Device for straw plaited article bleaching and dyeing

A technology of straw weaving and circulating liquid, which is applied in the field of straw weaving production, which can solve problems such as uneven distribution of reaction liquid, uneven temperature distribution, and reduced strength of straw weaving, and achieve the effects of shortened reaction time, beautiful bleaching and dyeing color, and uniform reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in further detail below through examples, and examples are only used to illustrate the present invention, and do not limit the scope of the present invention.

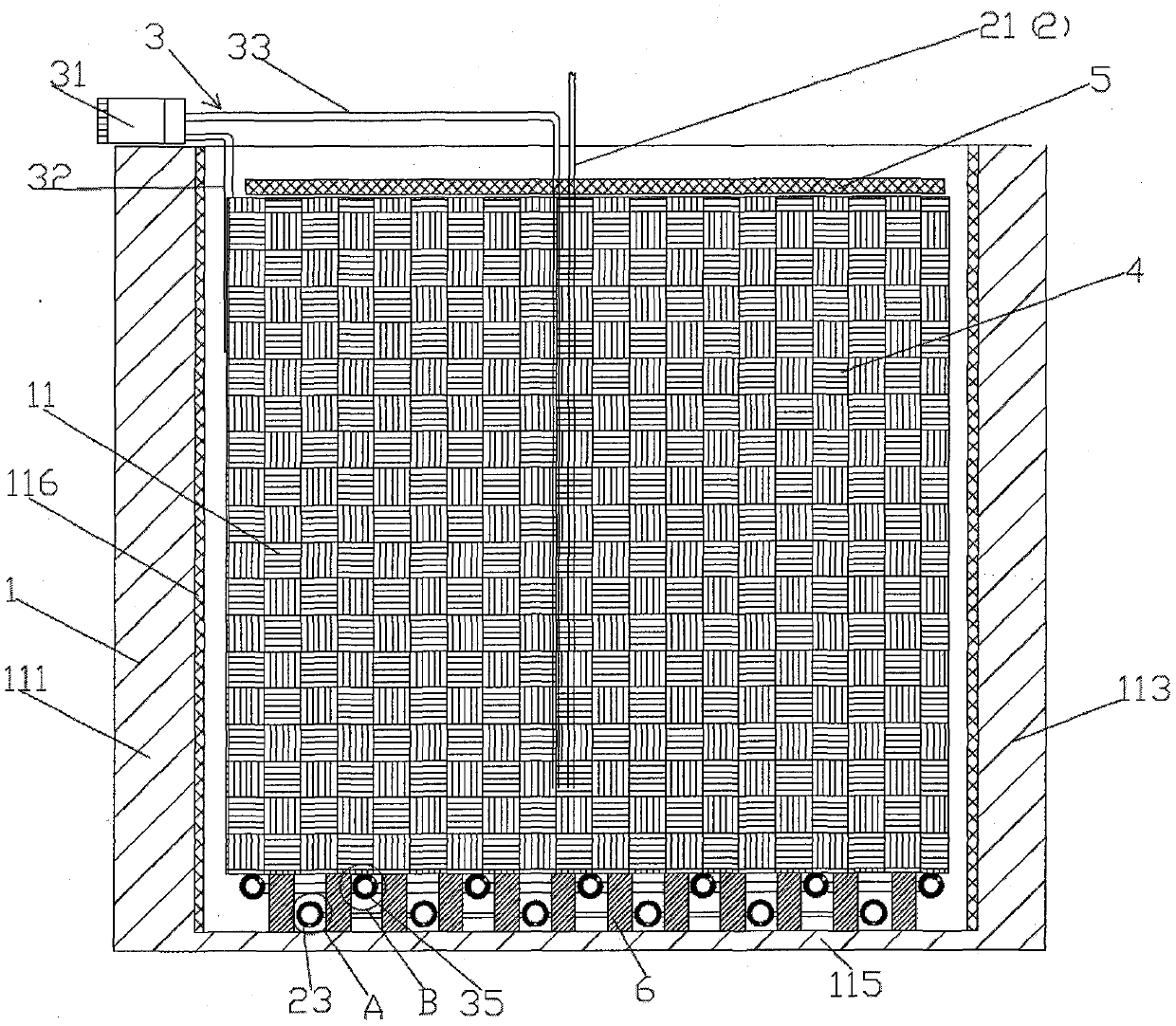

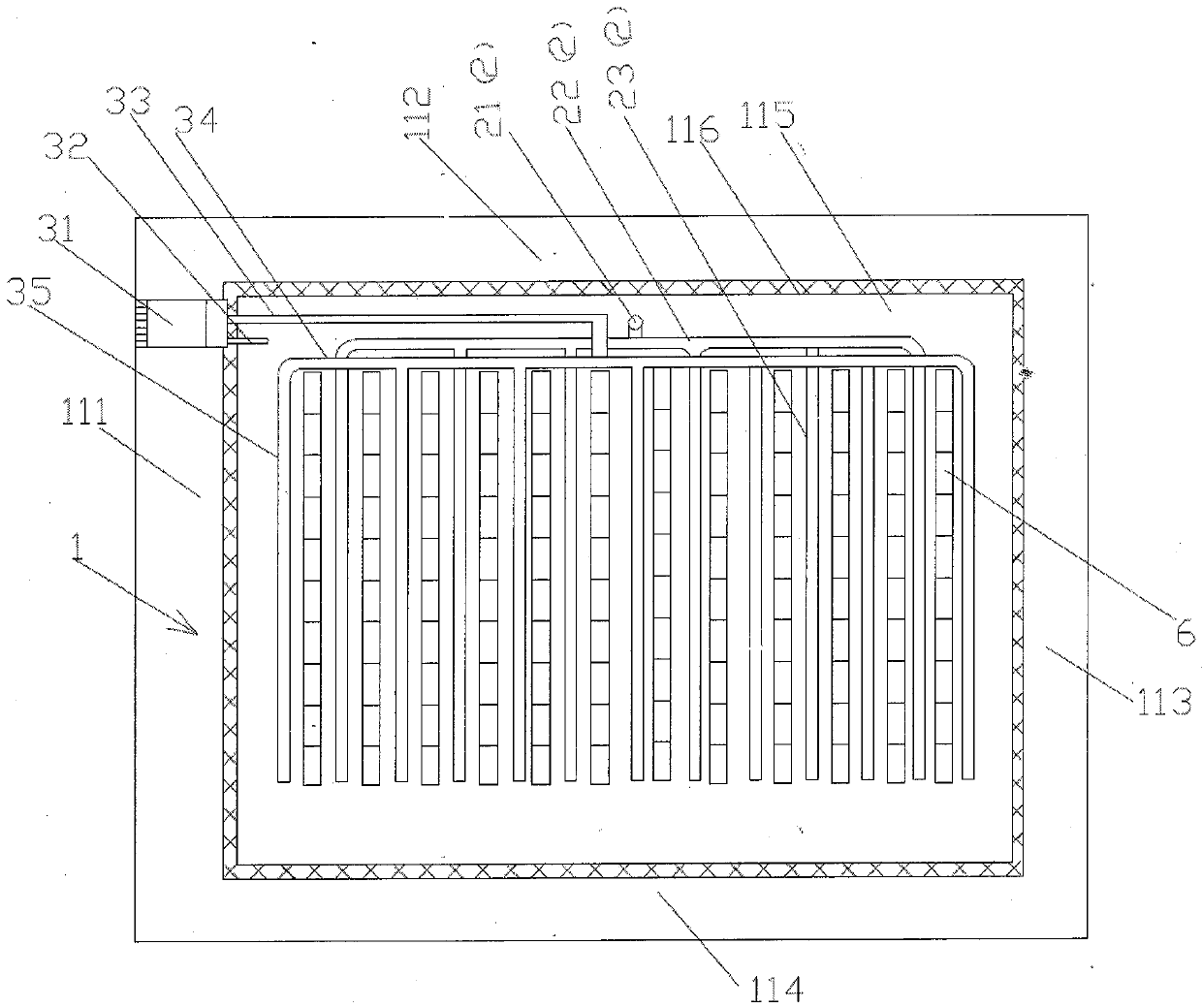

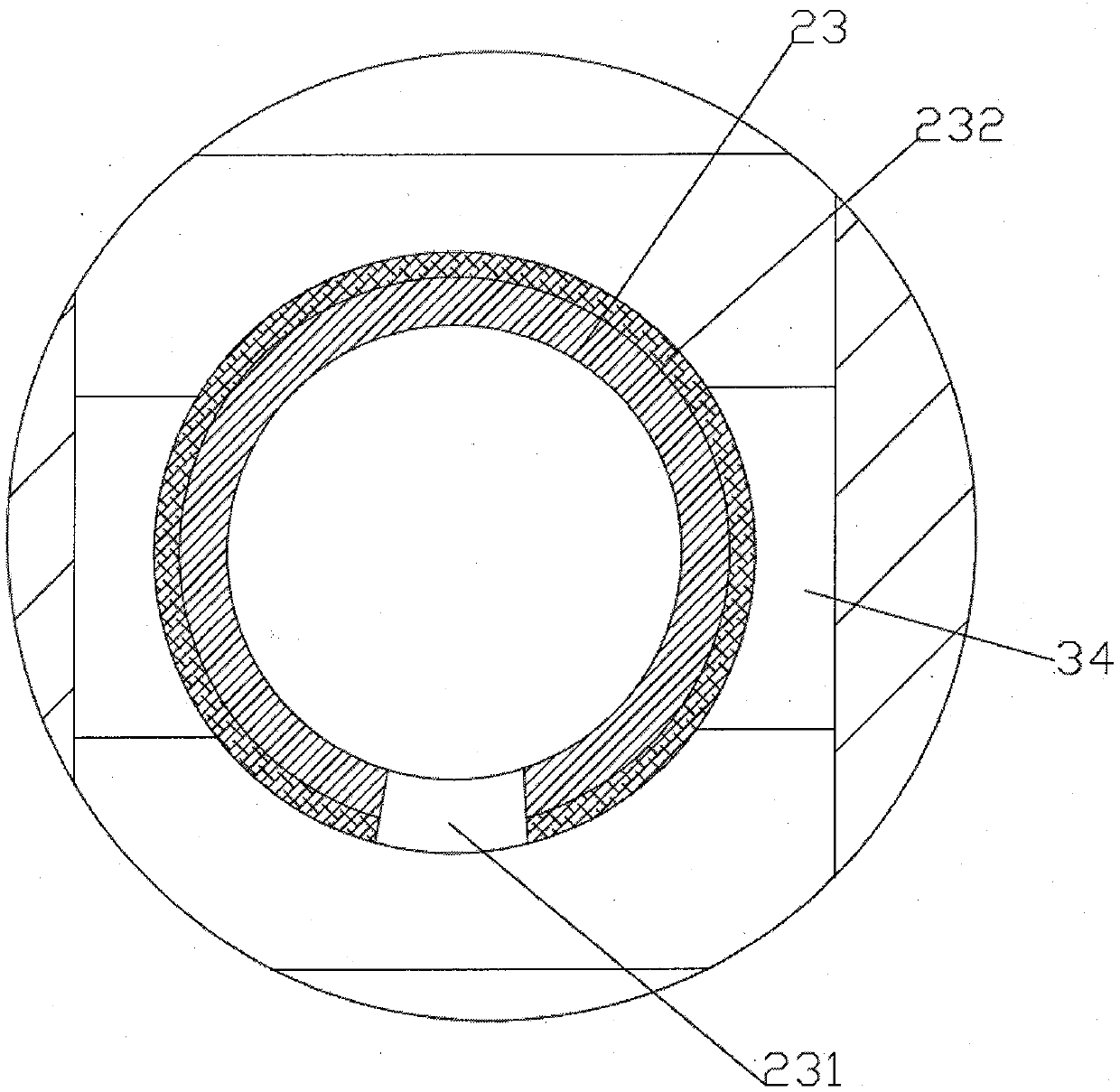

[0028] see Figure 1-7 A device for bleaching and dyeing straw is shown, including a concrete pool body 1, a steam pipe assembly 2, and a circulating fluid assembly 3. The steam pipe assembly 2 and the circulating fluid assembly 3 are arranged in the concrete pool body 1; the concrete pool body 1 is a three-dimensional The concrete pool body 1 is provided with a pool cavity 11. The concrete pool body 1 includes side wall one 111, side wall two 112, side wall three 113, side wall four 114 and bottom wall 115. The bottom wall 115 is rectangular, and the side wall The first wall 111, the second side wall 112, the third side wall 113, and the fourth side wall 114 are connected end to end and are vertically fixedly connected to each other. Around the edge of wall 115, pool bod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com