Process for energy-saving wall built of multi-row static air hole thermal insulation building blocks

A technology of thermal insulation block and still air, applied in thermal insulation, wall, building and other directions, can solve the problems of complex construction, high cost, poor durability, etc., and achieve the effect of long life, stable quality and perfect processing technology of the wall.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

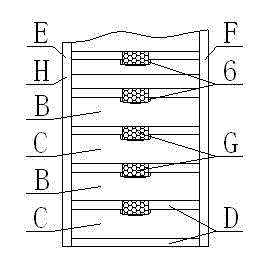

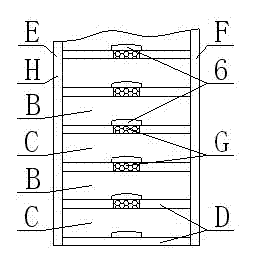

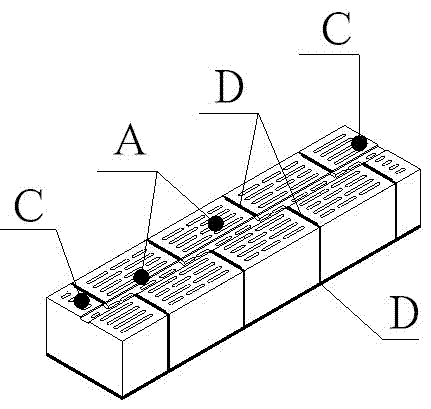

[0052] Embodiment 1. The first layer of masonry energy-saving wall:

[0053] (1) Spread a layer of anti-crack masonry mortar (D) with an appropriate thickness on the upper surface of the foundation or foundation beam according to the setting line, and bond the lower surface of the anti-crack masonry mortar (D) to the upper surface of the foundation or foundation beam;

[0054] (2) Take a large block (B) or small block (C) of a multi-row static air hole insulation block and build it according to the set-out line. The bottom plane of the large block (B) (big b) or the small block The bottom plane (b small) of (C) is bonded to the upper plane of crack-resistant masonry mortar (D), and then take a main block (A) of multi-row static air hole thermal insulation block and place it on the outer end surface 1 left and inner Evenly spread a layer of 5mm anti-cracking masonry mortar (D) on the left side of the end face 4, and then connect with the inner end face 4 right and outer end fa...

Embodiment 2

[0065] Embodiment 2, the first layer of masonry energy-saving wall:

[0066] (1) Spread a layer of anti-crack masonry mortar (D) with an appropriate thickness on the upper surface of the foundation or foundation beam according to the setting line, and bond the lower surface of the anti-crack masonry mortar (D) to the upper surface of the foundation or foundation beam;

[0067] (2) Take a large block (B) or small block (C) of a multi-row static air hole insulation block and build it according to the set-out line. The bottom plane of the large block (B) (big b) or the small block The bottom plane (b) of (C) is bonded to the upper plane of the crack-resistant masonry mortar (D) on the upper surface of the foundation or foundation beam, and then take a main block (A) of multi-row static air hole thermal insulation block and place it on the Evenly spread a layer of 10mm crack-resistant masonry mortar (D) on the left side of the outer end face 1 and the left side of the inner end f...

Embodiment 3

[0078] Embodiment 3, the first layer of masonry energy-saving wall:

[0079] (1) Spread a layer of anti-crack masonry mortar (D) with an appropriate thickness on the upper surface of the foundation or foundation beam according to the setting line, and bond the lower surface of the anti-crack masonry mortar (D) to the upper surface of the foundation or foundation beam;

[0080] (2) Take a large block (B) or small block (C) of a multi-row static air hole insulation block and build it according to the set-out line. The bottom plane of the large block (B) (big b) or the small block The bottom plane (b small) of (C) is bonded to the upper plane of crack-resistant masonry mortar (D), and then take a main block (A) of multi-row static air hole thermal insulation block and place it on the outer end surface 1 left and inner Evenly spread a layer of 15mm anti-cracking masonry mortar (D) on the left side of the end face 4, and then connect with the inner end face 4 right and outer end f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com