Method for continuously preparing glyceryl triacetate with phenyl phosphate biomimetic catalyst

A technology of glyceryl acetate and phenyl phosphate, which is applied in chemical instruments and methods, physical/chemical process catalysts, organic compounds/hydrides/coordination complex catalysts, etc., can solve the problem of low triacetin content, biodiesel Complicated components, high cost of ionic liquids, etc., to achieve the effects of low acidity, high yield, and good mass and heat transfer effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

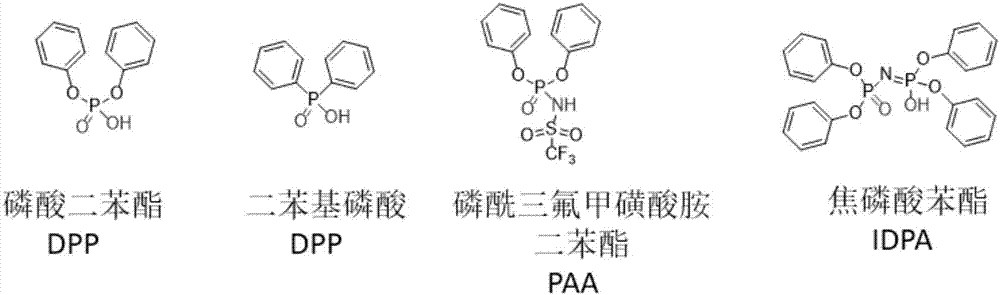

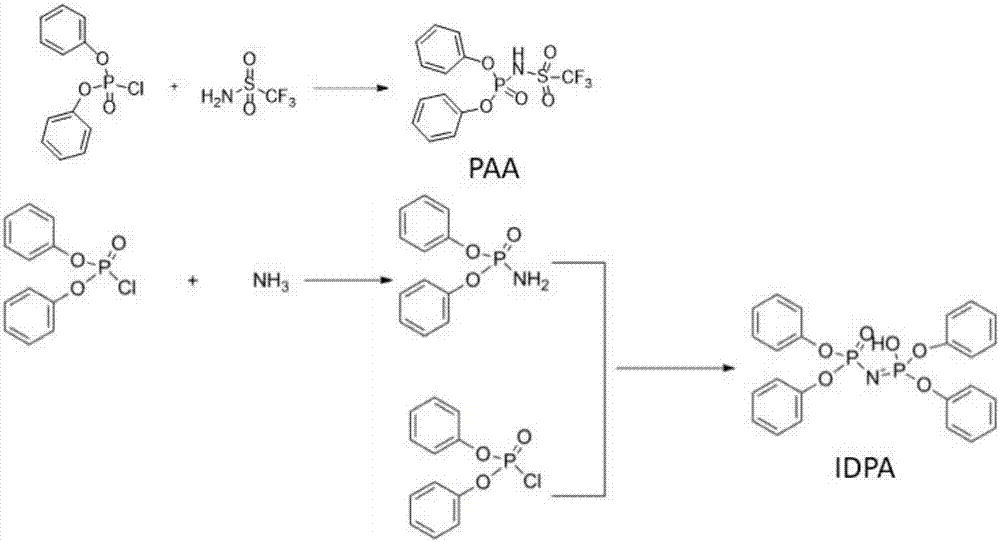

[0032] Preparation of phenyl phosphate biomimetic catalysts: diphenyl phosphate (DPP), diphenyl phosphoric acid (DPA) can be purchased from Aladdin reagents, and the preparation of diphenyl phosphoryl trifluoromethanesulfonate imide (PAA): In an anhydrous and oxygen-free environment, take 2 mmol of diphenyl chlorophosphate in a 50 ml flask, add 3 mmol of ammonium trifluoromethanesulfonate to it at -78°C, and react for 2 hours. After the reaction is completed, remove the cooling bath and vacuum the product Dry and purify by column chromatography (dichloromethane as eluent).

[0033] Preparation of pyrophosphoric acid catalyst (IDPA): first synthesize diphenyl ester phosphoramide, take 3 mmol of diphenyl chlorophosphate in a 50ml flask in an anhydrous and oxygen-free environment, pass ammonia gas into it at -78°C, and react for 2 hours , After the reaction, the cold bath was removed, the product was vacuum-dried, and purified by column chromatography to obtain the product (dichl...

Embodiment 2

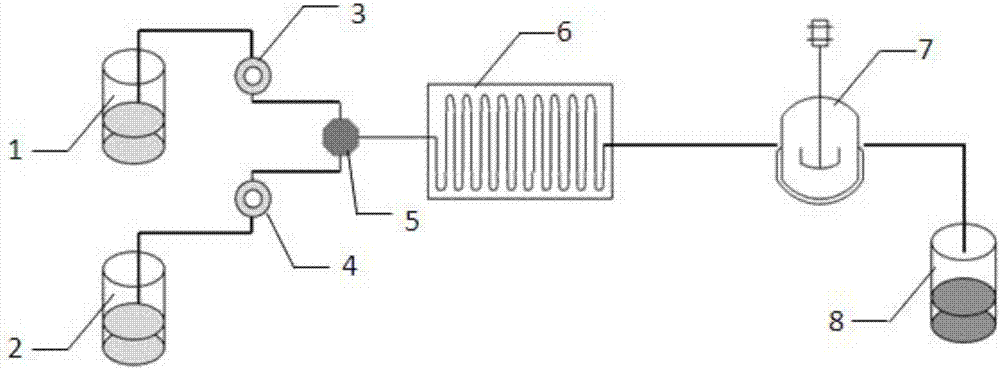

[0035] Configure 100ml of glycerol benzene solution of 4mol / L as material tank 1, configure 100ml of acetic acid solution of 12mol / L, 16mol / L, and 20mol / L respectively as material tank 2, and add bionic catalyst pyrophosphoric acid catalyst (IDPA) 0.4mol therein , the material tank 1 and the material tank 2 are pumped into the microchannel reactor according to the flow rate ratio of 1:1, and kept at 70°C for 30 minutes. After the reaction, the effluent is taken for liquid phase detection to determine the content of each component.

[0036] Table 1 Effect of acetic acid concentration on glycerol conversion and acetate selectivity in acylation reaction

[0037] Acetic acid concentration

Embodiment 3

[0039] 100ml of glycerol benzene solution of 4mol / L is configured as material tank 1, 100ml of acetic acid solution of 20mol / L is configured as material tank 2, and 0.4mol of biomimetic catalyst pyrophosphoric acid catalyst (IDPA) is added thereto, material tank 1 and material tank 2 according to Pump into the microchannel reactor at a flow rate ratio of 1:1, and retain at 60, 70, and 80°C for 30 minutes (Example 5, 6, 7). After the reaction, take the effluent for liquid phase detection to determine the content of each component.

[0040] Table 2 Effect of microchannel reactor temperature on glycerol conversion and acetate selectivity in acylation reaction

[0041]

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com