Dyeing method of Eulaliopsis binata for straw braiding

A dyeing method, the technology of asparagus, which is applied in the field of dyeing of asparagus for straw weaving, can solve the problems of less research on dyeing performance, poor fiber fastness to rubbing, and high moisture regain, so as to improve the comprehensive performance of dyeing and improve the Dye dyeing, improve the effect of fiber roughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

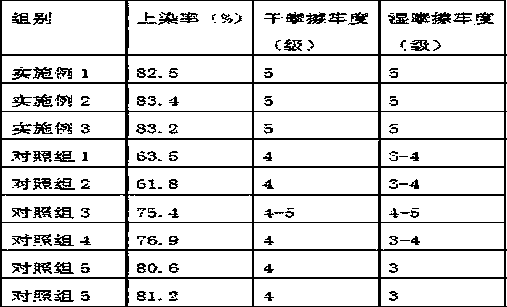

Examples

Embodiment 1

[0017] A dyeing method of asparagus for straw weaving, comprising the following contents:

[0018] (1) Soak the collected asparagus in an aqueous solution of proanthocyanidins with a mass concentration of 1.4%, and use 60 Irradiation treatment by Co-γ-ray irradiation device, the total irradiation dose is 18kGy;

[0019] (2) Dye the treated Asparagus in dyeing agent, keep it under the condition of negative pressure of 0.04MPa for 2 hours under the condition of dyeing temperature of 70°C, and then pressurize to 0.45MPa and keep it for 40 minutes After returning to normal pressure and keeping it for 2.5 minutes, pressurize again to 1.35MPa and keep it for 35 minutes;

[0020] The dyeing agent includes the following raw materials in parts by weight: 4 parts of dye, 1.2 parts of N-bromosuccinimide, 0.3 part of polyoxyethylene sorbitan monopalmitate, 0.3 part of sodium hexametaphosphate, 25 parts of polyester polyol part, 130 parts of deionized water;

[0021] (3) Wash with water...

Embodiment 2

[0029] A dyeing method of asparagus for straw weaving, comprising the following contents:

[0030] (1) Soak the collected asparagus in an aqueous solution of proanthocyanidins with a mass concentration of 1.2%, and use 60 Irradiation treatment by Co-γ-ray irradiation device, the total irradiation dose is 20kGy;

[0031] (2) Dye the treated Asparagus in a dyeing agent, keep it under the condition of negative pressure of 0.02MPa for 2 hours at the dyeing temperature of 65°C, and keep it for 45 minutes under the condition of pressurized to 0.4MPa After returning to normal pressure and maintaining it for 2 minutes, pressurize again to 1.45MPa and maintain it for 30 minutes;

[0032] The dyeing agent includes the following raw materials in parts by weight: 3 parts of dye, 0.8 part of N-bromosuccinimide, 0.2 part of polyoxyethylene sorbitan monopalmitate, 0.1 part of sodium hexametaphosphate, 30 parts of polyester polyol part, 120 parts of deionized water;

[0033] (3) Wash with ...

Embodiment 3

[0041] A dyeing method of asparagus for straw weaving, comprising the following contents:

[0042] (1) Soak the collected asparagus in an aqueous solution of proanthocyanidins with a mass concentration of 1.6%, and use 60 Irradiation treatment by Co-γ-ray irradiation device, the total irradiation dose is 16kGy;

[0043] (2) Dye the treated Asparagus in a dyeing agent, keep it under a negative pressure of 0.06MPa for 2 hours at a dyeing temperature of 75°C, and then keep it under a pressure of 0.5MPa for 35 minutes After returning to normal pressure and keeping it for 3 minutes, pressurize again to 1.25MPa and keep it for 40 minutes;

[0044] The dyeing agent includes the following raw materials in parts by weight: 5 parts of dye, 1.6 parts of N-bromosuccinimide, 0.4 part of polyoxyethylene sorbitan monopalmitate, 0.5 part of sodium hexametaphosphate, 20 parts of polyester polyol part, 140 parts of deionized water;

[0045] (3) After the dyeing is completed, wash with water,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com