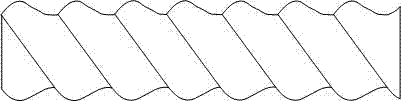

Interlocking armored forming die and process

A technology of interlocking armoring and forming molds, applied in the manufacturing of electrical components, circuits, cables/conductors, etc. The effect of safety and reliability, perfect processing technology, and reduced processing difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

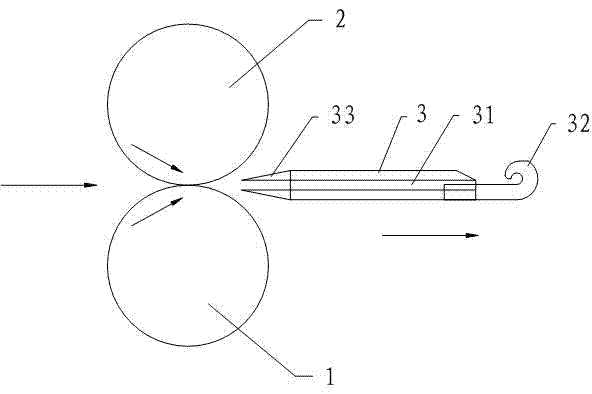

[0026] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0027] The present invention takes the interlocking armoring forming mold of the international universal metal strip with a processing width of 9.5 mm and a thickness of 0.5 mm as an example to specifically illustrate the detailed structure of the present invention.

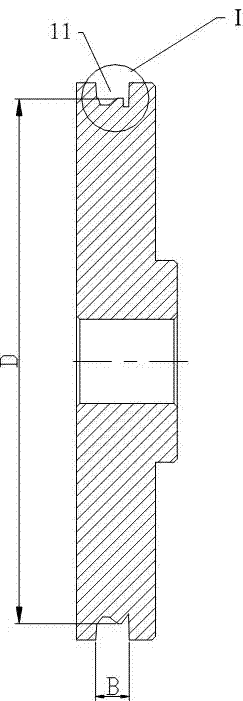

[0028] refer to figure 2 As shown, a kind of interlocking armor forming mold comprises a pair of rolls 1, 2 and a guide rail 3, the rolls are divided into a fixed roll 1 and an adjustment roll 2, and the guide rail 3 is arranged along the direction of the extension line where a pair of rolls mesh, namely After the fixed roll 1 and the adjusting roll 2 are matched, the tangential direction of the engagement between the two is the direction in which the guide rail 3 is set, and the metal strip after being pressed by the roll enters the guide rail 3, and there is a channel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com