Environment-friendly straw weaving product manufacturing method

A production method and an environment-friendly technology, which is applied in the direction of manufacturing tools, reed/straw treatment, wood treatment, etc., can solve the problems of complex structure, unfavorable environmental protection, etc., and achieve the effect of good quality, environmental protection, and enhanced strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

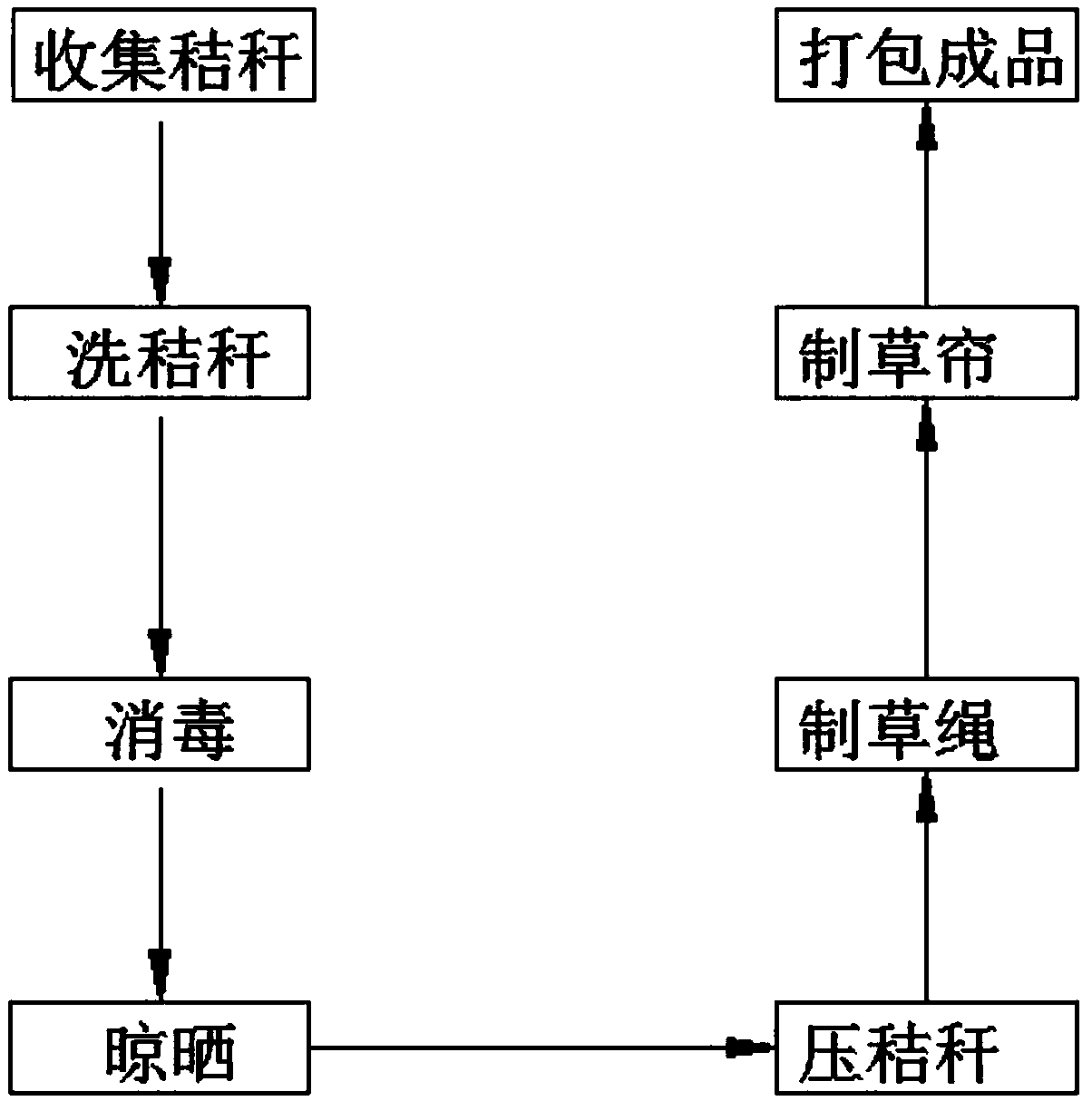

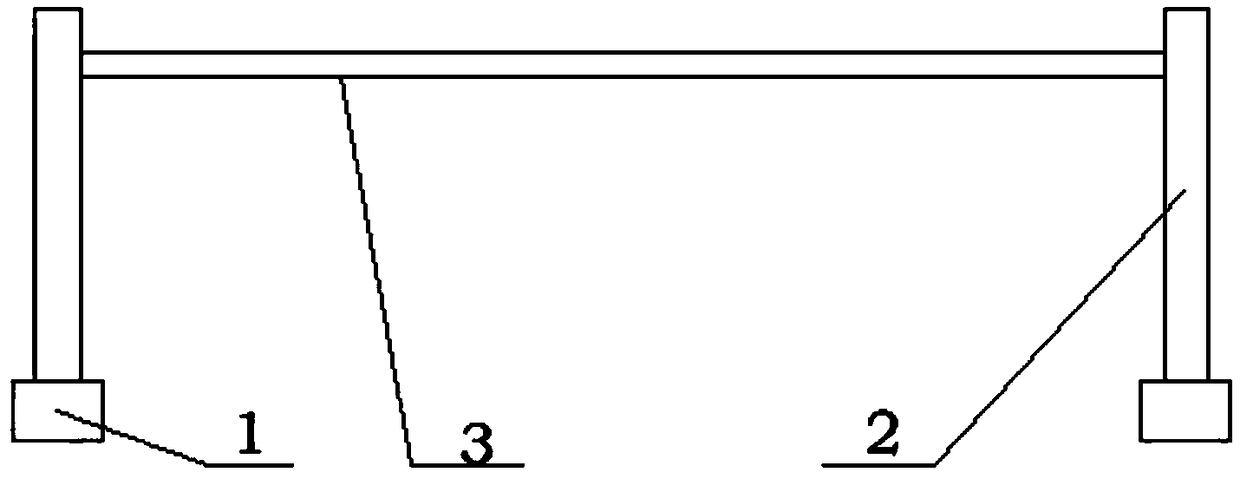

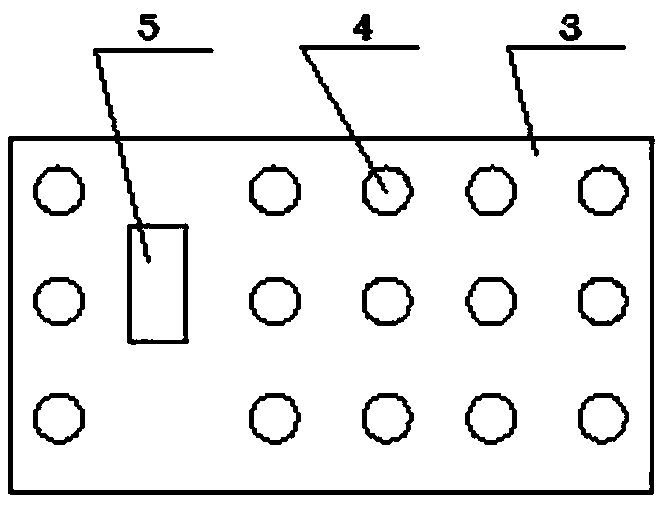

[0027] Such as figure 1 , figure 2 and image 3 Shown, a kind of environment-friendly straw product production method comprises the following steps:

[0028] (1) Collect straw: bundle the straw in the farmland into a cuboid block, load the bundled straw into a truck, and transport the block straw to the production center;

[0029] (2) Straw washing: spread out the blocky straws, put them evenly into the pool with flame retardant, stir the straws, remove other impurities in the straws, and pick out the clean and impurity-free straws for next use one step use;

[0030] (3) Disinfection: Put the selected stalks into the disinfection tank, add disinfectant to the disinfection tank to sterilize the straws, and take out the straws after the disinfection is completed;

[0031] (4) Drying: spread the sterilized stalks evenly on the drying board on the drying site for drying, and when the moisture content in the stalks is lower than 12%, the stalks can be put away for later use; ...

Embodiment 2

[0042] Such as figure 1 , figure 2 and image 3 Shown, a kind of environment-friendly straw product production method comprises the following steps:

[0043] (1) Collect straw: bundle the straw in the farmland into a cuboid block, load the bundled straw into a truck, and transport the block straw to the production center;

[0044] (2) Straw washing: spread out the blocky straws, put them evenly into the pool with flame retardant, stir the straws, remove other impurities in the straws, and pick out the clean and impurity-free straws for next use one step use;

[0045] (3) Disinfection: Put the selected stalks into the disinfection tank, add disinfectant to the disinfection tank to sterilize the straws, and take out the straws after the disinfection is completed;

[0046] (4) Drying: spread the sterilized stalks evenly on the drying board on the drying site for drying, and when the moisture content in the stalks is lower than 12%, the stalks can be put away for later use; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com