Method for preparing high-activity double-effect seed crystals from metatitanic acid

A double-effect seed crystal, metatitanic acid technology, applied in chemical instruments and methods, titanium dioxide, titanium compounds, etc., can solve problems such as inability to perform hydrolysis, and achieve shortened bleaching time, high seed crystal activity, and improved efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

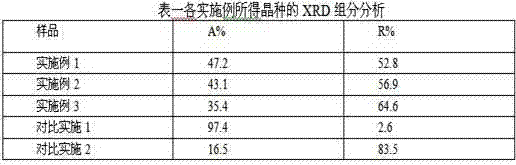

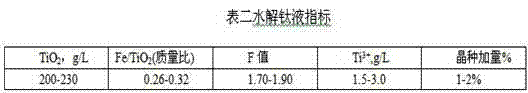

Examples

Embodiment 1

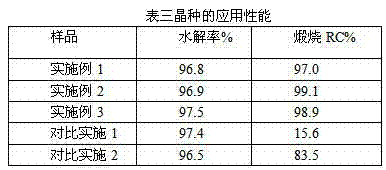

[0021] Beat the rinsed metatitanic acid (Fe≤50ppm) into TiO 2 The concentration is 300g / L, take 1000ml and pour it into a 3000ml flask, add 665ml of concentrated sulfuric acid while stirring, boil under normal pressure to make titanium sulfate clear liquid, after the titanium sulfate clear liquid is cooled to 60°C, add distilled water while stirring ( It can also be diluted with desalted water) to 120g / L (using TiO 2 meter), filter. Slowly add the filtrate to 150g / L sodium carbonate solution, control the temperature of the material 2 The solution is dripped into the washing solution without white precipitate). Beat the filter cake to 50g / L (as TiO 2 meter), then press TiO 2 : HCl 0.3 and TiO 2 Concentrated hydrochloric acid and hydrofluoric acid are added at a mass ratio of HF of 0.03, wherein the order of addition of concentrated hydrochloric acid and hydrofluoric acid is not limited. After the mixed acid is added, it is stirred for 30 minutes, and then the temperature of...

Embodiment 2

[0023] Beat the rinsed metatitanic acid (Fe≤50ppm) into TiO 2 The concentration is 350g / L, take 1000ml and pour it into a 3000ml flask, add 776ml of concentrated sulfuric acid while stirring, boil under normal pressure to make a titanium sulfate solution, cool to 30°C, add desalinated water while stirring to dilute to 160g / L (with TiO 2 meter), filter. Slowly add it to 200g / L sodium carbonate solution, control the material temperature 2 The solution is dripped into the washing liquid without white precipitate). Beat the filter cake to 80g / L (as TiO 2 meter), adding concentrated hydrochloric acid and hydrofluoric acid, in which TiO 2 The mass ratio to HCl is 0.45, TiO 2 The mass ratio to HF is 0.03. After stirring for 30 minutes, heat up to 78°C and keep it warm for 6 minutes to obtain a colloidal seed crystal with a slight blue opalescence. Add 1 / 5 times the volume of the colloidal seed crystal in desalted water and quench to - ≤2g / L, beating is 80 g / L (based on TiO 2 co...

Embodiment 3

[0025] Beat the rinsed metatitanic acid (Fe≤50ppm) into TiO 2 The concentration is 450g / L, take 1000ml and pour it into a 3000ml flask, add 998ml of concentrated sulfuric acid while stirring, boil under normal pressure to make a titanium sulfate solution, cool to 45°C, add distilled water to dilute to 200g / L while stirring, filter. Slowly add the filtrate to 175g / L sodium carbonate solution, control the temperature of the material 2 The solution is dripped into the washing liquid without white precipitate). Beat the filter cake to 100g / L, add concentrated hydrochloric acid, in which TiO 2 :HCl=0.6 (mass ratio), TiO 2 : HF=0.04 (mass ratio), after stirring for 30 minutes, heat up to 80°C and hold for 4 minutes to obtain a colloidal seed crystal with a slight blue opalescence, add 1 / 5 times the volume of the colloidal seed crystal in desalted water to quench To - ≤2g / L, beating to 100 g / L (based on TiO 2 count), get crystal seeds.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com