An optical fiber annealing tube and its preparation process

A preparation process and technology for annealing tubes, which are applied in the field of optical fiber production, can solve problems such as poor performance of annealing tubes and affect the production efficiency and quality of optical fiber drawing, and achieve the effects of excellent performance, uniform density, and guaranteed purity and strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

[0049] The preparation steps of the coke primary powder in this preparation example are as follows: calcining 120 kg of coke at 1200° C. for 22 days, and pulverizing it after cooling to obtain a coke primary powder with a D50 of 10 μm.

preparation example 2

[0051] The preparation raw materials of the polymethacrylic acid diethanolamine salt of this preparation example include 2 kg of sodium bisulfite, 50 kg of water, 0.05 kg of potassium persulfate, 5 kg of methacrylic acid and diethanolamine.

[0052] The preparation steps of the polymethacrylic acid diethanolamine salt of this preparation example are:

[0053] S1, 2kg sodium bisulfite is added to 30kg water, stirred until completely dissolved;

[0054] S2, heating the oil bath of the solution in step S1 and keeping it at 70°C;

[0055] S3, 0.05kg potassium persulfate, 20kg water and 5kg methacrylic acid are successively added dropwise to the solution obtained by step S2, respectively, and the reaction is incubated for 3h;

[0056] S4, cooling the mixed solution obtained in step S3 to 30° C., adding diethanolamine to adjust the pH to 9 to obtain a neutralized solution;

[0057] S5, the neutralization liquid obtained in step S4 is distilled under reduced pressure to obtain poly...

Embodiment 1

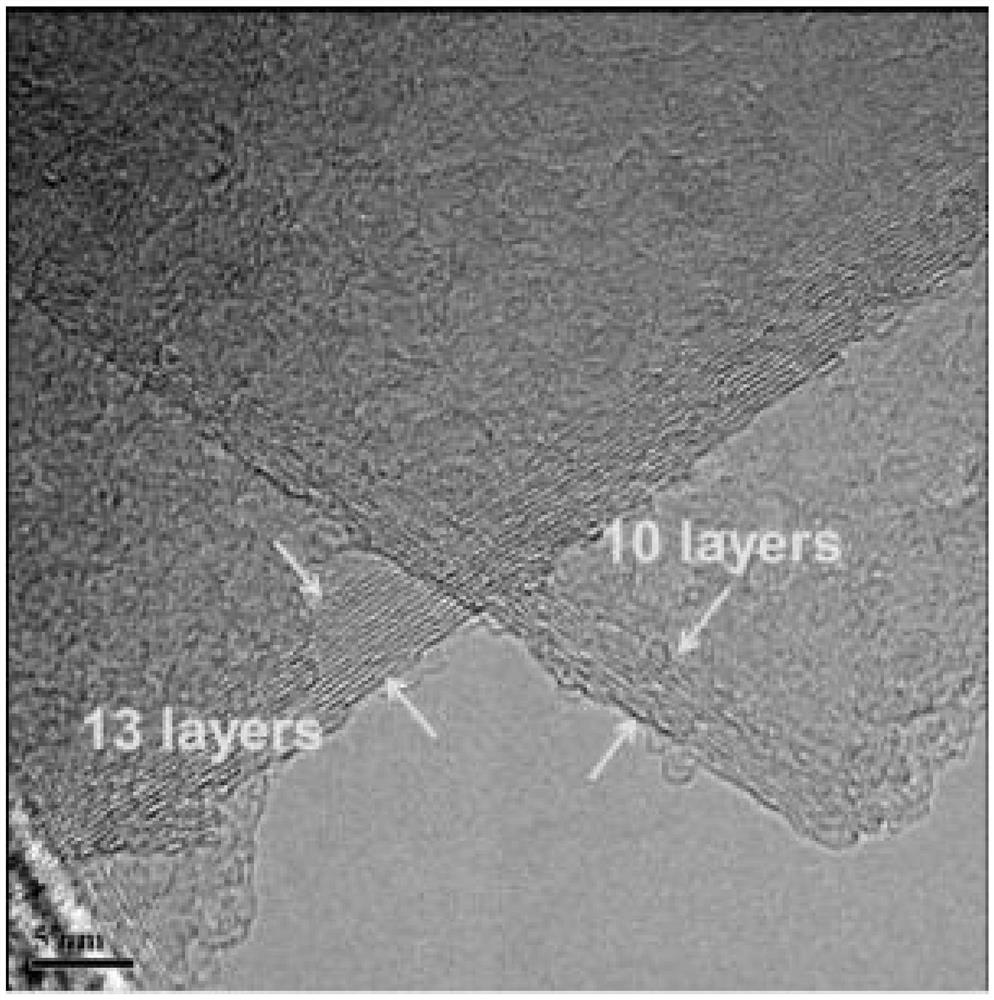

[0060] The graphene microflake powder used in this example is graphene prepared by physical methods, purchased from Shenzhen Xinchanglong New Materials Research Institute Co., Ltd., D50 is 6.84 μm, from figure 1It can be seen that the number of layers of graphene microflake powder used in this example is about 10 layers; the high-temperature asphalt is granular high-temperature asphalt purchased from Zhenjiang Xinguang New Material Technology Co., Ltd., and the softening point is 120 ° C.

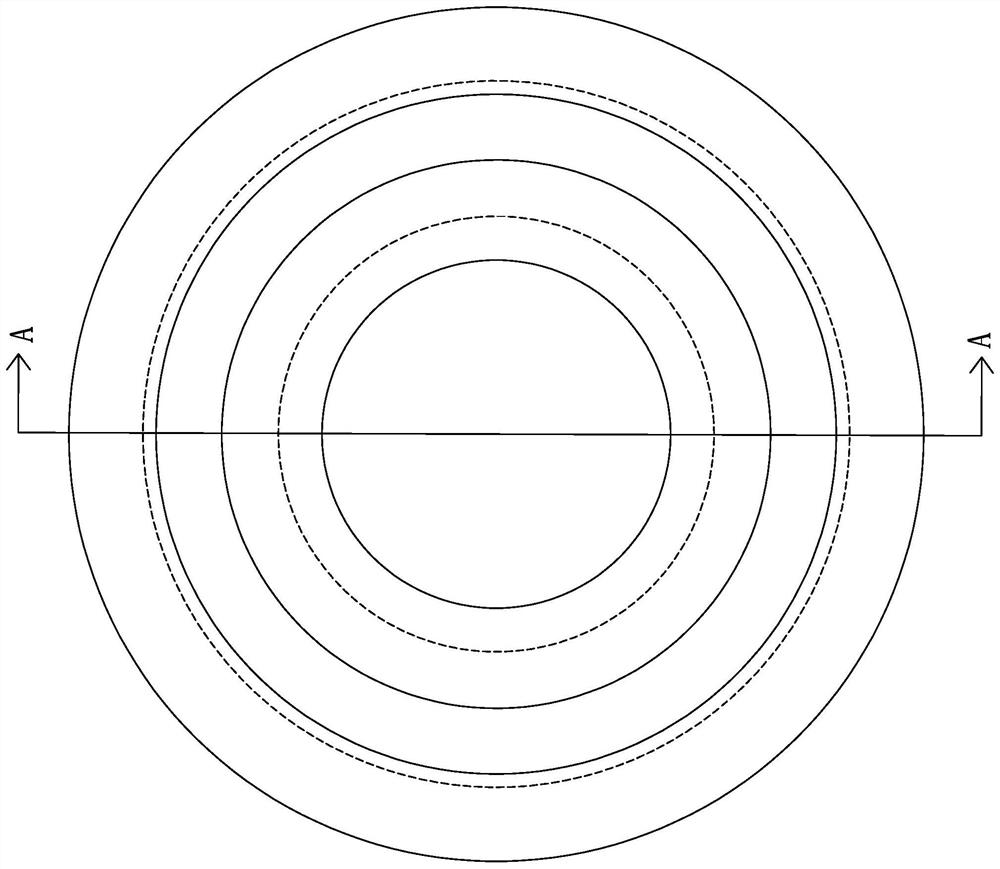

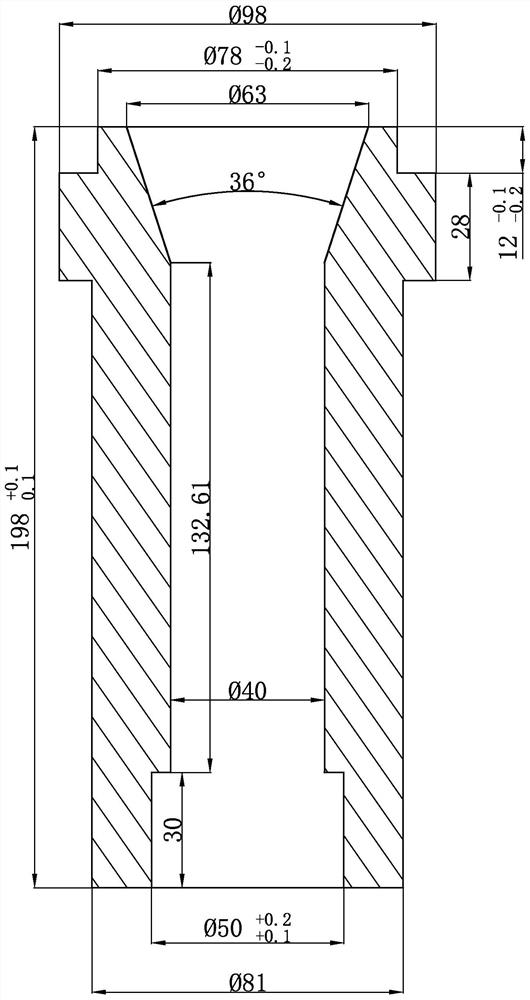

[0061] The shape and size of the annealed tube produced in this example are as follows: figure 2 and image 3 shown, its dimensions are in mm.

[0062] The preparation raw materials of an optical fiber annealing tube in this embodiment are 80 kg of coke primary powder prepared in Preparation Example 1, 10 kg of high-temperature pitch and 10 kg of graphene flake powder.

[0063] The preparation steps of an optical fiber annealing tube in this embodiment are:

[0064] S1. Dry mixing the c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com