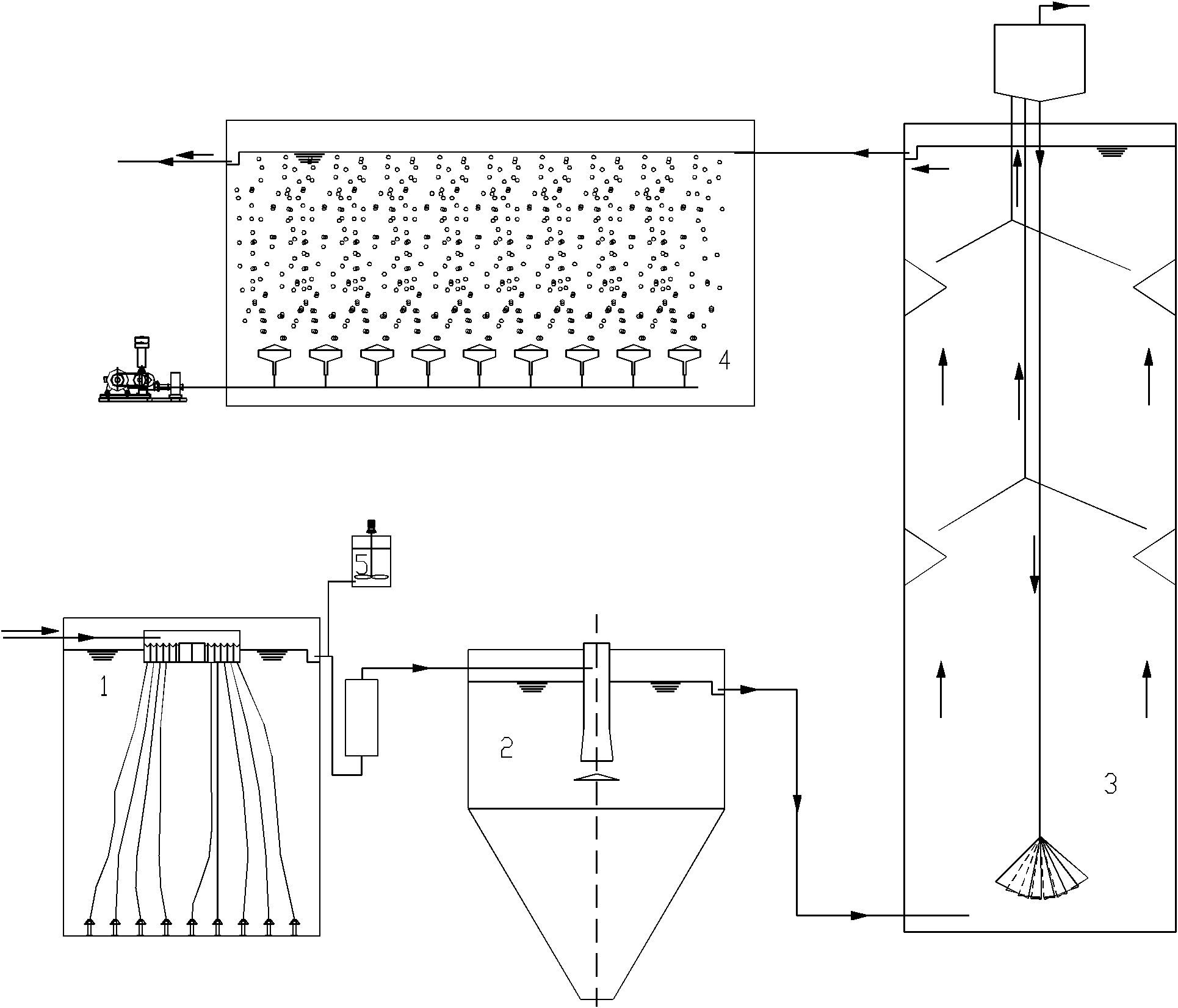

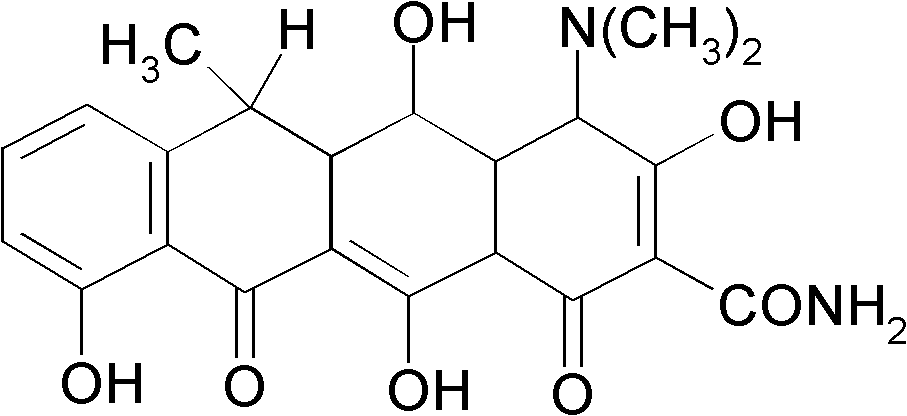

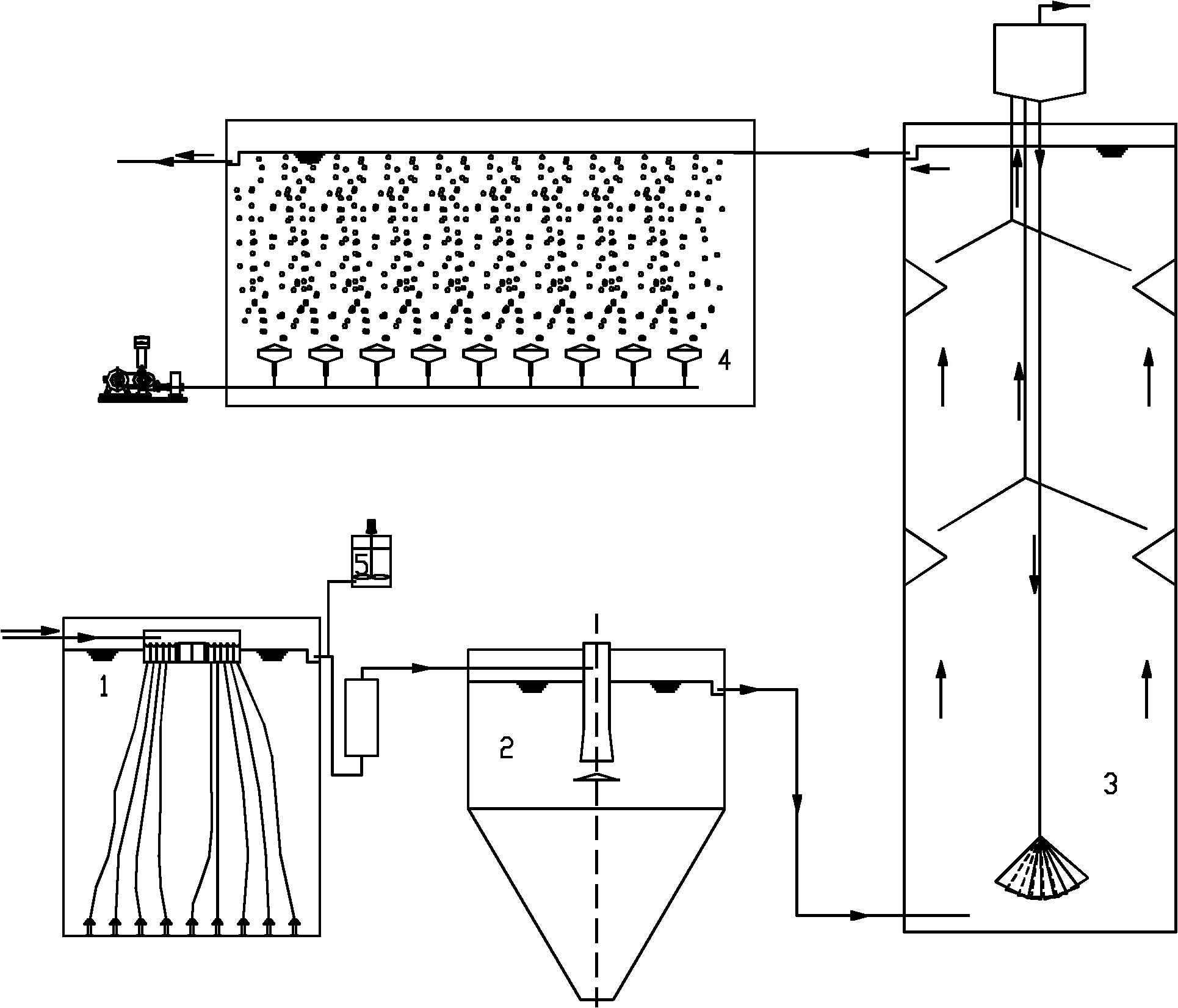

System and process for treating oxytetracycline waste water by anaerobic bio-treatment method

An anaerobic biological, oxytetracycline technology, applied in anaerobic digestion treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve the problems of high operating cost, poor effect, complicated operation, etc. , to achieve the effect of low operating cost, improved biochemical performance and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] 1. After the pH value of the wastewater is adjusted, the pH value of the influent water is adjusted to 6.5, and enters the hydrolytic acidification tank. The hydrolytic acidification reaction is controlled by controlling the hydraulic retention time. The reaction of organic matter in this stage is only the hydrolytic acidification stage. The residence time of the pool is 8-9 hours. Within this time range, the first two stages of anaerobic fermentation, namely hydrolysis and acidification, can be used to degrade most of the high-molecular toxic substances such as oxytetracycline in the wastewater into low-molecular organic substances. , to facilitate subsequent biological treatment.

[0035] The hydrolytic acidification process does not require strict anaerobic conditions, so the operating conditions are easier to control, and the residence time is short, which can adapt to higher COD and BOD loads. This process improves the biodegradability of wastewater and reduces the...

Embodiment 2

[0041] 1. After the pH value of the wastewater is adjusted, the pH value of the influent water is adjusted to 7, and then enters the hydrolytic acidification tank. The hydrolytic acidification reaction is to control the hydraulic retention time to control the reaction of organic matter at this stage. The residence time of the pool is 8-9 hours. Within this time range, the first two stages of anaerobic fermentation, namely hydrolysis and acidification, can be used to degrade most of the high-molecular toxic substances such as oxytetracycline in the wastewater into low-molecular organic substances. , to facilitate subsequent biological treatment.

[0042] The hydrolytic acidification process does not require strict anaerobic conditions, so the operating conditions are easier to control, and the residence time is short, which can adapt to higher COD and BOD loads. This process improves the biodegradability of wastewater and reduces the toxicity of wastewater due to the degradatio...

Embodiment 3

[0048] 1. After the pH value of the wastewater is adjusted, the pH value of the influent water is adjusted to 7.5, and enters the hydrolytic acidification tank. The hydrolytic acidification reaction is controlled by controlling the hydraulic retention time. The reaction of organic matter in this stage is only the hydrolytic acidification stage. The residence time of the pool is 8-9 hours. Within this time range, the first two stages of anaerobic fermentation, namely hydrolysis and acidification, can be used to degrade most of the high-molecular toxic substances such as oxytetracycline in the wastewater into low-molecular organic substances. , to facilitate subsequent biological treatment.

[0049] The hydrolytic acidification process does not require strict anaerobic conditions, so the operating conditions are easier to control, and the residence time is short, which can adapt to higher COD and BOD loads. This process improves the biodegradability of wastewater and reduces the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com