Wetting-resisting super-hydrophobic membrane and preparation method thereof

A super-hydrophobic and hydrophobic membrane technology, applied in the field of membrane separation, can solve the problems of membrane body damage, membrane strength decrease, toxicity, etc., and achieve the effects of low surface energy, increased water production, and improved hydrophobicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0043] Preparation of PDMS solution

[0044] Dissolve 3 g of PDMS in 300 ml of n-hexane, stir at room temperature for one hour, then add 0.5 ml of ethoxysilane crosslinking agent and 0.2 ml of organotin catalyst and continue stirring for one hour at room temperature.

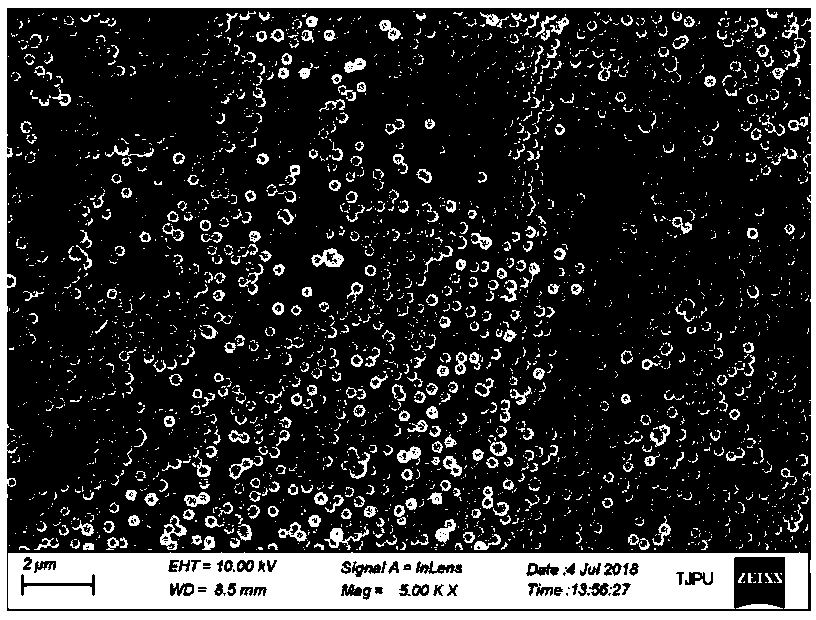

[0045] Preparation of silica sol solution

[0046] Stir the mixed solution of 170ml of absolute ethanol, 21ml of ammonia water and 13ml of deionized water at 55°C for 30 minutes, then add an appropriate amount of mixed solution of 21ml of tetraethyl orthosilicate and 5ml of absolute ethanol dropwise, and continue stirring for 2 hours.

Embodiment 1

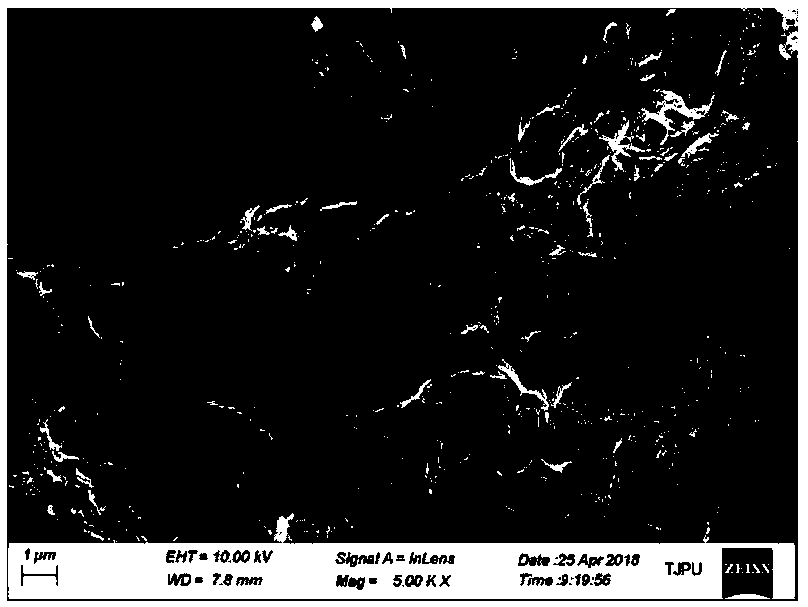

[0047] Example 1: The original PVDF membrane was fully cleaned and dried, and then membrane distillation test was carried out.

Embodiment 2

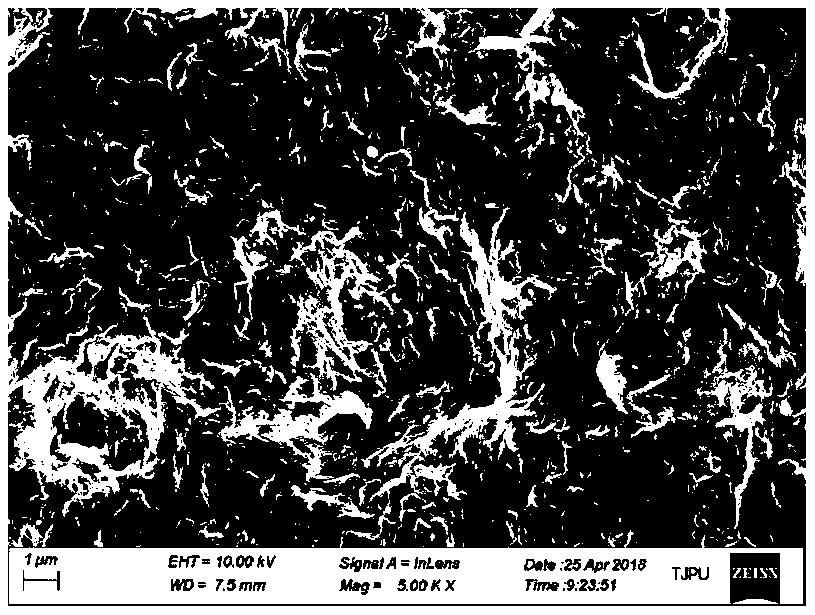

[0048]Example 2: Immerse the washed and dried PVDF original membrane into a 2wt% PDMS solution, take it out, cure it at high temperature, and perform a membrane distillation test.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com