Preparation method of chloride-free activated carbon-loaded ruthenium-based ammonia synthesis catalyst

A technology for the synthesis of activated carbon and ammonia, which is applied in the direction of catalyst activation/preparation, ammonia preparation/separation, chemical instruments and methods, etc. It can solve the problems of ruthenium loss, safety risks, long washing time, etc., and achieves easy operation, reduced loss, highly active effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

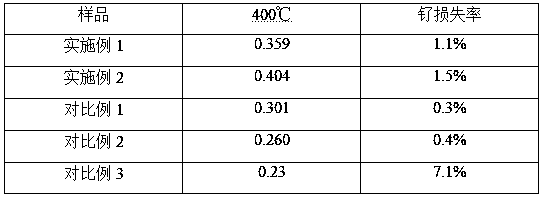

Embodiment 1

[0016] Take 0.1 mol / L RuCl 3 100 mL of aqueous solution, 50 mL of 0.6 mol / L KOH aqueous solution was added dropwise during stirring, and after mixing, let it stand for 1 h. Centrifuge the resulting mixture at 3000 r / min for 3 min. Pour out the supernatant. Then add absolute ethanol to stir, centrifuge and wash. The above washing process was repeated 5 times, and the ICP analysis of the washing solution showed that there was no ruthenium metal ion. Add 20 mL of HNO to the resulting precipitate 3 Solution (3 mol / L) to completely dissolve it, and then immerse it on activated carbon. The amount of ruthenium metal added based on the mass of activated carbon is 10%. The prepared sample was reduced in a nitrogen-hydrogen mixed atmosphere containing 75% hydrogen at 450°C for 6 hours, and then cooled to room temperature in the above atmosphere. Finally, the obtained sample is immersed in an aqueous potassium nitrate solution to a potassium metal content of 12% based on the mass of the ...

Embodiment 2

[0018] Divide 0.2 mol / LRuCl 3 50 mL of aqueous solution, 30 mL of 1.0 mol / L KOH aqueous solution was added dropwise during the stirring process, mixed and allowed to stand for 10 h, the resulting mixture was centrifuged at 3000 r / min for 3 min, and the supernatant was discarded. Then add absolute ethanol to stir, centrifuge and wash. The above washing process was repeated 15 times, and the ICP analysis of the washing liquid showed that there was no ruthenium metal ion. Add 80 mL of HNO to the resulting precipitate 3 Solution (1 mol / L) to completely dissolve it, and then immerse it on activated carbon. The amount of ruthenium metal added is 10% based on the mass of activated carbon. The prepared sample was reduced at 500°C for 4 hours in a 25% hydrogen-containing nitrogen-hydrogen mixed atmosphere, and cooled to room temperature in the above atmosphere. Finally, the obtained sample is immersed in an aqueous potassium nitrate solution until the amount of potassium metal is 12% b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com