A device and a method for bleaching waste textiles with gas phase chlorine dioxide

A technology for waste textiles and chlorine dioxide, which is applied to a device for bleaching waste textiles with gaseous chlorine dioxide and the field of bleaching waste textiles with gaseous chlorine dioxide. The effect of reducing the amount of wastewater treatment, reducing the degree of damage, and shortening the bleaching time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

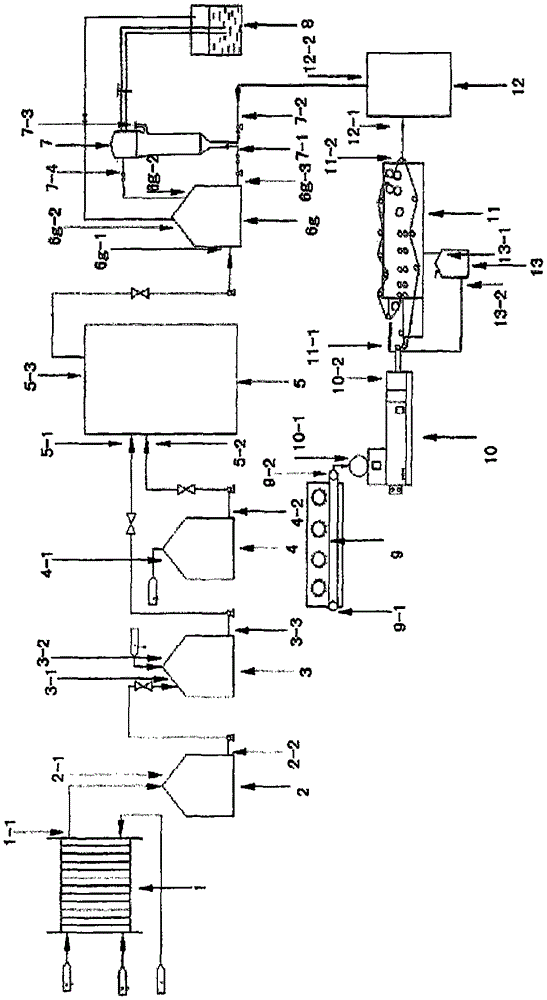

[0041] What embodiment 1 represented is the device for bleaching waste and used textiles with gaseous chlorine dioxide of the present invention.

[0042] combined with figure 1 , a device for bleaching waste textiles with gaseous chlorine dioxide, comprising a chlorine dioxide generating system and a gaseous bleaching system; wherein, the chlorine dioxide generating system includes a hydroxyl radical active oxygen pharmaceutical machine 1, a chemical tank 2, a mixed chemical Tank 3, hydrochloric acid tank 4, chlorine dioxide generator 5, chlorine dioxide storage tank 6g; the drug outlet 1-1 of the hydroxyl radical active oxygen pharmaceutical machine is connected to the inlet 2-1 of the drug tank, and the outlet 2-2 of the drug tank Connect the first inlet 3-1 of the mixed medicament tank, the described medicament tank also includes the second inlet 3-2 for feeding sodium chlorate, the outlet 3-3 of the mixed medicament tank is connected to the first chlorine dioxide generator...

Embodiment 2

[0044] In this embodiment, the waste clothes are bleached. specifically is:

[0045] A method for bleaching waste and used clothes with gas-phase chlorine dioxide, the method comprising a chlorine dioxide generation step and a gas-phase bleaching step; wherein, the chlorine dioxide generation step includes: hydroxyl radical active oxygen pharmaceutical machine 1 preparation Hydroxyl radical active oxygen agent, the agent is stored in the agent tank 2, the agent in the agent tank is passed into the mixed agent tank 3 according to the required amount, and sodium chlorate solid is added to the mixed agent tank 3 at the same time, so that after dissolving The concentration of sodium chlorate is 400g / L; the mixed liquid mixed evenly in the mixed agent tank is poured into the chlorine dioxide generator 5, and sulfuric acid with a concentration of 4mol / L is added thereto, the temperature is raised to 60°C, and the reaction is performed for two hours Finally, gaseous chlorine dioxide...

Embodiment 3

[0047] A method for bleaching waste textiles with gas-phase chlorine dioxide, the method comprising a chlorine dioxide generation step and a gas-phase bleaching step; wherein, the chlorine dioxide generation step includes: hydroxyl radical active oxygen pharmaceutical machine 1 to produce hydroxyl Free radical active oxygen agent, the agent is stored in the agent tank 2, the agent in the agent tank is passed into the mixed agent tank 3 according to the required amount, and sodium chlorate solid is added to the mixed agent tank 3 at the same time, so that the dissolved chlorine The concentration of sodium nitrate is 400g / L; the mixed liquid mixed evenly in the mixed agent tank is poured into the chlorine dioxide generator 5, and sulfuric acid with a concentration of 4mol / L is added thereinto, the temperature is raised to 60°C, and after two hours of reaction , to obtain gaseous chlorine dioxide, which is stored in 6 g of chlorine dioxide storage tanks; the gaseous phase bleachin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| whiteness | aaaaa | aaaaa |

| whiteness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com