Method for beaching shellac using chlorine dioxide and alcohol solvent, and application thereof

A technology for bleaching shellac and alcohol solvents, which is applied in the direction of applications, medical preparations of non-active ingredients, pharmaceutical formulas, etc. It can solve the problems of prolonging the bleaching time, affecting the bleaching efficiency, and short product life, so as to improve the bleaching efficiency. The effect of increasing the application range and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

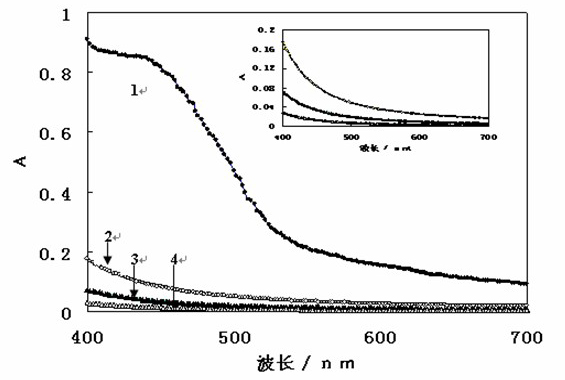

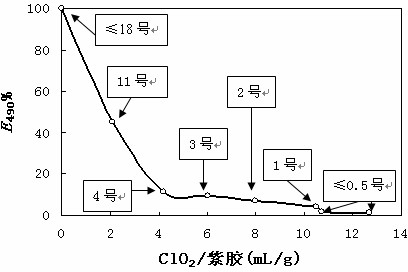

[0024] Take 100g of purple film (commercially available grade A purple film, the color is purple-red, color index ≤18) and 300g of absolute ethanol are mixed, the constant temperature water bath is heated to 65 ℃, the mixture is put into the water bath and fully stirred to obtain a mass ratio of 1:3 lac ethanol solution, add 210mL chlorine dioxide (commercially available industrial product), the available chlorine content is 10g / L, control the pH between 4.0-6.0 during the bleaching process, stir and bleach at 65℃ for 2h to obtain bleaching Glue solution, add dilute sulfuric acid with a mass percentage of 5% to the bleached glue solution, adjust the pH of the bleached glue solution to 3, and make the bleached shellac precipitate flocculent, and then repeatedly rinse with water to precipitate the shellac to wash water After the pH value is 7, filter and dry at room temperature for more than 7 days to obtain bleached shellac with dark yellow color and the absorbance of ethanol sol...

Embodiment 2

[0026] Take 100g of purple film (commercially available grade A purple film, the color is purple, color index ≤18) and 500g of absolute ethanol are mixed, the constant temperature water bath is heated to 70 ℃, the mixture is put into the water bath and fully stirred to obtain a mass ratio of 1:5 methanol solution of shellac, add 420mL chlorine dioxide (commercially available industrial product), the available chlorine content is 20g / L, control the pH between 4.0-6.0 during the bleaching process, stir and bleach at 70℃ for 4h to obtain bleaching Glue solution, add 3% dilute sulfuric acid to the bleaching glue solution to adjust the pH of the bleaching glue solution to 4, so that the bleached shellac will precipitate out in a flocculent state, and then repeatedly rinse with water to precipitate shellac to the pH value of the washing water After it is 7, filter dry and dry at room temperature for more than 7 days to obtain bleached shellac with yellow color. E 490 It is 11.3% of th...

Embodiment 3

[0028] Take 100g of purple film (commercially available grade A purple film, the color is purple, color index ≤18) and 200g of absolute ethanol are mixed, the constant temperature water bath is heated to 80 ℃, the mixture is put in the water bath and fully stirred to make the mass ratio 1:2 lac ethanol solution, add 595mL chlorine dioxide (commercially available industrial product), the available chlorine content is 20g / L, control the pH between 4.0-7.0 during the bleaching process, stir and bleach at 80℃ for 1h to obtain bleaching Glue solution, add 10% dilute sulfuric acid to the bleaching glue solution to adjust the pH of the bleaching glue solution to 2, so that the bleached shellac will precipitate out in flocs, and then repeatedly rinse with water to precipitate the shellac to the pH value of the washing water After it is 7, filter and dry at room temperature for more than 7 days to obtain bleached shellac with light yellow color. E 490 It is 9.6% of the original purple fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com