Inorganic composite thermal mortar

A thermal insulation mortar and inorganic composite technology, which is applied in the field of building materials, can solve the problems of serious environmental pollution, high smoke coefficient, and application restrictions, and achieve the effects of high technical requirements, simple construction operation, and improved construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

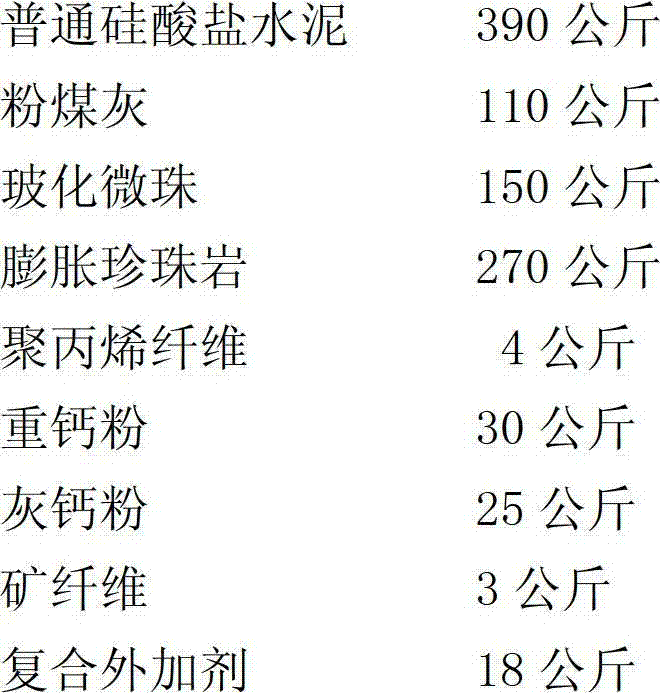

Embodiment 1

[0035] Embodiment 1: a kind of inorganic composite thermal insulation mortar, its component grading ratio is:

[0036]

[0037] The composite admixture is 50% of redispersible latex powder, 15% of cellulose ether, 15% of HPMC, 5% of sepiolite, 5% of diatomite, 5% of water-repellent agent, and 5% of air-entraining agent.

[0038] In the preparation method of the present invention, cement, fly ash, heavy calcium powder, gray calcium powder, and polypropylene fiber are added in sequence, and the flying knife is turned on to stir for 2 minutes, and then the flying knife is stopped to quickly add the remaining components and stir evenly to make dry-mixed mortar.

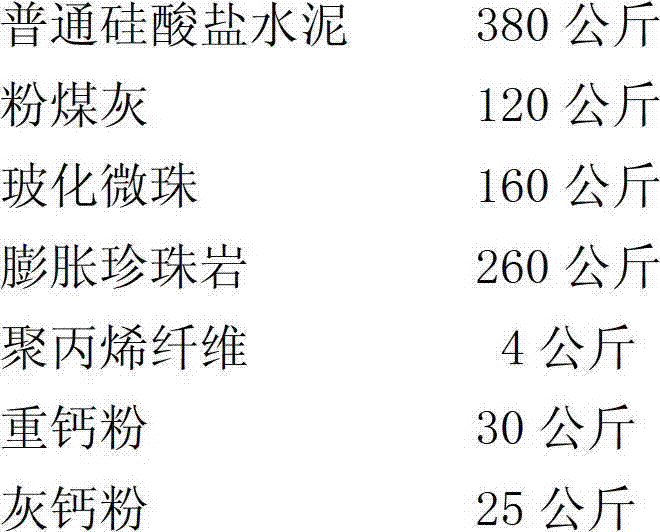

Embodiment 2

[0039] Embodiment 2: a kind of inorganic composite thermal insulation mortar, its component grading ratio is:

[0040]

[0041]

[0042] The composite admixture is 50% of redispersible latex powder, 15% of cellulose ether, 15% of HPMC, 5% of sepiolite, 5% of diatomite, 5% of water-repellent agent, and 5% of air-entraining agent.

[0043] In the preparation method of the present invention, cement, fly ash, heavy calcium powder, gray calcium powder, and polypropylene fiber are added in order, and the flying knife is turned on to stir for 2 minutes, and then the flying knife is stopped to quickly add the remaining components and stir evenly to make a dry-mixed mortar.

Embodiment 3

[0044] Embodiment 3: a kind of inorganic composite thermal insulation mortar, its component grading ratio is:

[0045]

[0046] The composite admixture is 50% of redispersible latex powder, 15% of cellulose ether, 15% of HPMC, 5% of sepiolite, 5% of diatomite, 5% of water-repellent agent, and 5% of air-entraining agent.

[0047] In the preparation method of the present invention, cement, fly ash, heavy calcium powder, gray calcium powder, and polypropylene fiber are added in order, and the flying knife is turned on to stir for 2 minutes, and then the flying knife is stopped to quickly add the remaining components and stir evenly to make a dry-mixed mortar.

[0048] In the above-mentioned embodiment, the vitrified microbeads are selected with a bulk density≤110kg / M 3 products; the expanded perlite is selected from the light expanded perlite at the middle outlet of Tianjin Zhendong Perlite Factory. The bulk density is ≤76kg / M 3 The fresh product; the equipment selected for t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com