Gas well reservoir water block removing agent and preparation method thereof

A technology for dehydrating water lock agent and reservoir, applied in chemical instruments and methods, drilling composition and other directions, can solve the problems of unstable production, low production, and shale gas wells unable to rely on their own energy to maintain production, etc., to improve effective penetration. rate, the ability to improve the flow, the effect of improving the conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

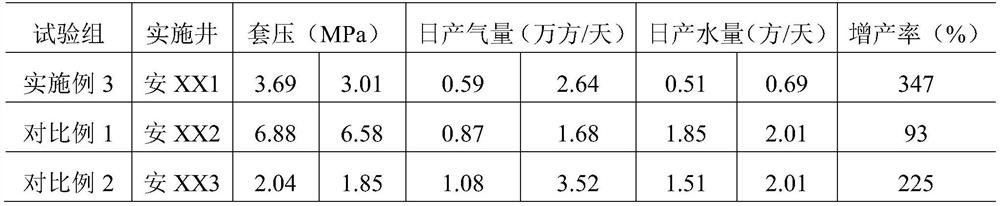

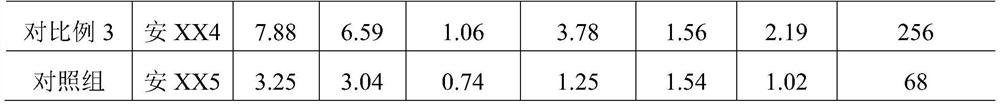

Examples

Embodiment 1

[0027] The gas well reservoir water-blocking agent is composed of the following raw materials in mass fraction: cetyltrimethylammonium bromide 30%, coconut oil fatty acid diethanolamide 20%, limonene 20%, fumed silica 5%, dimethyl carbonate Esters 25%.

[0028] The preparation method of the gas well reservoir dewatering and locking agent of this embodiment is to mix cetyltrimethylammonium bromide, coconut oil fatty acid diethanolamide, limonene, fumed silica, and dimethyl carbonate uniformly.

Embodiment 2

[0030] The water-blocking agent for gas well reservoirs is composed of the following raw materials in mass fractions: octadecyl dimethyl benzyl ammonium chloride 28%, Tween 20 23%, limonene 18%, fumed silica 4%, dimethyl carbonate 27%.

[0031] The preparation method of the gas well reservoir dewatering and locking agent in this embodiment is to mix octadecyldimethylbenzyl ammonium chloride, Tween 20, limonene, fumed silica, and dimethyl carbonate uniformly.

Embodiment 3

[0033] The water-blocking agent for gas well reservoirs is composed of the following raw materials in mass fractions: 25% polyacrylamide, 22% octanol polyoxyethylene ether, 17% limonene, 3% fumed silica, and 33% dimethyl carbonate.

[0034] The preparation method of the dehydration and locking agent for the gas well reservoir in this embodiment consists in uniformly mixing polyacrylamide, octanol polyoxyethylene ether, limonene, fumed silica, and dimethyl carbonate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com