Patents

Literature

34results about How to "Inhibition of the reverse reaction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

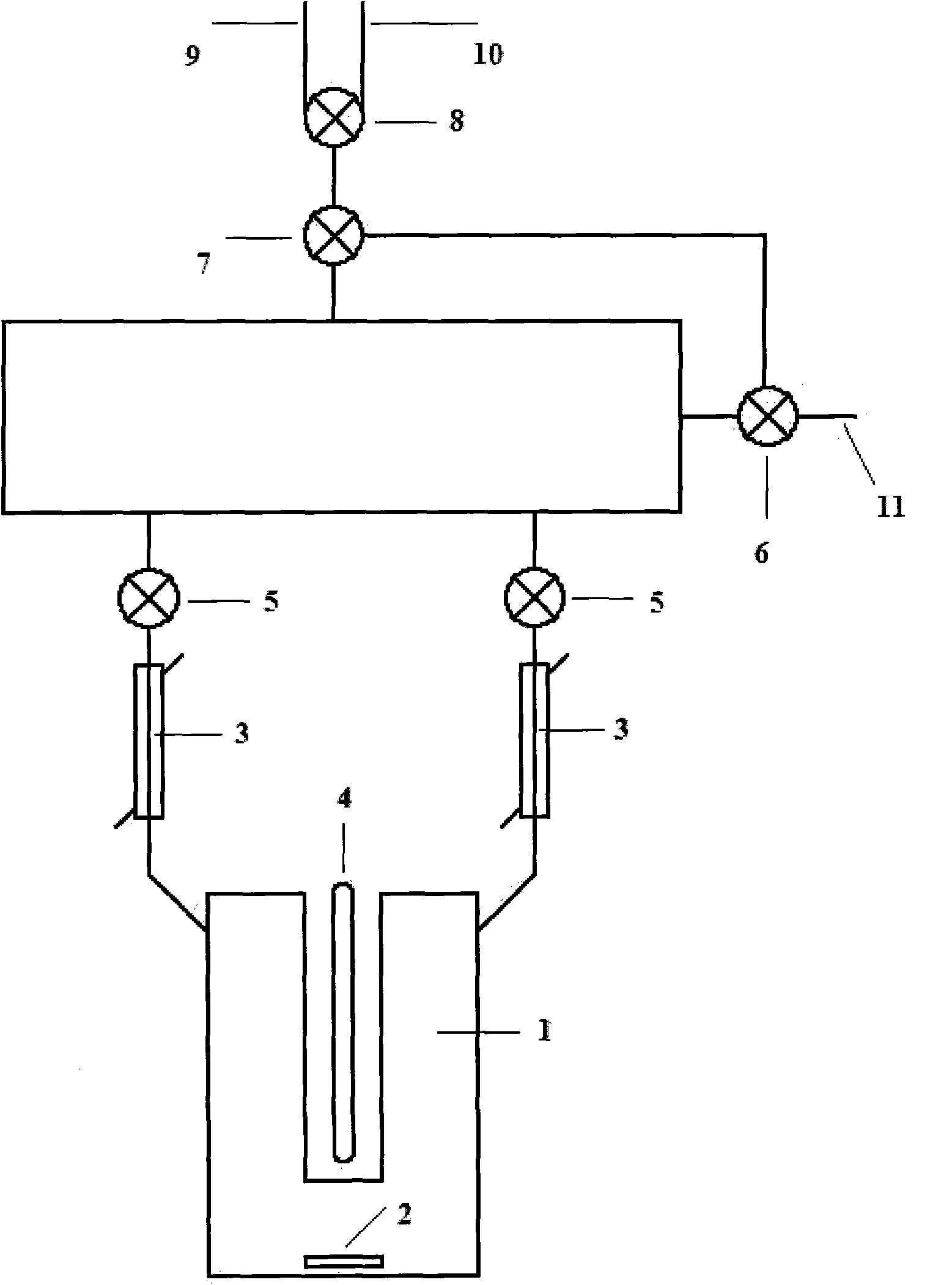

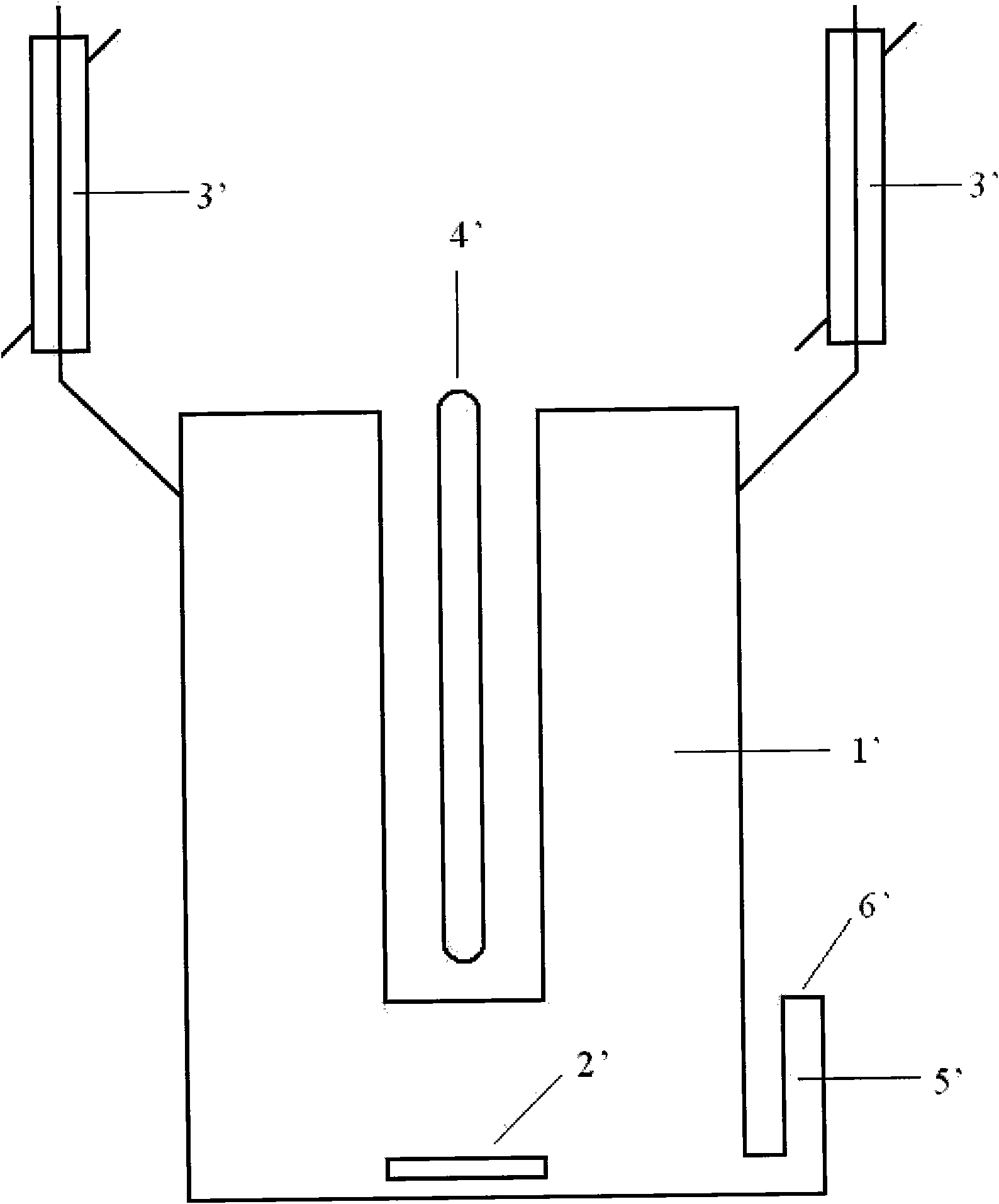

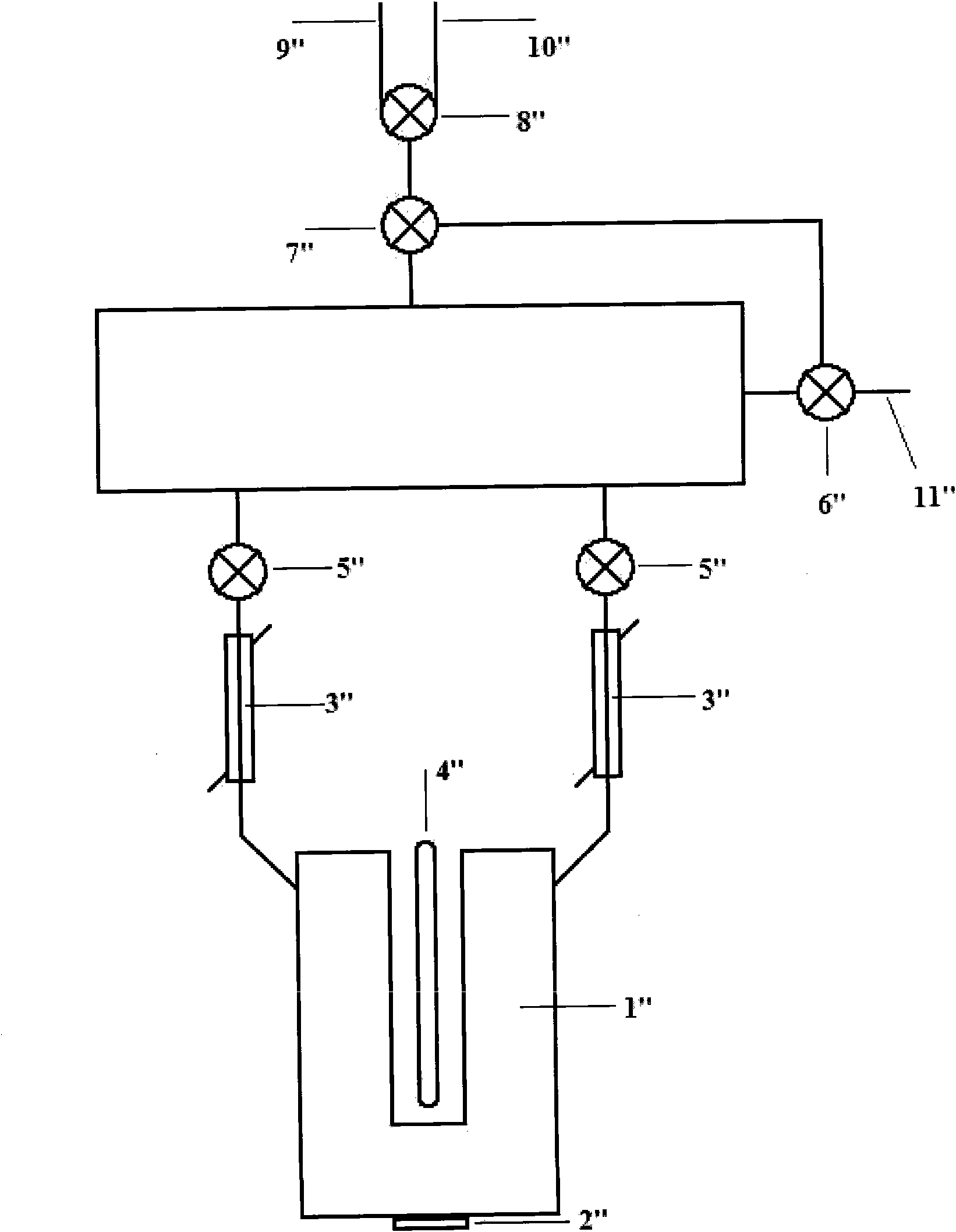

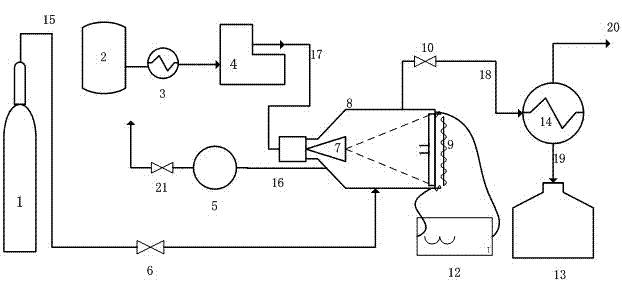

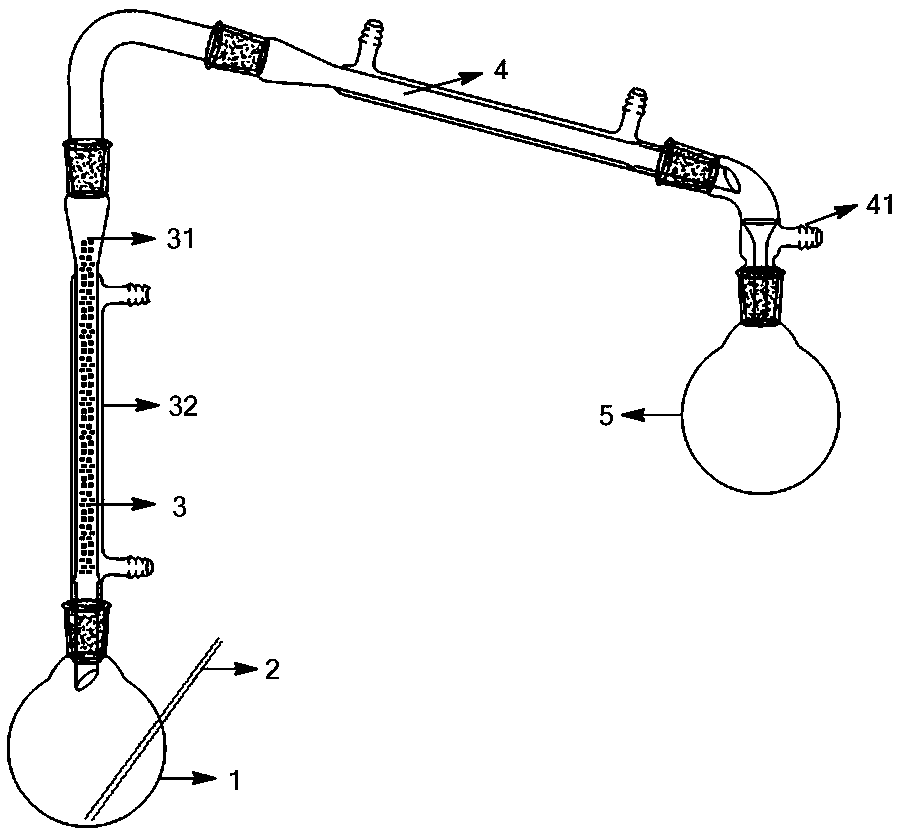

Method and device for photocatalytic reaction

InactiveCN102068954AScatter Chance IncreasedIncrease profitEnergy based chemical/physical/physico-chemical processesHydrogenPhotocatalytic reaction

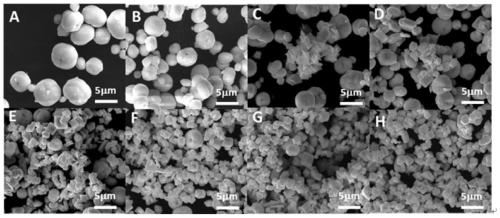

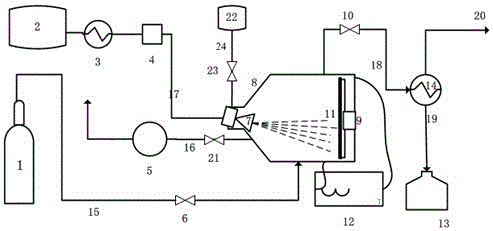

The invention provides a photocatalytic reaction method, comprising the steps of: atomizing a solution or suspension containing a photocatalyst and a reactant to form mist; and leading the mist to be subjected to photocatalytic reaction by utilizing a light source. The invention also provides a photocatalytic reaction device, which comprises a reaction vessel, an atomizer arranged inside or outside the reaction vessel, a condensation sleeve communicated with the reaction vessel, and the light source used for photocatalytic reaction. By means of the method and the device, a gas-liquid interface is enlarged by changing the form of water, i.e. atomizing the liquid-phase solution of the catalyst, so as to reduce the escape path of hydrogen gas and effectively inhibit the occurrence of reverse reaction, meanwhile, because the scattering probability of light in the mist is increased and the effective absorption is enhanced, the light utilization rate and the catalytic efficiency of the photocatalyst are greatly improved.

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI

Method for continuously polymerizing nylon from bi-component monomer serving as raw material

The invention discloses a method for continuously polymerizing nylon from a bi-component monomer serving as a raw material. The method comprises the following steps of: reacting and rectifying a nylon salt aqueous solution serving as a raw material in a pre-condensing tower in which a liquid phase is a continuous phase, a gas phase is a dispersed phase and falling liquid and rising bubbles keep flat push flow respectively under a low pressure to generate a prepolymer of which the polymerization degree 5-50 (preferably 20-40) and a terminal carboxyl group, a terminal amino group and the like are of equal molar amounts; and pre-heating the pre-polymer to generate a polymer of which the polymerization degree reaches process indexes in the pre-condensing tower. In the pre-condensing tower, a film falling or strip falling method is adopted, so that evaporation of condensed water is accelerated, the reaction temperature is lowered, reaction time is shortened, and gel is reduced; and a kettle wall is coated with a falling liquid film, so that kettle wall scars are avoided. The method has the advantages of short flow, large mono-line scale, saving in investment, low running cost, good product quality, long continuous running period, environment friendliness and suitability for continually polymerizing nylon 66, nylon 56 and other nylon made of bi-component monomers serving as raw materials.

Owner:XCEED CHEMTECH

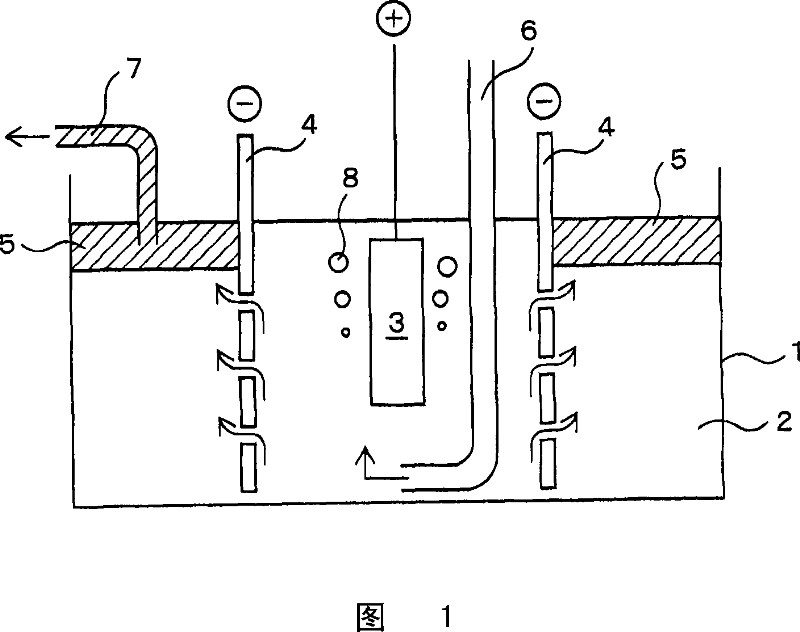

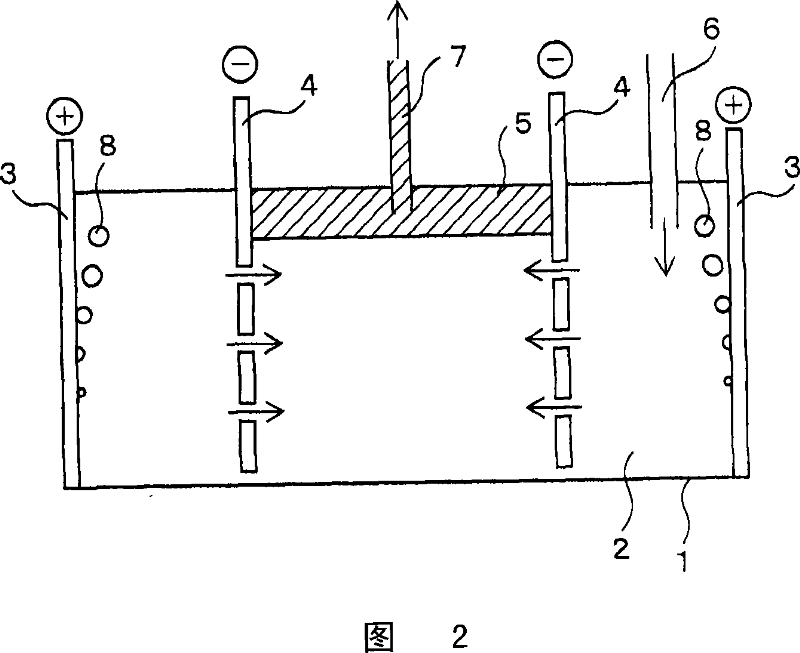

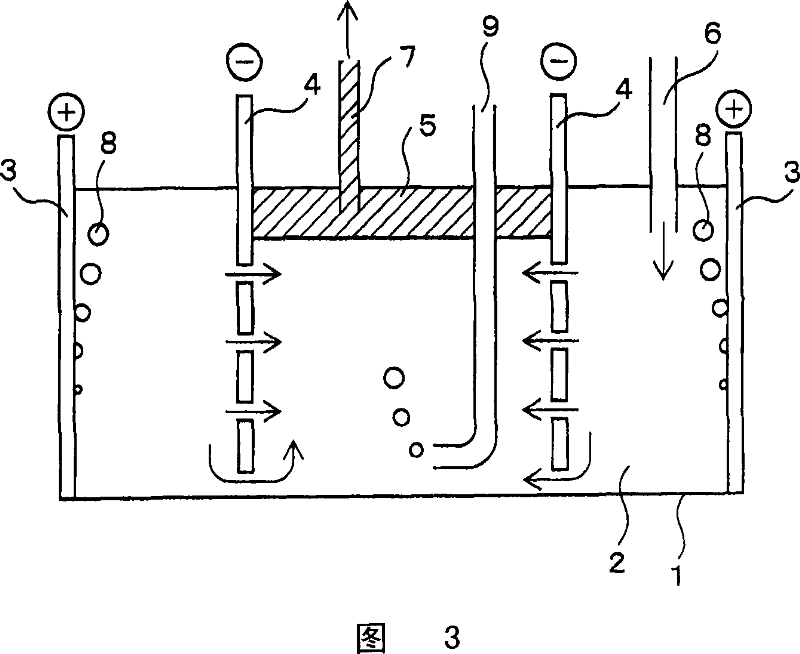

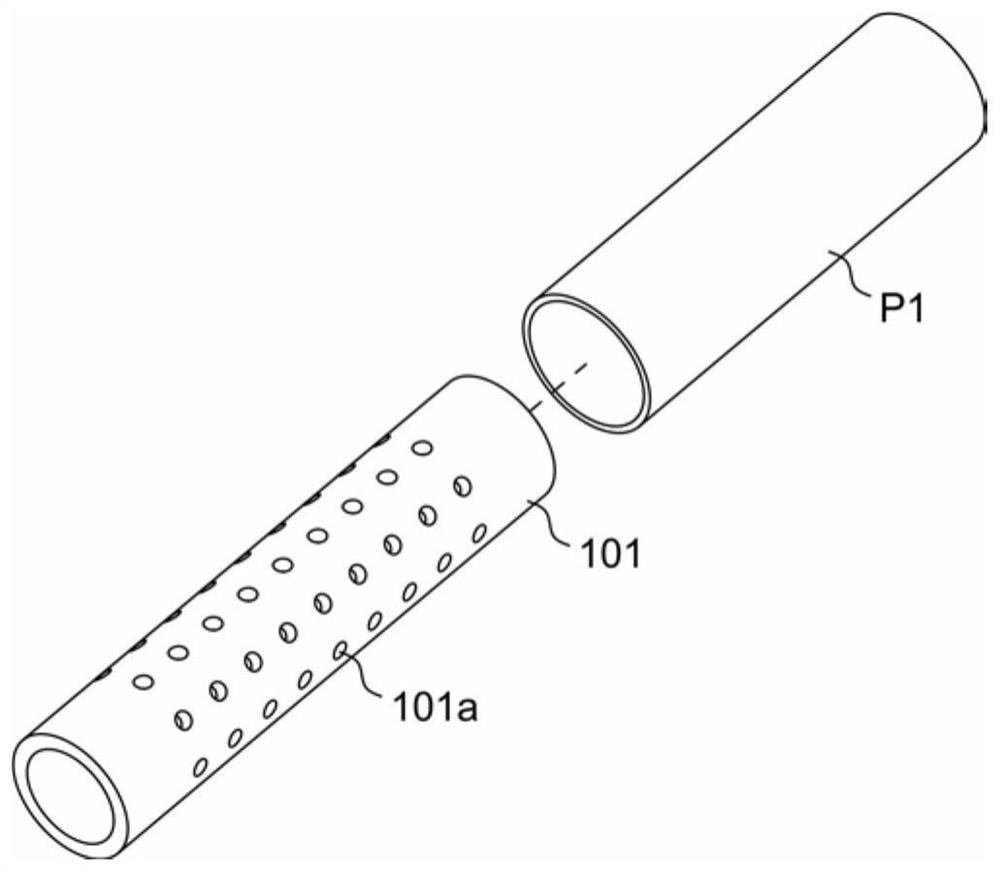

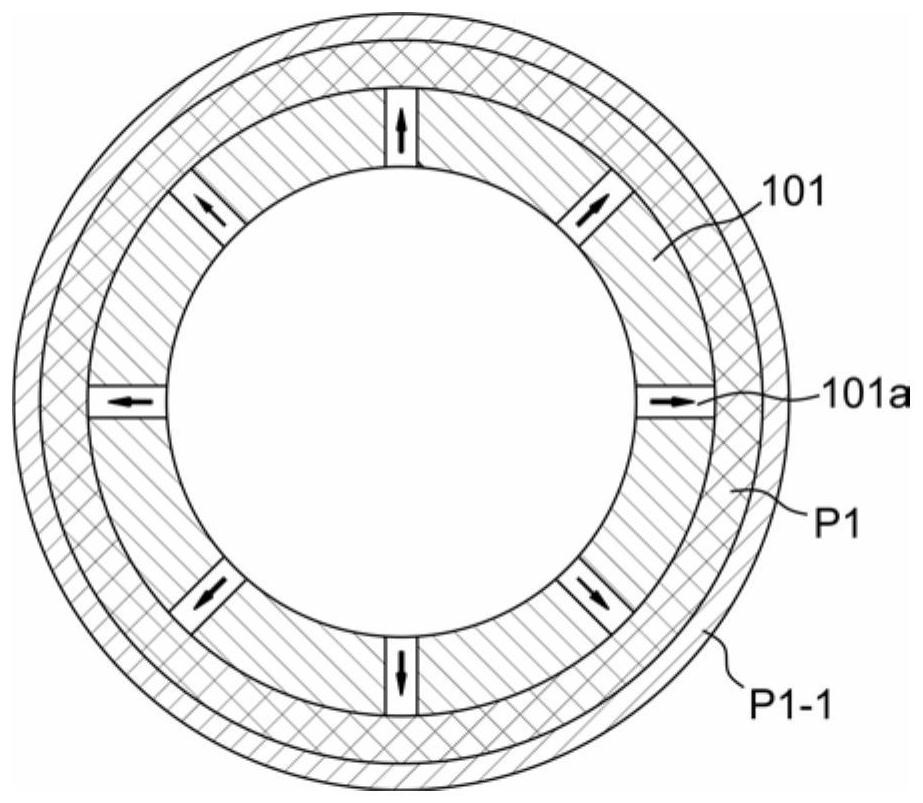

Metal producing method and producing device by molten salt electrolysis

InactiveCN101044268AInhibition of the reverse reactionEfficient preparationElectrodesElectrolysisMolten salt

The present invention provides a metal producing method by molten salt electrolysis carried out with calcium chloride molten salt filled in an electrolytic bath provided with an anode and a cathode, characterized in that either one electrode of the anode and the cathode is provided so as to surround the other electrode, the cathode is provided with at least one communication port to allow communication between an inner area surrounded by the cathode and an outer area, and molten salt is allowed to flow from one area, out of the inner area and the outer area, on the anode-provided side to the other area via the communication port.

Owner:TOHO TITANIUM CO LTD +1

Method for synthesizing 4-fluoro-2-nitroaniline by micro-channel reactor

PendingCN111018717AImprove mixing efficiencyImprove heat exchange capacityOrganic compound preparationAmino compound preparationAcetic anhydrideIce water

The invention discloses a method for synthesizing 4-fluoro-2-nitroaniline through a micro-channel reactor. The method is characterized by comprising the steps; adopting a Corning high-flux continuousflow micro-channel reactor, with the molar ratio of p-fluoroacetanilide to nitric acid being 1:(1.0-1.5) as a benchmark, respectively setting the flow rates of an acetic acid-acetic anhydride solutionof 20%-40% of p-fluoroacetanilide and 68% of nitric acid to be 40.0-100.0 mL / min and 4.0-30.0 mL / min, and preheating; carrying out a reaction for 50-200 s at a temperature of 30 DEG C-70 DEG C; and dissolving the product in water, carrying out hydrolysis reaction at the temperature of 90 DEG C-100 DEG C for 2-4 h, stirring in ice water at the temperature of 0 DEG C-5 DEG C for 0.5 h, filtering, washing a filter cake until the filter cake is weakly acidic or neutral, adding petroleum ether, mixing, and drying to obtain the orange solid 4-fluoro-2-nitroaniline with the yield of 83-94%. The method has the advantages of short time, high efficiency, few byproducts and safe, stable and controllable reaction process.

Owner:成都艾必克医药科技有限公司

Method for preparing pharmaceutical intermediate 4(H) quinnazolidone

InactiveCN101899009AInhibition of the reverse reactionReduce volatilityOrganic chemistryNitrogenFormamide

The invention discloses a method for preparing pharmaceutical intermediate 4(H) quinnazolidone, which comprises the following steps of: dissolving ortho-aminobenzoic acid and formamide in an inert solvent of o-dichlorobenzene; performing heat preservation reaction by steps under the protection of nitrogen, namely performing intermolecular condensation reaction and then intramolecular cyclization reaction; meanwhile, removing water generated in the process of reaction in time by using a water knockout trap to ensure that the positive reaction is performed smoothly; and decoloring, crystallizing and drying to obtain an ultimate product, namely the 4(H) quinnazolidone, wherein the mass ratio of the o-dichlorobenzene to the ortho-aminobenzoic acid is 3.0-3.5:1; the molar ratio of the ortho-aminobenzoic acid to the formamide is 1:1; and when the heat preservation reaction is performed by steps, the heat is preserved at the temperature of 50+ / -2 DEG C for 1 hour, 80+ / -2 DEG C for 3 hours, 120+ / -2 DEG C for 4 hours and 140+ / -2 DEG C for 4 hours. The preparation method has the advantages of simple process, zero emission, energy conservation, environmental protection and capacity of ensuring the quality and the yield of the product.

Owner:JIANGSU HAOHUA FINE CHEM

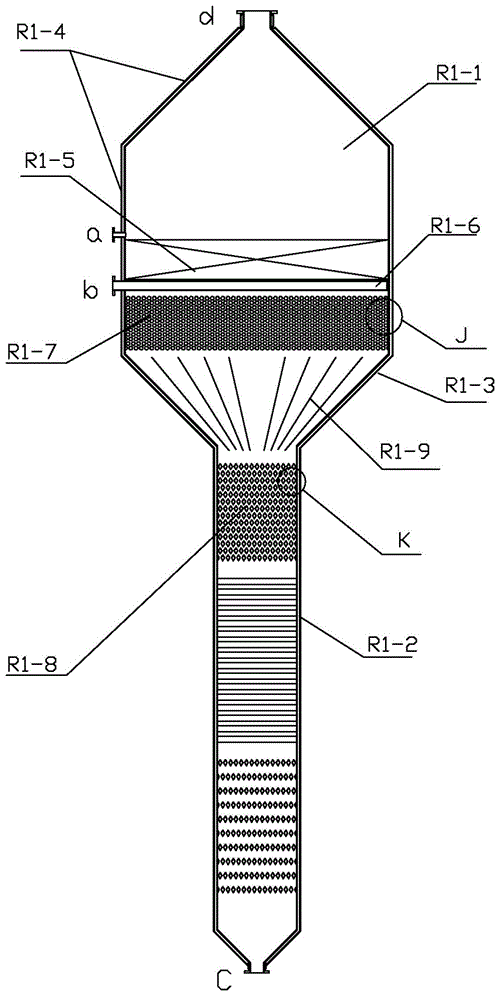

Method and device for catalytic preparation of hydrogen from naphthenic hydrocarbon

InactiveCN103043607AImprove catalytic performanceLower reaction costHydrogen productionCycloparaffinsOrganic fluid

The invention provides a method and a device for catalytic preparation of hydrogen from naphthenic hydrocarbon. The method comprises the following steps of: fixing a catalyst at the bottom of a reactor after the catalyst is washed by absolute ethyl alcohol; vacuumizing the reactor and introducing nitrogen into the reactor; heating the bottom of the reactor under nitrogen protection to ensure that the temperature of the catalyst slowly rises; stopping introducing the nitrogen after the catalyst is dried to open an organic liquid condenser; setting a dehydrogenation reaction temperature; heating the bottom of the reactor to be the dehydrogenation reaction temperature; injecting and feeding the naphthenic hydrocarbon at a constant velocity; discharging the generated hydrogen from the system after condensation and separation; and condensing the other steam components in a condenser and gathering the components into a product storage tank. By the method and the device, a precious metal catalyst is replaced by cheap raney nickel, so that the reaction cost is reduced, and the catalytic effect of the catalyst is good; the feeding is carried out in a jetting mode under a wet-and-dry multi-phase reaction condition, so that the dehydrogenation reaction efficiency is improved; and the gas is not needed to be carried or blown, the prepared hydrogen is high in purity and not needed to be separated again.

Owner:ZHEJIANG UNIV

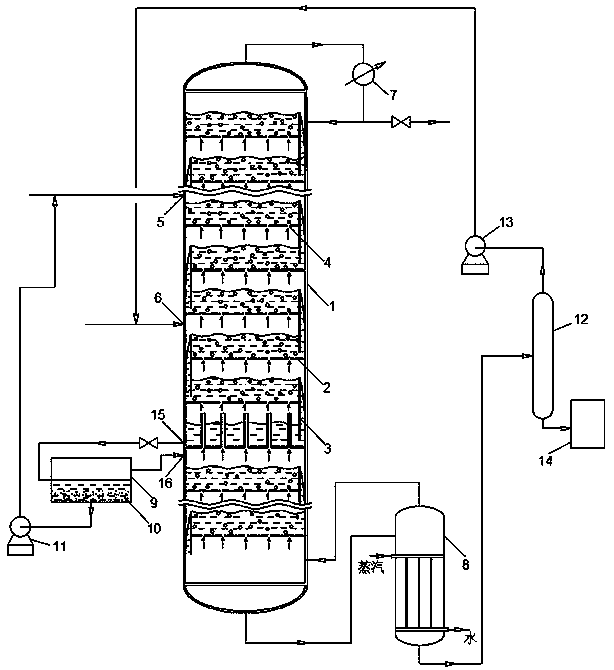

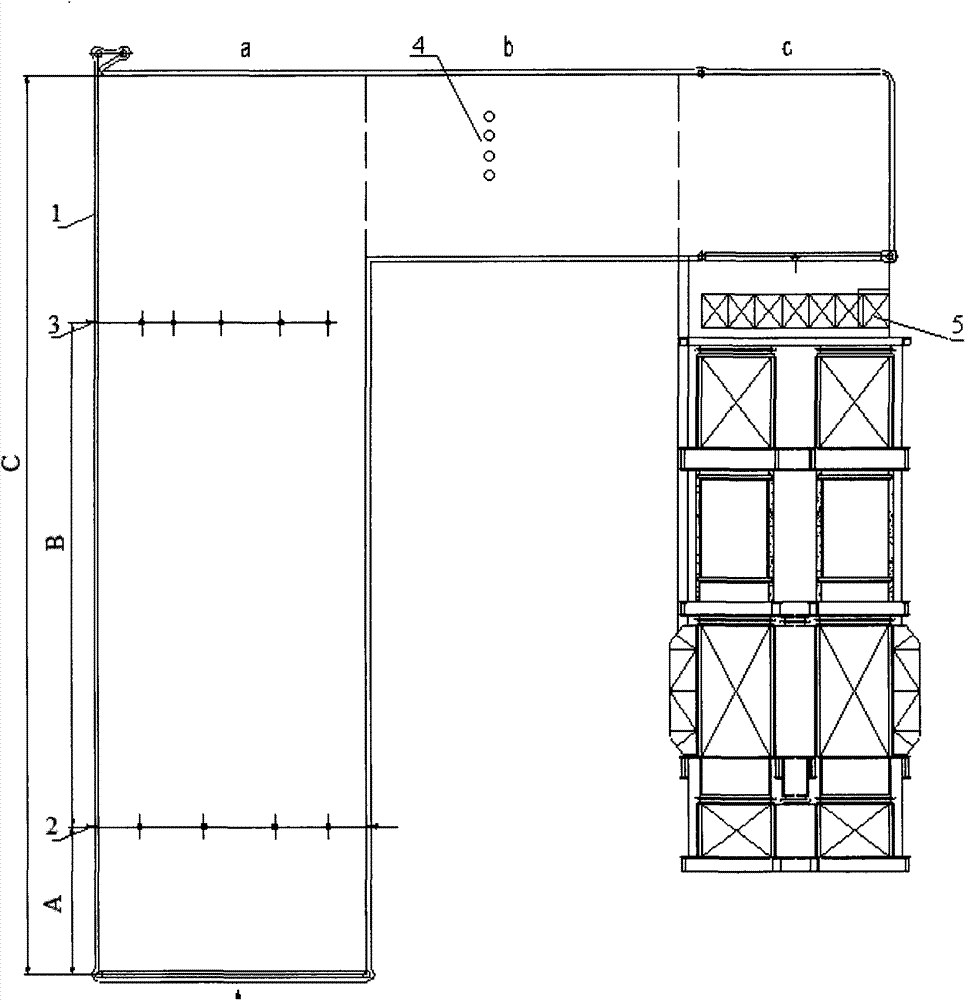

Reaction rectification device and method for preparing cyclohexanol by hydrating cyclohexene

InactiveCN108997081AIncrease conversion rate per passHigh purityOrganic compound preparationPreparation by hydroxy group additionHydration reactionCyclohexene

The invention belongs to the technical field of a chemical process and equipment, and relates to a reaction rectification device and a reaction rectification method for preparing cyclohexanol by hydrating cyclohexene. The device comprises four parts, namely a reaction rectification tower, a settling separator, a separation tower and a liquid storage tank. Steam and slurry in the reaction rectification tower are in reverse contact to generate violent disturbance, so that the cyclohexene hydration reaction process is realized; reaction products are subjected to settling separation and only the organic phase is added into a stripping section, so that reverse reaction of the cyclohexanol can be inhibited; in the settling separator, the aqueous phase and the organic phase are separated, and water and a catalyst can be recycled; the cyclohexene, a cosolvent and the cyclohexanol in the separation tower are separated to obtain high-purity cyclohexanol, and the cyclohexene and the cosolvent canbe recycled; and the high-purity cyclohexanol is stored in the liquid storage tank. By the device and the method, the problems that conversion per pass of the cyclohexene is low and the reaction energy consumption is high in the cyclohexene hydration reaction; moreover, the device and the method has the following advantages: the whole flow can be operated continuously and stably, the water and the catalyst can be recycled, and the cyclohexene and the cosolvent can be recycled.

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY

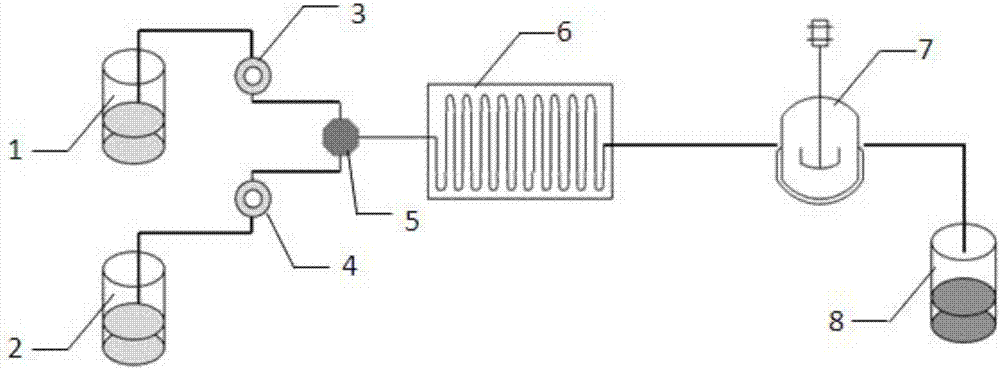

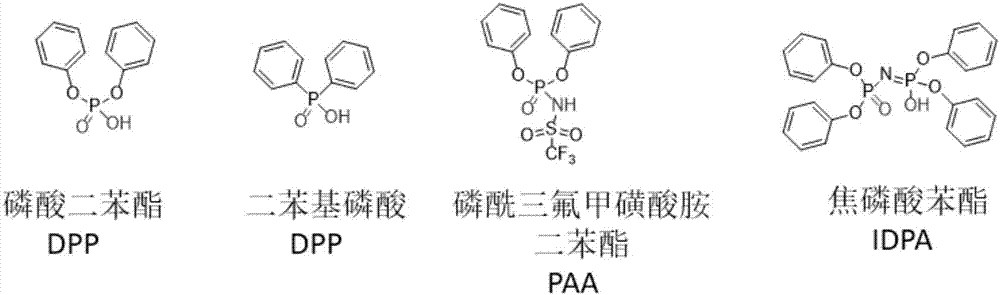

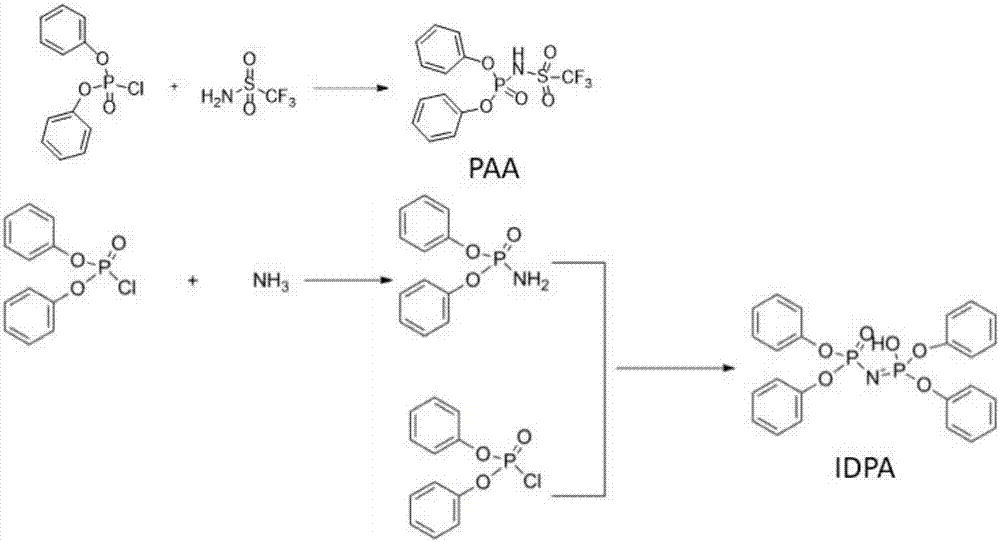

Method for continuously preparing glyceryl triacetate with phenyl phosphate biomimetic catalyst

InactiveCN107200686AReduce acidityHigh catalytic efficiencyOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsAcetic acidAcetic anhydride

The invention provides a method for continuously preparing glyceryl triacetate with a phenyl phosphate biomimetic catalyst, and belongs to the field of synthesis of chemical products. Glycerinum, acetic acid, a catalyst and a solvent are pumped into a microchannel reactor and are subjected to an esterification reaction under the catalytic action of the phenyl phosphate catalyst, and an obtained product and acetic anhydride are subjected to an acylation reaction to obtain glyceryl triacetate. The phenyl phosphate biomimetic catalyst is adopted, the acidity of the phenyl phosphate biomimetic catalyst is relatively low as compared with that of a liquid acid, the equipment is less corroded, and the phenyl phosphate biomimetic catalyst is a bifunctional small-molecule catalyst and is higher in catalytic efficiency under the action of a hydrogen bond, the conversion rate of glycerinum is up to 100%, and the yield of glyceryl triacetate is up to more than 95%.

Owner:NANJING UNIV OF TECH

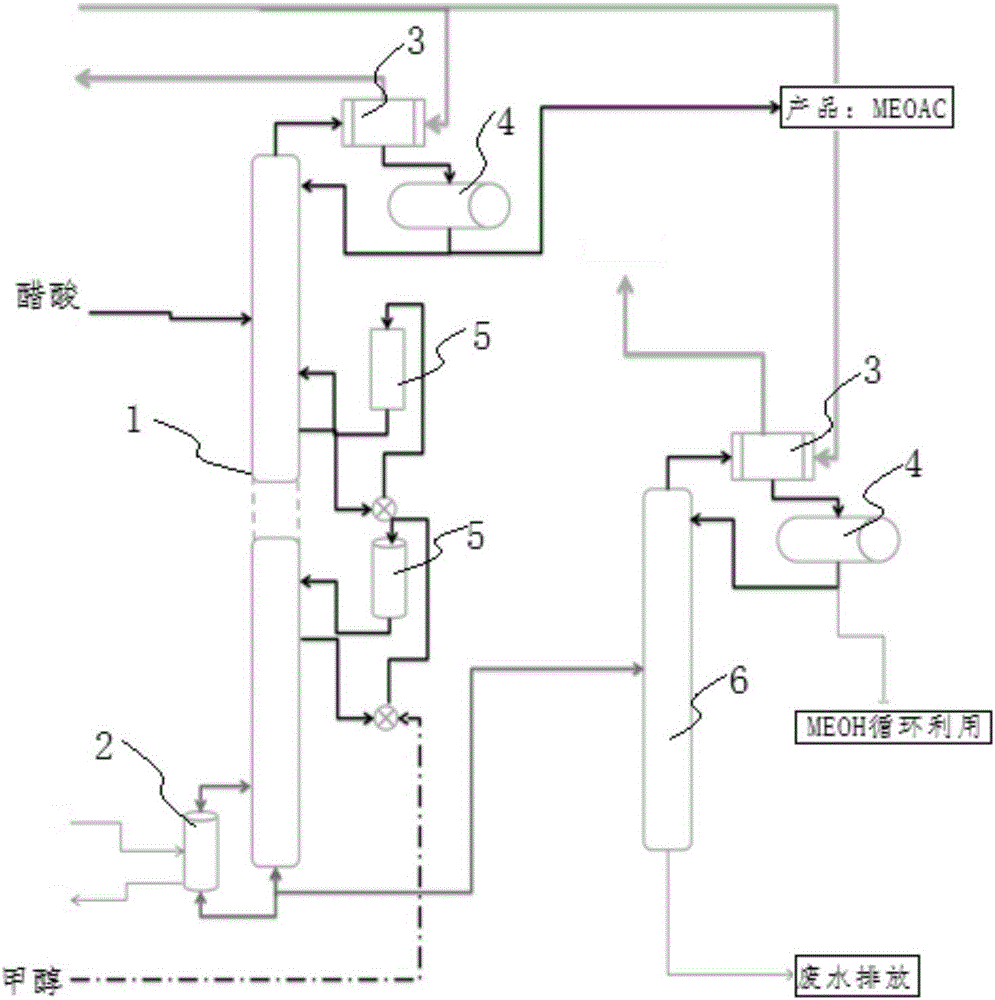

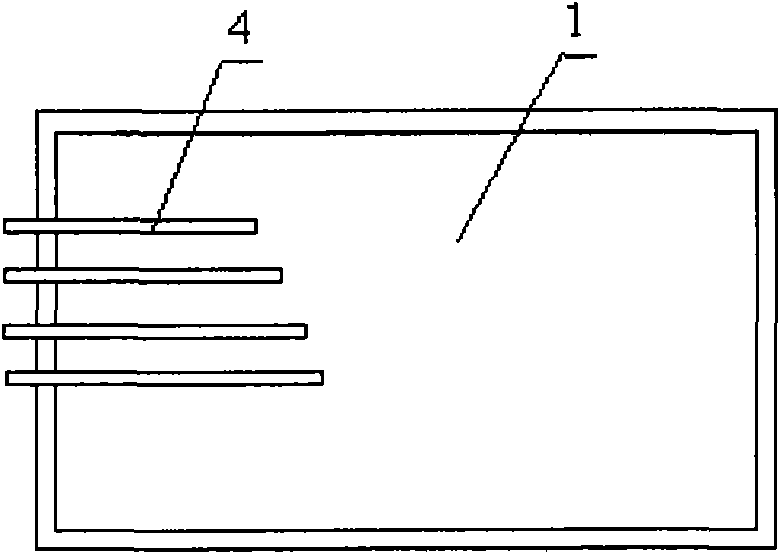

High-purity methyl acetate production process device and method

InactiveCN105968007AImprove conversion rateIncrease concentrationOrganic compound preparationChemical industryAlcoholReboiler

The invention discloses a high-purity methyl acetate production process device and method. The high-purity methyl acetate production process device comprises a reactive distillation column and a plurality of external reactors, wherein the reactive distillation column is dividend into a methyl alcohol separation section, a multilayer reaction section, an extraction section and a rectifying section from bottom to top. The multilayer reaction section is of a multilayer tower plate structure. The reaction section of each layer of tower plate is circularly connected with the corresponding external reactor through a pipeline. The extraction section is communicated with the multilayer reaction section and is provided with an acetic acid inlet. The top of the rectifying section is further connected with a condenser and a return tank. The separation section is provided with a methyl alcohol inlet, and the bottom of the separation section is circularly connected with a reboiler. Reaction and separation are organically combined, so that a reaction rate is increased, reverse reaction is suppressed, and a conversion rate is effectively improved. Therefore, the mass concentration of methyl acetate products is improved, and the device can be used for producing high-purity (97% or more) methyl acetate products and has the advantages of simplicity, high efficiency, remarkable economic benefits and the like.

Owner:湖北三里枫香科技有限公司

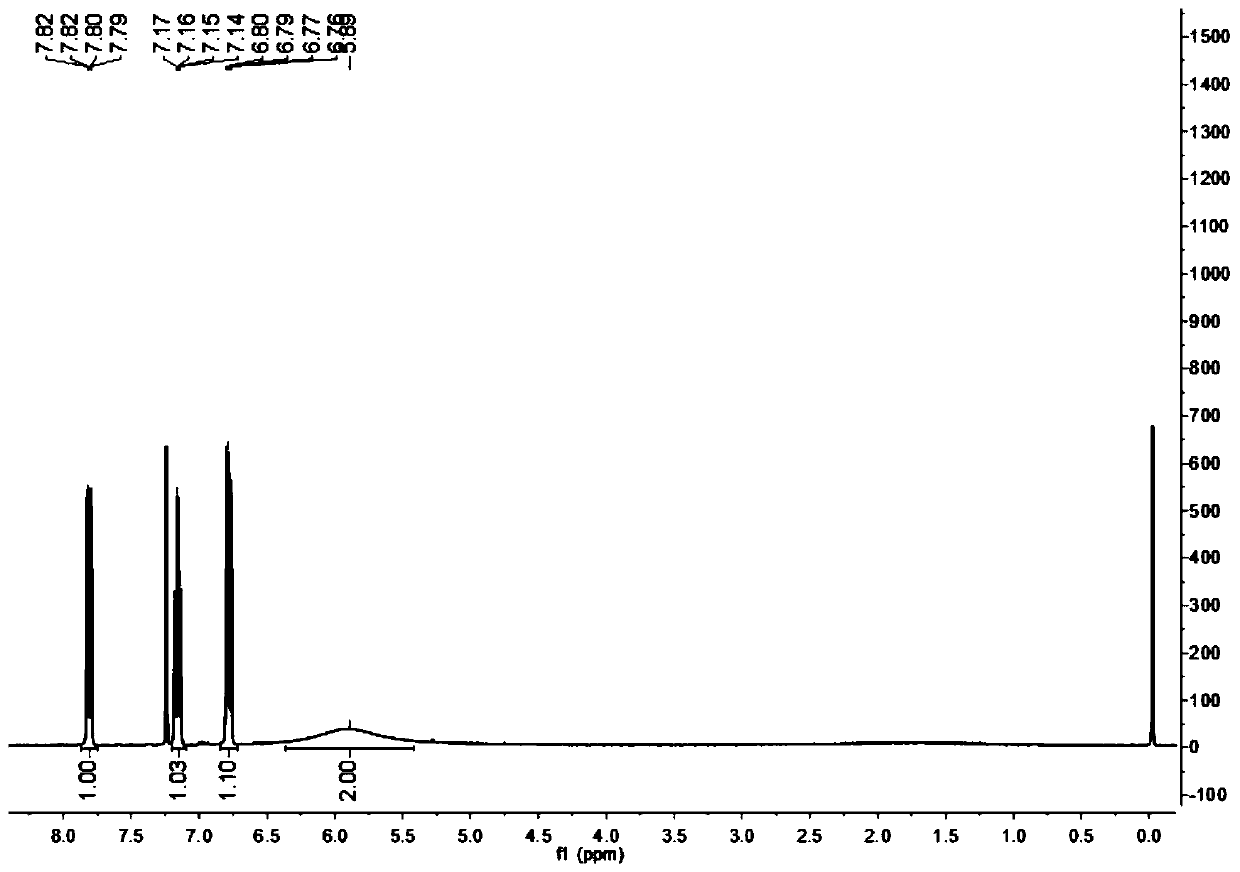

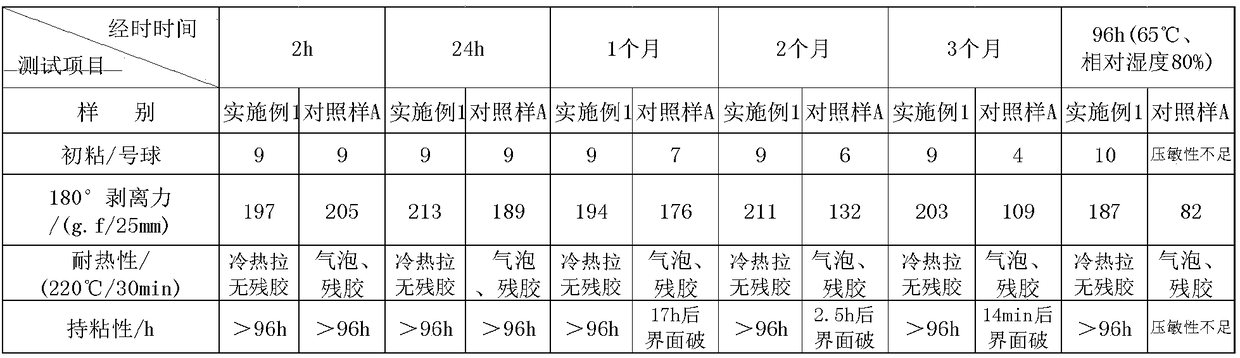

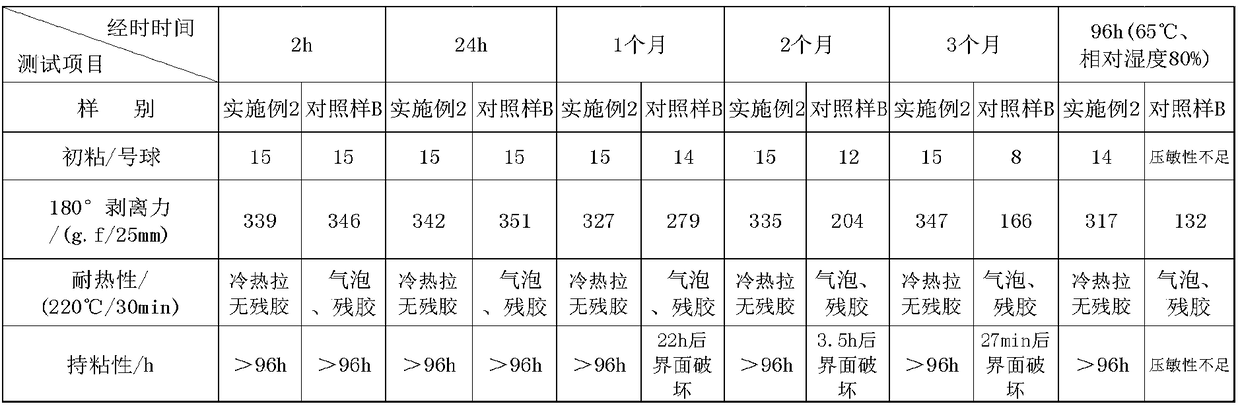

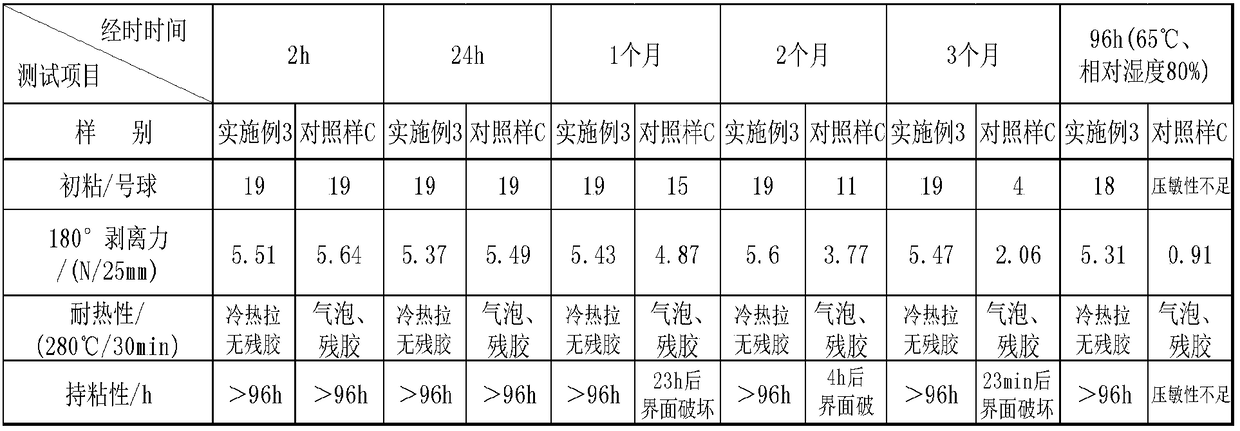

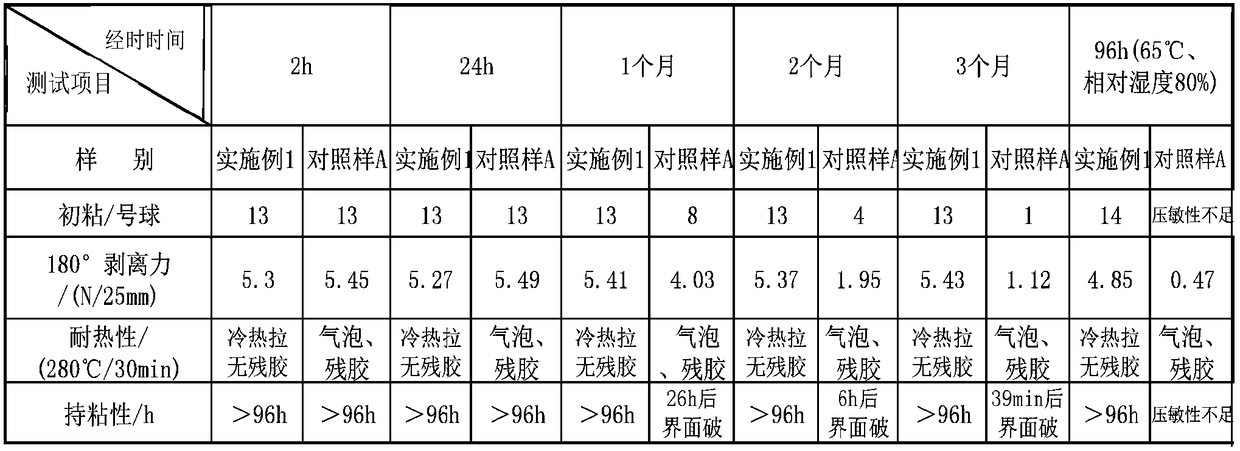

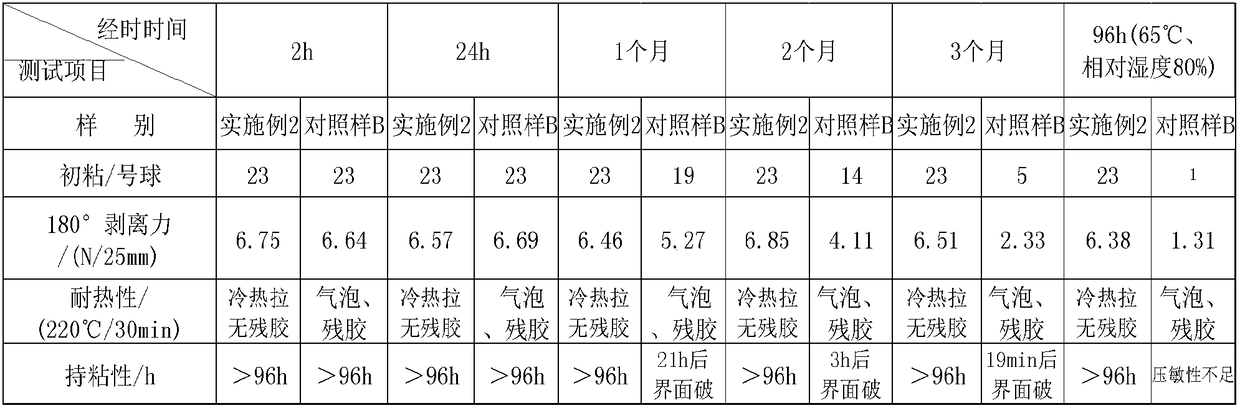

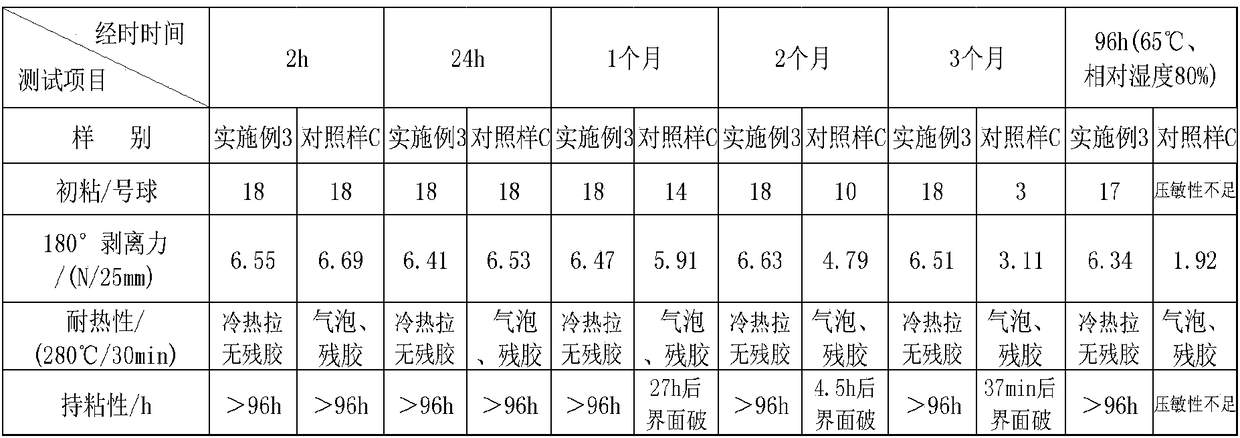

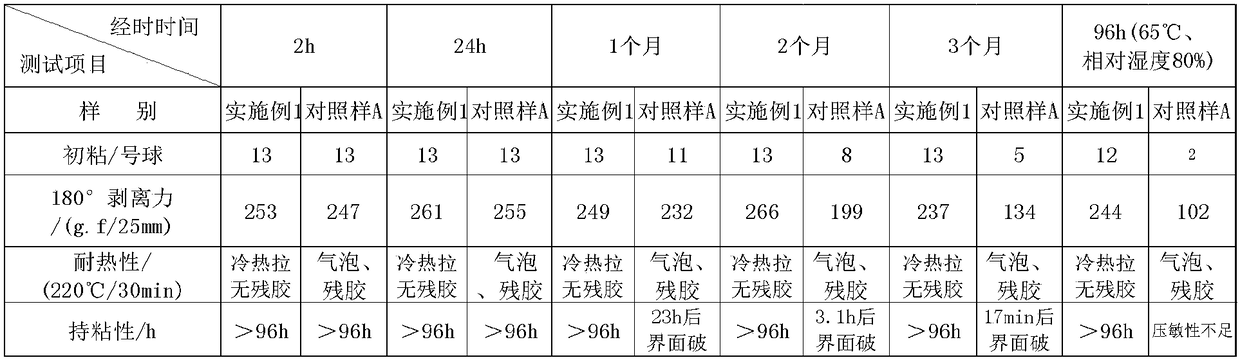

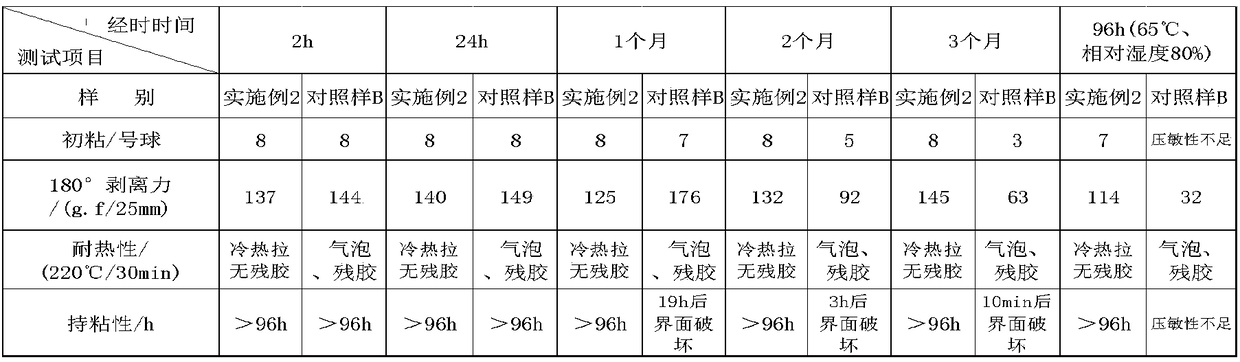

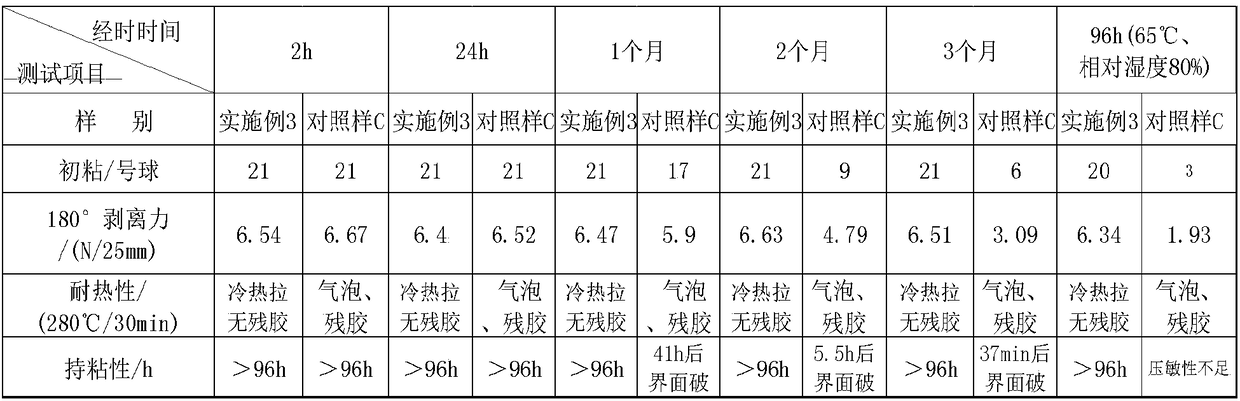

A method for improving the stability of silicone pressure-sensitive adhesives for protective films

ActiveCN105441017BStable temperature resistanceImprove storage performanceAdhesivesCarboxylic acidKetone

The invention relates to a method for improving stability of an organosilicone pressure-sensitive adhesive for a protective film. The method comprises steps as follows: step 1), removal of water and hydroxyl: a water and hydroxyl removal agent containing organic acyloxy silane compounds is added to a reaction system to reduce water left in the adhesive and hydroxyl left on an adhesive structure; step 2), thorough inactivation of a catalyst: a) when primary amine or secondary amine is used as a condensation polymerization catalyst, an adhesive reaction system is kept at the temperature of about 70 DEG C at the nitrogen reaction atmosphere, primary amine or secondary amine and aldehydes, ketones or low-level carboxylic acid react to generate Schiff base, generated unstable Schiff base reacts with diethyl malonate, and Schiff base becomes beta-amino acid without catalytic activity; b), when secondary amine or tertiary amine is used as a condensation polymerization catalyst, acidic compounds which can react with secondary amine or tertiary amine to generate a stable compound are added to the reaction system; step 3), residual small molecular substances are removed in the vacuum state; step 4), neutralization of residual acidic compounds: sodium alcoholate is added to neutralize residual acidic compounds in the adhesive.

Owner:ANHUI MINGXUN NEW MATERIAL TECH

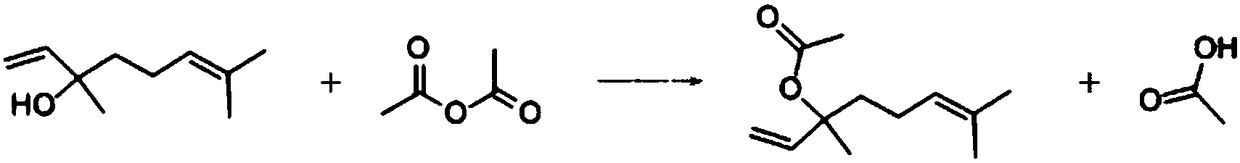

Technique based on vacuum and high temperature conditions to synthesize linalyl acetate

InactiveCN108373414AAccelerateInhibition of the reverse reactionOrganic compound preparationCarboxylic acid esters preparationLinalyl acetateAcetic anhydride

The invention discloses a technique based on vacuum and high temperature conditions to synthesize linalyl acetate. Linalyl acetate is synthesized from natural linalool and acetic anhydride via the steps of I, adding materials into a reactor in the ratio of 1:1, adding potassium carbonate accounting for 0.8-1.5% of total quantity of the reaction materials into the reactor as a catalyst; II, importing the generated product into a washing kettle, and adding an alkaline solution into the washing kettle; III, rectifying. The technique based on vacuum and high temperature conditions to synthesize linalyl acetate has the advantages that esterification is carried out under vacuum and high temperature; the esterification is reversible; pressure and temperature may effectively inhibit reverse reaction of the generated product and increase the speed of forward reaction; potassium carbonate is used as the catalyst during reacting so that the yield of product reaches 70% and above.

Owner:江西依思特香料有限公司

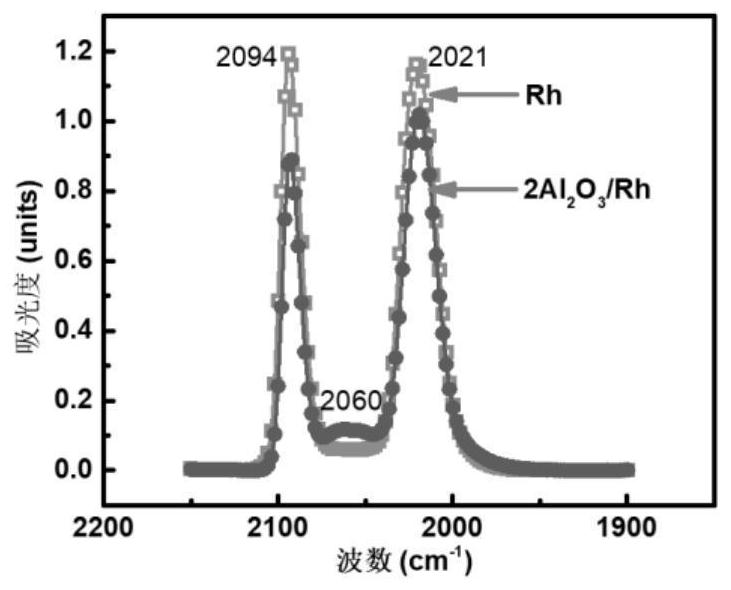

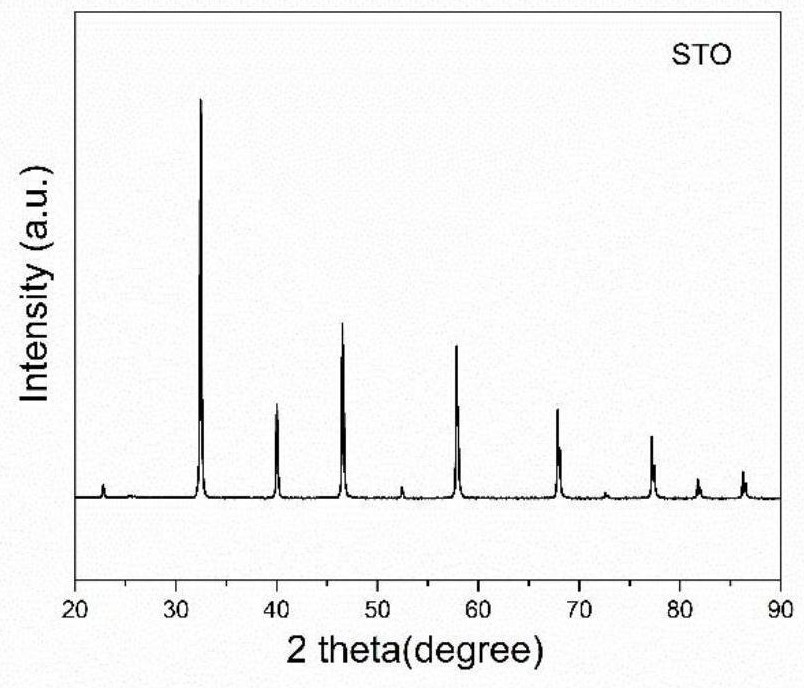

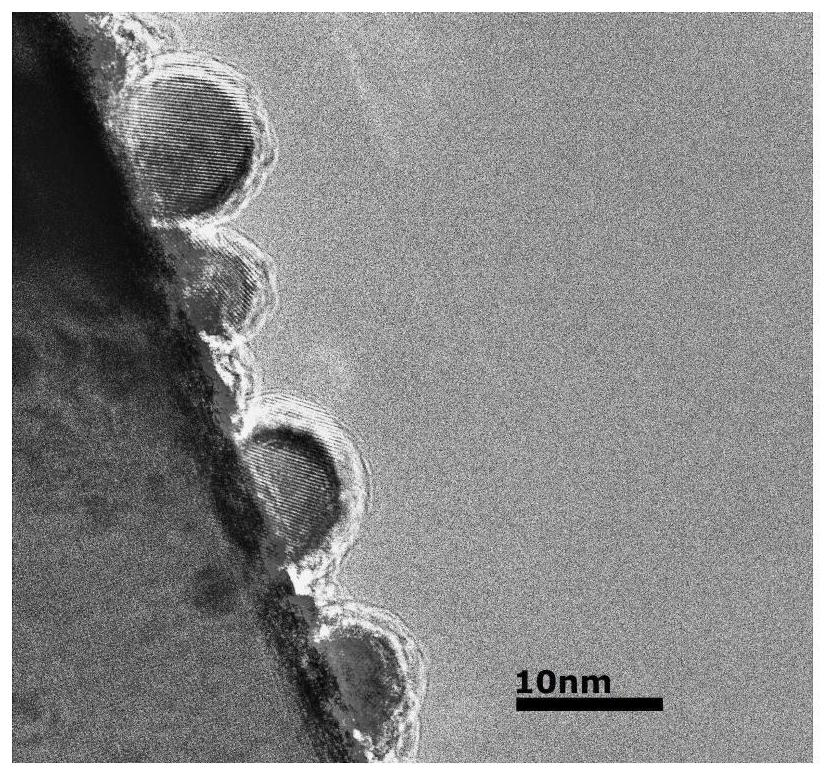

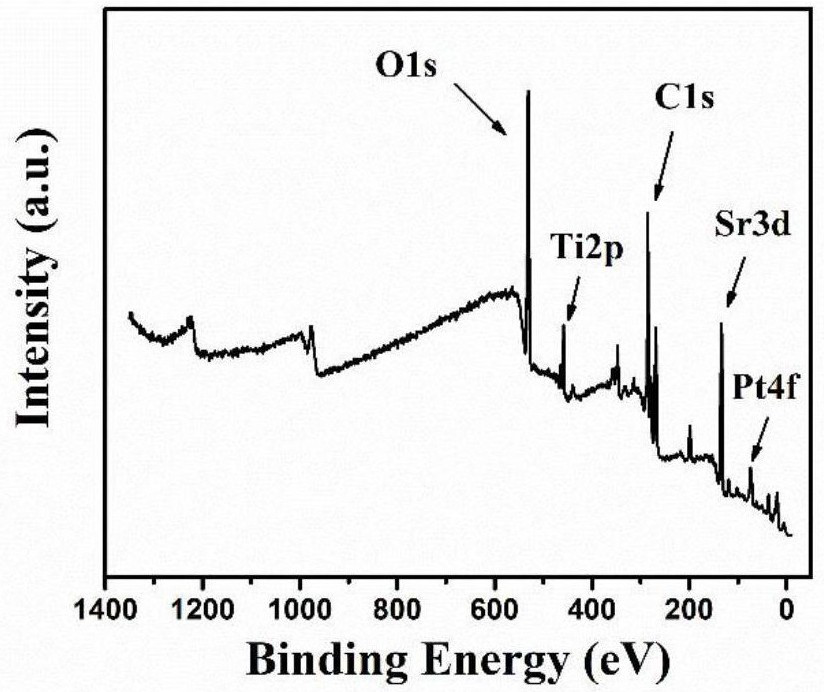

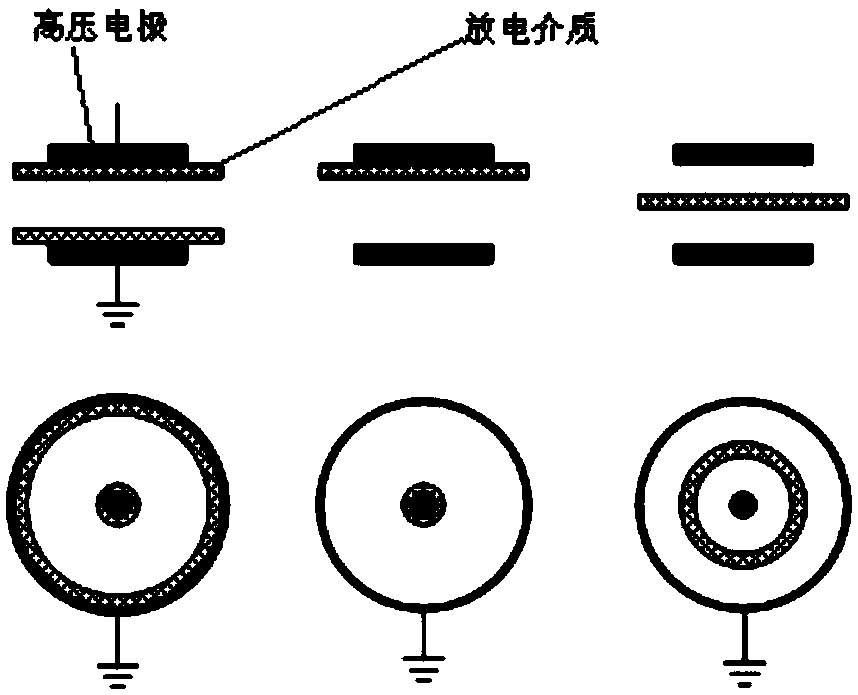

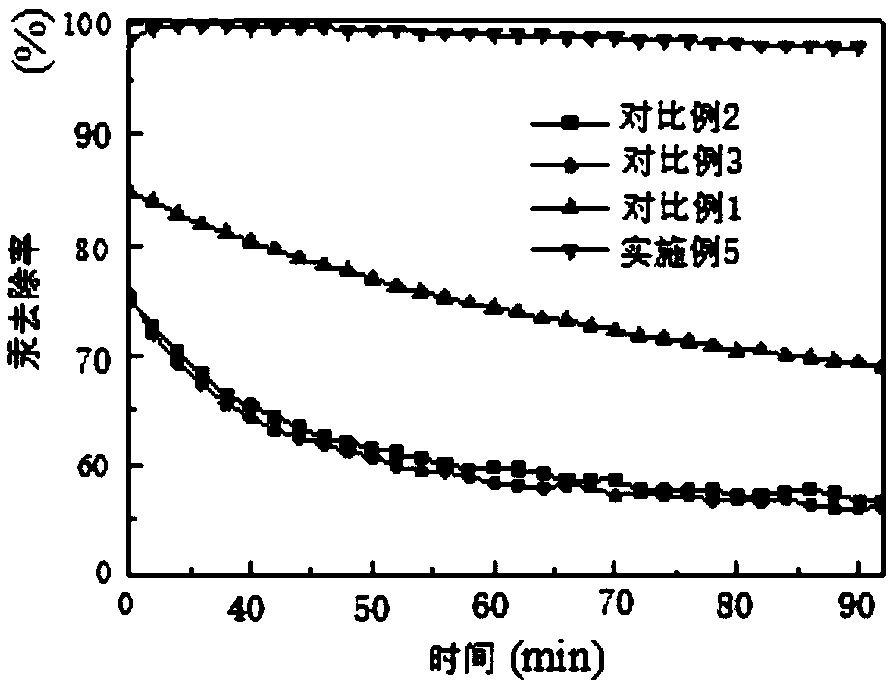

Semiconductor photocatalytic water splitting method capable of inhibiting reverse reaction

ActiveCN112777565AEasy to operateEasy to repeatPhysical/chemical process catalystsHydrogen productionPhotocatalytic water splittingSide reaction

The invention provides a semiconductor photocatalytic complete water splitting method capable of inhibiting reverse reaction. The surface of a semiconductor photocatalyst loaded with precious metal (Rh, Pt, Pd and the like) assistants is modified with a trace amount of Al2O3, SiO2 and other oxides through a powder atomic layer deposition method, so that the reverse reaction in the photocatalytic water splitting process is effectively inhibited. Different from other publicly reported reverse reaction inhibition methods, the modification strategy provided by the invention does not obviously increase the substance transfer resistance between the assistants and the solution environment, and does not introduce competitive side reactions, so that the water splitting performance of the photocatalyst can be greatly improved. The strategy can be used for inhibiting the hydrogen-oxygen reverse reaction in the photocatalytic complete water splitting reaction, and can also be used for preventing the hydrogen-oxygen composite reaction in the atmosphere due to safety factors in the presence of other noble metals.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

A method for extending the stability of silicone pressure-sensitive adhesives

The invention provides a method for expanding stability of an organosilicone pressure-sensitive adhesive. The method comprises the following steps: (1) removing water; (2) removing hydroxyl, namely adding a silicon hydroxyl remover containing a trialkyl silicon carboxylate compound to a reaction system to reduce residual oxhydryl in an adhesive molecular structure; (3) thoroughly inactivating a catalyst, wherein the step is performed according to the following two conditions: when primary amine or secondary amine is utilized as a polycondensation catalyst, enabling the primary amine or the secondary amine to react with aldehydes or ketones and low-level carboxylic acid to generate a schiff base in a nitrogen reaction atmosphere, enabling the generated instable schiff base to react with diethyl malonate, and changing the schiff base into beta-amino acid free of catalytic activity; and when secondary amine or tertiary amine is utilized as the polycondensation catalyst, adding an acid substance which can react with the secondary amine or the tertiary amine to form a stable compound to the reaction system; (4) removing residual small molecular substances in vacuum; and (5) neutralizing the residual acid substance.

Owner:ANHUI MINGXUN NEW MATERIAL TECH

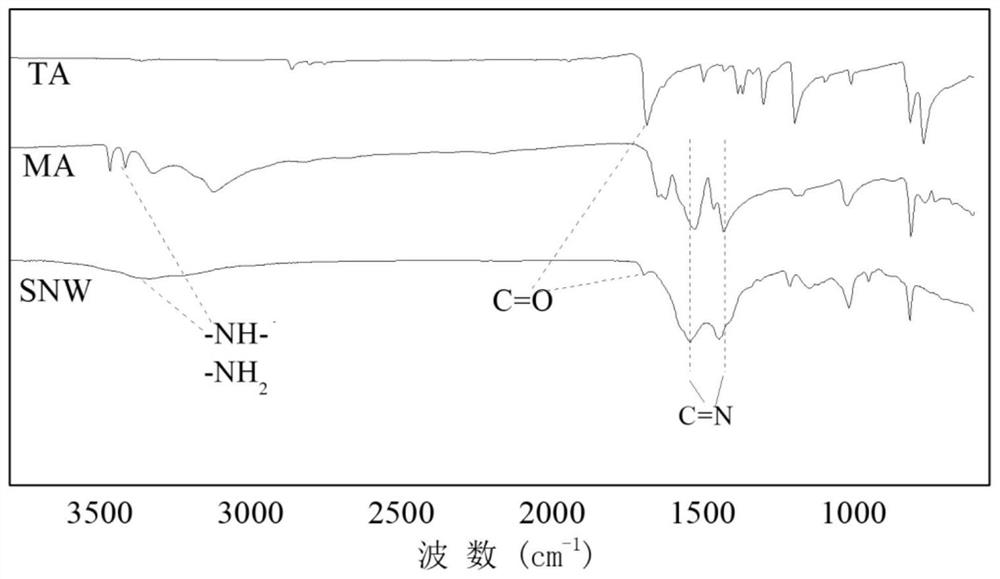

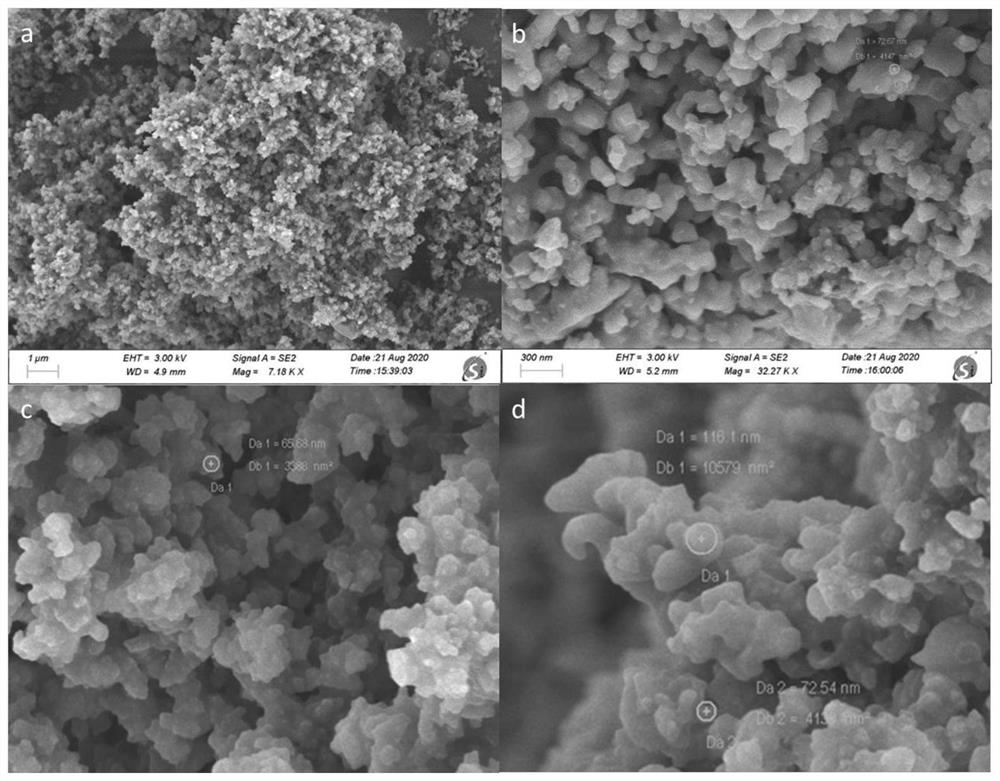

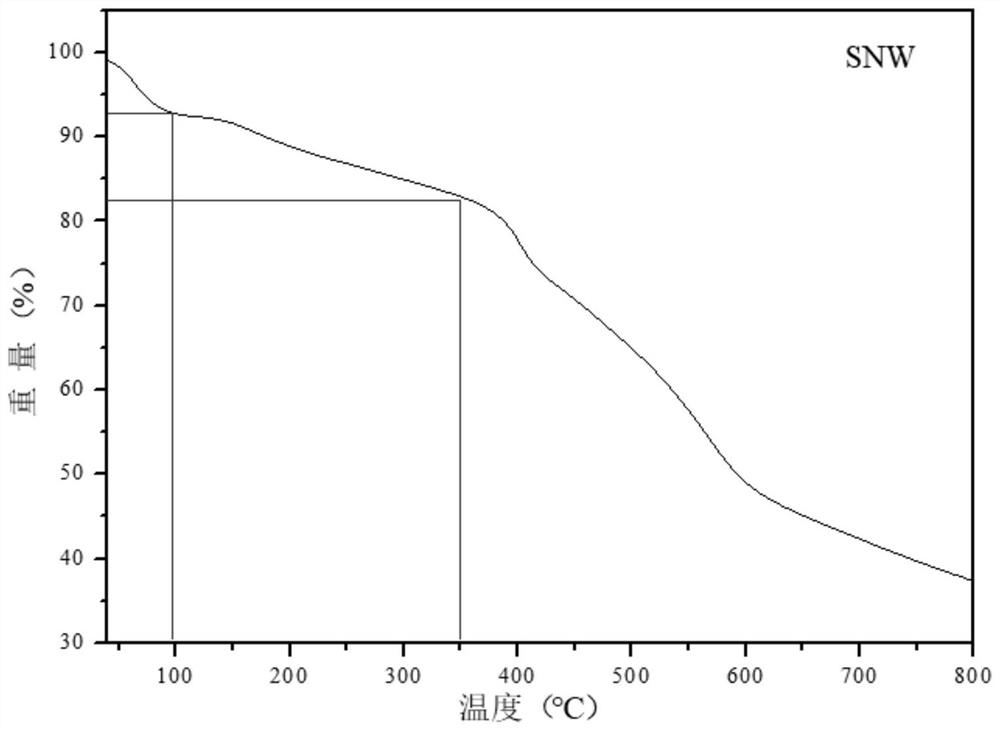

A kind of synthetic method of nitrogen-enriched Schiff base polymer

The invention discloses a method for synthesizing a nitrogen-enriched Schiff base polymer. , be warming up to the temperature up and down the boiling point of toluene, and carry out water separation and reflux to produce anhydrous; (2) continue to be warming up to the temperature above and below the boiling point of xylene to react under inert gas, and water separation and reflux until anhydrous production; (3) after the reaction finishes, The reaction product was lowered to room temperature, and the nitrogen-rich Schiff base polymer was obtained after suction filtration, solid separation, washing and drying. The synthesis method of the invention has simple operation, easy control and high yield, and the nitrogen-rich Schiff base polymer synthesized by the invention has high nitrogen content, stable structure and uniform particle size distribution.

Owner:HANGZHOU NORMAL UNIVERSITY

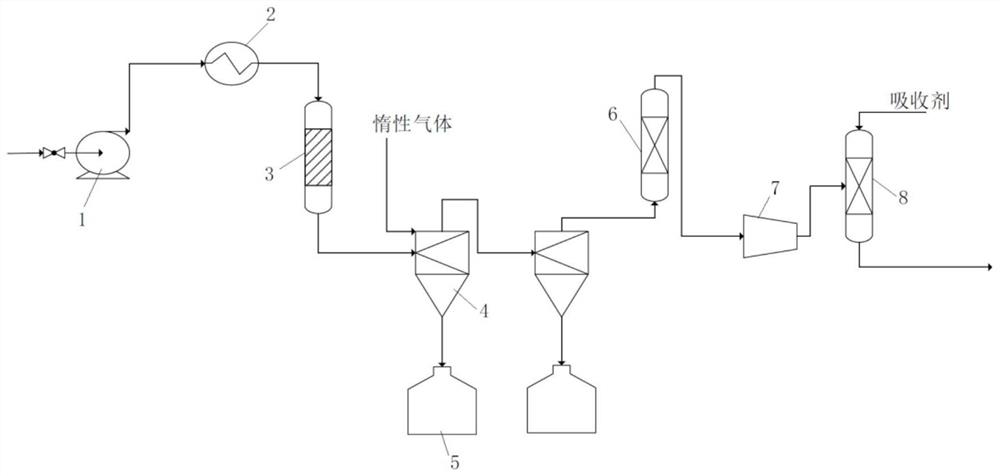

Preparation method, prepared ketene compound and application of compound

PendingCN114105748AShorten mixing timeInhibition of the reverse reactionOrganic compound preparationKetenes preparationOrganic acidFluid phase

The invention provides a preparation method, a prepared ketene compound and application of the compound, the preparation method comprises the following steps: 1) high-temperature cracking: preheating and gasifying an organic acid or anhydride cracking raw material, and then carrying out high-temperature cracking to obtain high-temperature cracking gas; 2) gas-liquid separation: conveying the high-temperature cracked gas into a cyclone separator for gas-liquid rapid separation; and (3) collecting a product: absorbing a gas-phase product from the cyclone separator through an absorbent or condensing the gas-phase product, and collecting the gas-phase product to obtain the ketene compound. According to the method, the cyclone separator is used for carrying out rapid gas-liquid separation on the cracking product, so that the reverse reaction of the gas-phase product due to overlong retention time in the liquid phase can be effectively avoided.

Owner:WANHUA CHEM GRP CO LTD

Preparation method and preparation device of sulfur dichloride

ActiveCN106829878BInhibition of reversible reactionsHigh puritySulfur dichlorideDistillationSilicon oxide

Owner:湖南海利常德农药化工有限公司

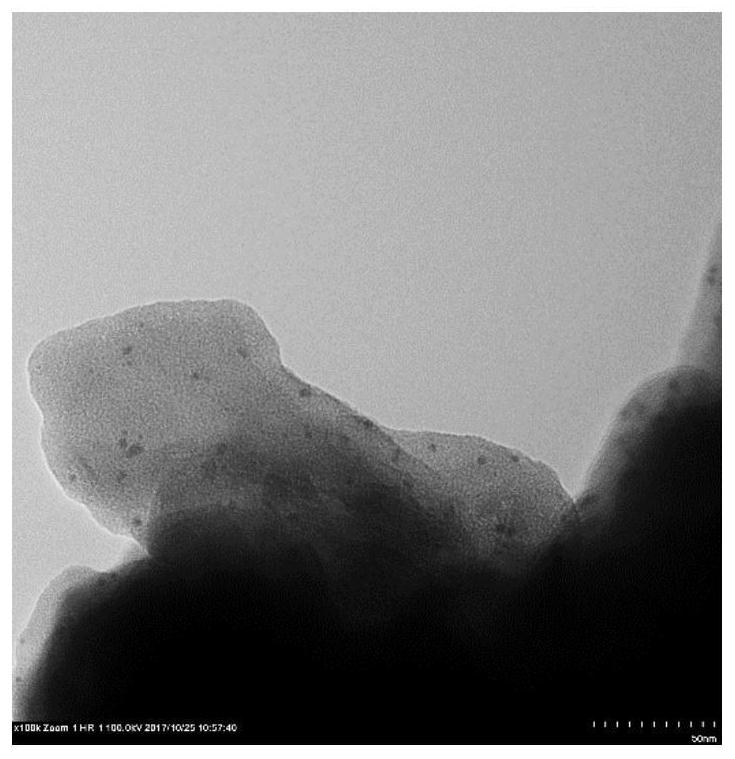

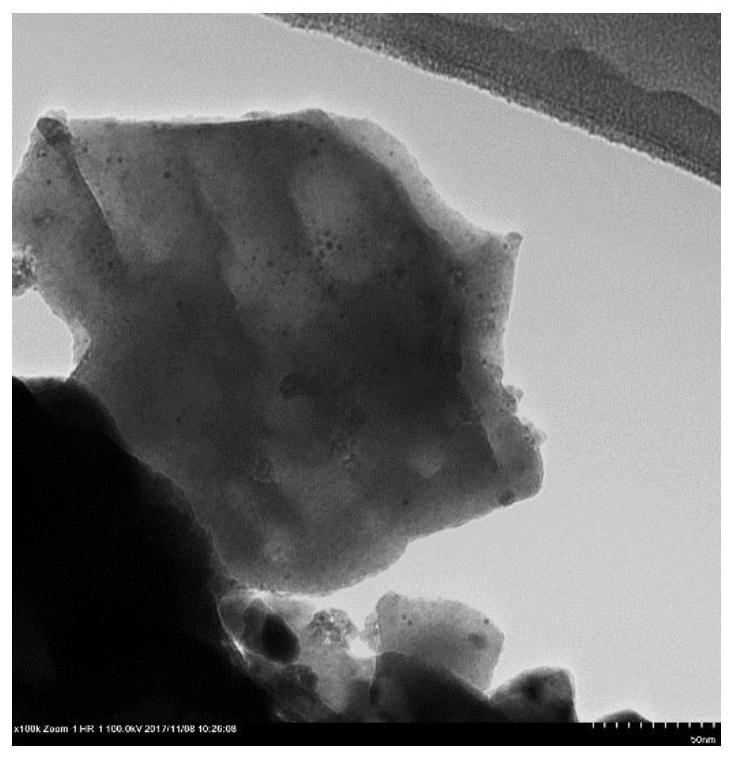

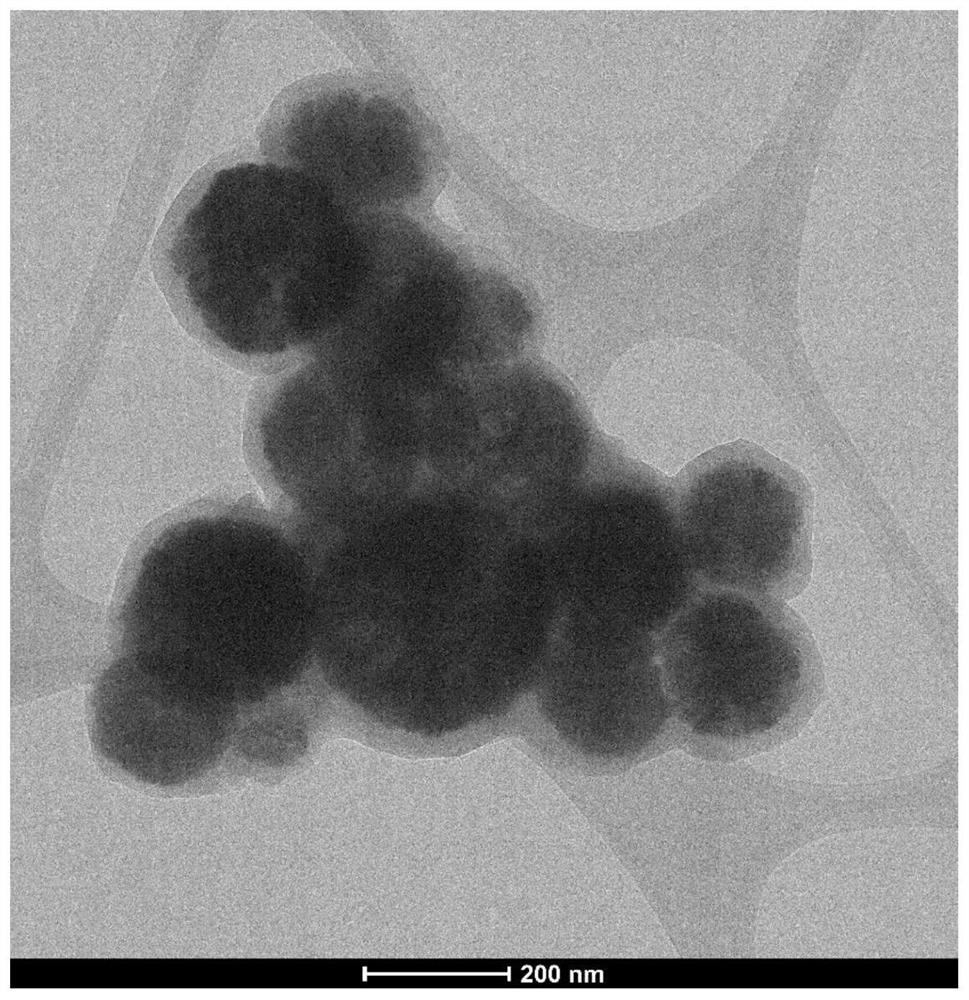

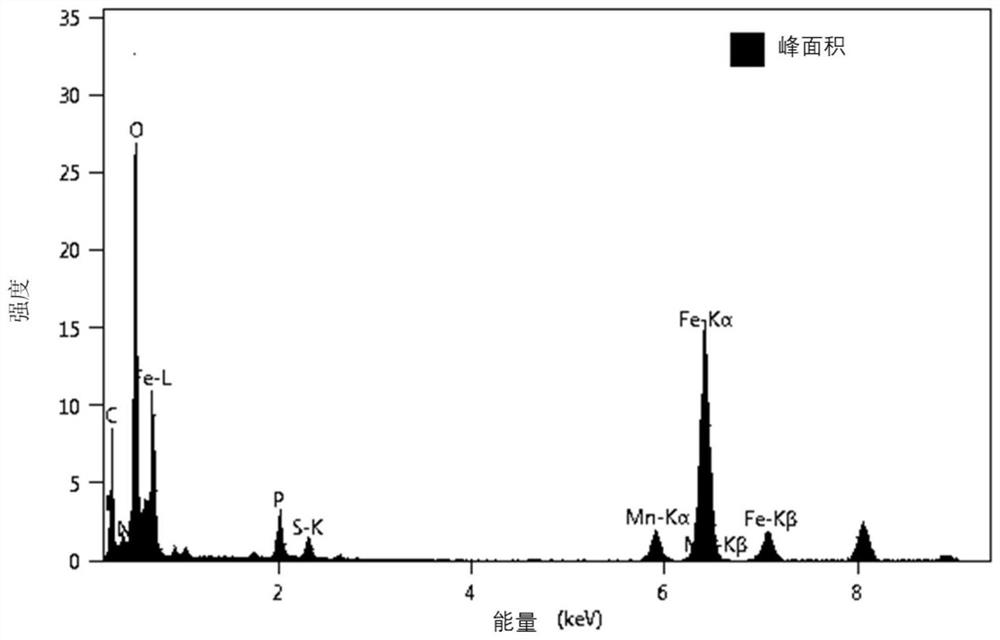

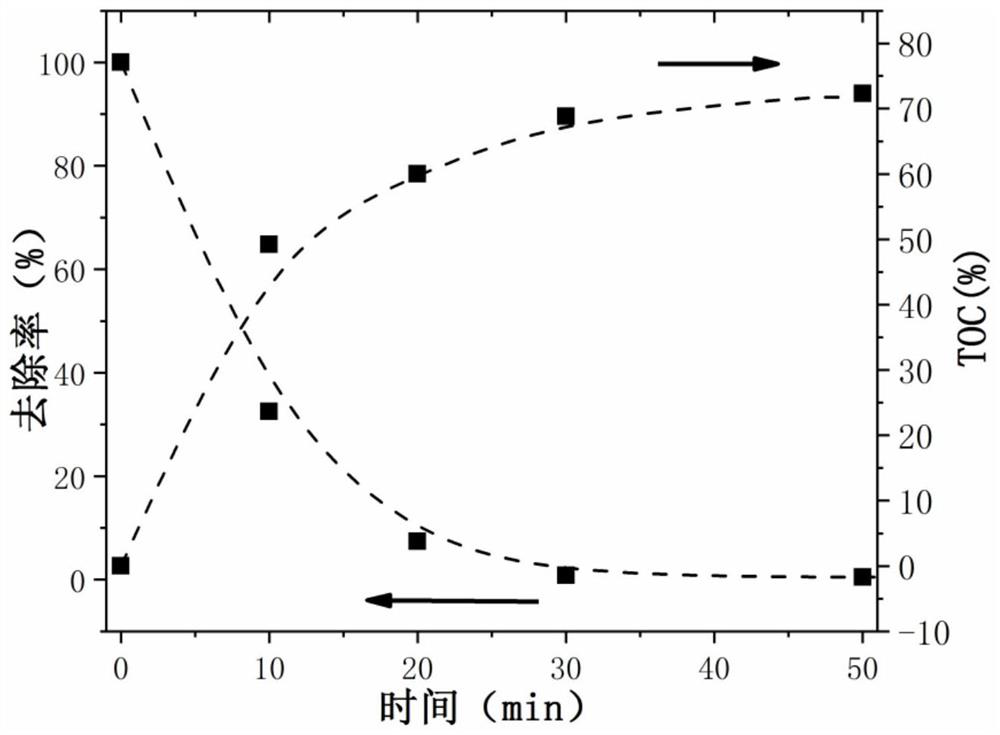

Bimetallic core-shell catalyst for electro-catalysis synergistic hydrogen production as well as preparation method and application of bimetallic core-shell catalyst

PendingCN112774713AImprove catalytic performanceAchieve separationPhysical/chemical process catalystsWater contaminantsPtru catalystThiourea

The invention discloses a bimetallic core-shell catalyst for electro-catalysis synergistic hydrogen production as well as a preparation method and application of the bimetallic core-shell catalyst. The bimetallic core-shell catalyst is formed by taking a MnFe3O4 nano-microsphere formed by polymerization of bimetallic Mn and Fe as a core and taking co-doped heteroatoms N, P and S as a shell layer, and the core-shell structure is obtained by carrying out ultrasonic treatment and reaction on N and P sources of phosphonitrilic chloride trimer, S source of thioacetamide or thiourea and MnFe3O4 nanoparticles in a solvent. The catalyst has excellent electro-catalytic performance, hydrogen production capacity and cycling stability and is not affected by electrolyte properties in the sewage treatment process as a compatible catalyst, and a cathode and an anode can be switched at will. The catalyst disclosed by the invention has a good electro-catalytic reaction and can be widely applied to wastewater treatment.

Owner:SOUTH CHINA UNIV OF TECH

Photocatalytic full-water-splitting cocatalyst, photocatalyst and preparation method thereof

ActiveCN113083275AAvoid contactIncrease speedMetal/metal-oxides/metal-hydroxide catalystsPhotocatalytic water splittingGraphite

The invention belongs to the technical field of photocatalytic water decomposition, and particularly relates to a photocatalytic full-water-splitting cocatalyst which comprises metal nanoparticles with the performance of catalyzing carbon graphitization and a graphite-phase carbon cage thin layer coating the surfaces of the metal nanoparticles. In addition, the invention also relates to a photocatalyst which comprises a semiconductor powder photocatalyst and a cocatalyst loaded on the semiconductor powder photocatalyst, and the cocatalyst is the photocatalytic full-water-splitting cocatalyst. In addition, the invention also relates to a preparation method of the photocatalyst. Compared with the prior art, the catalytic effect on the reverse reaction is inhibited on the basis of not influencing the acceleration of the positive reaction.

Owner:TIANJIN UNIV

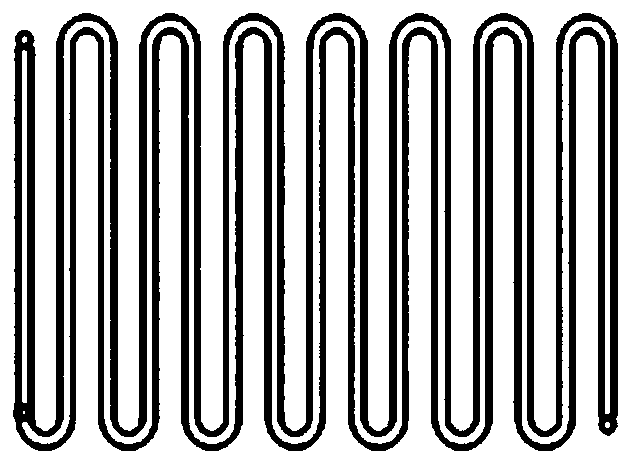

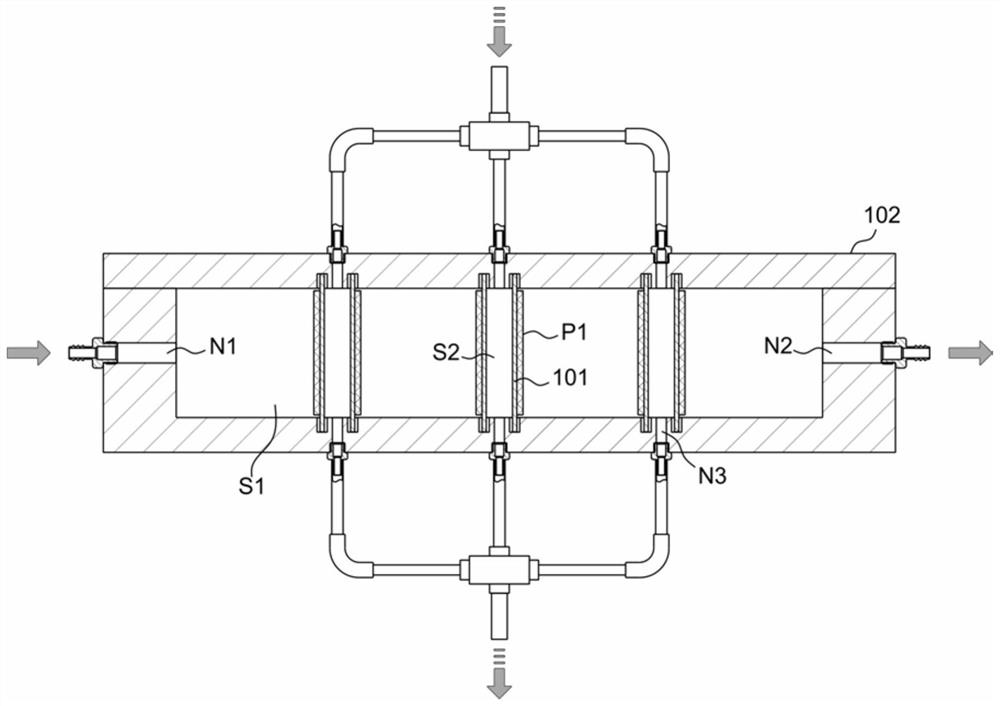

A Catalytic Membrane Reactor with Built-in Spoiler Structure

ActiveCN113041970BEnhanced transfer processAvoid mixingFlow mixersTransportation and packagingPtru catalystFluid phase

The invention discloses a catalytic membrane reactor with a built-in disturbance flow structure, which comprises a one-phase flow channel through which the first phase of reaction flows through the one-phase flow channel; and a two-phase flow channel through which the second phase reacts with the The flow through the two-phase channel, the angle between the flow direction of the reaction second phase and the flow direction of the reaction first phase is formed; wherein, the two-phase flow channel is placed in the reaction first phase In the flow direction of two phases, the two-phase flow channel and the one-phase flow channel are separated from each other by a single-phase permeable membrane attached with catalyst. The invention uses a built-in spoiler tube to destroy the concentration boundary layer caused by the reaction when the liquid phase reactant flows through the liquid flow channel, thereby strengthening the transfer process of the reactant and promoting the follow-up of the reaction; at the same time, the liquid flows through the spoiler tube to form a The vortex street also helps to strengthen the desorption and transfer of reaction products, inhibit the reverse reaction and promote the forward reaction.

Owner:NANJING UNIV OF SCI & TECH

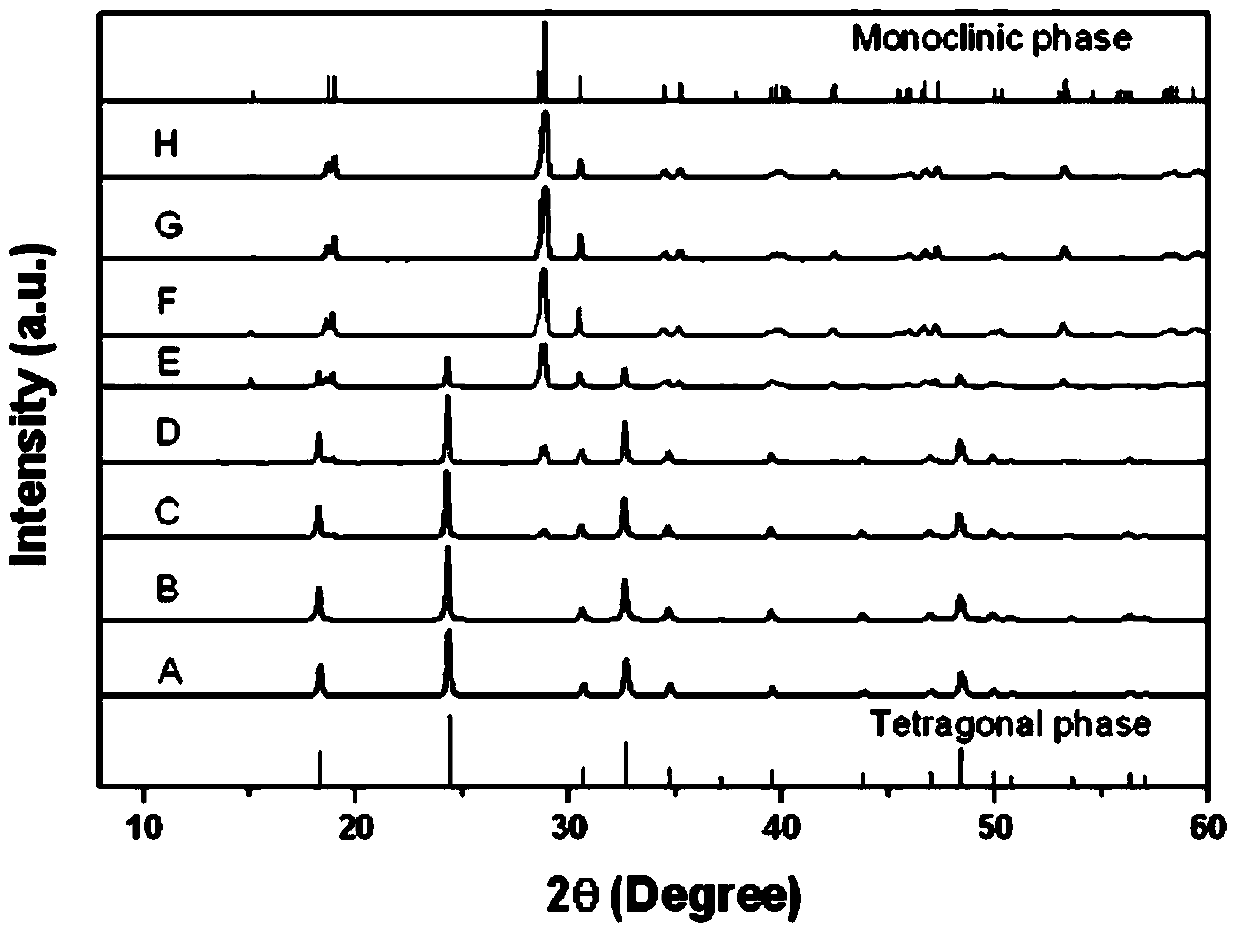

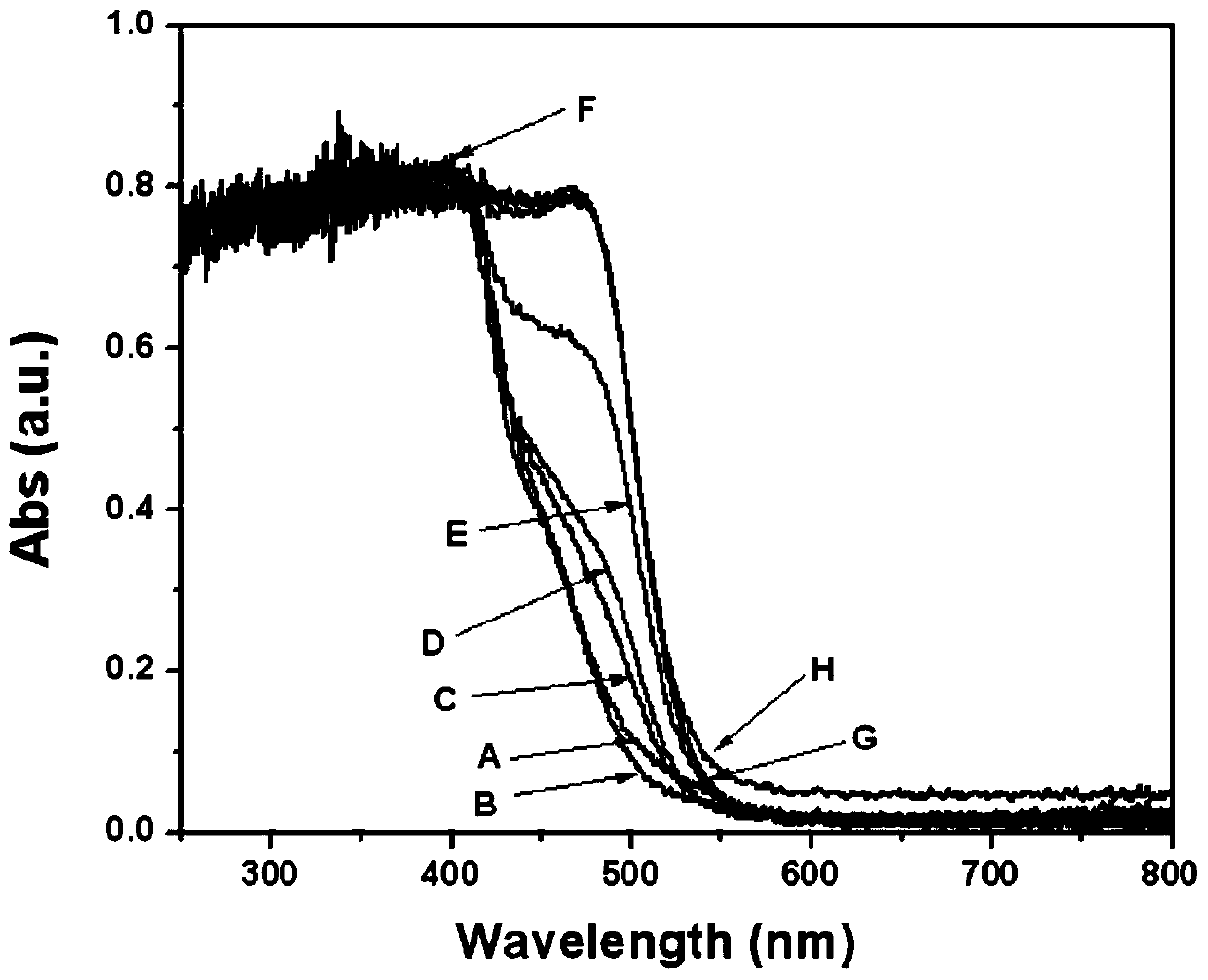

Synthesis, Catalyst and Application of Bismuth Vanadate Photocatalyst with Controlled Facet Ratio

ActiveCN107149932BSave raw materialsEasy to makePolycrystalline material growthFrom normal temperature solutionsSolar lightPtru catalyst

The invention provides a bismuth vanadate photocatalyst with controllable crystal plane ratio and its synthesis, which are used for efficient photocatalytic water oxidation. By controlling the growth process of bismuth vanadate-based photocatalysts, precisely regulating the phase structure transition from tetragonal to monoclinic, and the change of single crystal morphology from micro-spherical to regular decahedral, the (010 ) to (011) crystal plane ratio. The optimized decahedral bismuth vanadate photocatalyst on Fe 3+ In the presence of soluble electron acceptors, the activity of decomposing water to produce oxygen is over 60.0L / kg / h, and the apparent quantum efficiency of oxygen production at 460nm is over 60%. At the same time, the photocatalyst still exhibits good activity when applied to outdoor sunlight, and the catalyst can be recycled many times with good stability. The preparation process of this method is simple, and the prepared photocatalyst has high activity and stability, is non-toxic and green, and can realize efficient catalytic water oxidation under sunlight, and is expected to be coupled with a hydrogen-producing catalyst for large-scale solar photocatalytic water splitting to produce hydrogen.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

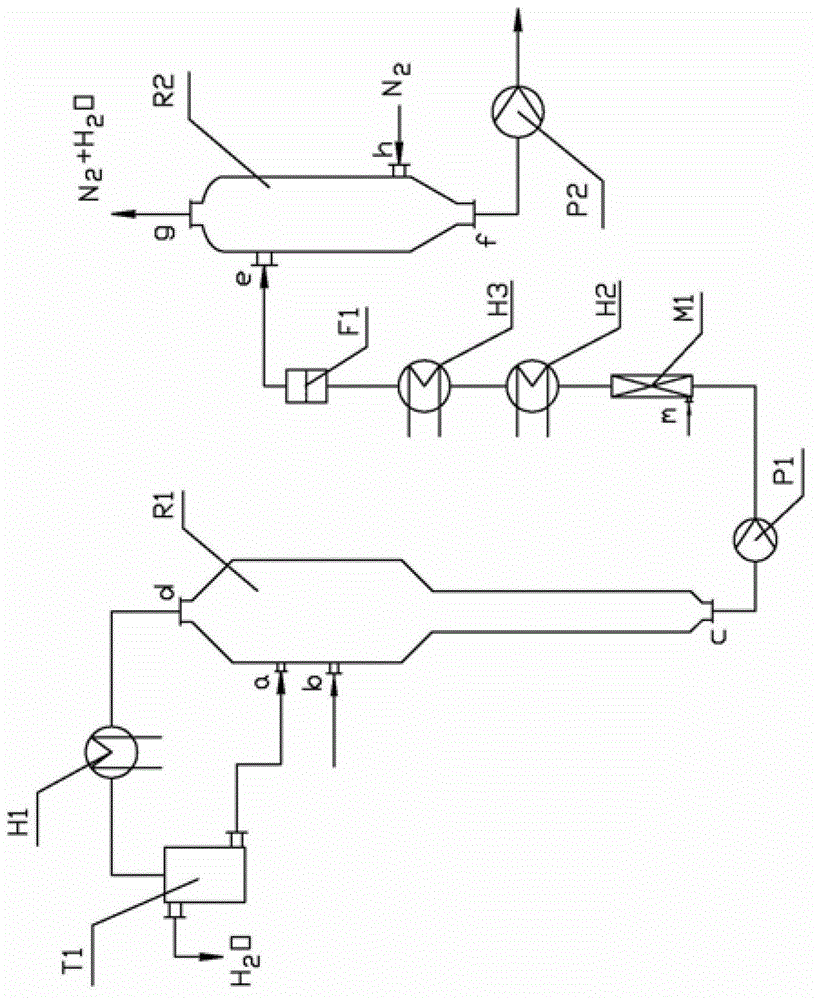

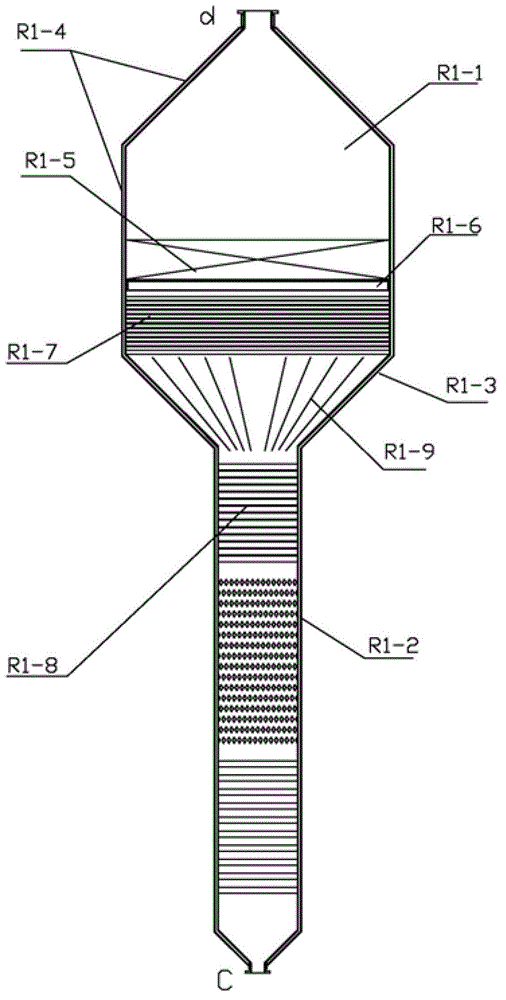

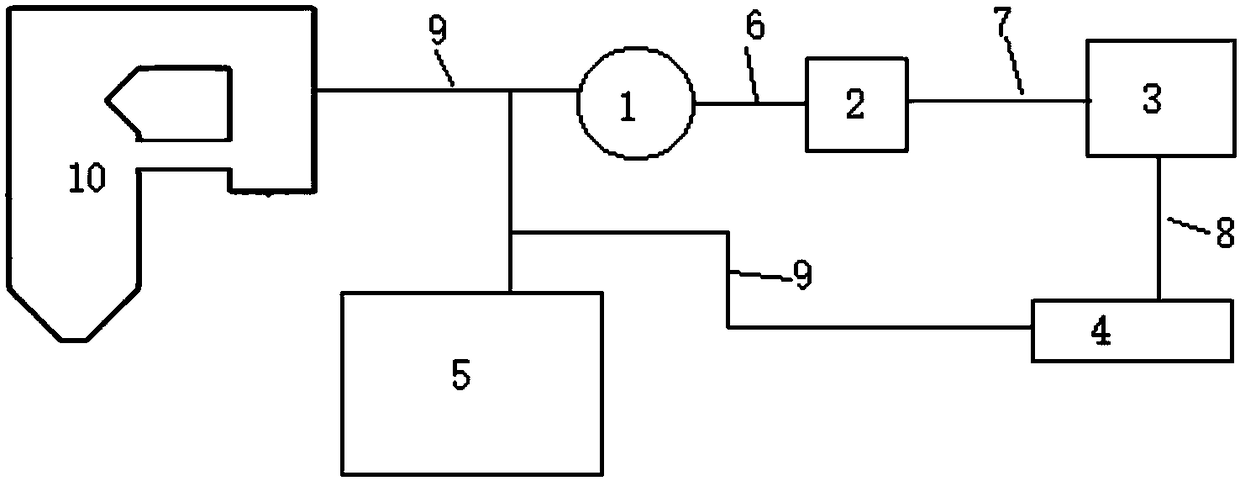

A method and device for catalytic hydrogen production suitable for hydrogen energy vehicles

InactiveCN104310309BHigh purityFewer separation stepsHydrogenChemical recyclingWater vaporDehydrogenation

The invention discloses a catalytic hydrogen production method and device suitable for a hydrogen energy automobile. The method disclosed by the invention specifically comprises the following steps: electromagnetically heating to dry a catalyst under nitrogen protection, stopping introduction of nitrogen and starting a liquid organic hydride cooler; starting a temperature control rheometer, maintaining the rotating speed of a rotary electromagnetic heating disc, and after the catalyst is stabilized at the reaction temperature, spraying, atomizing and feeding the liquid organic hydride intermittently; and condensing, separating and discharging the product hydrogen. According to the method and device disclosed by the invention, hydrogen production reaction conditions are uniformly designed and optimized to obtain the optimal reaction conditions. According to the method and device disclosed by the invention, a noble metal catalyst is replaced by cheap raney nickel, so that the reaction cost is lowered, and a carbon deposition deactivated catalyst can be regenerated by eliminating carbon with water vapor. A spraying and atomizing feeding method is adopted, the rotary electromagnetic heating is arranged, the surface temperature return time of the catalyst is fully utilized, and dehydrogenation reaction is carried out under a wet-dry multiphase reaction condition, so that the reaction efficiency is improved. No carrier gas is adopted, and the produced hydrogen is high in purity and free of being re-separated, so that the method and device are suitable for the hydrogen energy automobile.

Owner:ZHEJIANG UNIV

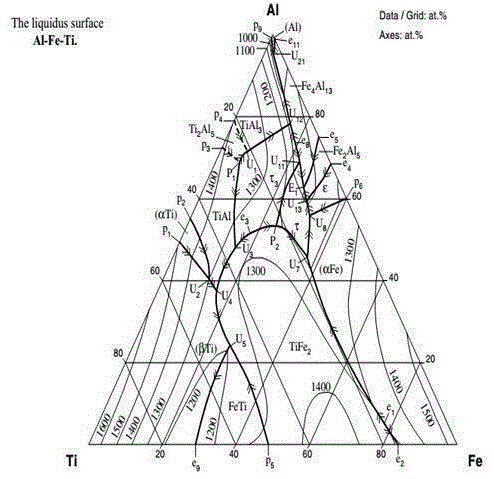

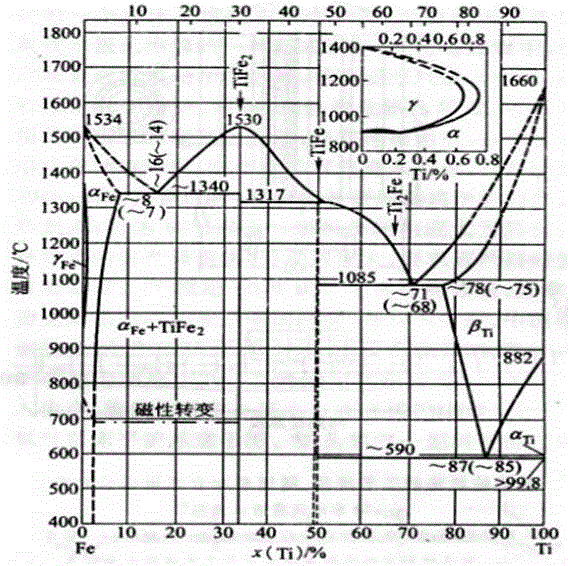

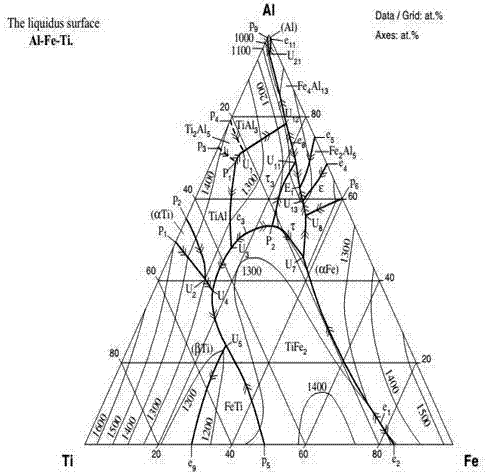

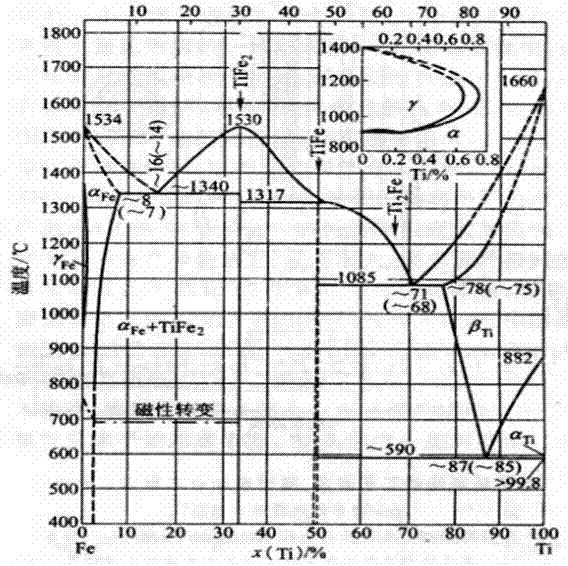

Production method of high-quality ferrotitanium by electric furnace remelting method of Panxi titanium raw material

The invention belongs to the field of ferrotitanium smelting and particularly relates to a production method of high-quality ferrotitanium by an electric furnace remelting method of a Panxi titanium raw material. The production method comprises the following steps: with 100Kg of raw materials including a Panxi-region titanium-rich material and a steel material as weight reference, adding auxiliary materials into the raw materials according to weight proportion; and smelting by an electric furnace remelting method to obtain a product of high-quality ferrotitanium in which the total impurity content is lower than 5%, wherein the raw materials include 30-90% of Panxi-region titanium-rich material and 10-70% of steel material, and the added auxiliary materials include 0.25-1.0Kg of aluminum reducing agent, 0.3-1.0Kg of auxiliary reducing agent and 1.0-1.5Kg of calcium metallurgy auxiliary material. In the invention, the source of raw materials is stable, the production technology is safe and reliable, the electric energy consumption is low, the ferrotitanium grade is high, the impurity content is low, a high-quality ferrotitanium product with stable quality is formed, and the production cost is reduced; and moreover, the industrialization of production by the ferrotitanium remelting method is realized, and the need of users for high-quality high-grade ferrotitanium is met.

Owner:攀枝花市银江金勇工贸有限责任公司

Production of Ferro-Titanium Alloy by Remelting Panxi Titanium Raw Material in Electric Furnace

The invention belongs to the field of ferrotitanium smelting and particularly relates to a production method of high-quality ferrotitanium by an electric furnace remelting method of a Panxi titanium raw material. The production method comprises the following steps: with 100Kg of raw materials including a Panxi-region titanium-rich material and a steel material as weight reference, adding auxiliary materials into the raw materials according to weight proportion; and smelting by an electric furnace remelting method to obtain a product of high-quality ferrotitanium in which the total impurity content is lower than 5%, wherein the raw materials include 30-90% of Panxi-region titanium-rich material and 10-70% of steel material, and the added auxiliary materials include 0.25-1.0Kg of aluminum reducing agent, 0.3-1.0Kg of auxiliary reducing agent and 1.0-1.5Kg of calcium metallurgy auxiliary material. In the invention, the source of raw materials is stable, the production technology is safe and reliable, the electric energy consumption is low, the ferrotitanium grade is high, the impurity content is low, a high-quality ferrotitanium product with stable quality is formed, and the production cost is reduced; and moreover, the industrialization of production by the ferrotitanium remelting method is realized, and the need of users for high-quality high-grade ferrotitanium is met.

Owner:攀枝花市银江金勇工贸有限责任公司

Method for preparing pharmaceutical intermediate 4(H) quinnazolidone

InactiveCN101899009BInhibition of the reverse reactionReduce volatilityOrganic chemistryNitrogenFormamide

The invention discloses a method for preparing pharmaceutical intermediate 4(H) quinnazolidone, which comprises the following steps of: dissolving ortho-aminobenzoic acid and formamide in an inert solvent of o-dichlorobenzene; performing heat preservation reaction by steps under the protection of nitrogen, namely performing intermolecular condensation reaction and then intramolecular cyclization reaction; meanwhile, removing water generated in the process of reaction in time by using a water knockout trap to ensure that the positive reaction is performed smoothly; and decoloring, crystallizing and drying to obtain an ultimate product, namely the 4(H) quinnazolidone, wherein the mass ratio of the o-dichlorobenzene to the ortho-aminobenzoic acid is 3.0-3.5:1; the molar ratio of the ortho-aminobenzoic acid to the formamide is 1:1; and when the heat preservation reaction is performed by steps, the heat is preserved at the temperature of 50+ / -2 DEG C for 1 hour, 80+ / -2 DEG C for 3 hours, 120+ / -2 DEG C for 4 hours and 140+ / -2 DEG C for 4 hours. The preparation method has the advantages of simple process, zero emission, energy conservation, environmental protection and capacity of ensuring the quality and the yield of the product.

Owner:JIANGSU HAOHUA FINE CHEM

Method for removing mercury and mercury-containing compounds from oxygen-enriched combustion flue gas, and adsorbent and preparation method thereof

InactiveCN108786392ASimple processEasy to operateGas treatmentOther chemical processesActivated carbonSorbent

The invention discloses a method for removing mercury and mercury-containing compounds from oxygen-enriched combustion flue gas. The method comprises the following steps: S01, acquiring combustion flue gas containing main components of CO2, H2O and O2, wherein the smoke contains 73%-97% of CO2, 1%-26% of H2O, 1%-5% of O2, and 0.02%-0.05 % of HCl in volume ratio; S02, transporting the recycled fluegas carrying activated carbon powder in the step S01 to a plasma reactor, and carrying out low temperature plasma treatment, so as to make the combustion flue gas components in a highly active atom or ionic state through plasma and form active functional groups on activated carbon to achieve adsorption and removal of mercury in the combustion flue gas; S03, delivering a mercury removal adsorbentto the mercury-containing combustion flue gas and attaching to a combustion flue gas filtering device, so as to form a fluidized bed for collecting and removing mercury and mercury compounds from thecombustion flue gas; and S04, updating the adsorbent on the fluidized bed, namely updating the mercury removal adsorbent on the filtering device every 120 minutes. The modified activated carbon is used for removing mercury and compounds from flue gas, and the mercury removal efficiency is high.

Owner:GUANGZHOU CR THERMOELECTRICITY CO LTD +1

A kind of method for improving the stability of silicone pressure-sensitive adhesive

The invention discloses a method for improving stability of an organosilicone pressure-sensitive adhesive. The method comprises steps as follows: step 1), removal of water and hydroxyl: a water and hydroxyl removal agent containing alpha-functional group siloxane compounds is added to a reaction system; step 2), thorough inactivation of a catalyst: inactivation is performed in the following two ways: a) when primary amine or secondary amine is used as a condensation polymerization catalyst, the adhesive reaction system is kept at the temperature of about 70 DEG C at the nitrogen reaction atmosphere, primary amine or secondary amine and aldehydes, ketones or low-level carboxylic acid react to generate Schiff base, generated unstable Schiff base reacts with diethyl malonate, and Schiff base becomes beta-amino acid without catalytic activity; b), when secondary amine or tertiary amine is used as a condensation polymerization catalyst, acidic compounds which can react with secondary amine or tertiary amine to generate a stable compound are added to the reaction system; step 3), residual acidic compounds are neutralized; step 4), residual small molecular substances are removed in the vacuum state.

Owner:ANHUI MINGXUN NEW MATERIAL TECH

Method for denitrating gas fume

ActiveCN101940878BReduce dosageEvenly distributedDispersed particle separationChemistrySelective catalytic reduction

The invention provides a method for denitrating gas fume. The method comprises the following steps of: contacting the gas fume with a denitrating agent under the condition of selective non catalyst reduction of the gas fume to obtain a first mixture; supplementing the denitrating agent and injecting a disturbing medium into the first mixture respectively to obtain a second mixture; and contactingthe second mixture with a catalyst under the condition of the selective catalyst reduction of the gas fume. The method can effectively solve the problem of high NOx content in the gas fume and completely denitrates the gas fume in the true sense by supplementing the denitrating agent and disturbing the denitrating agent and the gas fume between a selective non catalyst reduction process of the gas fume and another selective catalyst reduction process of the gas fume.

Owner:CHINA SHENHUA ENERGY CO LTD +2

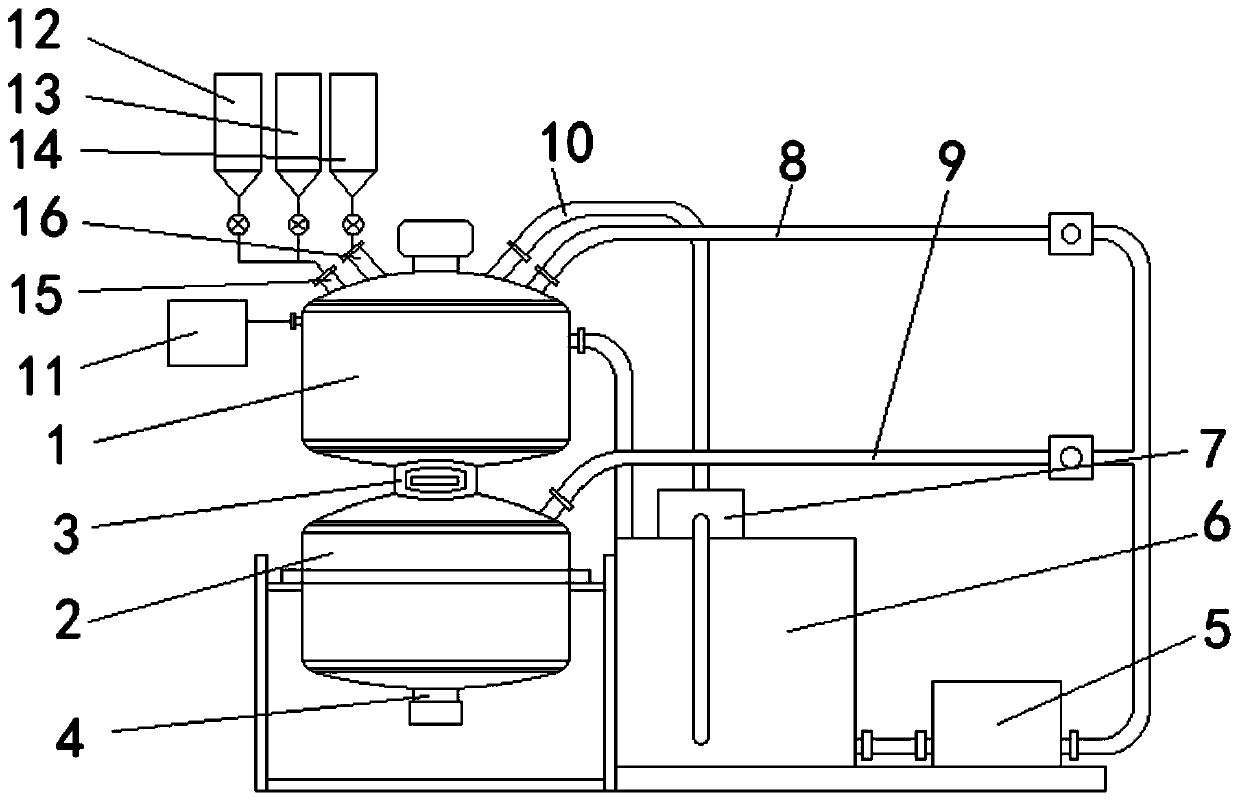

Methyl salicylate synthesis equipment and synthesis process thereof

PendingCN111408316APrevent volatilizationHigh yieldOrganic compound preparationCarboxylic acid esters preparationMethyl salicylateMethanol

The invention discloses methyl salicylate synthesis equipment which comprises a reaction kettle, a batching device for batching the reaction kettle, a dehydration device for reaction dehydration, anda support device for supporting the reaction kettle and the dehydration device, excessive methanol is added, and the pressure intensity is enhanced through a pressurizing device, so that volatilization of methanol is effectively inhibited, and the yield of methyl salicylate and the reaction rate of esterification reaction are increased; water generated by reaction in the first kettle body is reduced through continuous dehydration, and the effects of inhibiting reverse reaction of esterification reaction and improving the conversion rate of methyl salicylate are achieved by replacing addition of a water-carrying agent; the treatment device condenses and reflows methanol volatilized by the first kettle body, and when dehydration and methanol removal are performed in the second kettle body, the treatment device also condenses and reflows the volatilized methanol, so that the utilization rate of the methanol is increased.

Owner:ZHENJIANG GAOPENG PHARMA

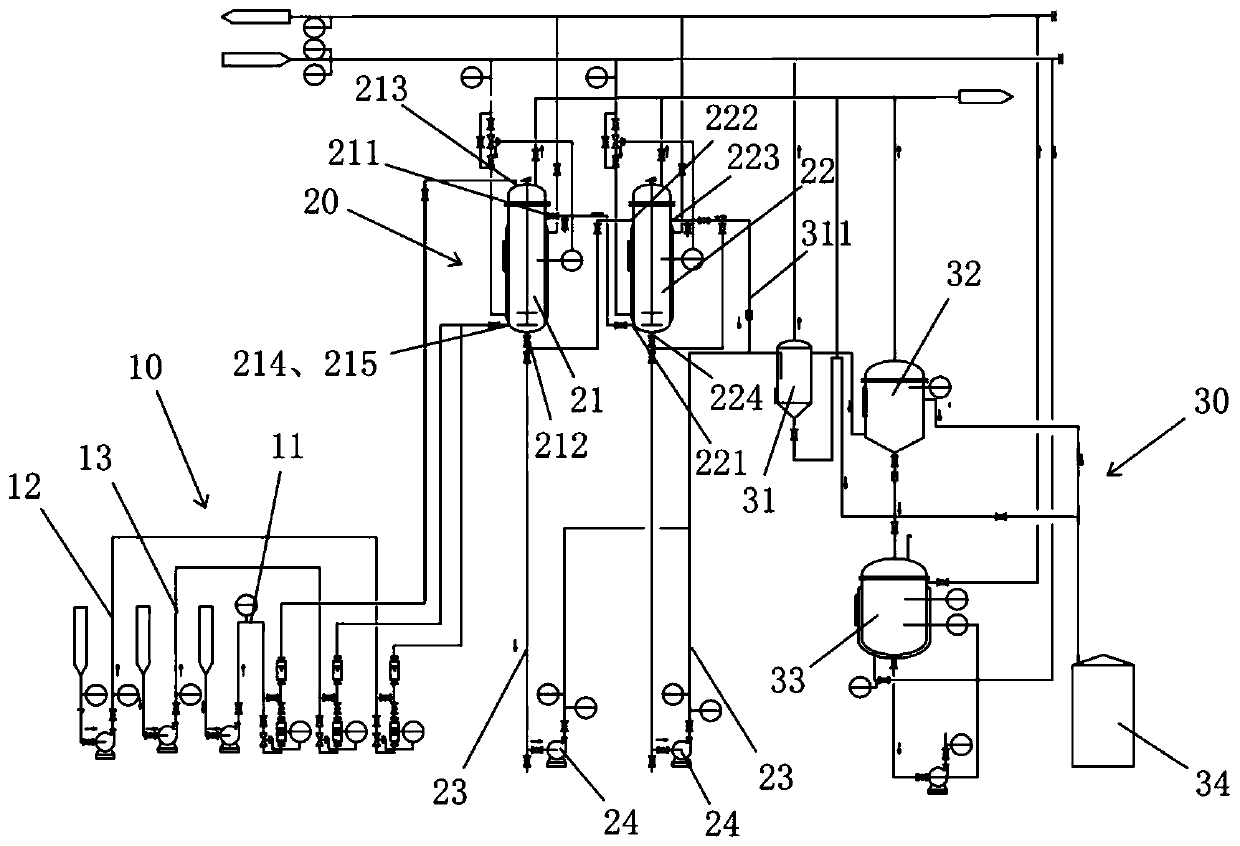

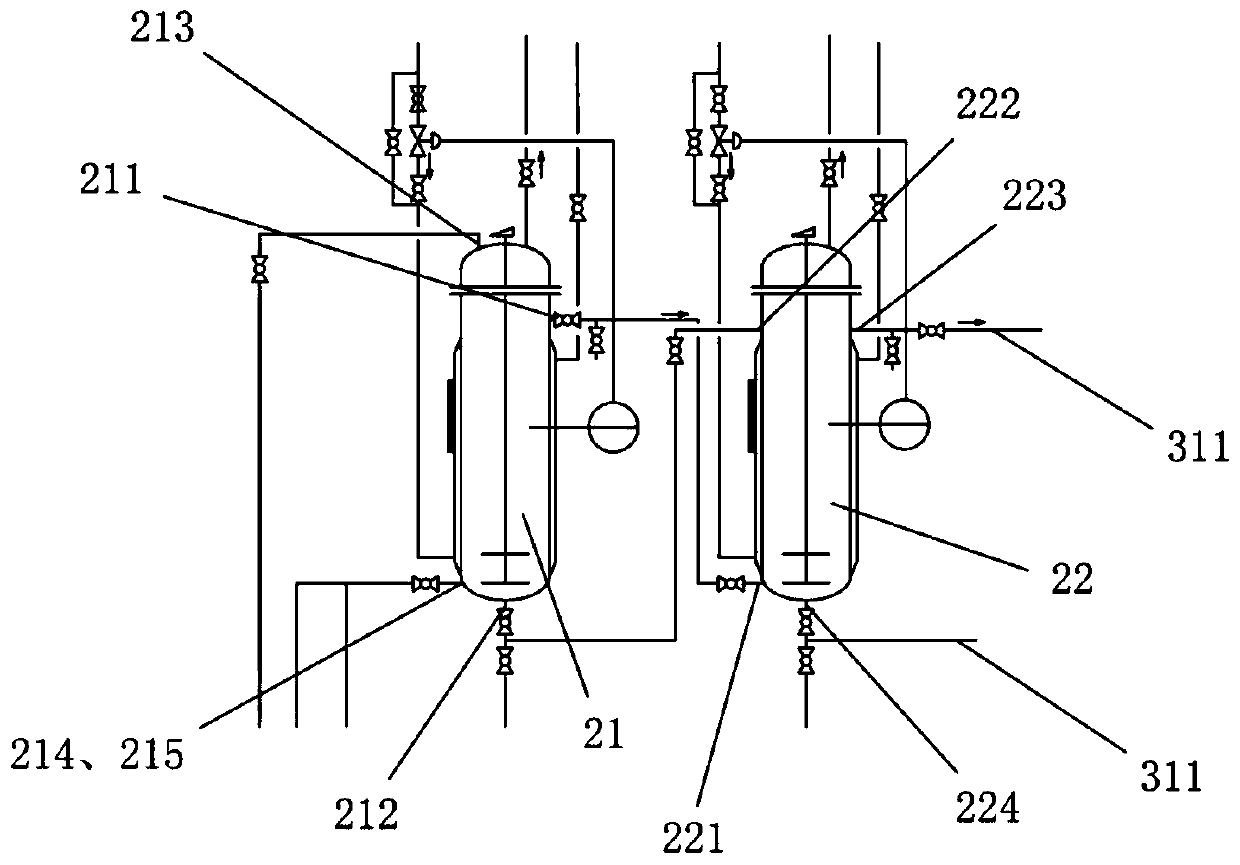

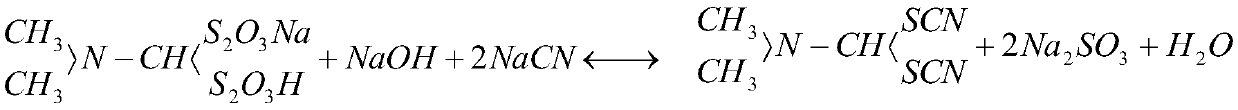

A kind of continuous production device and method of cartap intermediate thiocyanide

The invention discloses a continuous production device and method of a cartap intermediate thiocyanide. The continuous production device comprises a charging unit, a reacting unit and a postprocessingunit which are sequentially connected, wherein the reacting unit comprises a first-stage tubular reactor and a second-stage tubular reactor; a first-stage water phase outlet is formed in the upper part of the first-stage tubular reactor; a first-stage oil phase outlet is formed in the bottom of the first-stage tubular reactor; a second-stage water phase feeding opening is formed in the lower partof the second-stage tubular reactor; a second-stage oil phase feeding opening and a second-stage water phase outlet are formed in the upper part of the second-stage tubular reactor; a second-stage oil phase outlet is formed in the bottom of the second-stage tubular reactor; the first-stage water phase outlet communicates with the second-stage water phase feeding opening through a pipeline; and the first-stage oil phase outlet communicates with the second-stage oil phase feeding opening through a pipeline. Through the adoption of the continuous production device and the method disclosed by theinvention, the contact of sodium sulfite with the thiocyanide can be effectively reduced, a reverse reaction is restrained, and the reaction yield is increased.

Owner:HUNAN HAOHUA CHEM

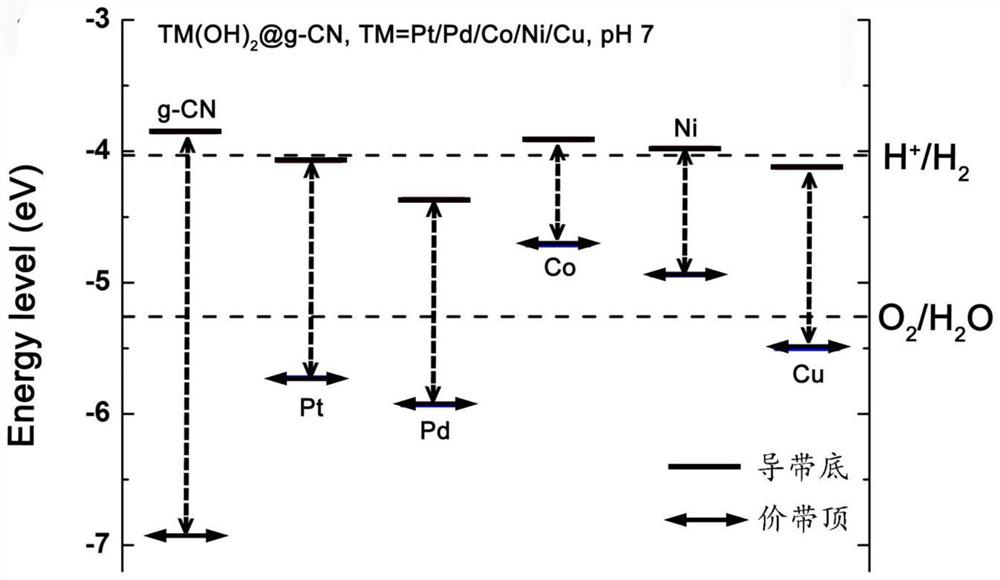

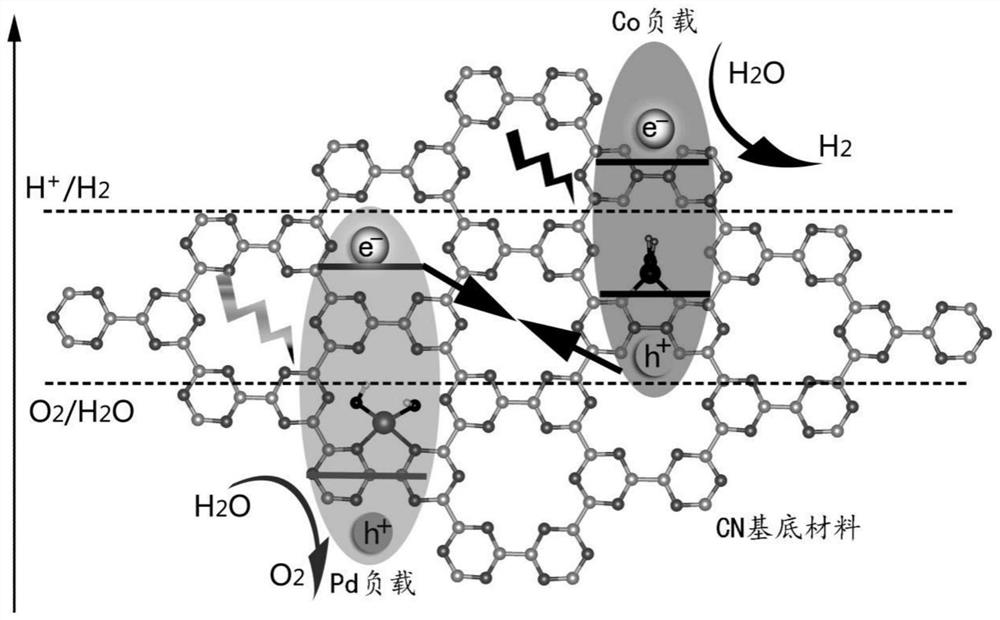

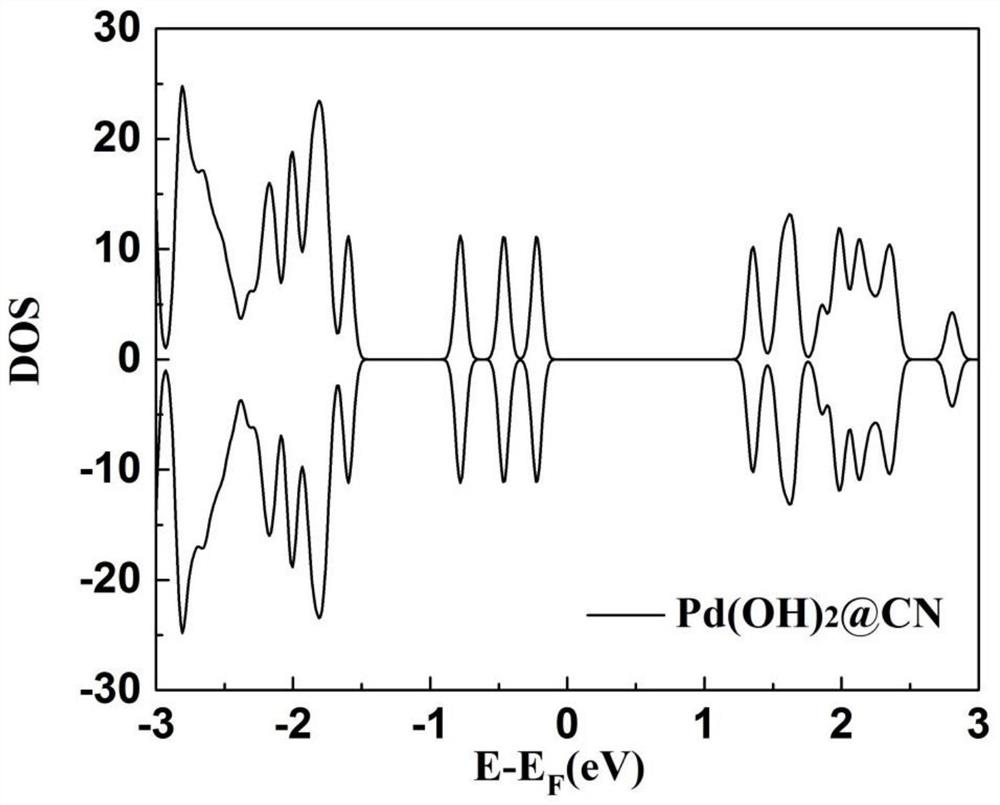

A kind of two-dimensional carbon-nitrogen-based composite material photocatalyst and its preparation method and application

ActiveCN109569693BEfficient use ofSolve the problem of difficult transmissionPhysical/chemical process catalystsHydrogen productionValence bandPtru catalyst

The invention discloses a two-dimensional carbon-nitrogen-based composite material photocatalyst and its preparation method and application, and relates to the technical field of photocatalytic materials. The two-dimensional carbon-nitrogen-based composite material is a two-dimensional carbon-nitrogen material loaded with transition metal elements The prepared two-dimensional carbon-nitrogen-based composite material can reduce the band gap to form a Z-scheme system, the top of the valence band is lower than the oxidation potential of water, and the bottom of the conduction band is higher than the reduction potential of water. In the present invention, electrons can be effectively transported inside the Z-scheme system composed of a two-dimensional carbon-nitrogen-based composite material photocatalyst, and the photocatalyst can simultaneously perform two reactions of hydrogen production and oxygen production on two reaction sites, and Since the band gap of the composite material is reduced after the transition metal ions are loaded, light energy in the visible range can be effectively utilized, and the problem of difficult transport of existing reactive electrons at the interface can be solved.

Owner:UNIV OF SCI & TECH OF CHINA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com