Metal liner cleaning and draining device

A metal liner and draining technology, which is applied in lighting and heating equipment, drying, drying solid materials, etc., can solve the problems of affecting production rhythm, slow draining efficiency, and affecting product quality, so as to achieve high production efficiency and avoid water marks , Improve the effect of product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

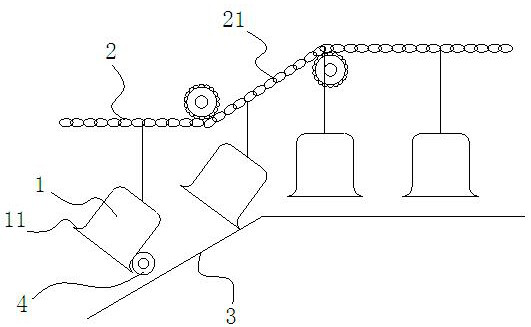

[0012] Below with reference to the accompanying drawings, through the description of the implementation examples, the specific embodiments of the present invention, such as the shape, structure, mutual position and connection relationship between each part, the role and working principle of each part, etc., will be further described. detailed description of the .

[0013] Such as figure 1 , the metal liner cleaning and draining device of the present invention includes a conveyor chain belt 2 for transporting the metal liner 1, the metal liner 1 is hung below the conveyor chain belt 2, and a draining area is provided below the conveyor chain belt 2, and the draining The area is provided with inclined panels 3 .

[0014] The present invention arranges the inclined plate 3 below the conveying chain belt 2, and when the conveying chain belt 2 hangs the metal liner 1 and slowly transports it through the inclined plate 3, the metal inner container 1 lightly touches the inclined pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com