Method for coagulation treatment of ultrasonic pulping wastewater by using cellulose-based green flocculation material

A pulping wastewater and ultrasonic technology, applied in the field of environmental engineering, can solve the problems of secondary pollution, difficult treatment, large amount of wastewater, etc., achieve the effects of reducing treatment costs, accelerating the process of industrialization, and improving the removal rate of turbidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

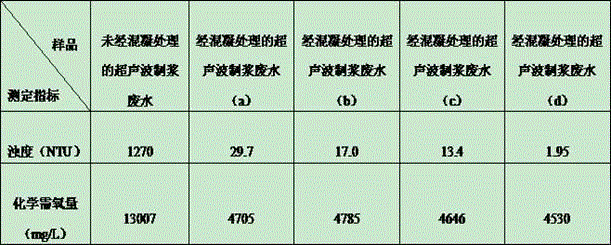

Embodiment 1

[0019] 1) Add cellulose-based green flocculation material to tap water to prepare a 3 wt% cellulose-based green flocculation material solution;

[0020] 2) Add coagulant polyaluminum chloride to tap water to prepare a polyaluminum chloride coagulant solution with a mass fraction of 4 wt%.

[0021] 3) Use 2 mol / L hydrochloric acid to adjust the pH value of wheat straw ultrasonic pulping wastewater to 4, and add the polyaluminum chloride coagulant solution prepared in step 2) to the above-mentioned adjusted In the wheat straw ultrasonic pulping wastewater with a pH value, stir at 150 rpm for 5 min, and then add the cellulose-based green flocculation material solution prepared in step 1) into the above-mentioned wheat straw ultrasonic pulping at a dosage of 10 mL / L In the wastewater, stir at 20 rpm for 9 minutes to obtain a mixed solution of wheat straw ultrasonic pulping wastewater with coagulation aids and flocculation materials added;

[0022] 4) The mixed solution of wheat s...

Embodiment 2

[0024] 1) Add cellulose-based green flocculation material to tap water to prepare a 3 wt% cellulose-based green flocculation material solution;

[0025] 2) Add the coagulant aid polymeric ferric chloride to tap water to prepare a polymeric ferric chloride coagulant aid solution with a mass fraction of 4 wt%.

[0026] 3) Use 2 mol / L hydrochloric acid to adjust the pH value of rice straw ultrasonic pulping wastewater to 5, and add the polyferric chloride coagulant solution prepared in step 2) to the above adjusted In the rice straw ultrasonic pulping wastewater with a pH value, stir at 250 rpm for 6 min, and then add the cellulose-based green flocculation material solution prepared in step 1) to the above-mentioned rice straw ultrasonic pulping at a dosage of 70 mL / L In the wastewater, stir at 50 rpm for 10 min to obtain a mixed solution of rice straw ultrasonic pulping wastewater with coagulation aids and flocculation materials added;

[0027] 4) The mixed solution of rice str...

Embodiment 3

[0029] 1) Add cellulose-based green flocculation material to tap water to prepare a 3 wt% cellulose-based green flocculation material solution;

[0030] 2) Add polyaluminum ferric chloride as a coagulant aid to tap water to prepare a polyaluminum ferric chloride coagulant aid solution with a mass fraction of 4 wt%.

[0031] 3) Use 2 mol / L hydrochloric acid to adjust the pH value of reed ultrasonic pulping wastewater to 6, and add the polyaluminum ferric chloride coagulant solution prepared in step 2) to the above-mentioned adjusted In the reed ultrasonic pulping wastewater with a pH value, stir at 190 rpm for 7 minutes, and then add the cellulose-based green flocculation material solution prepared in step 1) to the above reed ultrasonic pulping wastewater at a dosage of 40 mL / L , stirred at 40 rpm for 12 min to obtain a mixed solution of reed ultrasonic pulping wastewater with coagulation aids and flocculation materials added;

[0032] 4) Put the reed ultrasonic pulping waste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com