An iron-carbon reactor equipment and treatment process for treating high-concentration organic wastewater

A technology for organic wastewater treatment and high concentration, applied in water/sewage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve high investment costs, operating costs and operation management requirements, iron scrap supplementary labor High strength, slow reaction speed and other problems, to achieve the effect of improving the treatment effect, simple and easy treatment process, and simple equipment structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

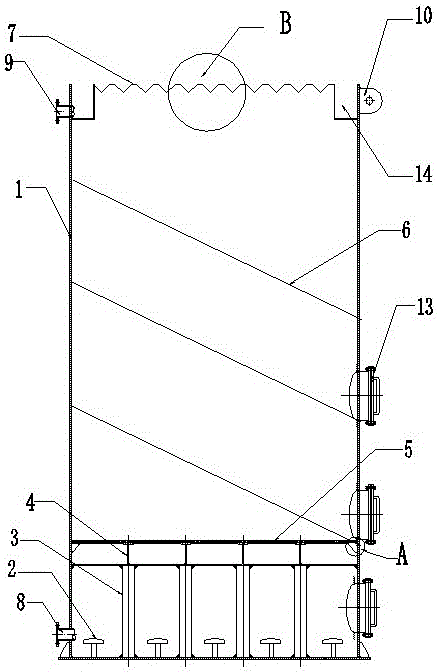

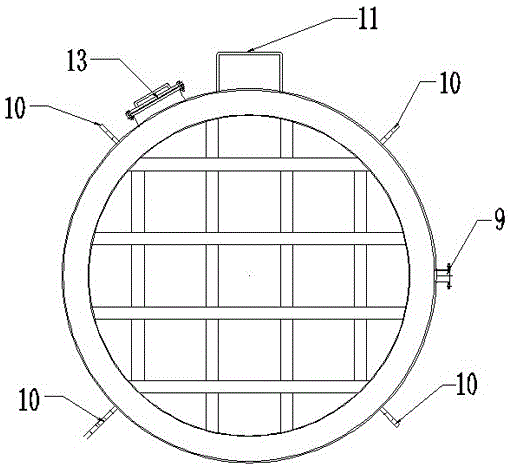

[0025] In order to make it easy to understand the technical means, creative features, objectives and effects achieved by the present invention, the present invention will be further explained below in conjunction with specific drawings.

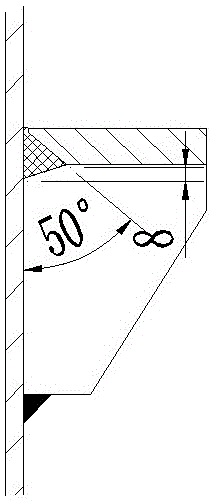

[0026] See figure 1 with figure 2 , An iron-carbon reactor equipment for treating high-concentration organic wastewater, including tank body (1), microporous aeration pan (2), standing steel pipe (3), I-beam beam (4), orifice plate (5) ) And a corrugated cover plate (7), the inner bottom of the tank body (1) is provided with a number of microporous aeration discs (2), and the I-beam beams (4) are installed in the tank body (1), so The I-beam beam (4) is connected and supported by vertical bracing steel pipes (3), the I-beam beam (4) is provided with a perforated plate (5), and the top of the tank body (1) is provided with a corrugated cover plate ( 7) An annular groove (13) is provided around the corrugated cover plate (7), a water inlet (8) is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com