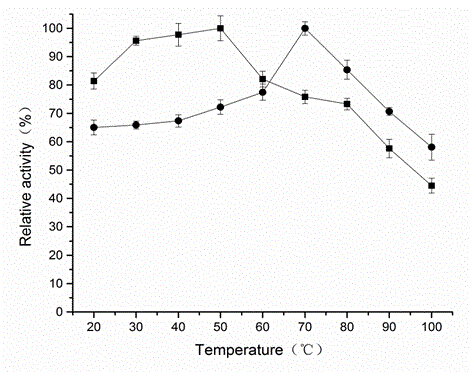

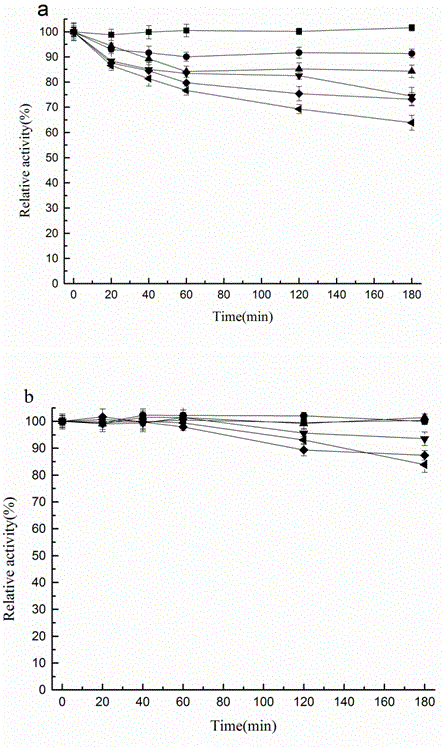

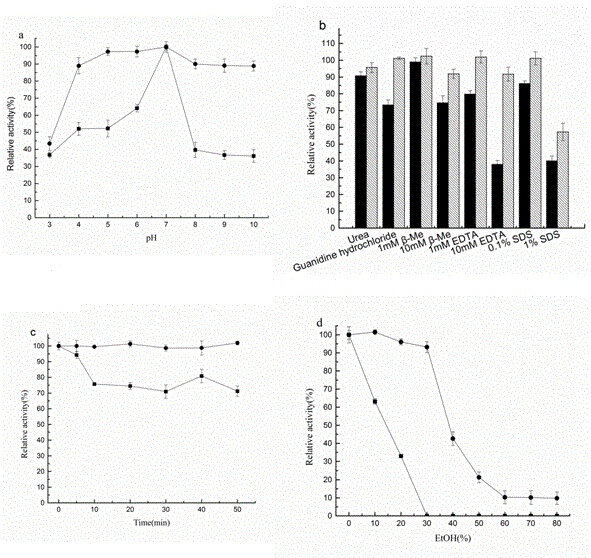

Genetic engineering transformed thermal-resistant adverse-resistant SOD as well as encoding gene and application thereof

InactiveCN104946606AImprove stabilityOvercome chemical instabilityMicroorganism based processesOxidoreductasesDismutaseSuperoxide dismutases

The invention discloses high-temperature-resistant superoxide dismutase as well as an encoding gene and application thereof. The superoxide dismutase comprises protein with an amino acid residue sequence as shown in SEQ ID NO.1. The expression method comprises the following steps: establishing a recombinant expression vector containing a thermal-resistant superoxide dismutase gene, introducing the established recombinant expression vector into a host cell, and inducing so as to express the thermal-resistant superoxide dismutase gene. The expression product disclosed by the invention is outstanding in thermal resistance, good in adverse resistance, good in resistance to acid, alkali, organic solvents, detergent, protein denaturants and inhibitors, easy to purify, good in stability, and side in industrial application prospect.

Owner:北京迈恩泰生物科技有限公司

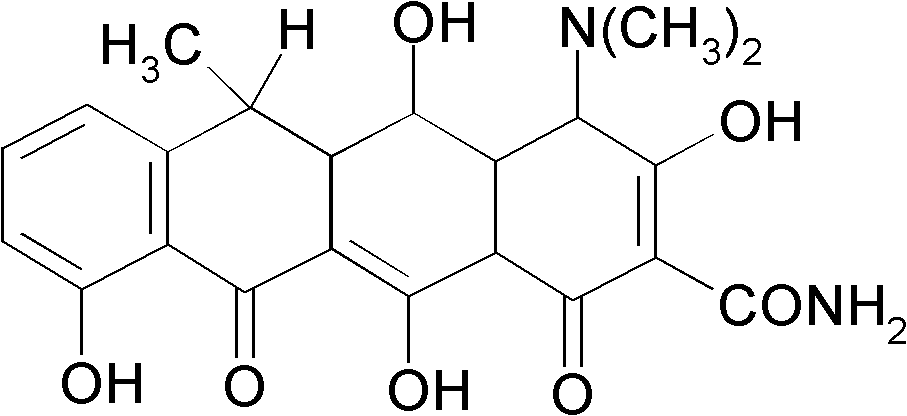

System and process for treating oxytetracycline waste water by anaerobic bio-treatment method

InactiveCN102126813AImprove biochemical behaviorSimple processWater contaminantsWaste based fuelChemical oxygen demandCalcium ion binding

The invention relates to a system and process for treating oxytetracycline waste water by an anaerobic bio-treatment method, which has the advantages of stable process, low investment, small occupied area and low energy consumption. The system comprises a hydrolysis and acidification tank, wherein waste water is hydrolyzed and acidified in the hydrolysis and acidification tank and the waste wateris then moved into a lime precipitation tank; in the lime precipitation tank, oxytetracycline in the waste water is combined with calcium ions to generate precipitates; then, the waste water is movedinto an anaerobic reactor; the anaerobic reactor removes most of COD (Chemical Oxygen Demand) in the outlet water and simultaneously emits generated marsh gas; and after going out of the anaerobic reactor, the waste water is moved into an aerobic tank, so that organic substances and ammonia nitrogen in the waste water can be further treated, thereby ensuring that the discharge of the waste water is reached the standards.

Owner:山东美泉环保科技有限公司

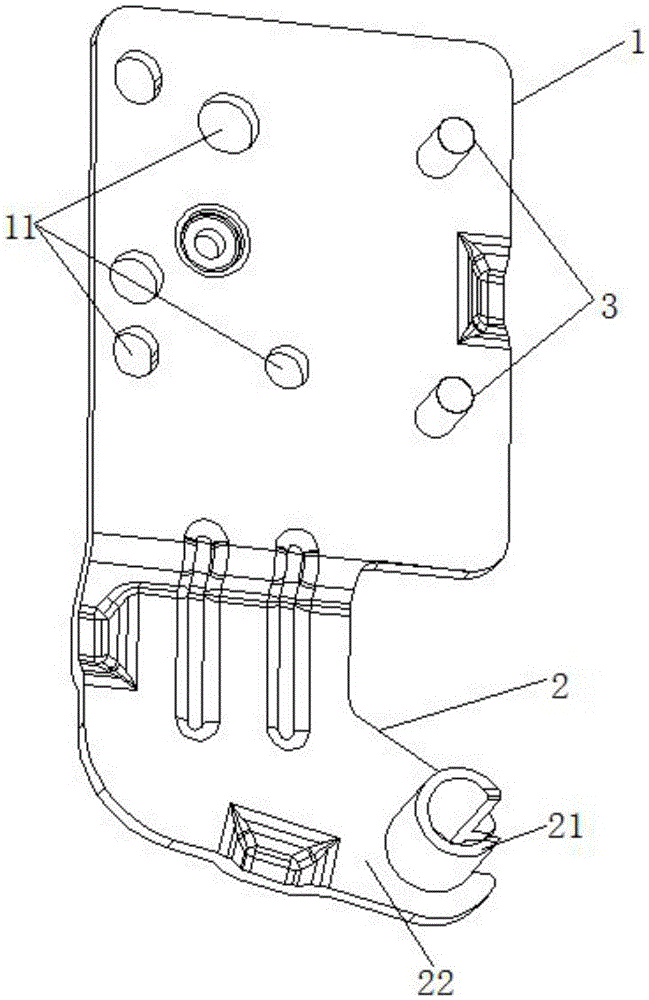

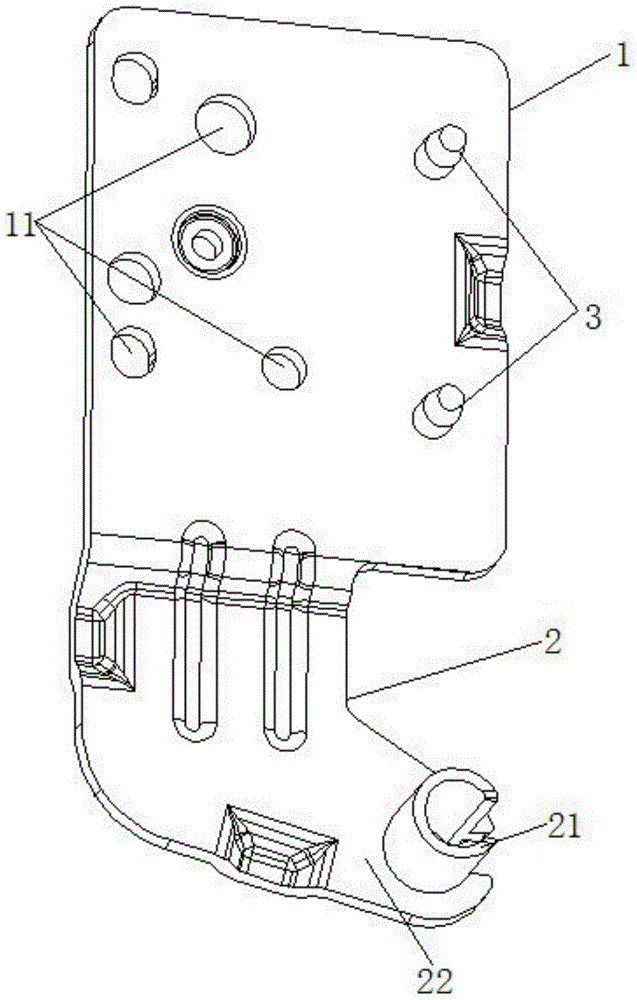

Hinge mechanism of refrigerator door and refrigerator provided with hinge mechanism

InactiveCN105466123AEffective installation positioningSolve the problem of inconsistent spacingDomestic cooling apparatusLighting and heating apparatusEngineeringRefrigerated temperature

Owner:HEFEI MIDEA REFRIGERATOR CO LTD +1

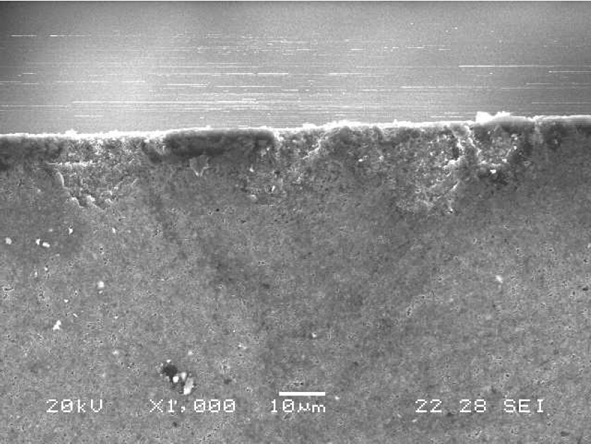

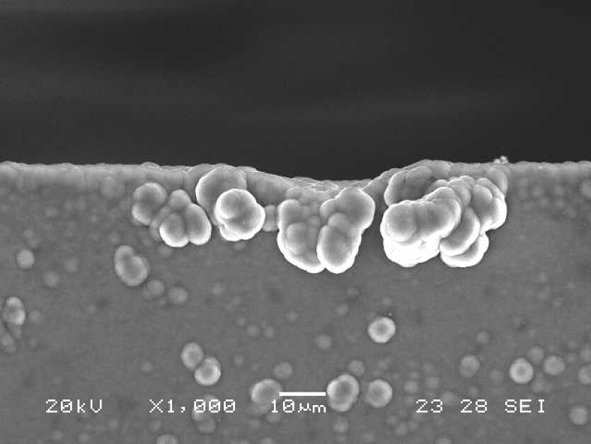

Processing technology of polyimide film

The invention belongs to the field of polyimide films, relates to a processing technology of a polyimide film, and aims to solve the problems that existing nanoparticles are large in specific surfacearea and surface energy, relatively strong in interaction among the particles and easy to agglomerate, and the problem that ideal nanoscale compounding is difficult to achieve between the nanoparticles and polymers with relatively high viscosity. In order to solve the problem that the comprehensive performance of a composite material is influenced, the invention provides the following technical schemes, the processing technology of the polyimide film comprises the following steps that: S1, preparing 1-10 parts of 4, 4'-diaminodiphenyl ether and 1-10 parts of 3, 3', 4, 4 '-benzophenonetetracarboxylic dianhydride, preparing 5-10 parts of N, N-dimethylformamide, and preparing 10-20 parts of aluminum oxide, silicon dioxide and boron nitride; and S2, preparing a reactor with nitrogen protection. The processing technology of the polyimide film is better improved; the corona resistance of the polyimide film is higher; the tensile resistance of the polyimide film is better; and the service life of the polyimide film is longer.

Owner:潍坊弘润新材料有限公司

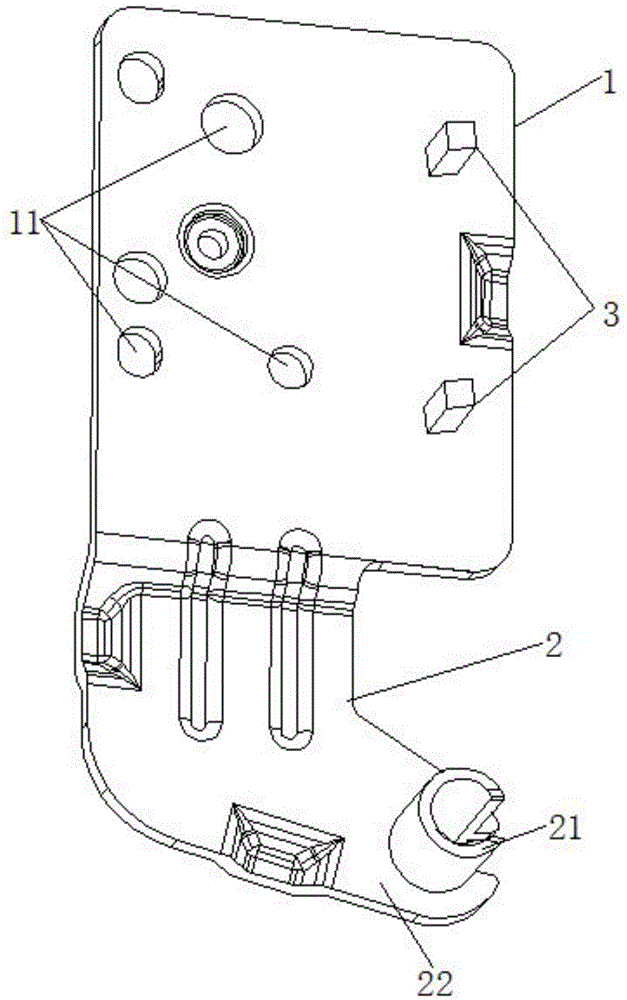

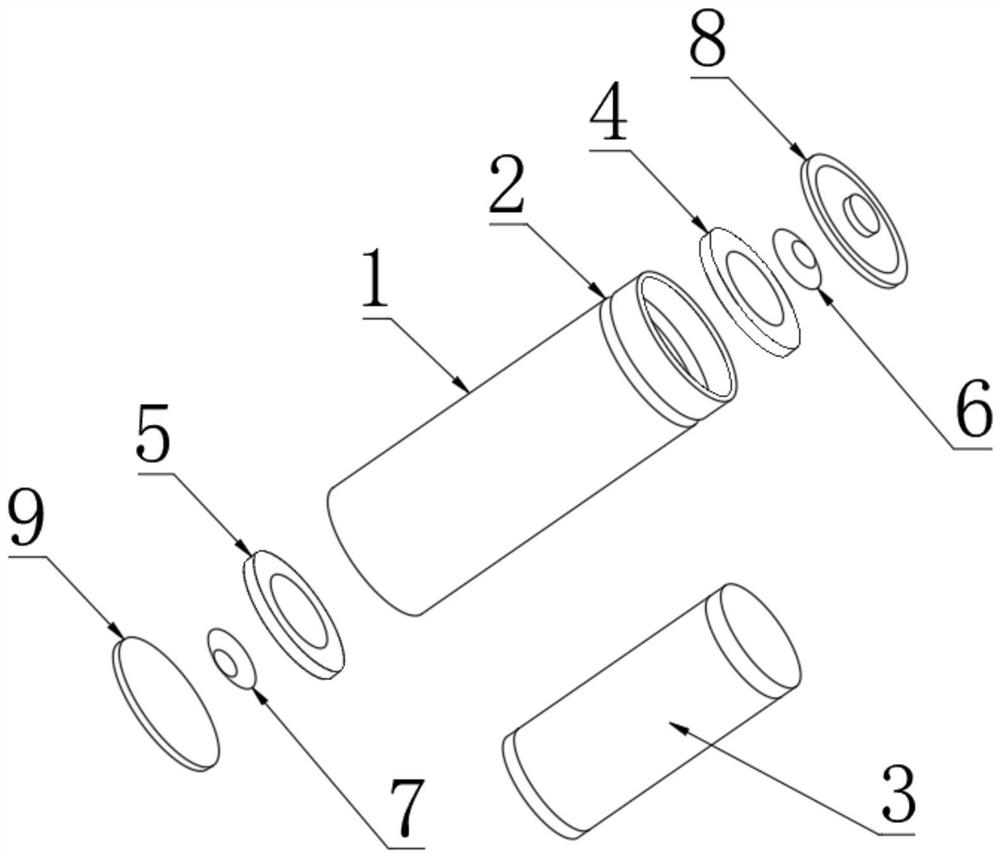

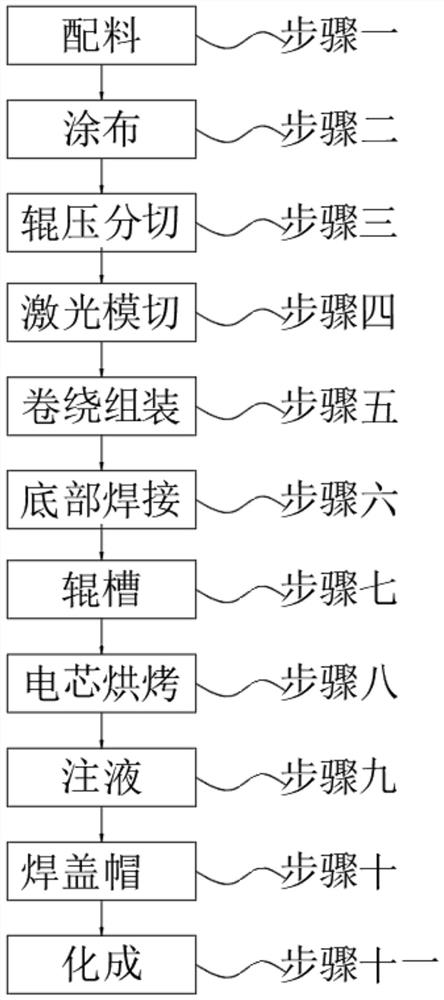

High-power cylindrical lithium ion battery and processing technology

InactiveCN113745640AAvoid damagePromote absorptionFinal product manufactureSmall-sized cells cases/jacketsLithium-ion batteryMechanical engineering

The invention discloses a high-power cylindrical lithium ion battery and a processing technology. The high-power cylindrical lithium ion battery comprises a shell, an arc groove, a roll core, a positive pole current collector, a negative pole current collector, a positive pole elastic gasket, a negative pole elastic gasket, a positive pole cap and a negative pole cap. The processing technology comprises the following steps of: step 1, burdening; step 2, coating; step 3, rolling and slitting; step 4, laser die cutting; step 5, winding and assembling; step 6, bottom welding; step 7, groove rolling; step 8, battery cell baking; step 9, liquid injection; step 10, cap welding; and step 11, formation. The high-power cylindrical lithium ion battery comprises the shell, the arc groove, the roll core, the positive pole current collector, the negative pole current collector, the positive pole elastic gasket, the negative pole elastic gasket, the positive pole cap and the negative pole cap. The high-power cylindrical lithium ion battery is safe and reliable; the battery cell is stably fixed in the battery shell through cooperative use of the positive pole elastic gasket, the negative pole elastic gasket and the arc groove, and damage caused by collision between the battery cell and the battery shell due to vibration is prevented.

Owner:DONGGUAN LILONG BATTERY TECH CO LTD

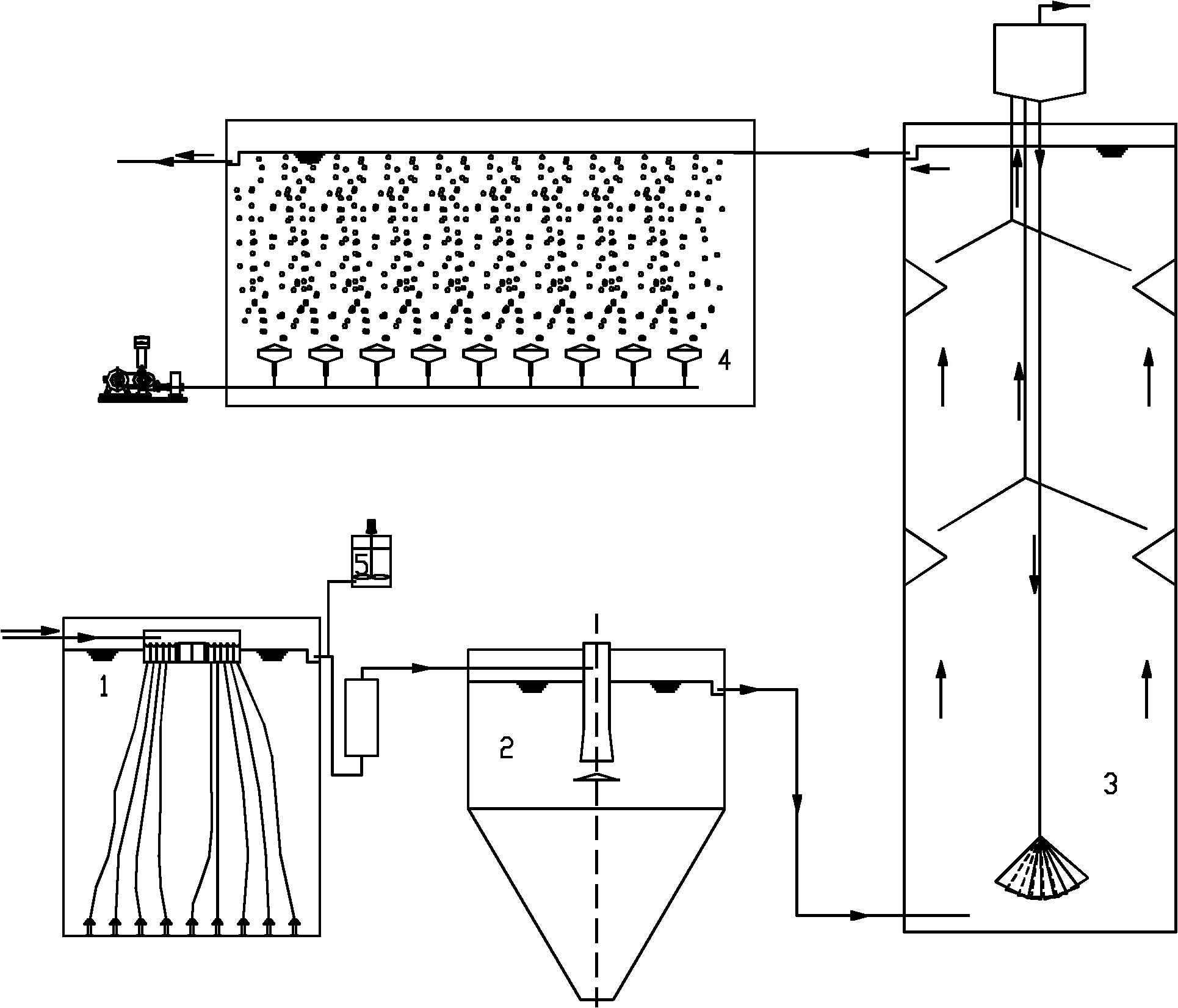

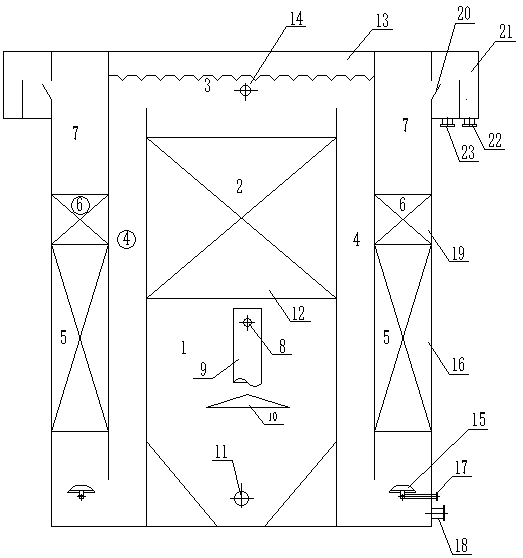

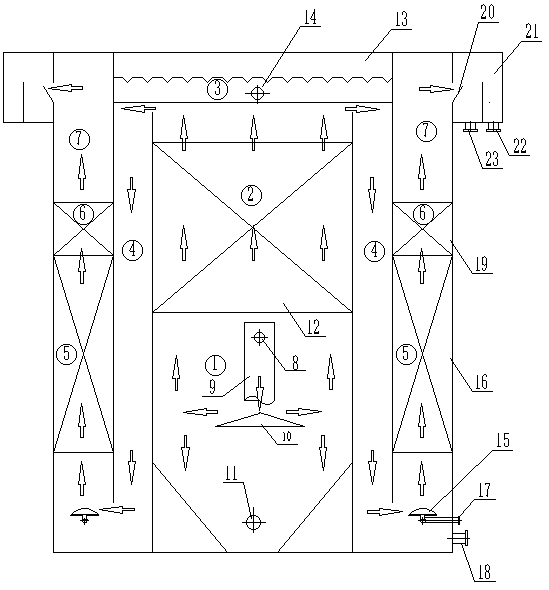

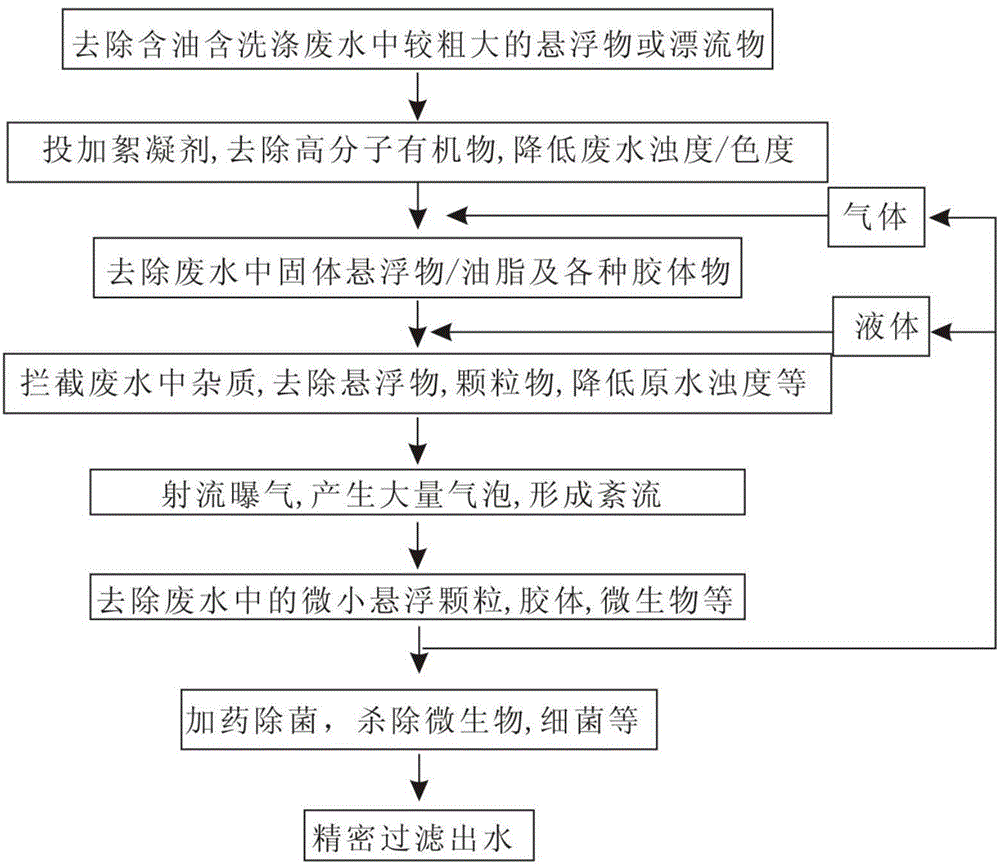

Multifunctional integrated sewage treating device and treating technology thereof

PendingCN109626749AEliminate clutterRigid body structure is beautiful and tidyWater treatment parameter controlFatty/oily/floating substances removal devicesFlocculationReaction zone

The invention discloses an integrated sewage treating device and a treating technology thereof. The sewage treating device uses structural features of Orbal oxidation ditches, vertical flow sedimentation tanks and biochemical treatment units, synthesizes technological features of flocculation, hydrolysis, membrane bioreactors and filtering, and is designed to be of an integrated cylindrical steelstructure and internally provided with an inner cylinder, a middle cylinder and an outer cylinder. The integrated sewage treating device is divided into seven zones according to the flow path and function of the treating technology, wherein the seven zones include the flocculent sedimentation zone, the hydrolytic acidification zone, the oil foam removing zone, the anoxic zone, the biomembrane reaction zone, the adsorption filtering zone and the clear water zone; unattended operation of effective treatment and automatic PLC control for sewage of different industries and different types, the operation can be divided into automatic running and intelligent control running according to the investment amount, and the sewage treating scale maximally reaches 250 ton / d by a single processor.

Owner:新乡市蓝海环境科技有限公司

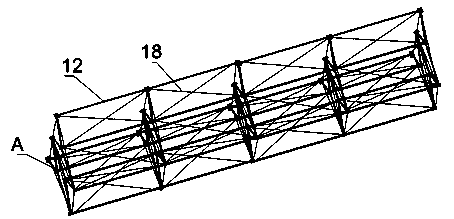

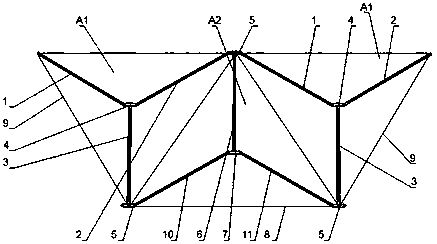

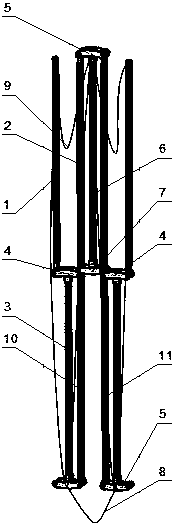

Large cable-strut truss type deployable antenna mechanism

ActiveCN111224210AExpand smoothlyIncrease stiffnessPivotable antennasAntenna adaptation in movable bodiesControl theoryTorsion spring

The invention belongs to the technical field of aerospace appliances and equipment, and particularly relates to a large cable-strut truss type deployable antenna mechanism. The cable-strut truss typedeployable antenna mechanism comprises a plurality of cable-strut truss type deployable units, wherein the plurality of deployable units are connected through connecting longitudinal rods to form thecable-strut truss type deployable antenna mechanism; each deployable unit comprises first deployable assemblies and a second deployable assembly arranged between the first deployable assemblies, the first deployable assemblies and the second deployable assemblies are triangular support bodies, and the first deployable assemblies and the second deployable assemblies are connected through third torsion spring connectors to form the deployable units. The large cable-strut truss type deployable antenna mechanism is good in reliability, compact in structure, good in rigidity after being completelyunfolded, capable of meeting the use requirement of a large space antenna and suitable for a satellite space folding and unfolding mechanism and the like.

Owner:TAIYUAN UNIV OF TECH

Nutritious fast and convenient food and preparation method thereof

InactiveCN103330199ARich health benefitsPerfect processing technologyFood preparationBiotechnologyCellulose

The invention discloses a nutritious fast and convenient food which is characterized by comprising the following raw materials in parts by weight: 200-300 parts of walnut kernels, 40-60 parts of raisin, 40-60 parts of carrots, 80-120 parts of pumpkin, 40-60 parts of sea vegetable, 100-200 parts of Chinese yam, 80-120 parts of potatoes, 120-180 parts of millet flour, 120-180 parts of corn flour, 300-500 parts of whole wheat flour, 100-200 parts of sweet potatoes, 40-60 parts of high-quality shell-less peanut meal, 150-200 parts of black sugar, 15-30 parts of salt, 40-60 parts of sesame, 200-300 parts of soybean oil, 40-60 parts of chestnut meal, 40-60 parts of Chinese date, and 40-60 parts of pawpaw. The nutritious fast and convenient food is abundantly nutritious and safe, can achieve the balanced supply of human nutrition, has effective health-care and recovery effects to a human body, is easily absorbed by the human body, and is long in retention time due to vacuum packaging, capable of improving the demand of the human body on various celluloses, and beneficial to protection and improvement of intestines and stomach health.

Owner:于才民

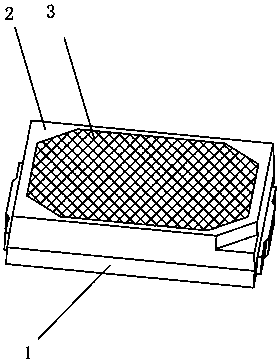

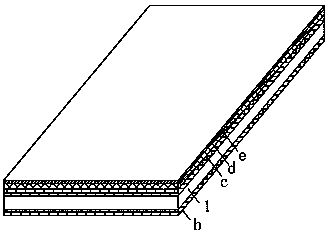

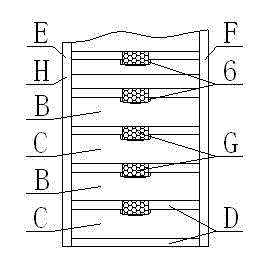

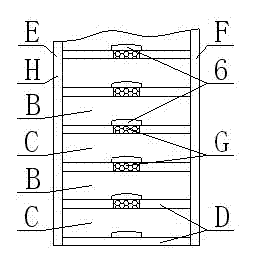

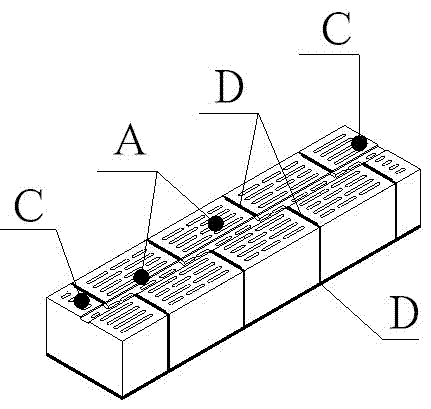

Process for energy-saving wall built of multi-row static air hole thermal insulation building blocks

InactiveCN103290949APrevent saggingPerfect processing technologyWallsHeat proofingCrack resistanceBrick

The invention relates to a process for an industrial and civil energy-saving wall built of multi-row static air hole thermal insulation building blocks, in particular to a process for the energy-saving wall which is uprightly or inversely built of multi-row static air hole thermal insulation building block main blocks (A), large matched blocks (B) and small matched blocks (C) in a Z-shaped butt joint mode and is provided with various veneers. The process is characterized in that the wall is built of the multi-row static air hole thermal insulation building block main blocks (A), the large matched blocks (B) and the small matched blocks (C) in the Z-shaped butt joint mode, and a direct connection heat bridge of vertical building seam mortar is cut off; thermal insulation plates (G) are placed between layers, and a direct connection heat bridge of horizontal building seam mortar is cut off; thermal insulation plates (H) adhere to the outer facade of the wall or the outer facade of the wall is coated with outer wall anti-cracking coating mortar (E) to form imitation face brick, an imitation curtain wall or a coating veneer; and the inner facade of the wall is coated with inner wall anti-cracking coating mortar (F) or inorganic thermal insulation slurry or gypsum boards adhere to the inner facade of the wall. The energy-saving wall has the advantages that the energy-saving wall has good crack resistance, weather resistance and stability, has the same service life as a building main body and is reasonable in cost performance, and a wall construction period is greatly shortened, and the like.

Owner:哈尔滨天硕建材工业有限公司

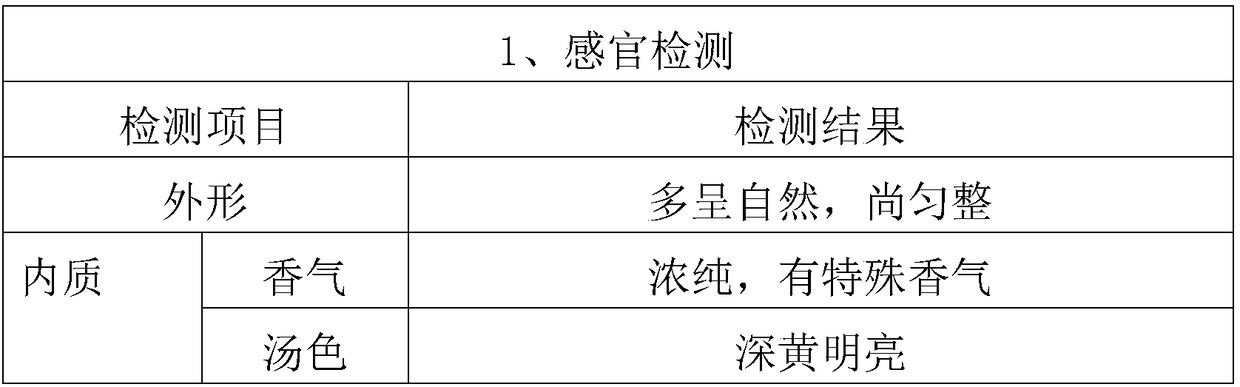

Manufacture method of macadimia nut leaf tea

InactiveCN108338249AWith special fragranceStrong tasteTea substituesAdditive ingredientEssential amino acid

The present invention provides a manufacture method of macadimia nut leaf tea. Macadimia nut tender leaves are used; the macadimia nut leaf tea is prepared by 8 elaborate processing steps of materialselecting, tedding, enzyme deactivating, cooling, rolling, shaping, drying and packaging; and the macadimia nut leaf tea has the same appearance as that of ordinary tea leaves, is similar to green teain tea drinking methods and hues, but also has a special aroma that ordinary green tea does not have, and is thick in taste and strong and pure in aroma. The product has been tested to completely show basic requirements of tea leaves. The macadimia nut leaf tea is purely hand-made; the manufacture method is simple and clear in processes, easy to operate and convenient to scale production. The produced macadimia nut leaf tea is rich in proteins, human body essential amino acids, vitamins, minerals, flavonoids and other various nutrients, does not contain caffeine, has mind-soothing effects, and can calm excitement, help sleep, present aging and enhance immunity in a long time drinking. The manufacture method fully preserves the various nutrients of the macadimia nut leaf tea; the tea leaves are thick, tender and curly; liquid is bright in color; and the macadimia nut leaf tea is strong and refreshing in taste, and has relatively high promotion value.

Owner:SUBTROPICAL CROPS INST OF GUIZHOU PROVINCE

System for recycling waste water containing oil and washing water

ActiveCN102874965AHigh recovery rateHigh removal rateMultistage water/sewage treatmentWastewaterWater collection

The invention provides a system for recycling waste water containing oil and washing water. The system comprises a waste water collection pool, a lift pump, a flocculating agent feeding device, an air lift flow reduction type reactor and an inner circulation system, wherein the waste water collection pool, the lift pump, the air lift flow reduction type reactor and the inner circulation system are sequentially connected with one another through pipelines; the flocculating agent feeding device feeds a flocculating agent into the pipeline between the lift pump and the air lift flow reduction type reactor; waste water containing the oil and the washing water sequentially flows through the waste water collection pool, the lift pump, the air lift flow reduction type reactor and the inner circulation system and then is purified; and the purification efficiency is high, and the process is simple.

Owner:鹏凯环境科技股份有限公司

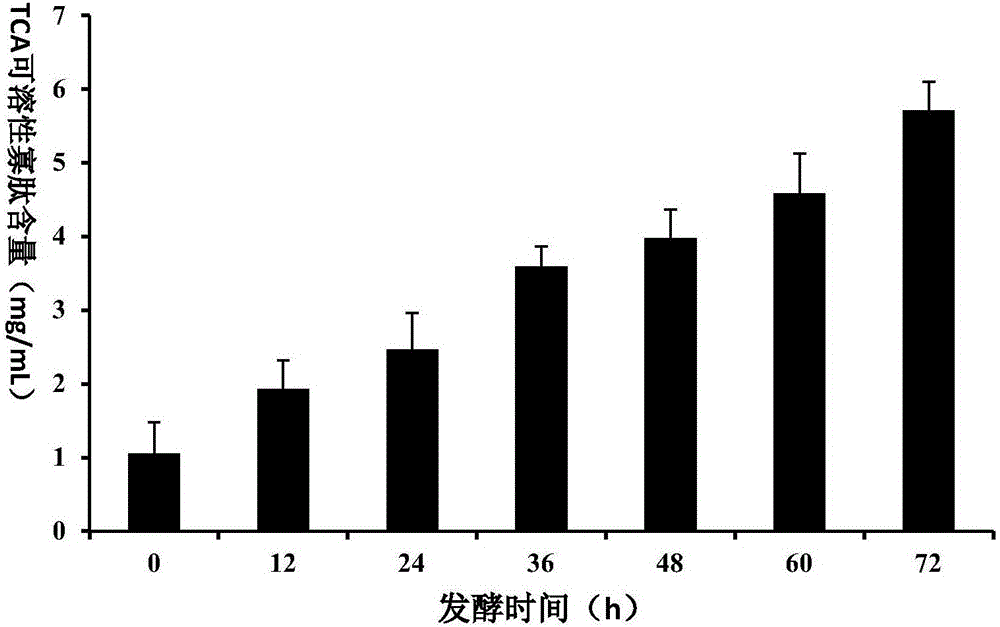

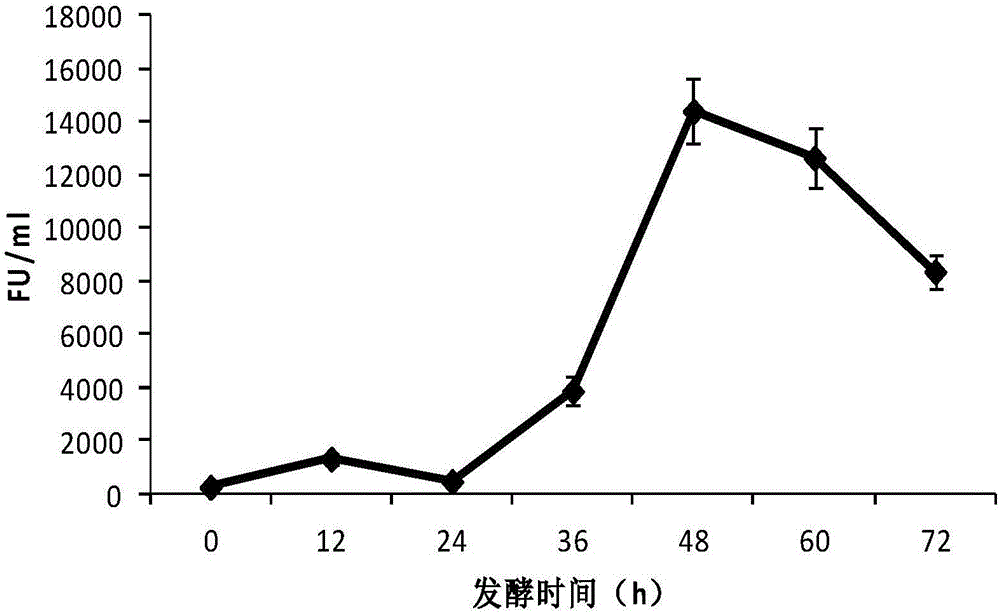

Preparation method for abalone fermentation product having thrombolytic antihypertensive function

InactiveCN106490511AEfficient decompositionIncreased sensitivityFood ingredient as antioxidantCardiovascular disorderFreeze-dryingComposite function

The invention discloses a preparation method for an abalone fermentation product having a thrombolytic antihypertensive function, wherein the preparation method comprises the following steps: taking abalone tissues, washing cleanly, draining, freeze-drying, and crushing, to obtain an abalone freeze-dried powder; mixing a carbon source and the abalone freeze-dried powder with water, and adjusting the pH to 6.2-9.2; sterilizing, adding a bacillus subtillis natto suspension, at the temperature of 35-44 DEG C, ventilating, culturing for 45-60 h in a shaker, and thus obtaining an abalone fermentation liquid; centrifuging the abalone fermentation liquid, collecting a supernatant, concentrating, and freeze-drying to obtain the abalone fermentation product having the thrombolytic antihypertensive function. The abalone tissues are fermented by bacillus subtilis natto, nattokinase having thrombolytic effect can be generated, and abalone proteins also are degraded into proteins and polypeptides with smaller molecular weight, so as to be conducive to digestion and absorption; at the same time, the function of the fermentation product is further enriched, and the fermentation product gives full play to the thrombolysis, antihypertensive and antioxidant composite functions and the like.

Owner:DALIAN POLYTECHNIC UNIVERSITY

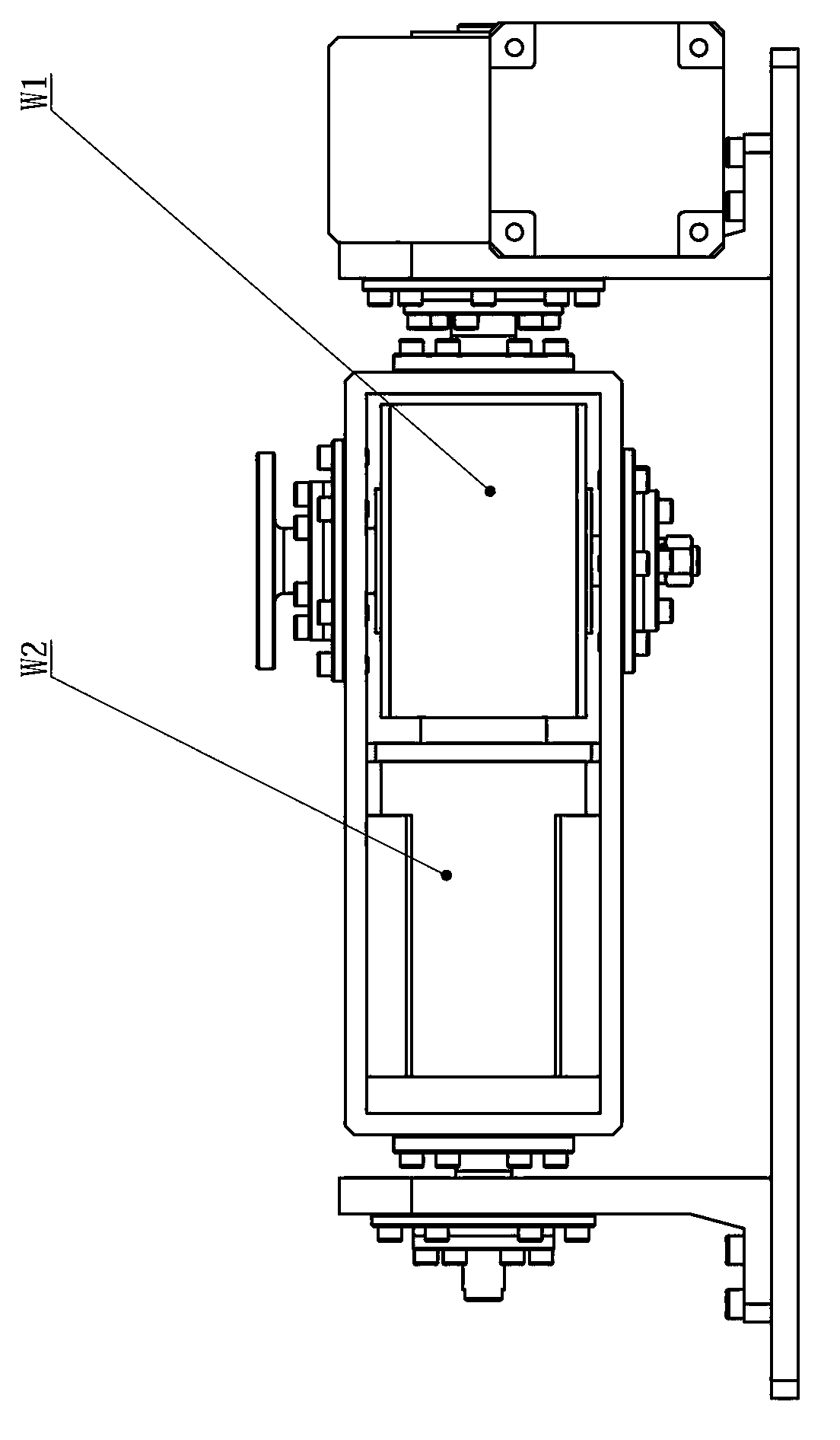

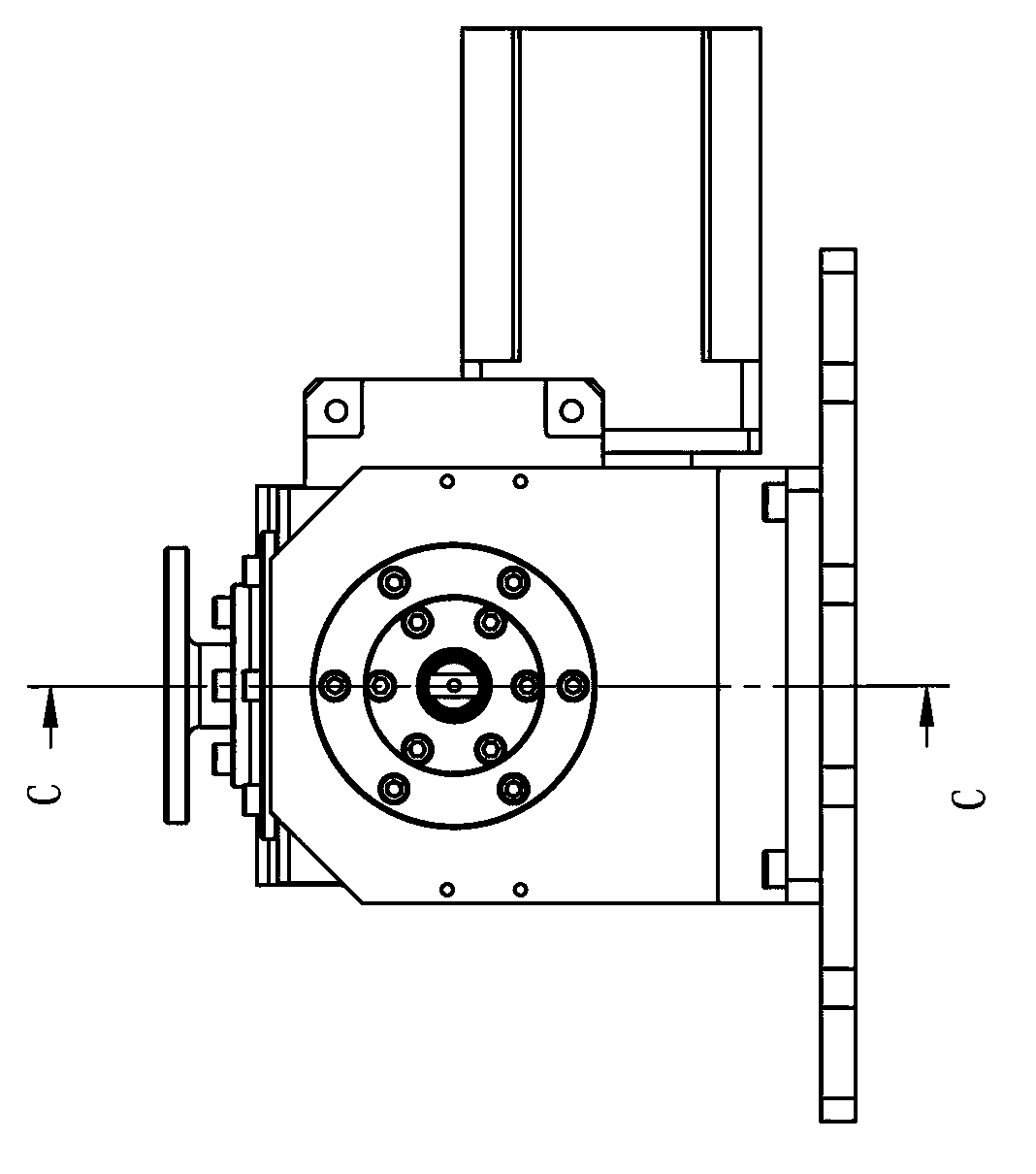

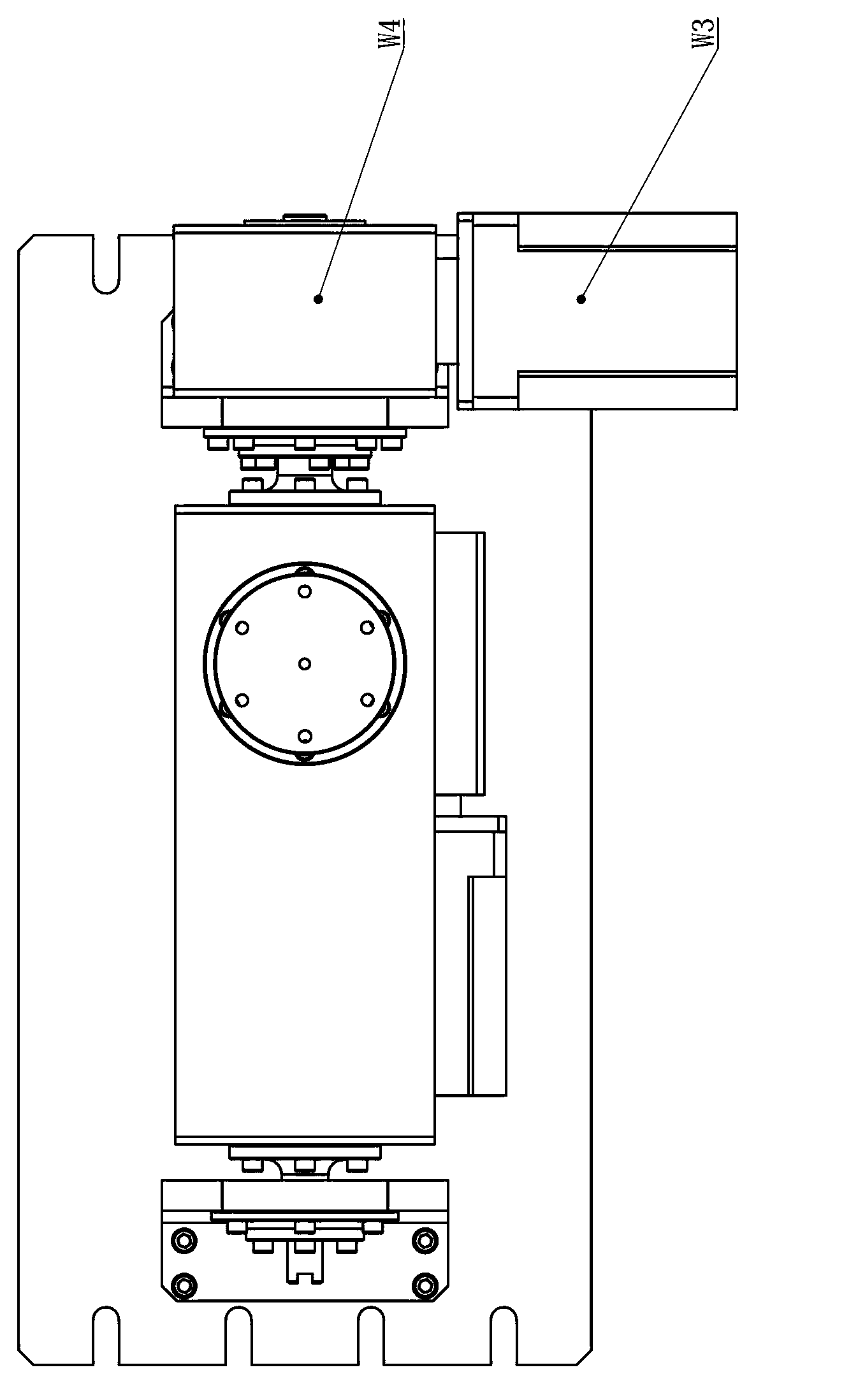

Numerical control double-shaft rotary table

InactiveCN103009069AImprove processing efficiencyPerfect processing technologyFeeding apparatusLarge fixed membersNumerical controlEngineering

The invention provides a numerical control double-shaft rotary table which comprises a frame. Both ends of the frame are respectively provided with pitch axes arranged along a first direction, so that the frame can rotate around the pitch axes; on end of one pitch axis is fixedly connected with the frame and the other end of the pitch axis is in power connection with a pitch servo motor; a rotating shaft and a rotating servo motor are arranged in the frame; the rotating shaft is arranged in the frame along the direction vertical to the first direction in a penetrating mode and is in power connection with the rotating servo motor; and one end of the rotating shaft extends out of the frame and is provided with a rotating platform. The numerical control double-shaft rotary table is fixed on a numerical control machine tool and both the pitch servo motor and the rotating servo motor are connected to the numerical control machine tool, so that installation is completed. At the moment, due to an original three-axis linear freedom degree of the numerical control machine tool and rotating freedom degrees in X-axis and Z-axis directions, which are newly increased in the invention, rotary feed and dividing movement can be realized in random direction.

Owner:HEILONGJIANG AGRICUTURAL ENGINEARING VOCATIONAL COLLEGE

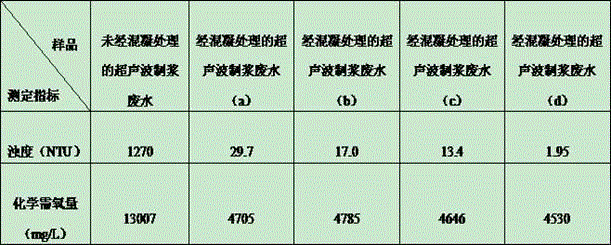

Method for coagulation treatment of ultrasonic pulping wastewater by using cellulose-based green flocculation material

InactiveCN106467335AHigh turbidity removal ratePerfect processing technologyMultistage water/sewage treatmentWater/sewage treatment by flocculation/precipitationCelluloseFlocculation

The present invention discloses a method for coagulation treatment of ultrasonic pulping wastewater by using a cellulose-based green flocculation material. The method is characterized in that ultrasonic pulping wastewater is adjusted to achieve a corresponding pH value, an appropriate amount of a coagulant aid is added and rapid stirring is performed, an appropriate amount of a cellulose-based green flocculation material is added and slow stirring is performed, and the suspended and slightly-soluble contaminants in the wastewater are removed through standing overflow. According to the present invention, the method is rapid and efficient, and is especially suitable for the coagulation treatment of the ultrasonic pulping wastewater; and the ultrasonic pulping wastewater is treated by using the novel cellulose-based green flocculation material so as to significantly improve the wastewater turbidity removal rate, reduce the treatment cost, reduce the secondary environment pollution caused by the flocculation sludge, further improve the wastewater treatment technology during the ultrasonic pulping process, accelerate the industrialization of the ultrasonic pulping technology, and provide the important social and environmental benefits and the industrial application values compared to the traditional polyacrylamide type flocculant.

Owner:ZHEJIANG SCI-TECH UNIV

Whole-cereal coarse cereal oat crispy biscuit and preparation method thereof

The invention discloses whole-cereal coarse cereal oat crispy biscuit and a preparation method thereof, and belongs to the technical field of food and a process thereof. The method comprises the following steps that (1) performing cleaning, soaking and steaming and boiling on a proper amount of oat; (2) performing freeze drying; (3) preparing biscuit raw materials of weak strength flour, oil, egg,sugar powder, brown sugar, baking soda, baking powder, salt and freeze-dried oat particles; (4) mixing and stirring the oil, sugar powder, brown sugar, baking soda, baking powder and salt; (5) addingegg; performing stirring; (6) adding weak strength flour and oat particles; performing uniform mixing; (7) performing shaping by a mold; (8) performing baking; (9) performing cooling and packaging. The freeze drying mode is used for treating the steamed and boiled oat particles; the oat particles are directly added into biscuit to be made into coarse cereal biscuit with the visible particles on the surface; the color, fragrance and shape of the oat can be maintained.

Owner:JIANGNAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com