Furnace burden drying device

A technology of drying device and charge, applied in the directions of drying, dryer, drying gas arrangement, etc., can solve the problems of uneven drying and heating of charge, and achieve the effects of improving capacity, speeding up discharge speed and improving work efficiency.

Active Publication Date: 2018-01-12

重庆琅博宛冶金材料有限公司

View PDF6 Cites 7 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0004] The object of the present invention is to provide a furnace charge drying device to solve the problem of uneven drying and heating of the furnace charge

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0017] Below in conjunction with accompanying drawing and specific embodiment the present invention will be described in further detail:

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

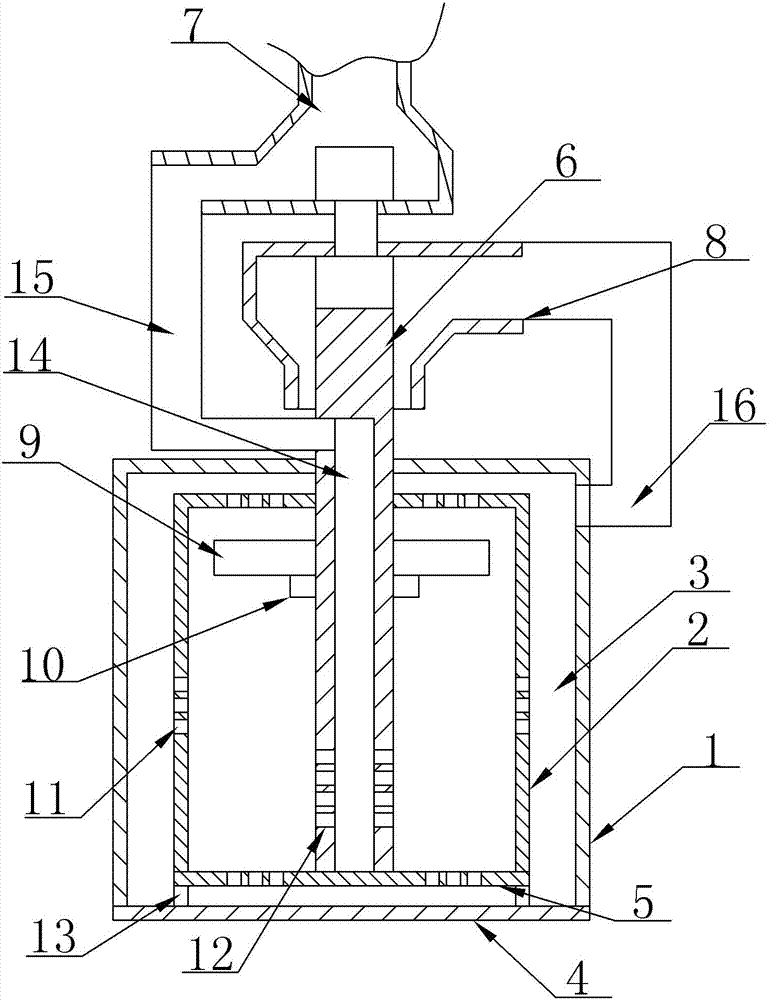

The invention relates to the technical field of metallurgical furnace burden, and discloses a furnace burden drying device. The furnace burden drying device comprises a rack, an inner furnace body, anouter furnace body, an air blower and a turbocharger. The outer furnace body is fixedly mounted on the rack, the outer furnace body is arranged on the outer side of the inner furnace body in a sleeving mode, and a flowing cavity is formed between the inner furnace body and the outer furnace body. The inner furnace body is fixedly mounted on the outer furnace body, air vents communicating with theflowing cavity are formed in the side wall and the upper portion of the inner furnace body, a rotary shaft fixedly connected with a turbine of the turbocharger is arranged in the inner furnace body,and the rotary shaft is rotatably connected with the inner furnace body. A spiral electric coil for heating is fixed to the interior of the side wall of each of the inner furnace body and the rotary shaft, an air inlet of a compression wheel of the turbocharger communicates with an air outlet of the air blower, and a turbine air suction port of the turbocharger communicates with the flowing cavity. The furnace burden drying device can dry furnace burden evenly, and can rapidly treat the moisture generated in the drying process of the furnace burden, the working efficiency is improved, and thequality of the furnace burden is improved.

Description

technical field [0001] The invention relates to the technical field of metallurgical charge, in particular to a charge drying device. Background technique [0002] In the production process, the charge is baked at high temperature to improve the strength of the charge product. The existing drying box has a single function, which is not conducive to the baking of the charge product. In the prior art, in order to discharge the moisture evaporated from the charge, an air outlet is set on the top of the oven, and an air exhauster is connected to the air outlet to extract the moisture. However, this arrangement makes the moisture near the air outlet easy to be sucked out gas, and the moisture far away from the air outlet is not easy to discharge. The accumulation of moisture in some areas has a greater impact on the quality of the furnace charge in this part, and the wind speed at the air outlet is faster, resulting in a lower temperature in this area, which affects the The heat...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): F26B11/16F26B21/00F26B25/00F26B25/04

Inventor 胡丰强

Owner 重庆琅博宛冶金材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com