Preparation method for abalone fermentation product having thrombolytic antihypertensive function

The technology of a fermentation product and a production method, which is applied in the field of abalone food processing, can solve the problems of simplification of abalone processed products, the processing technology does not keep up, and the efficacy of medicine is unstable, and achieves the advantages of being conducive to digestion and absorption, less ingredients and low energy consumption. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Take the freeze-dried abalone gastropod, powder, take 8g, add 120mL of water, add 2.4g of sucrose, adjust the pH to 7.2, autoclave at 121℃ for 15min, after cooling, insert 6mL of natto bacteria suspension, and finally The concentration is 10 7 CFU / mL, at 37℃, 180rpm conditions, ventilated culture for 72h. The fermentation broth was centrifuged at 7000 r / min for 20 minutes, and the supernatant was concentrated, lyophilized, and pulverized to obtain 4.1 g of abalone fermentation product with thrombolytic and hypotensive function.

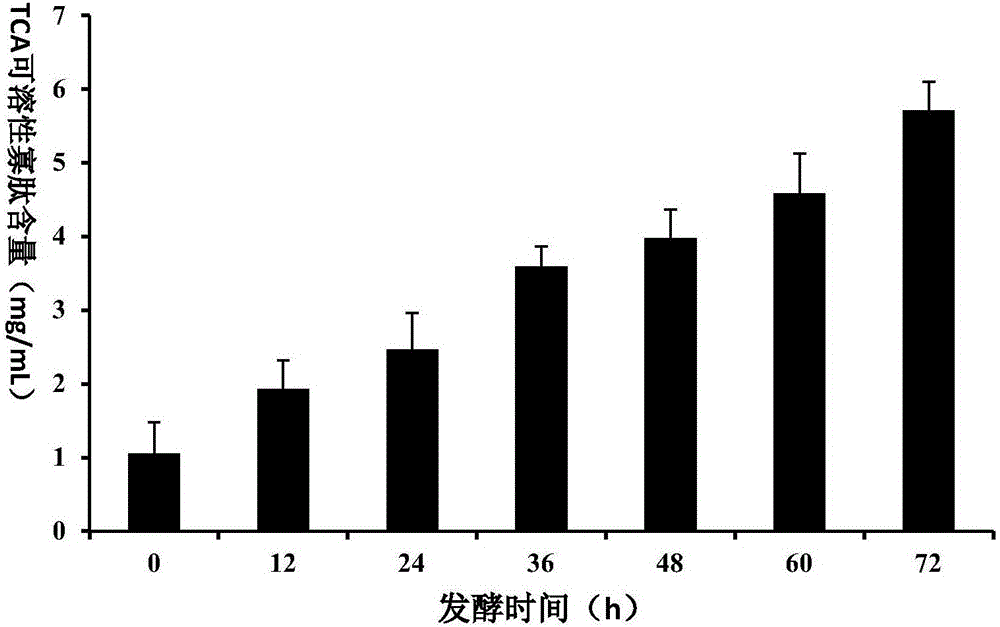

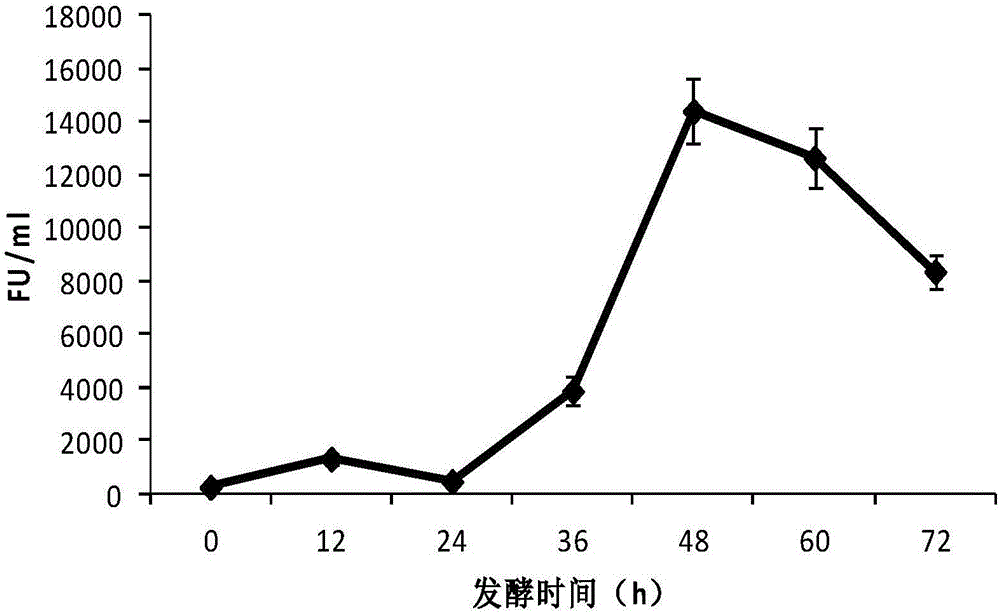

[0030] During the fermentation process, the changes in the content of TCA soluble oligopeptides in the fermentation product were tested according to the method described in Test 1 every 12 hours, and the test results are shown in figure 1 . Check the thrombolytic activity of the fermented product according to the method in Test 2 every 12h, see the test results figure 2 . For the 48h fermentation product, the ACE inhibitory activity was tested ...

Embodiment 2

[0034] Take the freeze-dried abalone tissue, powder it, take 8g, add water to 120mL, add 2.5g glucose, adjust the pH to 8.2, autoclave at 121℃ for 15min, after cooling, insert 6mL natto bacteria suspension, and finally The concentration is 10 7 CFU / mL, at 37℃, 180rpm conditions, ventilation culture for 48h. The fermentation broth was centrifuged at 7000 r / min for 20 minutes, and the supernatant was concentrated, lyophilized, and pulverized to obtain 5.9 g of abalone fermentation product with thrombolytic and hypotensive function.

[0035] In this example, the total protein content of the abalone fermentation product obtained by Folin-phenol was 25 mg / mL, and the TCA soluble oligopeptide content was 14 mg / mL using the test 1 method, of which TCA soluble oligopeptides accounted for 56%.

[0036] The thrombolytic activity of nattokinase in the fermentation product and the ACE inhibitory activity of the fermentation product were tested according to the methods in Tests 2 and 3. The tes...

Embodiment 3

[0038] Take the lyophilized abalone skirt, powder it, take 8g, add 120mL of water, add 3g of starch, adjust the pH to 6.2, autoclave at 121℃ for 15min, after cooling, insert 6mL of natto bacteria suspension, and finally The concentration is 10 7 CFU / mL, at 37℃, 180rpm conditions, ventilation culture for 48h. The fermentation broth was centrifuged at 7000 r / min for 20 minutes, and the supernatant was concentrated, lyophilized, and crushed to obtain 6.1 g of abalone fermentation product with thrombolytic and hypotensive function.

[0039] In this example, Folin-phenol was used to measure the total protein content of the obtained abalone fermentation product to be 29 mg / mL, and the TCA soluble oligopeptide content was measured to 18 mg / mL using the test 1 method, of which TCA soluble oligopeptides accounted for 61%.

[0040] The thrombolytic activity of nattokinase in the fermentation product and the ACE inhibitory activity of the fermentation product were tested according to the meth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com