A Cationic Composite Magnetic Flocculant and Its Application in Wastewater Treatment

A composite magnetic, cationic technology, used in flocculation/sedimentation water/sewage treatment, water/sewage treatment, water/sludge/sewage treatment, etc. problem, to achieve the effect of high turbidity removal rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

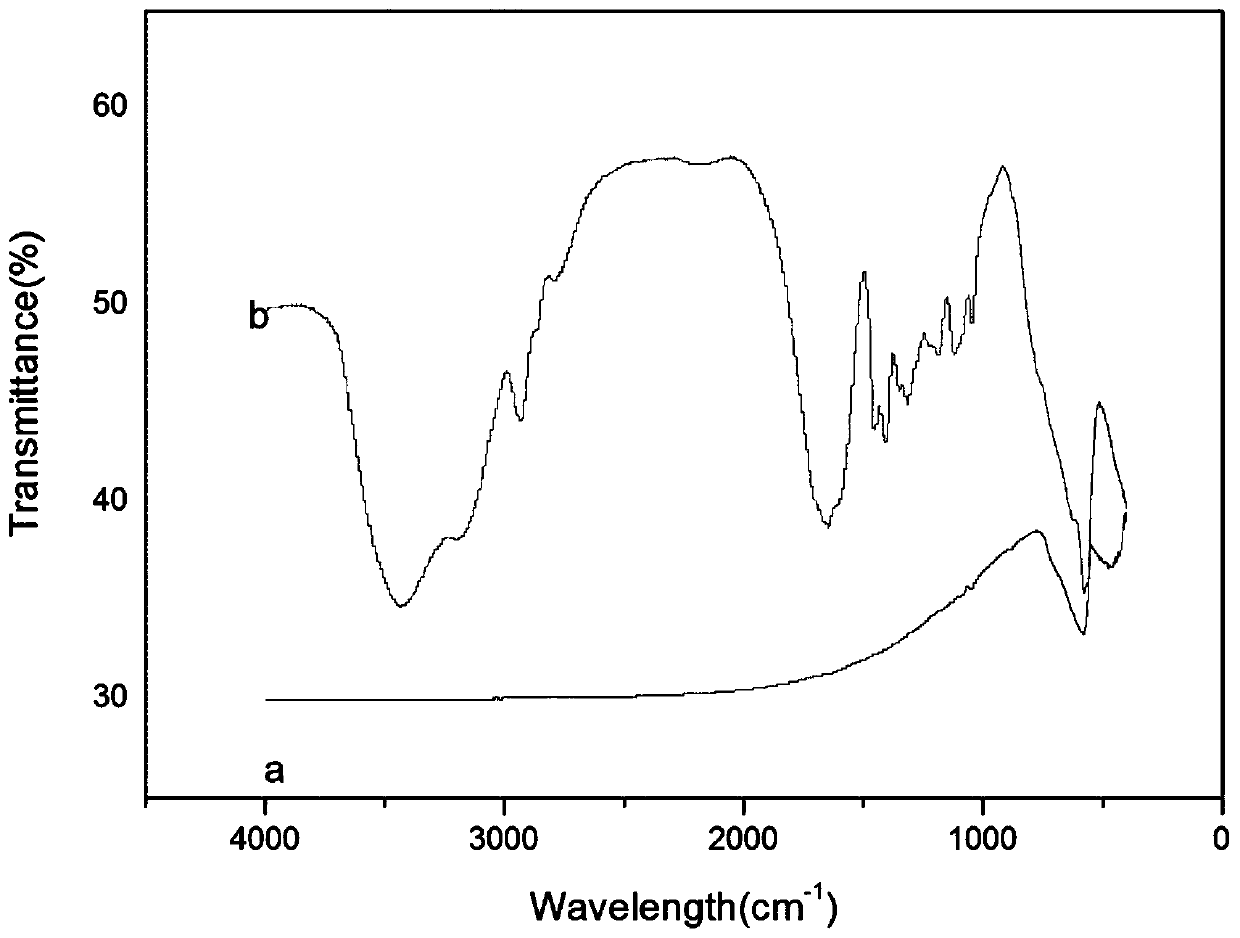

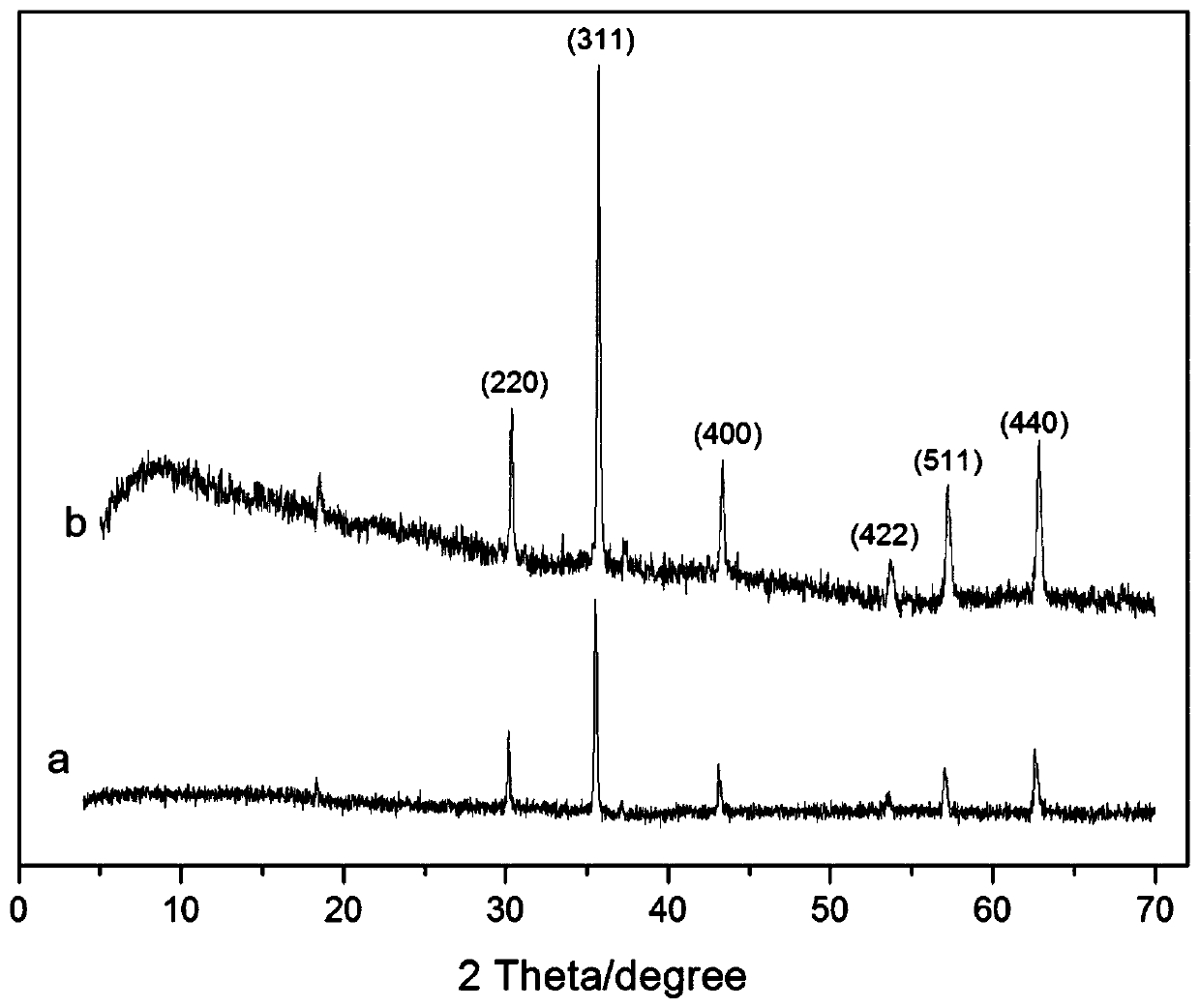

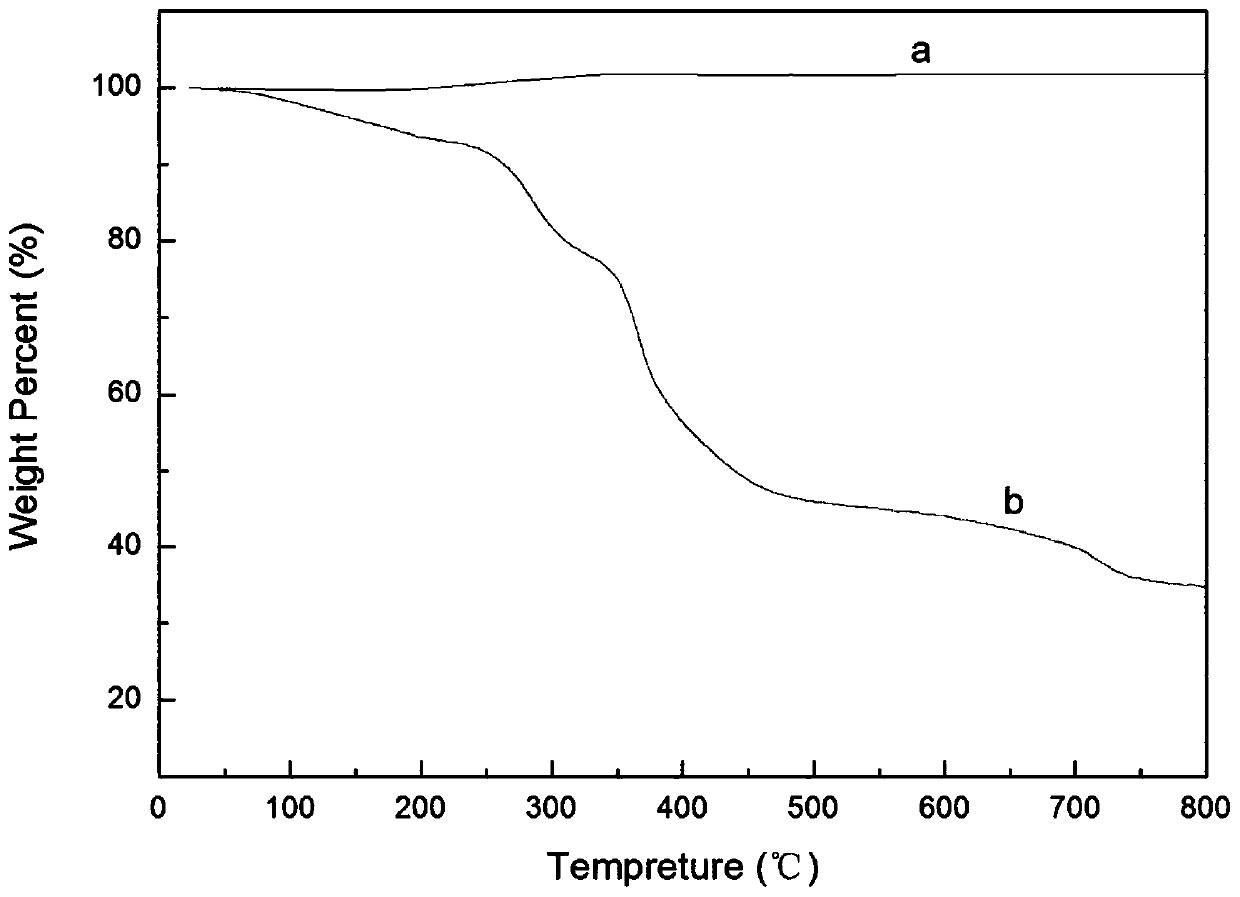

[0017] A cationic composite magnetic flocculant, in the process of copolymerization of dimethyl diallyl ammonium chloride and acrylamide monomer, the introduction of oleic acid modified Fe 3 o 4 Particles, a new type of composite magnetic flocculant synthesized by adding initiators.

[0018] The specific operation is as follows:

[0019] Weigh the acrylamide monomer and dimethyl diallyl ammonium chloride according to the solid-liquid ratio of 7-10g / ml, and dissolve them in 40-60 times distilled water;

[0020] Then add Fe modified by oleic acid 3 o 4 Particles, Fe 3 o 4 The mass ratio of particles to acrylamide monomer is 1:20-30;

[0021] After stirring evenly, nitrogen gas is introduced. After 30 minutes, the initiator is added, and it is continuously stirred in a water bath at 40-50°C for 4-8 hours; the product is washed with acetone for 3 times, dried in vacuum and crushed to obtain a cationic composite magnetic flocculant.

[0022] The technical problem to be solve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com