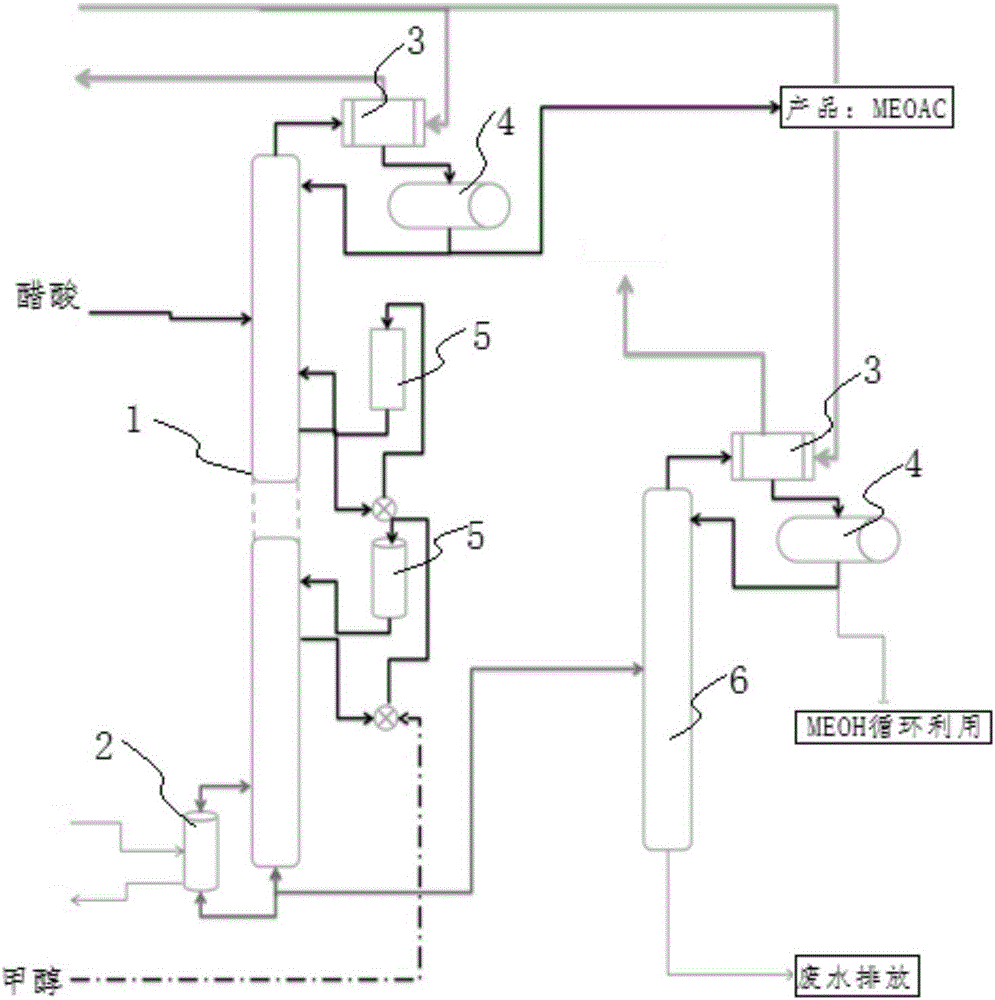

High-purity methyl acetate production process device and method

A technology of methyl acetate and production process, applied in the field of production devices of methyl acetate, can solve the problems of difficult separation, large equipment investment, and high energy consumption, and achieve the effects of improving reaction rate, significant economic benefit, and improving mass concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0031] Example: The feed mass flow rate of methanol is 2135.6kg / hr, the feed mass flow rate of acetic acid is 3364.9kg / hr, and BHS II type high-efficiency packing and strong acid cation exchange resin are used as catalysts. Through calculation and regression of industrial application practice , the diameter of the T1 tower is 1.2m, and the esterification reaction is carried out in the external reactor of the reactive distillation tower. The methyl acetate generated is first separated from the liquid phase reaction system of the tray, and then gasified and enters the upper tray. Through the concentration and separation of the extraction section, the azeotropic system is broken, so that the reaction balance continues to move towards the direction of methyl acetate, and at the same time, the methyl acetate product is continuously extracted from the top of the tower, and its mass fraction reaches more than 99%, wt%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com