A kind of method for improving the stability of silicone pressure-sensitive adhesive

A silicone pressure-sensitive adhesive and stability technology, applied in the field of adhesives, can solve problems such as viscosity and other use performance slowly changing, unable to meet use requirements, unstable use performance, etc., to ensure stability and use. good performance, stable temperature resistance and storage performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

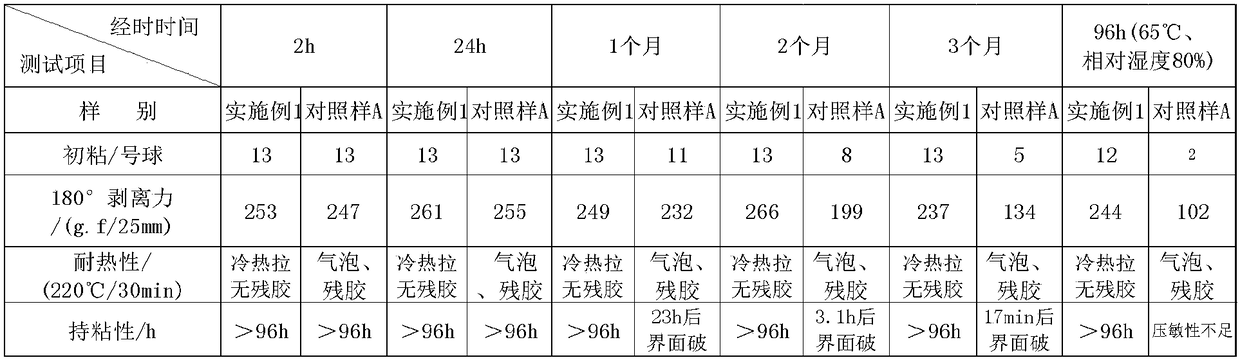

Embodiment 1

[0031] Step 1) polycondensation reaction

[0032]Put 100Kg of toluene and 200Kg of xylene into the reactor, add 500g of diethylamine, stir evenly, then add 300Kg of hydroxyl-terminated polydimethylsiloxane with a viscosity of about 6500mPa.s and 200Kg of nM / nQ MQ resin with Mn of 0.75 about 5000g / mol, Mw about 18000g / mol and hydroxyl content of about 3% was stirred for 30min under nitrogen protection, then heated to about 135°C and kept under reflux for a stable reaction of about 210min. During the reaction The generated water is continuously discharged through the Dean-Stark trap or U-shaped pipe trap;

[0033] Step 2) Dehydration and Residual Hydroxyl Removal

[0034] Lower the temperature in the reactor to about 45°C, and add 6Kg of NH to the reactor while stirring 2 (CH 2 ) 6 NHCH 2 -Si(CH 3 ) 2 -OCH 2 CH 3 , stirring and reacting for more than 90 minutes, then heating up to about 70°C, and starting to deactivate the polycondensation catalyst;

[0035] Step 3) Ca...

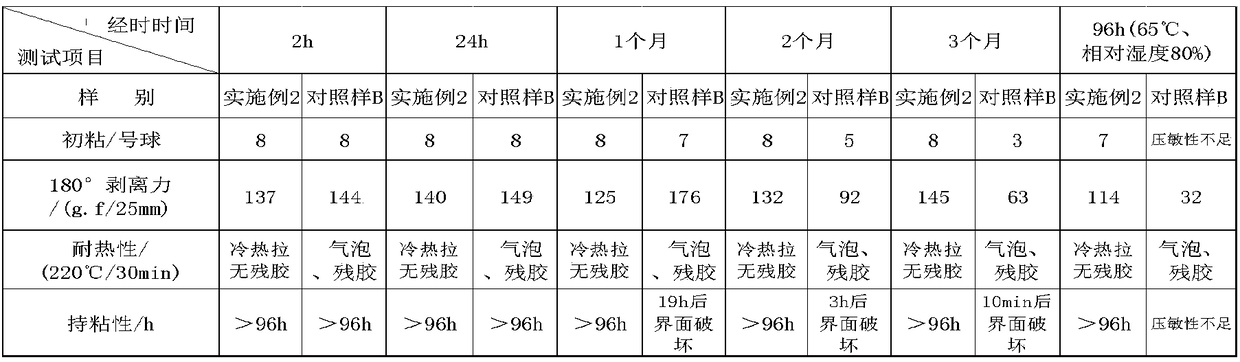

Embodiment 2

[0046] Step 1) polycondensation reaction

[0047] Put 100Kg of toluene and 200Kg of xylene into the reactor, add 500g of triethylamine, stir evenly, then add 200Kg of hydroxyl-terminated polydimethylsiloxane with a viscosity of about 7000mPa.s and 300Kg of nM / nQ MQ resin with Mn of 0.80 about 5000g / mol, Mw about 18000g / mol and hydroxyl content of about 3% was stirred for 30min under nitrogen protection, then heated to about 135°C and kept under reflux for a stable reaction of about 210min. During the reaction The generated water is continuously discharged through the Dean-Stark trap or U-shaped pipe trap;

[0048] Step 2) remove water and remove hydroxyl

[0049] Keep the temperature in the reactor at 40°C to 45°C, add 6.5Kg of (CH 3 CH 2 ) 2 N-CH 2 -Si(CH 3 ) 2 -OCH 2 CH 3 , stirred for more than 90 minutes, then raised the temperature to about 70°C, and started to deactivate the polycondensation catalyst;

[0050] Step 3) Catalyst deactivation treatment

[0051] K...

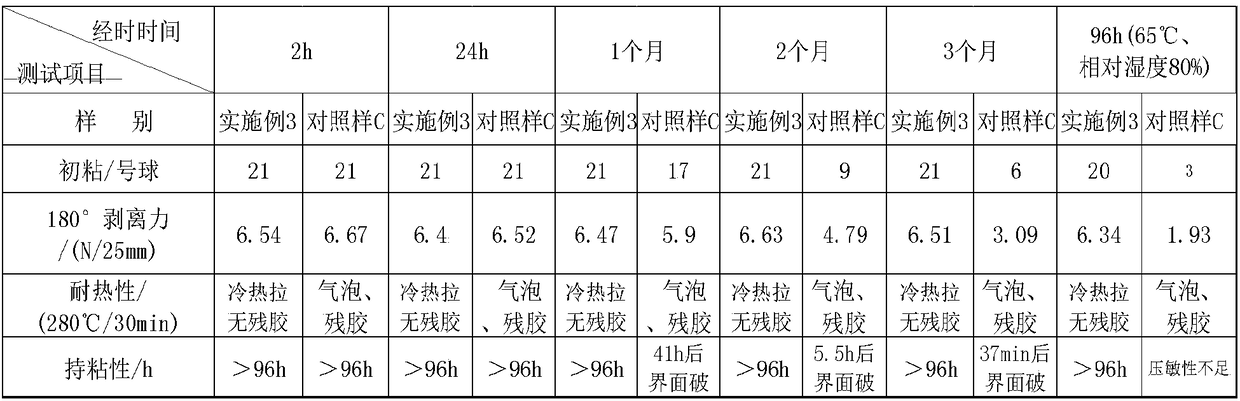

Embodiment 3

[0060] Embodiment 3 (improves the stability of finished product silicone pressure-sensitive adhesive)

[0061] Step 1) remove water and remove hydroxyl

[0062] Put 1000Kg of a domestically produced silicone pressure-sensitive adhesive in the reactor, and add 10.0Kg of CH 3 (CH 2 ) 3 N-CH 2 -Si(CH 3 ) 2 -OCH 3 , then heat up to about 40°C and continue to stir for more than 90min;

[0063] Step 2) Catalyst deactivation treatment

[0064] Keep the adhesive reaction system at about 70°C under a nitrogen reaction atmosphere, add 5% HCl ether solution containing 5.0Kg of pure HCl to the reaction kettle under stirring, and continue stirring for 90 minutes;

[0065] Step 3) Neutralize the remaining acidic substances in the adhesive: After step 2) is completed, reduce the temperature of the reactor to below 50°C, and then gradually add the toluene dispersion containing 5% sodium isopropoxide until the adhesive is detected by sampling. The viscous system is neutral, continue t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com