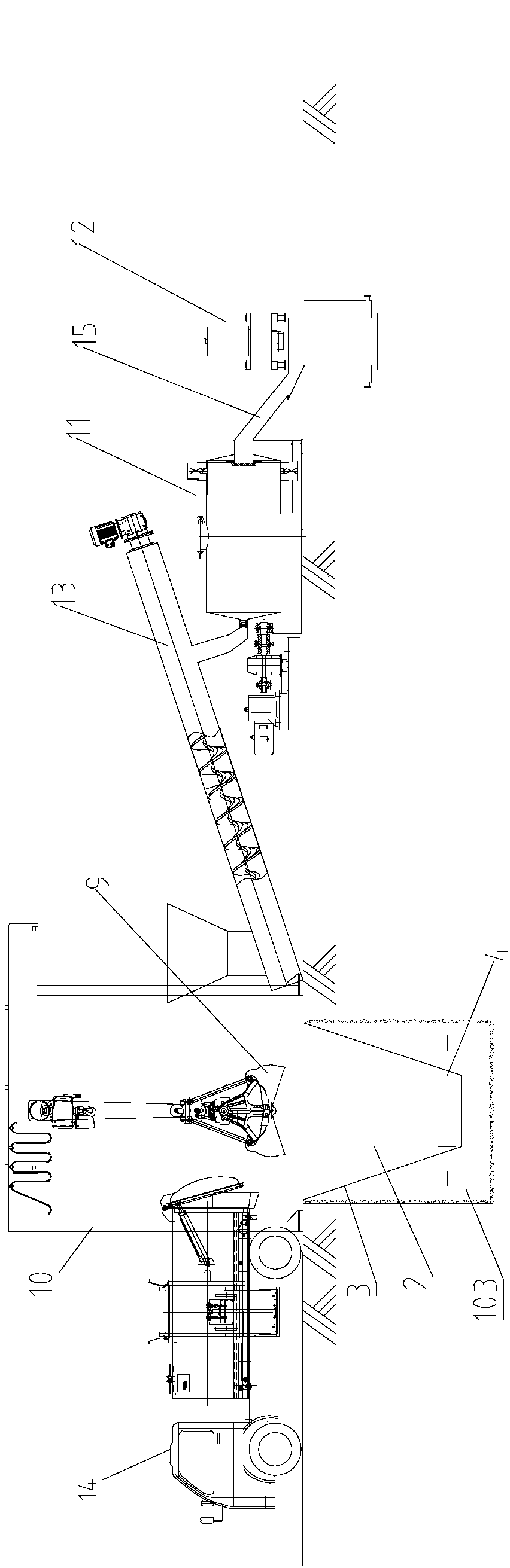

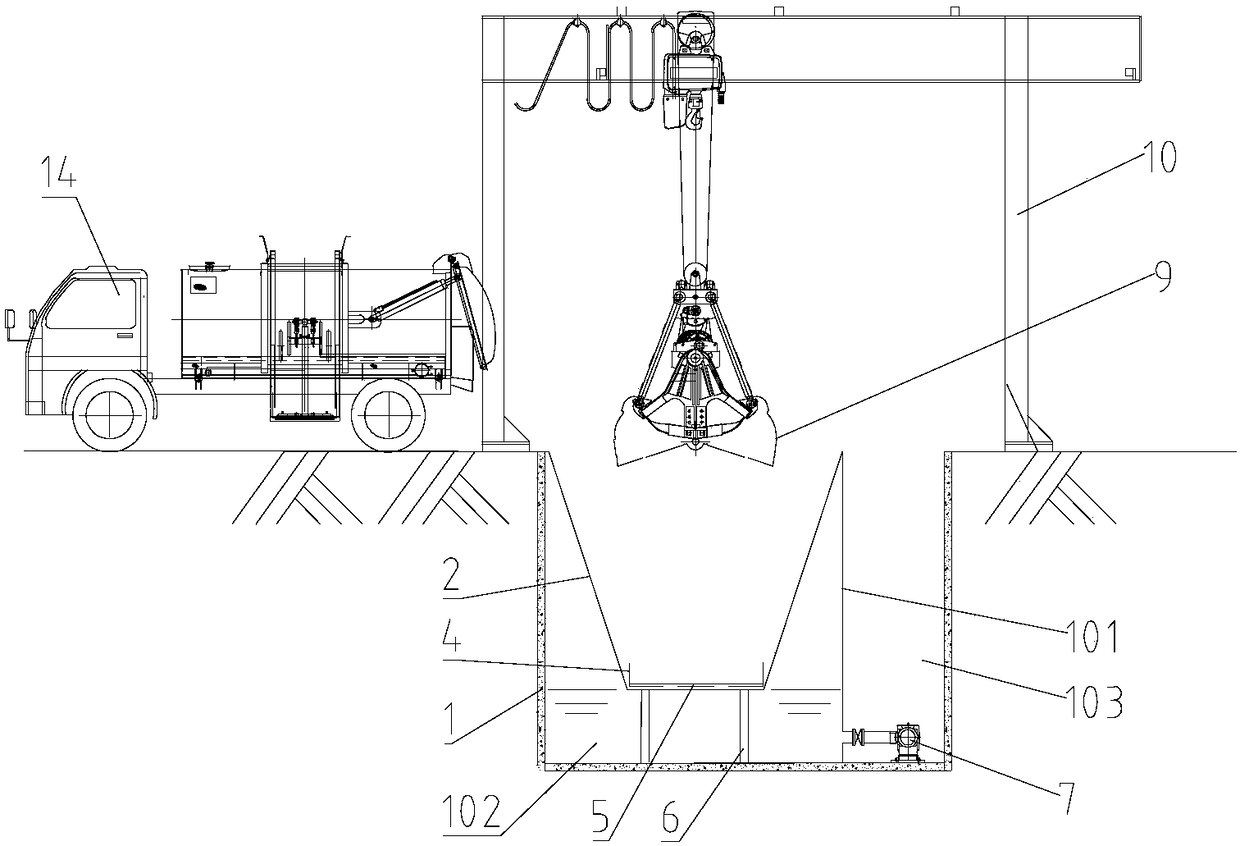

Kitchen waste pretreatment system and process

A kitchen waste and pretreatment technology, applied in grain processing, solid separation, transportation and packaging, etc., can solve the problems of organic matter loss, increase the failure rate of crushers, etc., and achieve less organic matter loss, good drainage effect, and high removal rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

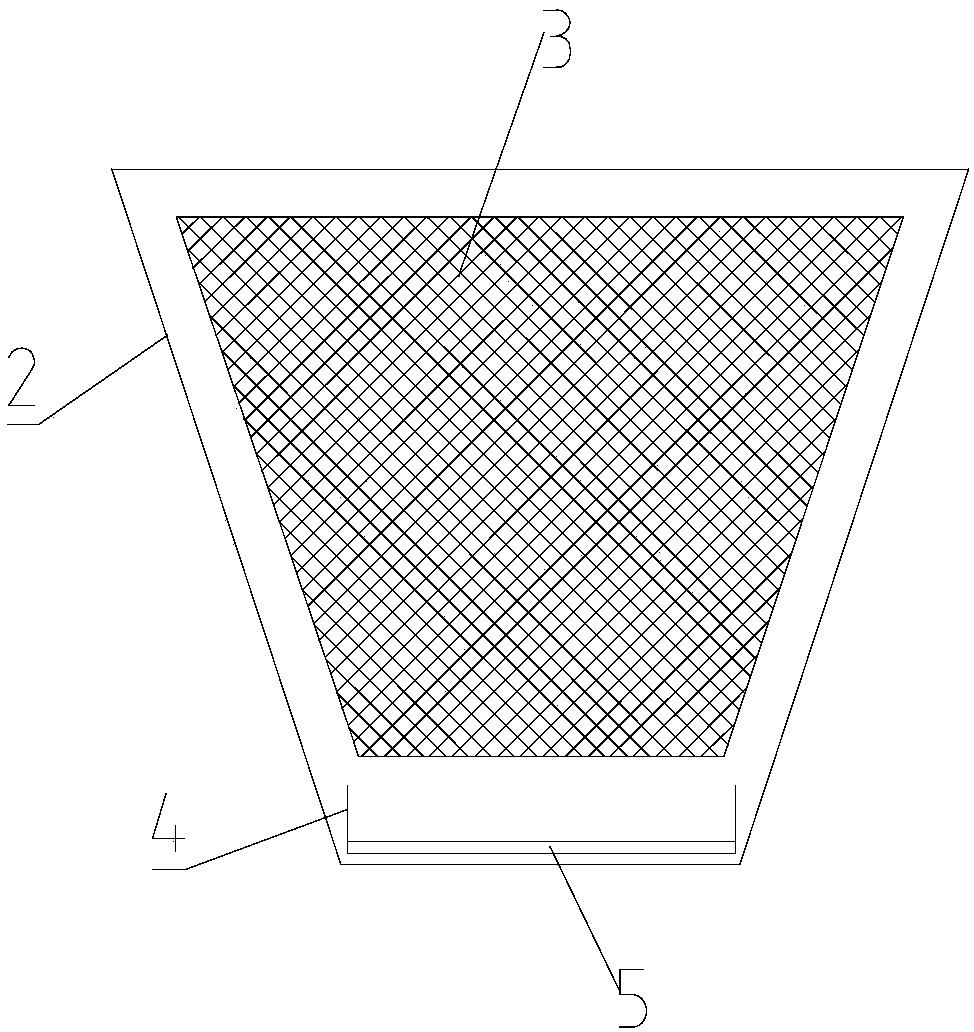

Method used

Image

Examples

Embodiment 2

[0063] The device for draining and removing heavy impurities from food waste described in this embodiment is basically the same as that in Embodiment 1, the difference is that:

[0064] Such as Figure 6 As shown, the magnet device 5 is a magnetic plate whose upper surface is a conical surface, and the conical surface can have a larger contact area than the plane, so as to improve the magnet device 5's ability to attract metal impurities.

[0065] In order not to make metal impurities get together and adsorb, the edge of the magnet device 5 and the metal collection box 4 are arranged in a form of sliding and sealed connection. The bottom of the magnet device 5 and the bottom of the metal collection box 4 are fixedly connected by a spring 8. There can be slight up and down shaking under the collision of etc., so that the metal impurities are evenly contacted with the magnet device 5, and the metal impurities are avoided from being piled up and adsorbed.

[0066] The pretreatme...

Embodiment 3

[0069] The device for draining and removing heavy impurities from food waste described in this embodiment is basically the same as that in Embodiment 2, except that:

[0070] Such as Figure 7 As shown, the magnet device 5 is a magnetic plate with a wavy upper surface, and the wavy shape can increase the contact area between the magnet and the metal impurities in the kitchen waste.

[0071] The edge of the magnet device 5 is in sliding and sealing connection with the metal collection box 4 , and the bottom of the magnet device 5 and the bottom of the metal collection box 4 are fixedly connected by a spring 8 . In this arrangement, during the falling process of the food waste, the magnet device 5 can move up and down slightly in the metal collection box 4 along with the food waste falling, so as to increase the contact area between the metal impurities and the magnet device 5 , so that metal impurities will not accumulate at a certain point or part of the magnet device.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com