Sun-block raffia straw hat dyeing method

A dyeing method and straw weaving technology, which is applied in the dyeing field of sunscreen raffia straw hats, can solve the problems of difficult raffia coloring, unstable properties, easy color change and fading, etc., and achieve bright color, stable dyeing performance, and enhanced penetration ability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

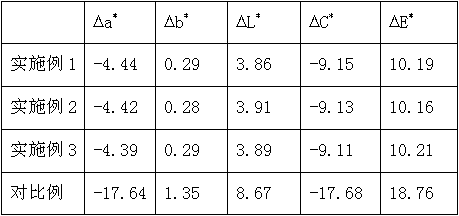

Examples

Embodiment 1

[0015] In the embodiment of the present invention, a kind of dyeing method of sunscreen raffia hat, concrete method is as follows:

[0016] (1) Put the woven raffia hat into a constant temperature steam treatment at a temperature of 280°C for 9 minutes, cool down to 170°C at a cooling rate of 6°C / min and continue the constant temperature steam treatment for 8 minutes, take it out, and immerse it in the dyeing agent Soak for 60 minutes, pass through ultrasonic wave for ultrasonic treatment and put in magnetic field for magnetization treatment;

[0017] The dyeing agent is made of the following raw materials in parts by weight: 0.7 parts of chromium trioxide, 5.4 parts of ferric oxide, 2.2 parts of calcium chloride, 0.4 parts of potassium fluoroborate, 1.2 parts of chitosan, 1.7 parts of calcium pyruvate 8 parts of rose flower juice, 2 parts of sucrose fatty acid ester, 110 parts of deionized water;

[0018] (2) Put the raffia straw hat treated in step (1) under the conditions ...

Embodiment 2

[0024] In the embodiment of the present invention, a kind of dyeing method of sunscreen raffia hat, concrete method is as follows:

[0025] (1) Put the woven raffia hat into a constant temperature steam treatment at a temperature of 285°C for 10 minutes, cool down to 175°C at a cooling rate of 6.5°C / min and continue the constant temperature steam treatment for 9 minutes, take it out, and immerse it in the dyeing agent After soaking for 65 minutes, ultrasonic treatment is carried out by ultrasound and magnetic field is used for magnetization treatment;

[0026] The dyeing agent is made of the following raw materials in parts by weight: 0.8 parts of chromium trioxide, 5.6 parts of ferric oxide, 2.3 parts of calcium chloride, 0.45 parts of potassium fluoroborate, 1.3 parts of chitosan, 1.8 parts of calcium pyruvate 8.5 parts of rose flower juice, 2.5 parts of sucrose fatty acid ester, 115 parts of deionized water;

[0027] (2) Put the raffia straw hat treated in step (1) into th...

Embodiment 3

[0033] In the embodiment of the present invention, a kind of dyeing method of sunscreen raffia hat, concrete method is as follows:

[0034] (1) Put the woven raffia hat into a constant temperature steam treatment at a temperature of 290°C for 11 minutes, cool down to 180°C at a cooling rate of 7°C / min and continue the constant temperature steam treatment for 10 minutes, take it out, and immerse it in the dyeing agent Soak for 70 minutes, pass through ultrasonic wave for ultrasonic treatment and put in magnetic field for magnetization treatment;

[0035] The dyeing agent is made of the following raw materials in parts by weight: 0.9 parts of chromium trioxide, 5.8 parts of ferric oxide, 2.4 parts of calcium chloride, 0.5 parts of potassium fluoroborate, 1.4 parts of chitosan, 1.9 parts of calcium pyruvate 9 parts of rose flower juice, 3 parts of sucrose fatty acid ester, 120 parts of deionized water;

[0036] (2) Put the raffia straw hat treated in step (1) into the temperatur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com