Method for improving color fastness of straw plaited products

A technology for color fastness and products, applied in the direction of manufacturing tools, reed/straw treatment, wood treatment, etc., can solve the problems of easy decolorization and poor dyeing fastness, and achieve the effect of high color fastness, improved effect, and not easy to decolorize

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

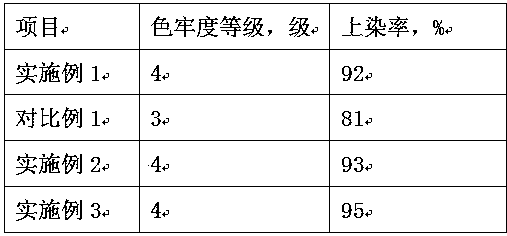

Examples

Embodiment 1

[0015] A method for improving the color fastness of straw products, comprising the following steps:

[0016] (1) Dry the woven straw products to a moisture content of 8%, spray the surface with a modification solution, and then dry it naturally, wherein the modification solution is made of the following components by weight: trisodium isocitrate 11 8 parts of sodium borate, 2 parts of sodium 8-ethoxyquinoline-5-sulfonate, 1 part of sodium allyl sulfonate, 190 parts of water;

[0017] (2) Add the dried straw woven product into the dyeing solution, then heat it up to 85°C, heat it for 35 minutes, take it out, wash it with water, and dry it to obtain a finished product. The dyeing solution consists of the following parts by weight Components: 1 part of disperse dye, 2 parts of N-benzylglycine hydrochloride, 4 parts of hydroxylamine disodium salt, 1 part of triisopropanolamine, 2 parts of sodium 1-pentanesulfonate, 110 parts of water .

[0018] Specifically, in the above step (1...

Embodiment 2

[0022] A method for improving the color fastness of straw products, comprising the following steps:

[0023] (1) Dry the woven straw products to a water content of 10%, spray the surface with a modification solution, and then dry it naturally, wherein the modification solution is made of the following components by weight: trisodium isocitrate 13 10 parts of sodium borate, 3 parts of sodium 8-ethoxyquinoline-5-sulfonate, 2 parts of sodium allyl sulfonate, 195 parts of water;

[0024] (2) Add the dried straw woven product into the dyeing solution, then heat it up to 90°C, heat it for 38 minutes, take it out, wash it with water, and dry it to obtain a finished product. The dyeing solution consists of the following parts by weight Made of components: 2 parts of disperse dye, 3 parts of N-benzylglycine hydrochloride, 5 parts of hydroxylamine disodium salt, 2 parts of triisopropanolamine, 3 parts of sodium 1-pentanesulfonate, 115 parts of water .

[0025] Specifically, in the abo...

Embodiment 3

[0029] A method for improving the color fastness of straw products, comprising the following steps:

[0030] (1) Dry the woven straw products to a water content of 12%, spray the surface with a modification solution, and then dry it naturally, wherein the modification solution is made of the following components by weight: trisodium isocitrate 15 12 parts of sodium borate, 5 parts of sodium 8-ethoxyquinoline-5-sulfonate, 3 parts of sodium allyl sulfonate, 200 parts of water;

[0031] (2) Add the dried straw woven product into the dyeing solution, then heat it up to 95°C, heat it for 40 minutes, take it out, wash it with water, and dry it to obtain a finished product. The dyeing solution consists of the following parts by weight Made of ingredients: 3 parts of disperse dye, 5 parts of N-benzylglycine hydrochloride, 6 parts of hydroxylamine disodium salt, 3 parts of triisopropanolamine, 5 parts of sodium 1-pentanesulfonate, 120 parts of water .

[0032] Specifically, in the ab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com