Dyeing method for enhancing mechanical property of para-aramid paper

A technology of para-aramid paper and dyeing method, which is applied in the field of dyeing to enhance the mechanical properties of para-aramid paper, and can solve the lack of chemically active groups on the surface of aramid fiber, limitations in use quality and application quality, difficult chemical reactions or other problems. To achieve excellent dyeing effect, uniform and thorough dyeing, and reduce waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

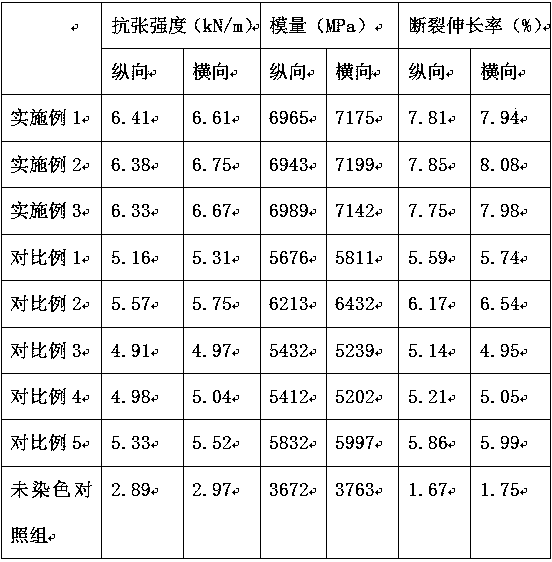

Examples

Embodiment 1

[0017] In the embodiment of the present invention, a dyeing method for enhancing the mechanical properties of para-aramid paper, the specific method is as follows:

[0018] (1) Submerge the para-aramid paper in an aluminum sulfate aqueous solution with a mass fraction of 6.2% and a temperature of 43°C for 18 minutes, take out the drain, and perform steam treatment to obtain pretreated para-aramid paper;

[0019] (2) Submerge the pretreated para-aramid paper in the dyeing agent for 16 minutes and pass it through ultrasonic waves for ultrasonic treatment, remove the agent, and vacuum treat it for 8 minutes at a temperature of 33 ° C and a vacuum degree of 0.14 MPa. Vacuum treatment for 15 minutes at a temperature of 24°C and a vacuum degree of 0.31 MPa to obtain pre-dyed para-aramid paper;

[0020] The dyeing agent is made of the following raw materials in parts by weight: 6.2 parts of goat milk, 21 parts of purple mulberry, 27 parts of fresh amaranth, 15 parts of fresh black wo...

Embodiment 2

[0027] In the embodiment of the present invention, a dyeing method for enhancing the mechanical properties of para-aramid paper, the specific method is as follows:

[0028] (1) Submerge the para-aramid paper in an aluminum sulfate aqueous solution with a mass fraction of 6.5% and a temperature of 44°C for 20 minutes, take out the drain, and perform steam treatment to obtain pretreated para-aramid paper;

[0029] (2) Submerge the pretreated para-aramid paper in the dyeing agent for 18 minutes and pass it through ultrasonic waves for ultrasonic treatment, remove the leach agent, and vacuum treat it for 9 minutes at a temperature of 34 °C and a vacuum degree of 0.15 MPa. Vacuum treatment for 16 minutes at a temperature of 25°C and a vacuum degree of 0.32 MPa to obtain pre-dyed para-aramid paper;

[0030] The dyeing agent is made of the following raw materials in parts by weight: 6.5 parts of goat milk, 21.5 parts of purple mulberry, 28 parts of fresh amaranth, 15.5 parts of fresh...

Embodiment 3

[0037] In the embodiment of the present invention, a dyeing method for enhancing the mechanical properties of para-aramid paper, the specific method is as follows:

[0038](1) Submerge the para-aramid paper in an aluminum sulfate aqueous solution with a mass fraction of 6.8% and a temperature of 45°C for 22 minutes, take out the drain, and perform steam treatment to obtain pretreated para-aramid paper;

[0039] (2) Submerge the pretreated para-aramid paper in the dyeing agent for 20 minutes and pass it through ultrasonic waves for ultrasonic treatment, remove the leach agent, and vacuum treat it for 10 minutes at a temperature of 35 ° C and a vacuum degree of 0.16 MPa. Vacuum treatment for 17 minutes at a temperature of 26°C and a vacuum degree of 0.33 MPa to obtain pre-dyed para-aramid paper;

[0040] The dyeing agent is made of the following raw materials in parts by weight: 6.8 parts of goat milk, 22 parts of purple mulberry, 29 parts of fresh amaranth, 16 parts of fresh bl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com