Photocatalytic full-water-splitting cocatalyst, photocatalyst and preparation method thereof

A photocatalyst and co-catalyst technology, applied in physical/chemical process catalysts, chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, etc., to achieve the effect of easy availability of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0030] Preparation of photocatalyst system:

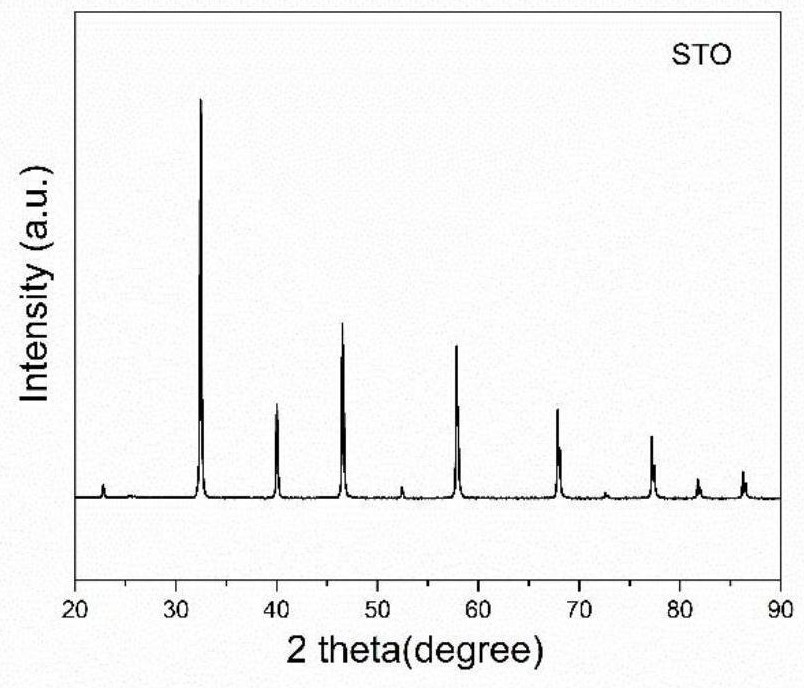

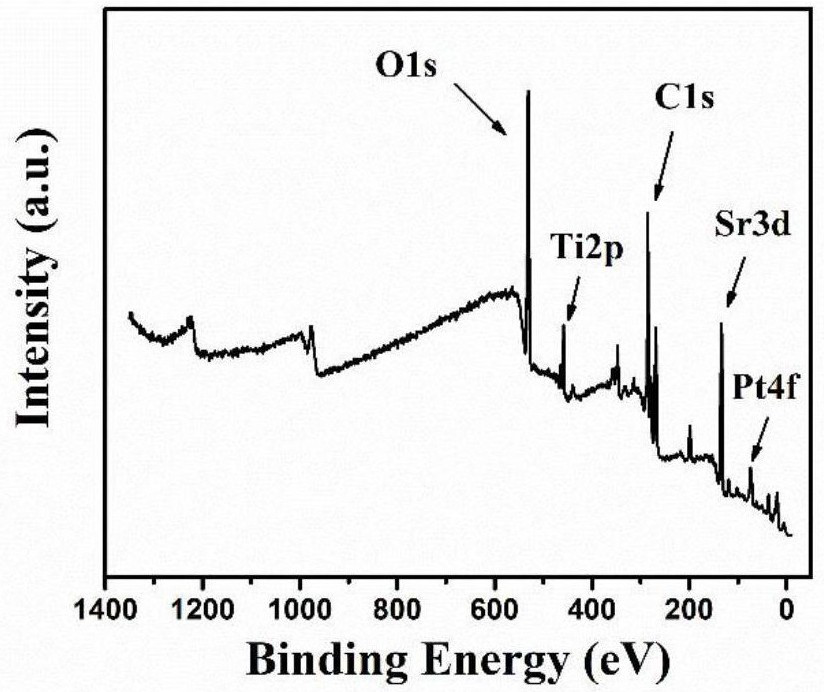

[0031] 1) Preparation of semiconductor powder photocatalyst: 2g of strontium titanate was weighed, and 30g of strontium chloride hexahydrate and 0.01g of nano-alumina were added thereto, and the mixture powder was added into an agate mortar and thoroughly ground. After mixing, the mixed powder was added to an alumina crucible with a capacity of 100 ml. The mixed powder was sintered in Tianjin Zhonghuan FURNACE 1600°C, model SX-G03163 energy-saving box-type electric furnace. The sintering condition is calcination at 1100°C for 10h in air. After the program is finished, the obtained powder is washed with water until no AgCl precipitation is detected with a silver nitrate solution, and dried overnight to obtain a strontium titanate semiconductor powder photocatalyst for use.

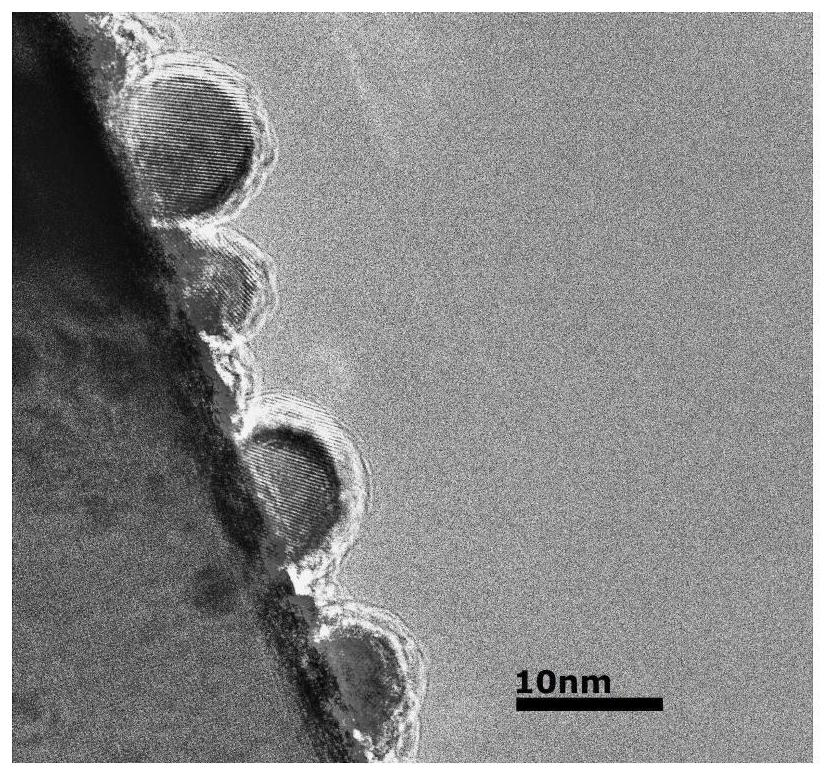

[0032] 2) Preparation of semiconductor powder photocatalyst loaded with platinum nanoparticles:

[0033] Prepared by impregnation method: according to the ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com