Manufacturing method of LED light source manufactured through vacuum sputtering technology

An LED light source, vacuum sputtering technology, applied in electrical components, circuits, semiconductor devices, etc., can solve the problems of device pollution failure, blackening of the silver-plated layer at the bottom of the bracket, gold wire breakage, etc., to improve reflectivity and gloss. , Various effects of forming process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

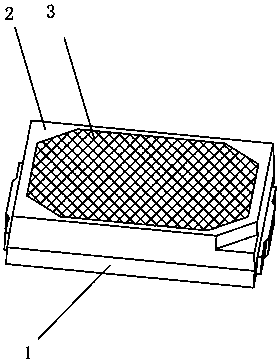

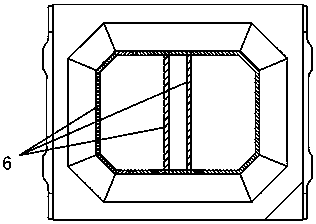

[0020] Specific implementation mode one: as Figure 1-6 As shown, this specific embodiment adopts the following technical scheme: it includes a base material 1, a bracket filling glue material a, an LED bracket 2, a fluorescent glue 3, a chip 4, a gold wire 5 and an air-avoiding device 6, and the top of the base material 1 passes through The base material filling glue a is fixedly connected with the LED bracket 2, and the upper middle part of the LED bracket 2 is provided with an air-avoiding device 6, and a chip 4 is installed above the air-avoiding device 6, and a gold wire 5 is welded on the chip 4, and the chip 4 Fluorescent glue 3 is packaged above the gold wire 5 .

[0021] As a preference, the bottom of the LED bracket 2 is an inverted T-shaped design.

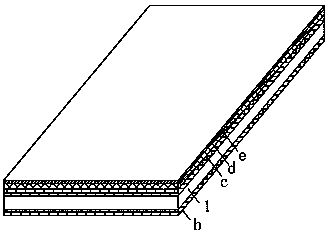

[0022] Preferably, materials such as copper, silver, tin, nickel, or zinc are deposited on the upper surface of the substrate 1 by vacuum sputtering technology.

[0023] Further preferably, an aluminum oxide layer, a ...

specific Embodiment approach 2

[0025] Specific implementation mode two: refer to Figure 7 The difference between this specific embodiment and specific embodiment 1 is that: the upper surface of the substrate 1 is treated in a different way, wherein, the upper surface of the substrate 1 is sequentially deposited three layers from bottom to top by vacuum sputtering technology. Aluminum oxide layer, titanium dioxide and silver mixed layer, titanium dioxide and silicon dioxide mixed layer, titanium dioxide layer; other compositions and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0026] Specific implementation mode three: refer to Figure 8 The difference between this specific embodiment and specific embodiment 1 is that: the upper surface of the substrate 1 is treated in a different way, wherein, the upper surface of the substrate 1 is sequentially deposited three layers from bottom to top by vacuum sputtering technology. Aluminum oxide thin film layer, titanium dioxide and silver mixed layer, aluminum oxide layer, titanium dioxide layer; other compositions and connections are the same as those in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com