Slip-resistant shoe sole

A technology of anti-slip and convex parts, which is applied in the direction of shoe soles, footwear, applications, etc., and can solve problems such as difficulty in stopping sliding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0080] Adding a vulcanizing agent, a vulcanization accelerator, an antioxidant, a filler, and a coloring agent to a rubber material composition composed of natural rubber and styrene butadiene rubber, and performing roll kneading to obtain a composition for forming a sole member thing. Low hardness (approximately 45 to 55), medium hardness (approximately 56 to 65) and high hardness (approximately 66 to 80) Three different levels of sole member composition.

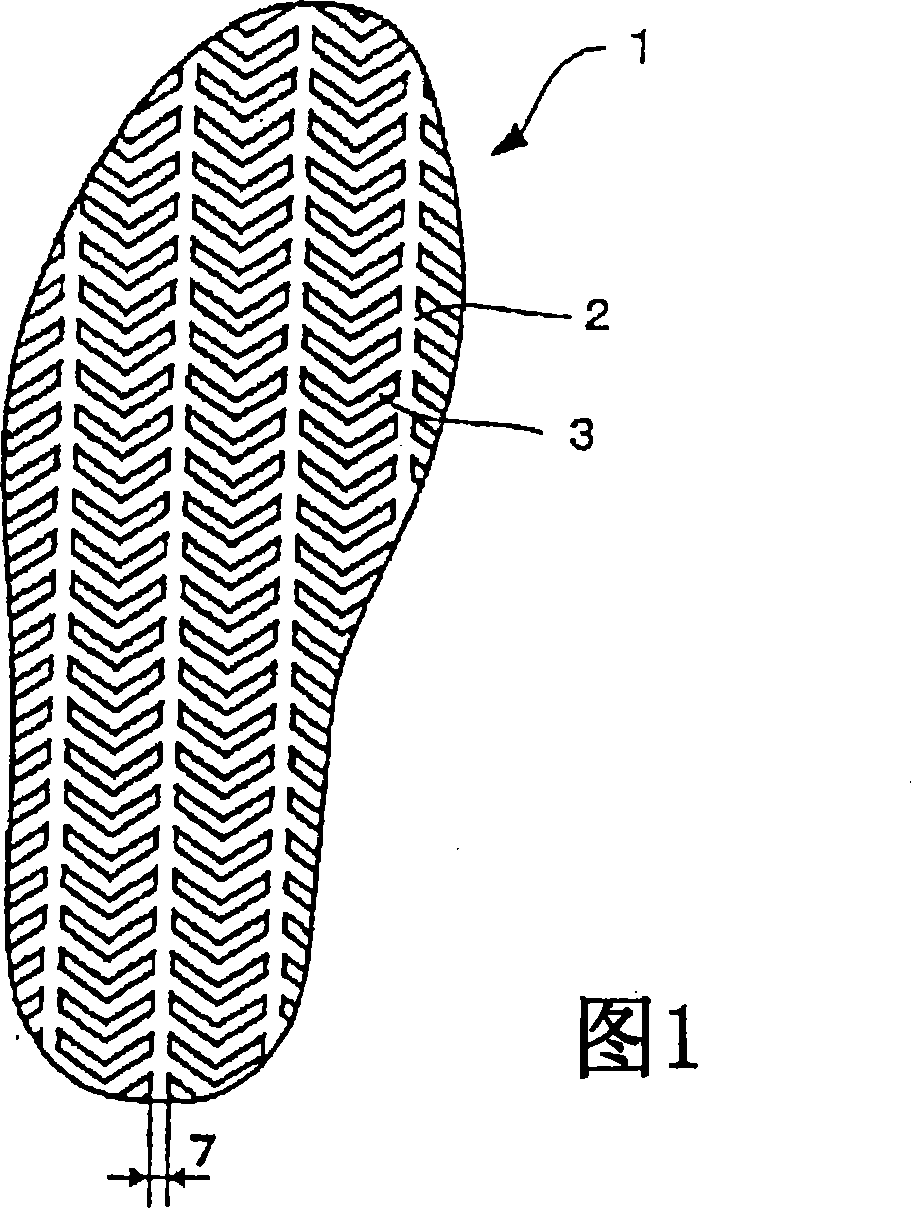

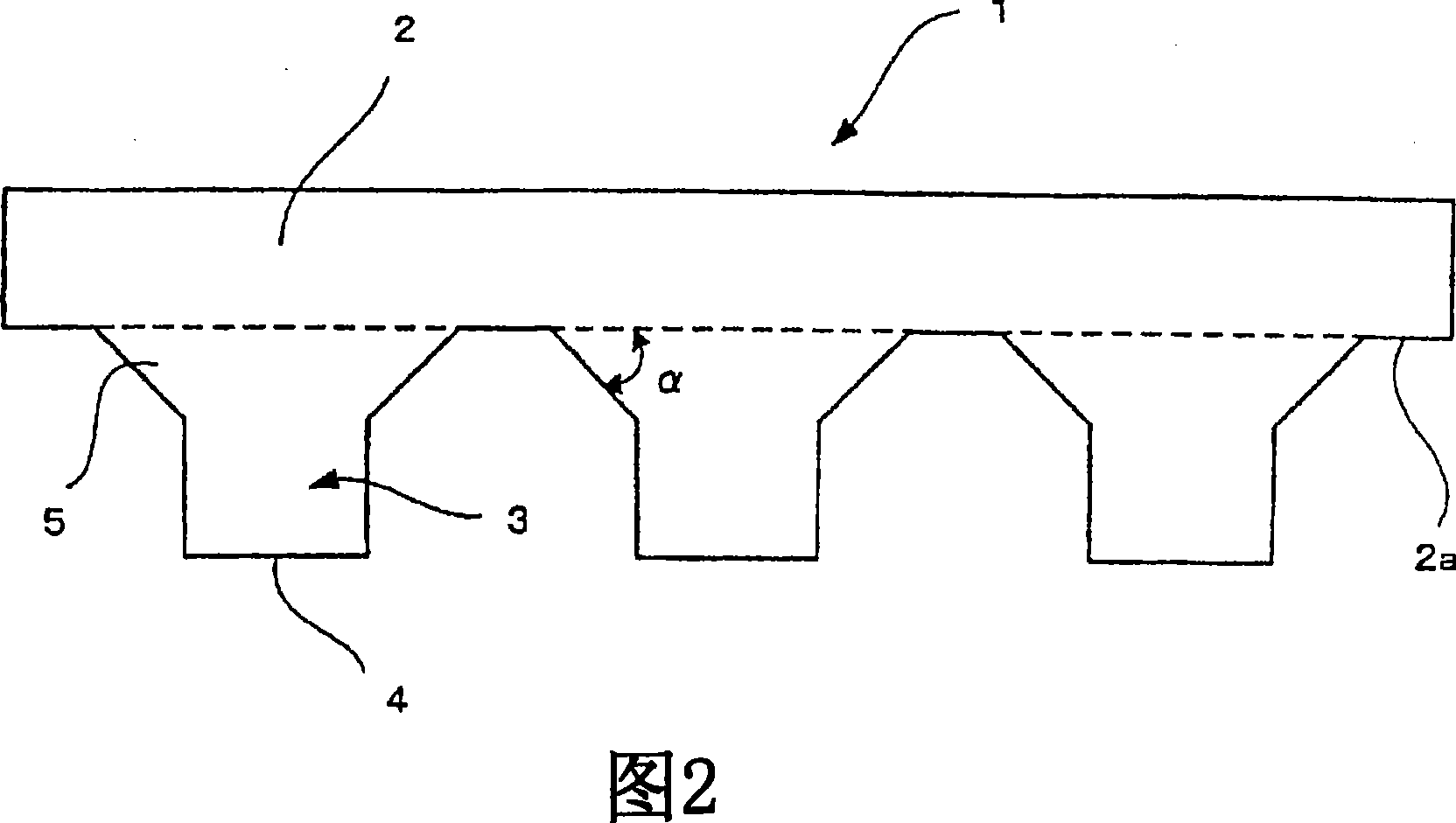

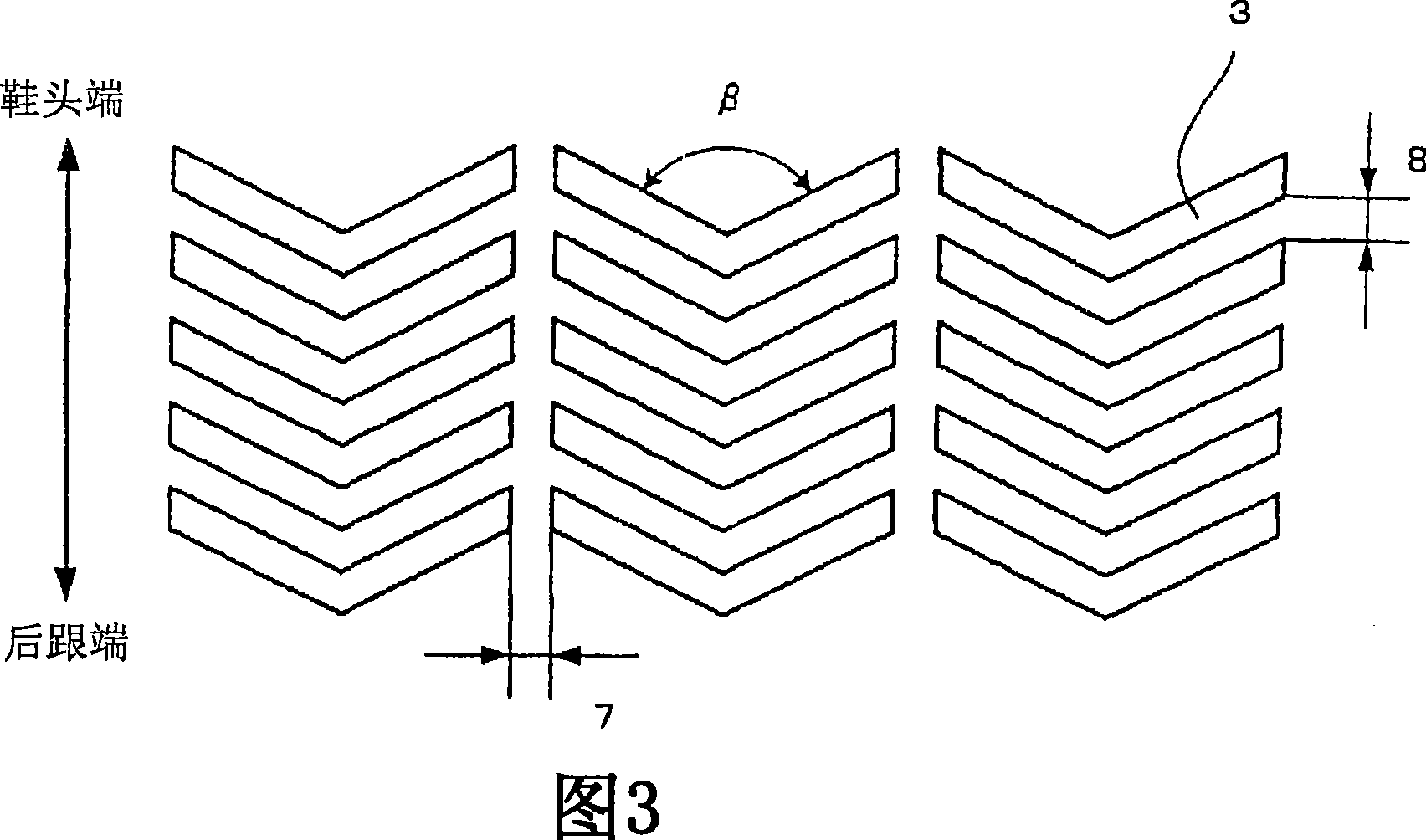

[0081] The sole member compositions of the three hardness levels were formed into sheets having a thickness of about 10 mm. Each sheet is cut to a predetermined width and length, resulting in slices for sole forming members. Then, the non-slip sole 1 as shown in FIG. 1 is formed from the slices. The ground protrusion 3 is provided with an inclined reinforcing portion 5 having an inclined angle α of about 45°. The average opening angle β of the V-shaped protrusions is about 96°. The surface roughness of the ground bump...

Embodiment 2

[0086] A vulcanizing agent, a vulcanization accelerator, an antioxidant, a filler and a coloring agent are added to a composition composed of a mixture of standard natural rubber and polybutadiene rubber for shoe soles, followed by roller kneading to obtain a shoe sole material. This material is used to form a non-slip sole 1 as shown in FIG. 7 . The inclination angle α of the inclined reinforcing portion 5 , the opening angle β of the V shape of the grounding protrusion 3 , the surface roughness of the grounding protrusion surface 4 , and the interval 8 in the longitudinal direction are the same as in the first embodiment. The JIS-A hardness of the ground protrusion 3 is set to medium hardness (56 to 65°). FIG. 12 shows the results of measuring the kinetic friction coefficient of the thus obtained anti-slip sole in the same manner as in Example 1. FIG. For comparison, the coefficient of dynamic friction of the conventional shoe sole used in Example 1 is also shown in FIG. 12...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com