Patents

Literature

51results about How to "Viscous stability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Non-cured rubber asphalt waterproof paint

InactiveCN104119799AWill not harmCompletely sealed and waterproofUnspecified rubber coatingsConjugated diene hydrocarbon coatingsBituminous waterproofingPolymer science

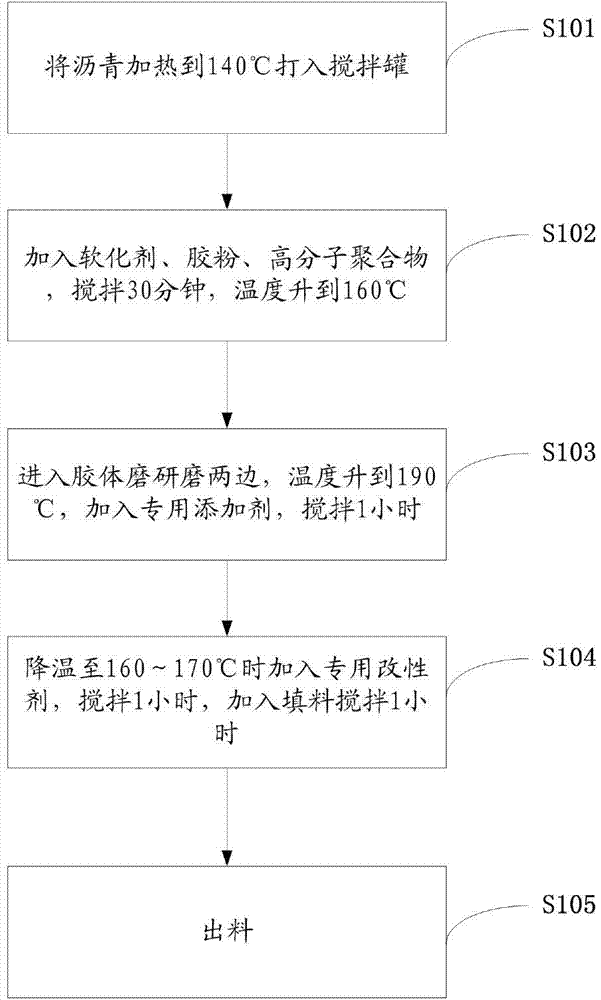

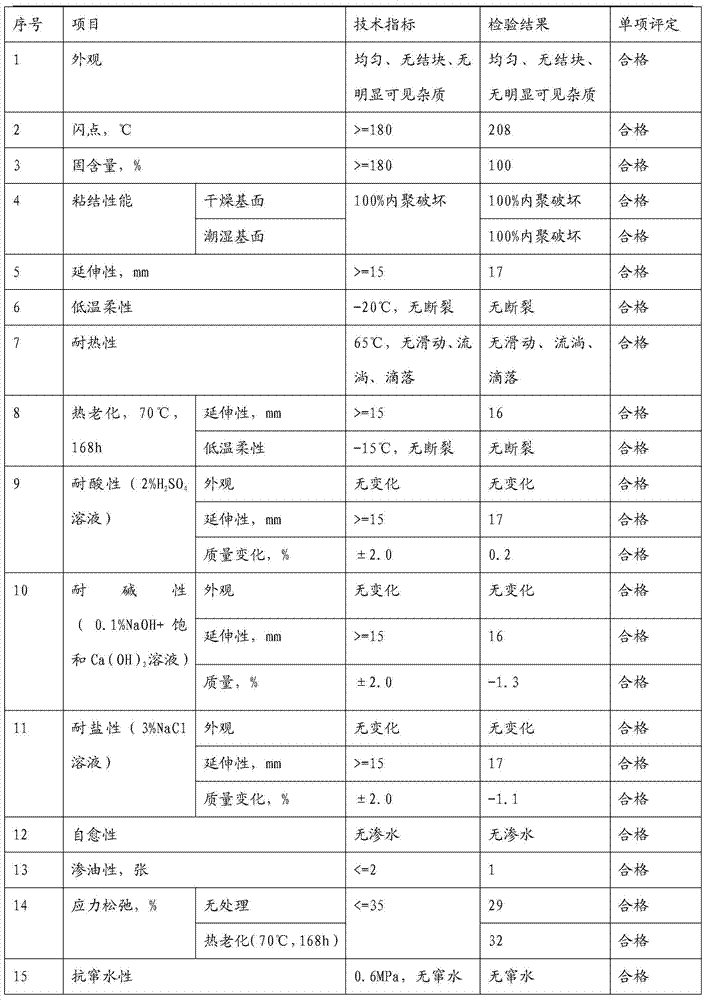

The invention discloses a non-cured rubber asphalt waterproof paint. The preparation technology of the paint comprises the following steps: heating the asphalt to 140 DEG C, loading the heated asphalt into a stirring tank, adding a softening agent, rubber powder, and polymer, stirring for 30 minutes, heating to 160 DEG C, delivering the mixture to a colloid mill to grind the two edges, heating to 190 DEG C, adding a special additive, stirring for one hour, cooling to 160 to 170 DEG C, adding an auxiliary agent, stirring for one hour, adding a filling material, stirring for one hour, and finally discharging. The paint solves the problems of waterproof layer fracture due to the cracking stress, which is transferred from the basic layer to the waterproof layer, and the accelerated aging due to the flexural fatigue and high stress state of the waterproof layer. Moreover, because of the cohesiveness of the paint, the capillary pores and cracks in the basic layer can be perfectly sealed by the paint, thus the problem of water leaking in the waterproof layer is solved, and the waterproof reliability is greatly improved.

Owner:徐立

Preparation method of ball clay for high-grade sanitary appliance

InactiveCN101844913AWhiteness stabilityHigh strengthCeramic materials productionClaywaresSocial benefitsLower grade

The invention relates to a preparation method of ball clay for high-grade sanitary appliance, which is characterized in that blackmud, plaster and kaolin are used as raw materials for preparing ball clay used by the high-grade sanitary appliance; the size comprises according to the percentage by volume: 10-60% of blackmud, 10-20% of plaster and 20-80% of kaolin; the preparation method overcomes the defect which is brought about by changeable raw material components caused by organic impurity and sand contents of low-grade ball clay; the formed ball clay has stable whiteness, intensity and stickiness and good slip-casting mobility, can be widely applied to high-grade ceramic industries and is the vanguard and demonstration in the process of national ceramic raw material standardizing, and has obvious economic benefic and social benefit.

Owner:广州市花都区梯面金鹏高岭土原料厂 +1

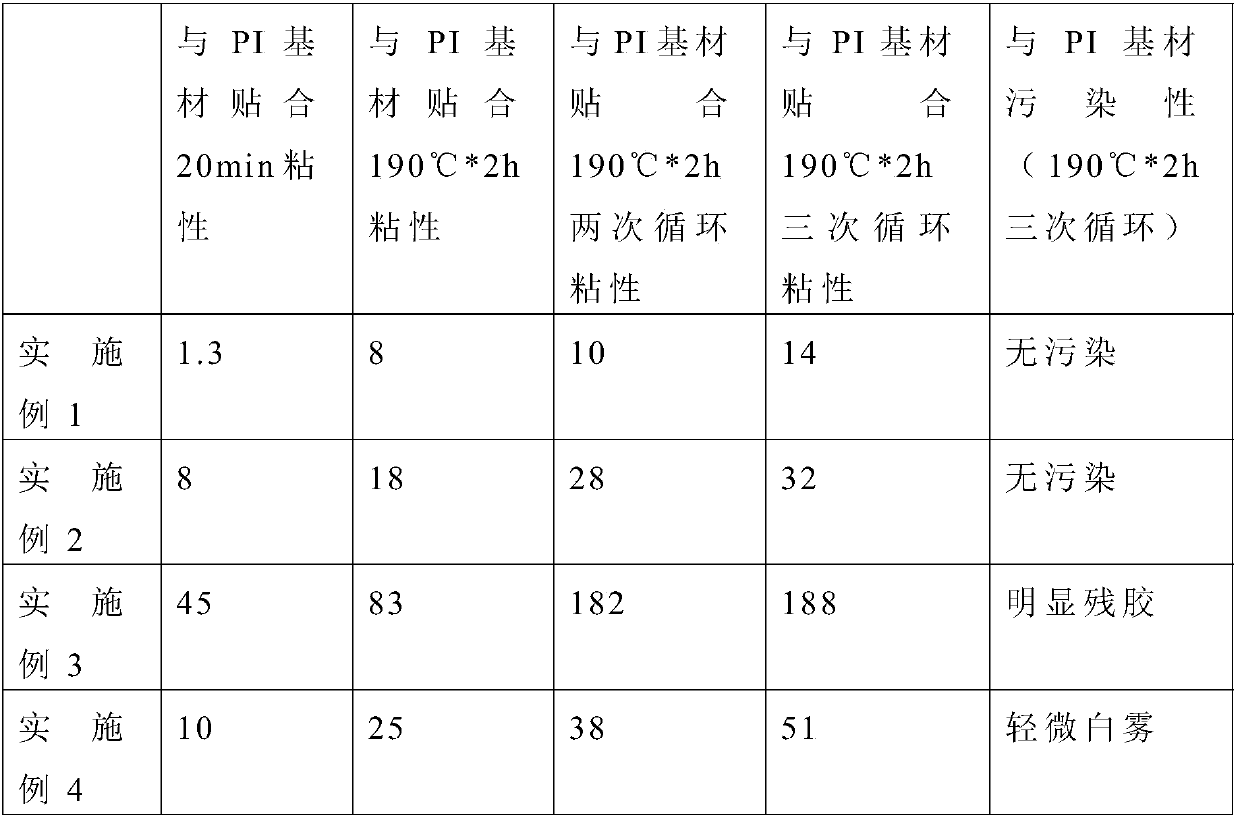

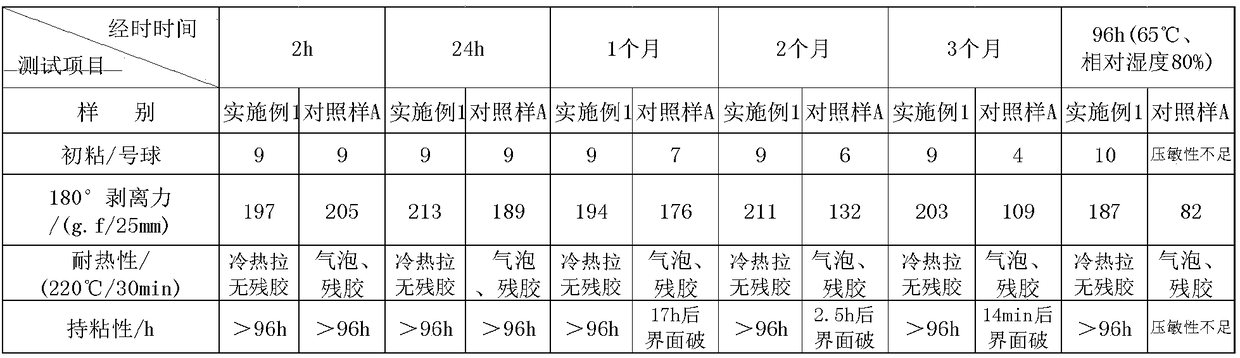

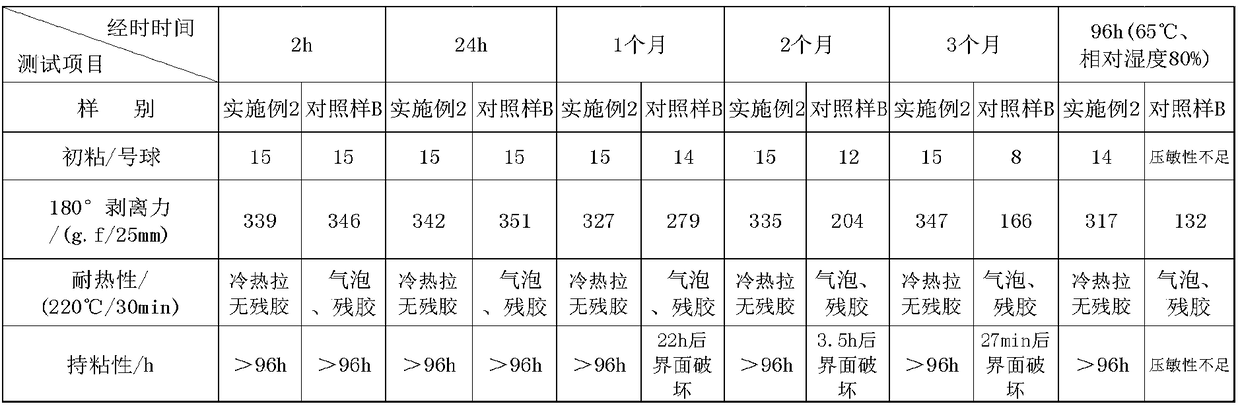

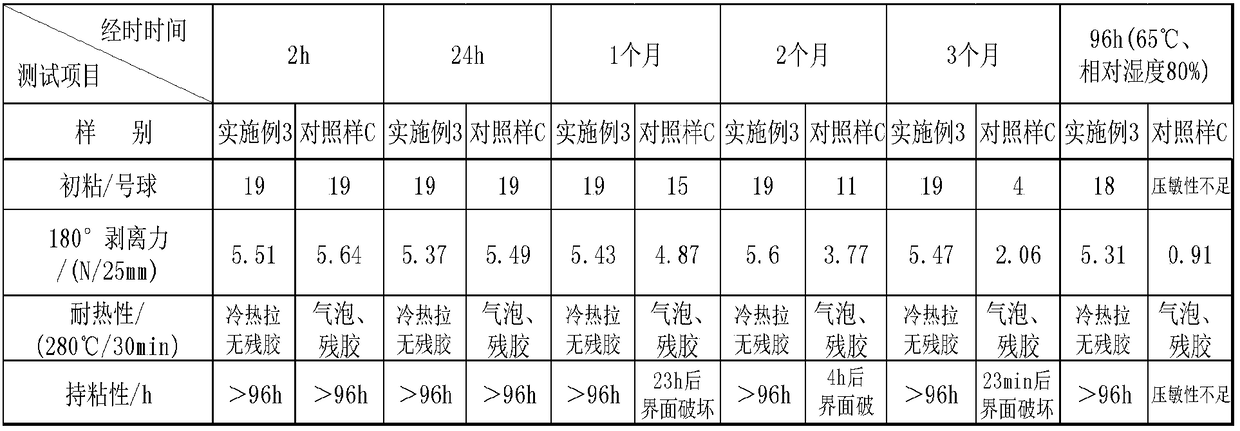

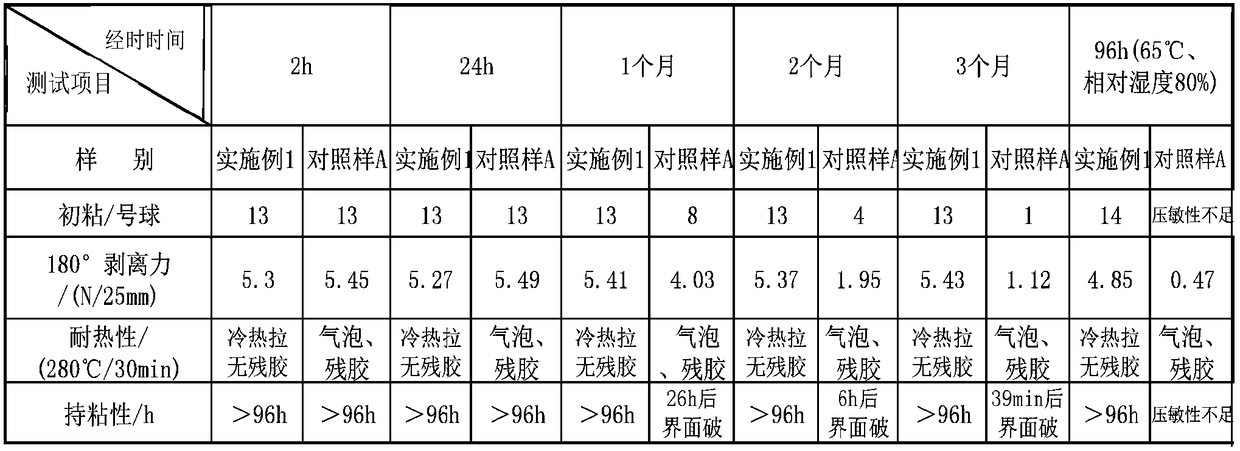

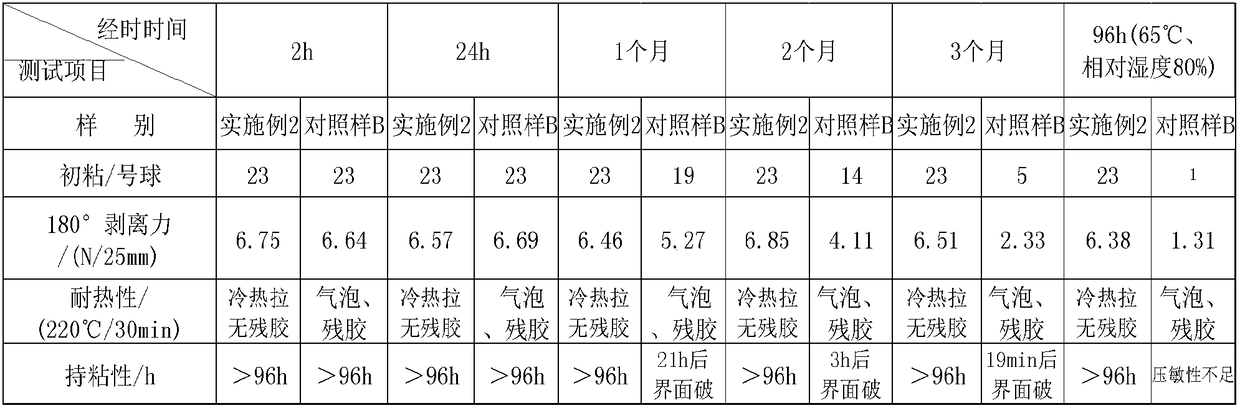

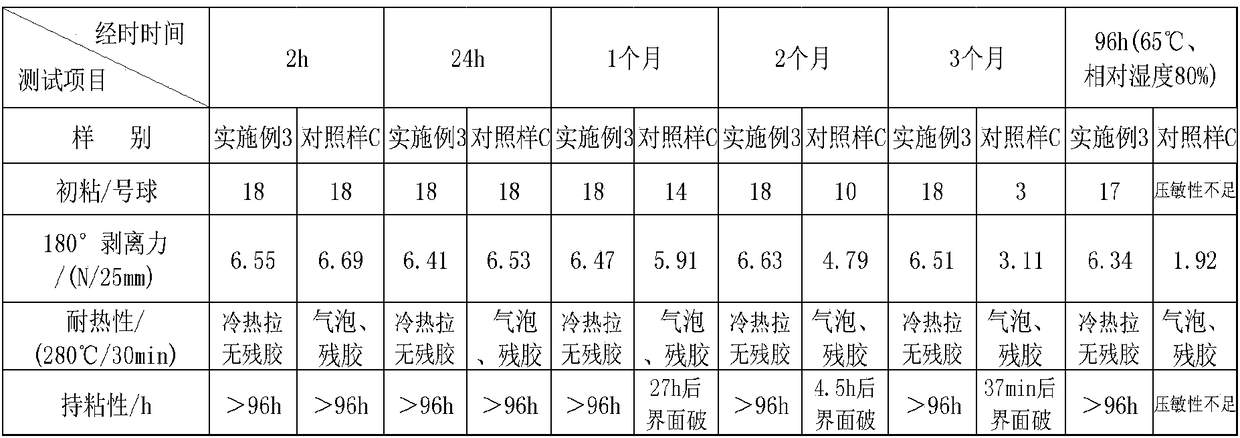

A pressure-sensitive adhesive tape capable of reducing viscosity through thermal expansion and a preparing method thereof

InactiveCN106566428ASolving Consistency IssuesSolve regularityNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesElectric capacityThermal expansion

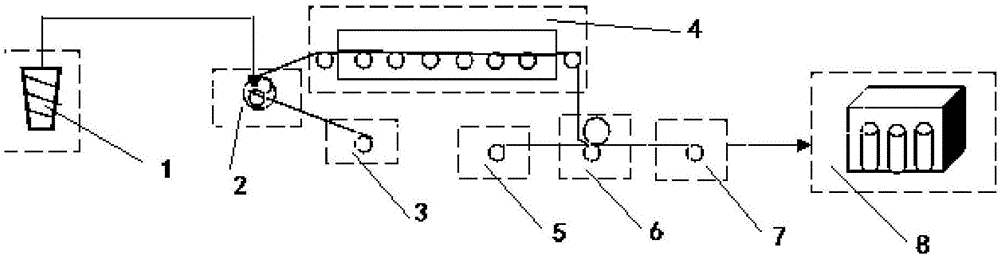

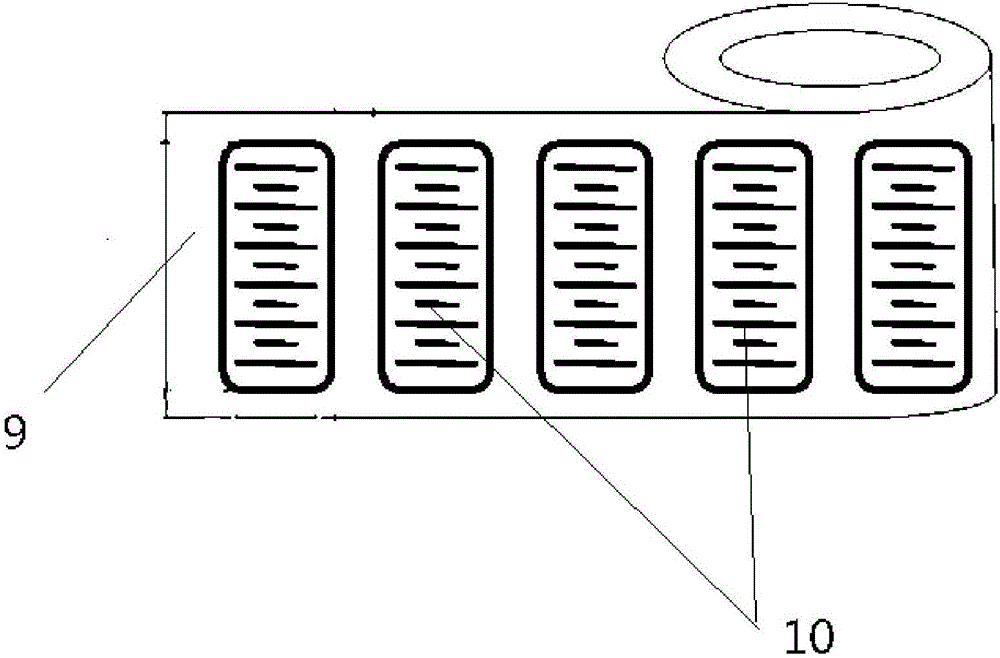

A pressure-sensitive adhesive tape capable of reducing viscosity through thermal expansion and a preparing method thereof are provided. The adhesive tape is prepared from 1) 40.4-66% by mass of a pressure-sensitive adhesive, 2) 15.5-33.5% of a thermosensitive expansive type polymer material, 3) 0.8-1.6% of a crosslinking agent, 4) 2.7-4.5% of an inorganic filler and 5) 15-20% of an organic solvent. The adhesive tape has stable viscosity at room temperature, the viscosity is reduced after high-temperature roasting, and the adhesive tape is free of residual adhesive and free of pollution to an adhered object and is convenient to clean. The adhesive tape is prepared through die cutting, and curving direction uniformity and regularity after the adhesive tape is heated and expanded are overcome. The adhesive tape is used for continuous coating of lithium battery cathode and anode slurry, the production efficiency is greatly increased, electric capacity of lithium batteries is greatly increased and battery space is reduced.

Owner:DONGGUAN AOZON ELECTRONICS MATERIAL

Integrated envelope and repositionable note

Owner:MAILAGAIN

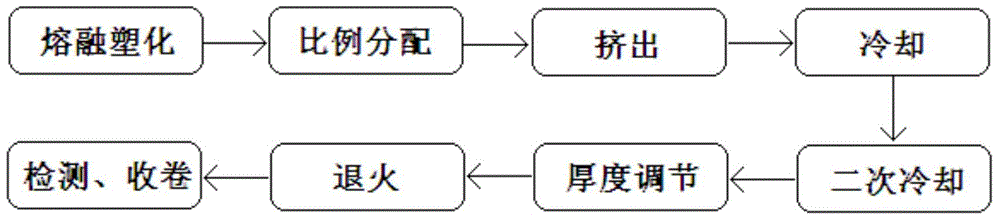

Production technology for high-viscosity CPP self-sticking protection film

InactiveCN105128496AViscous stabilityImprove flatnessLaminationLamination apparatusBlack pointDistributor

The invention relates to a production technology for a high-viscosity CPP self-sticking protection film. The production technology includes the steps that firstly, a sticking-resisting layer raw material, a base layer raw material and a sticking layer raw material are added into a single screw extruder to be melted and plasticized, and the raw materials are filtered through a filter and then conveyed into a distributor to be subjected to interlayer proportional distribution; secondly, melts of the three layers of raw materials are conveyed to a die head to be evenly distributed and plasticized and are then extruded through a die lip, and the melts make contact with a main cooling roller to be cooled; thirdly, an obtained cast film is secondarily cooled through an auxiliary cooling roller, and then thickness adjustment is conducted; fourthly, annealing processing is conducted, flaw detection is conducted, and rolling is conducted. The production technology is simple in design, the operation efficiency is high, losses are small, the stability of the product quality is good, and cost is low. By means of the production technology, the prepared high-viscosity CPP self-sticking protection film can have extremely-low shrinkage, the flatness of a film body is good, viscosity is stable, and rolling and unrolling are convenient. In addition, the transparency of the product can be effectively improved, and the occurrence of problems of fish eyes, crystal points, black points, impurities and the like on the film body is inhibited.

Owner:昆山金华安电子科技有限公司

Backing-paper-free double-layer logistics label

InactiveCN104575254AViscous stabilityEasy to recycleStampsIdentification meansLogistics managementPulp and paper industry

The invention discloses a backing-paper-free double-layer logistics label. The backing-paper-free double-layer logistics label comprises a surface paper layer and a backing paper layer which are arranged from top to bottom in a sequence; a signature recovery copy which can be individually torn down is embedded into the surface paper layer; an adhesive layer is arranged on the lower surface beside the surface with the signature recovery copy, of the surface paper layer; the die cutting lines are arranged about an area under the signature recovery copy, of the backing paper layer; when the backing paper layer is torn down, part of backing paper in the die cutting line can be adhered to the lower surface of the surface paper layer. The backing-paper-free double-layer logistics label has the beneficial effects that the effect of a three-layer material label can be achieved by the double-layer material label; the adhering is stable; the recovery and printing are convenient; the preparation cost is relatively low; the low carbon and environmental protection are achieved; the backing-paper-free double-layer logistics label has a good market prospect.

Owner:上海正伟印刷有限公司

Micro-adhesion protection film, preparation method and applications thereof

InactiveCN109554138ANo problems with silicon transferViscous stabilityOrganic non-macromolecular adhesivePressure sensitive film/foil adhesivesEpoxyAcrylic resin

The present invention relates to a micro-adhesion protection film, which comprises a base material layer and an adhesive layer arranged on one surface of the base material layer, wherein the raw materials of the adhesive layer comprise, by mass, 80-98% of a resin monomer, and 2-20% of a curing agent, the resin monomer is a polyurethane resin monomer, an acrylic resin monomer, an epoxy resin monomer, a hot melt adhesive monomer or an UV curable adhesive monomer, and the curing agent is an aliphatic curing agent. According to the present invention, the micro-adhesion protection film does not have the silicon transfer problem of the silica gel protection film, has advantages of stable viscosity, low time-dependent peeling force change and no residual glue, and is suitable for electronics industry.

Owner:CYBRID TECHNOLOGIES INC

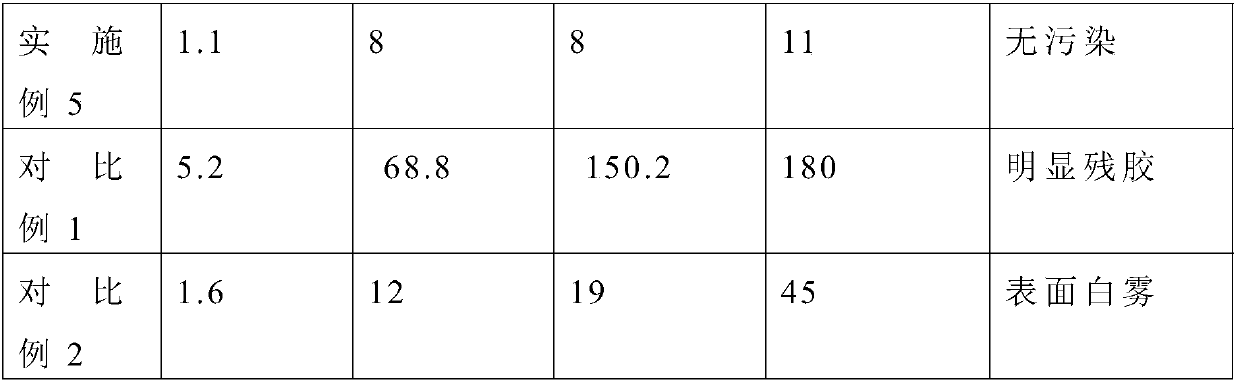

Self-adhesive protective film and preparation method thereof

InactiveCN107418486AExcellent peel strength stabilityViscous stabilityFilm/foil adhesivesSurface layerUltimate tensile strength

The invention belongs to the technical field of high polymer materials and discloses a self-adhesive protective film and a preparation method thereof. The self-adhesive protective film comprises a viscous layer, a sandwich layer and an outer surface layer which are sequentially in contact with one another, wherein the viscous layer is a Kraton viscous copolymer layer; the sandwich layer comprises one or more of PE, PP or a PE-PP copolymer; and the outer surface layer comprises one or more of PP, HDPE, LDPE, LLDPE or an LDPE-HDPE copolymer. The self-adhesive protective film is wide in viscosity and stripping strength adjustment range, has stable viscosity on polar or non-polar surfaces, and shows very good stability under a high-temperature condition. The preparation method of the self-adhesive protective film comprises the following steps: uniformly mixing the raw materials of the viscous layer, the sandwich layer and the outer surface layer by weight ratio, then sending the obtained mixture to a three-layered coextrusion film-blowing unit for extrusion film-blowing, and performing cooling. The one-step coextrusion process is adopted, so that the operation is simple and easy, the running efficiency is high, the loss is small, and the product quality is good in stability.

Owner:无锡市三力胶带有限公司

UV viscosity-reducing adhesive film applied to PVC substrate and used for film reversion of semiconductor chip, and preparation method thereof

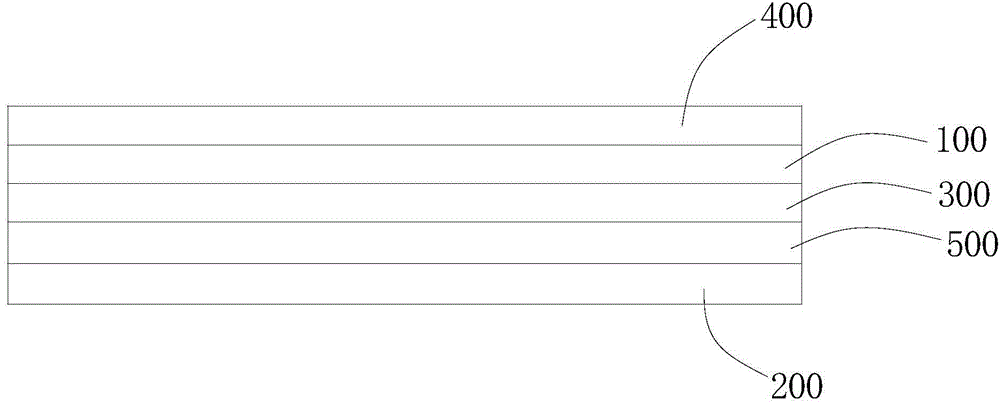

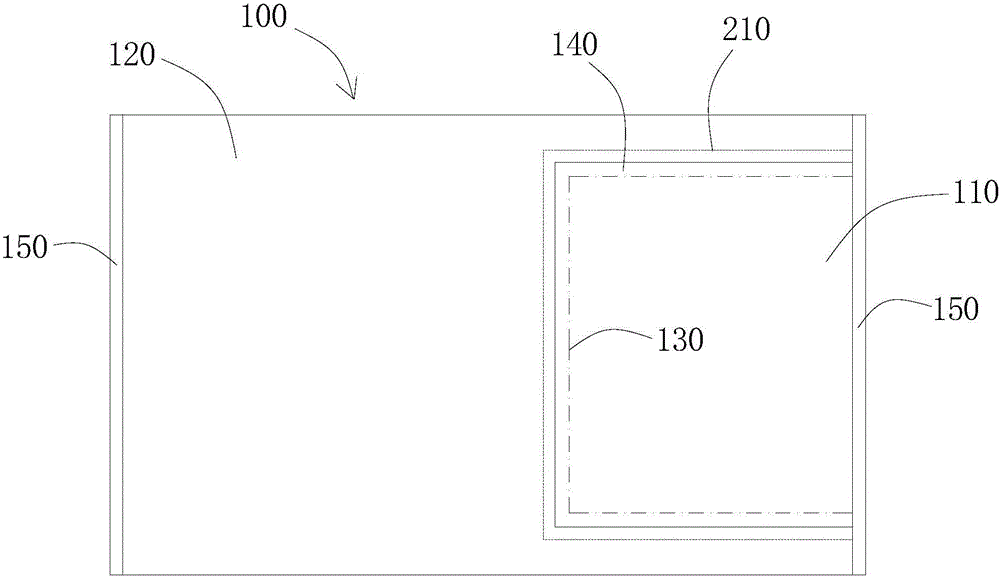

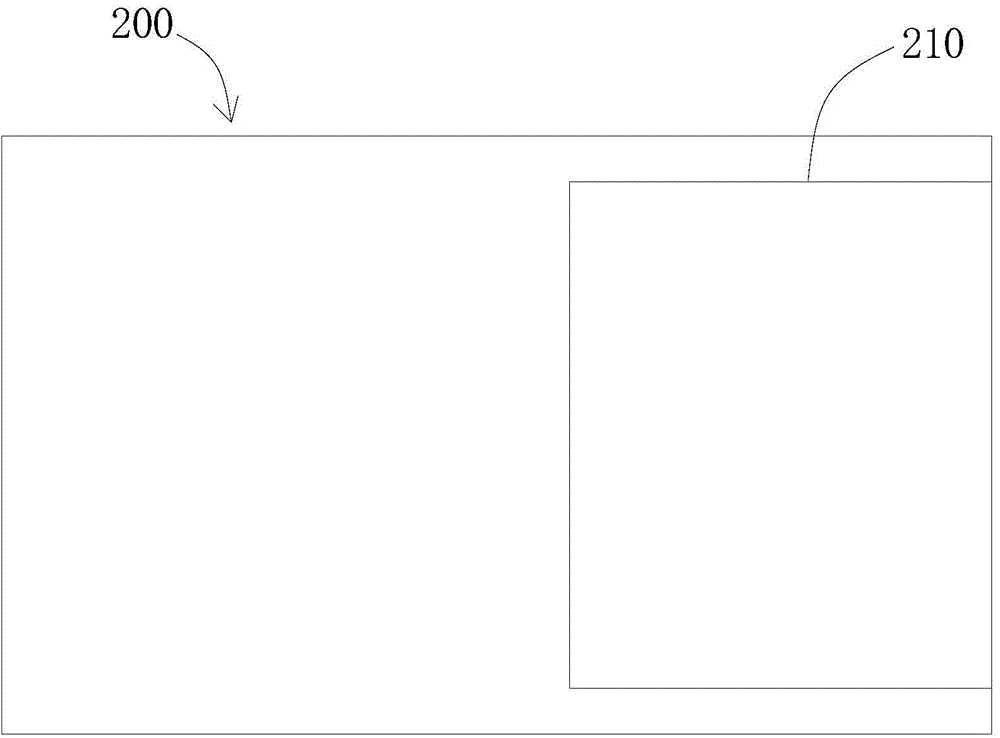

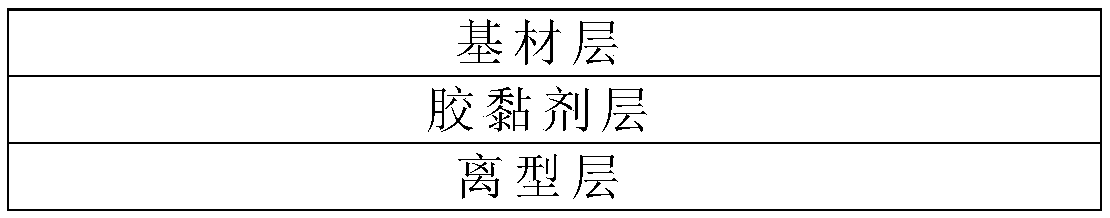

InactiveCN112680131AEffective control of hardnessViscous stabilityNon-macromolecular adhesive additivesFilm/foil adhesivesPolymer science(Hydroxyethyl)methacrylate

The invention discloses an UV viscosity-reducing adhesive film applied to a PVC substrate and used for film reversion of a semiconductor chip. The UV viscosity-reducing adhesive film comprises a substrate layer, an adhesive layer and a release film layer, wherein the adhesive layer is positioned between the substrate layer and the release film layer, and the adhesive layer is prepared by coating the substrate layer with UV viscosity-reducing glue and conducting drying. The UV viscosity-reducing glue comprises the following components in parts by weight: acrylic acid glue, UV monomers or oligomers, a curing agent, a photoinitiator and a plasticizer, wherein the acrylic acid glue is prepared from the following components in parts by weight: butyl acrylate, vinyl acetate, acrylic acid, hydroxyethyl methacrylate and azodiisobutyronitrile. According to the invention, the hardness of the glue is effectively controlled through formula design of an acrylic polymer, oligomer selection and increase and decrease of a plasticizer content, and a designed formula is high in crosslinking density; the concentration of the plasticizer of the adhesive layer and the concentration of the plasticizer of the PVC layer are balanced by controlling the amount of the plasticizer, and after the adhesive layer is attached to the substrate layer, the adhesive layer cannot be affected by the plasticizer in the substrate layer; and therefore, the adhesive layer achieves the effects of stable viscosity and no adhesive residue.

Owner:CYBRID TECHNOLOGIES INC

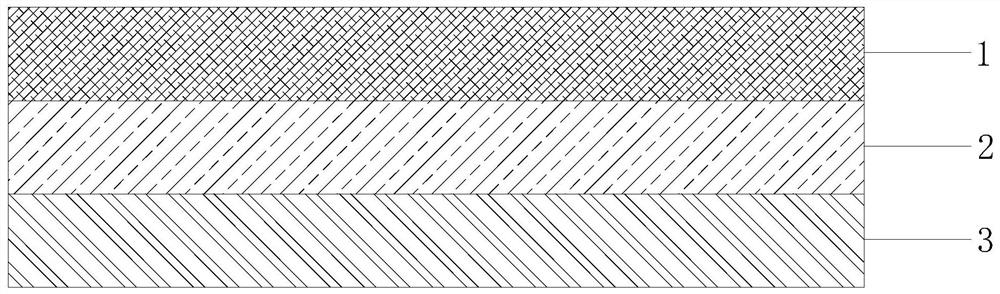

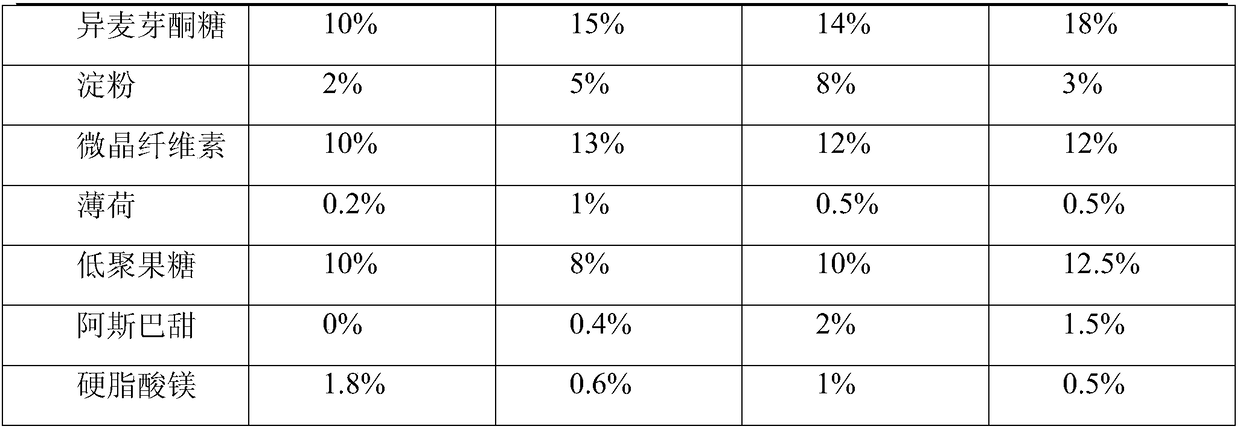

Chrysanthemum pressed candy containing pullulan and preparation method thereof

InactiveCN108056209AImprove tasteProlong chewing timeConfectionerySweetmeatsPeppermintsOligosaccharide

The invention relates to chrysanthemum pressed candy containing pullulan and a preparation method thereof. The candy is prepared from the following raw materials in percentage by weight: 20-40 percentof chrysanthemum, 5-15 percent of Chinese wolfberry fruits, 1-2 percent of pullulan, 10-20 percent of sorbitol, 10-25 percent of isomaltulose, 2-10 percent of starch, 10-25 percent of microcrystalline cellulose, 0.2-1 percent of peppermint, 5-20 percent of fructo-oligosaccharide, 0-2 percent of aspartame and 0.5-2 percent of magnesium stearate. The preparation method of the chrysanthemum pressedcandy containing pullulan comprises the following steps of powdering, mixing, granulating, drying and tableting. The chrysanthemum candy containing pullulan is convenient for people to eat and carry by adopting a tablet mode, and can be taken anytime and anywhere; and the pressed tablet can be firm and has better taste due to addition of the pullulan.

Owner:天津北洋百川生物技术有限公司

Acrylic protective film for aluminum-plastic film manufacturing process and preparation method of acrylic protective film

InactiveCN112574683ASolve the adsorption problemReduce the degree of crosslinkingNon-macromolecular adhesive additivesFilm/foil adhesivesPolymer scienceAcrylic resin

The invention discloses an acrylic protective film for an aluminum-plastic film manufacturing process. The acrylic protective film comprises an antistatic layer, a base material layer and an adhesivelayer; two sides of the base material layer are coated with the antistatic layer and the adhesive layer respectively, and the adhesive layer is obtained by coating the base material layer with an acid-free acrylic adhesive and drying the base material layer. The acid-free acrylic adhesive comprises the following components in parts by weight: acid-free acrylic resin, toluene diisocynate, an auxiliary agent, a surfactant and ethyl acetate, wherein an acid-free acrylic glue is glue with the solid content of 20%. The antistatic treatment is carried out on the PET surface of the base material layer, so that the problem of lamination adsorption is effectively solved; meanwhile, the acid-free acrylic glue is prepared, the reaction with a CPP layer on the surface of the aluminum-plastic film is avoided, the viscosity is stable, and no residual glue is left after stripping; and in addition, when the acid-free acrylic glue is prepared, proper acrylic resin is selected; and toluene diisocynate is matched, so that the crosslinking degree of the glue can be reduced, and the glue has the characteristic of high wettability.

Owner:CYBRID TECHNOLOGIES INC

Water-resistant high-viscosity wood adhesive

PendingCN111087949AImprove water resistanceHigh affinityNon-macromolecular adhesive additivesMacromolecular adhesive additivesPolymer scienceAdhesive

The invention discloses a water-resistant high-viscosity wood adhesive, and belongs to the field of adhesives. According to the invention, an acetic acid solution and swimming bladders are blended andmashed for dissolving out a part of colloid and protein; then chitosan, a plasticizer and macromolecules are mixed for interaction and preliminary shaping, wherein chitosan can react with swimming bladder protein, colloid and the like, so that the stability after gelatinization is improved, the water vapor transmission rate of the adhesive is reduced, plant oil-containing components and montmorillonite are ground and intercalated, hydrophobic and oily components are dispersed, and the water resistance of the adhesive is improved; according to the invention, cetyl alcohol polyoxyethylene ether, triethanolamine and the like are used as raw materials, micelle copolymerization synthesis is carried out, a hydrophobic monomer is used as an effective cross-linking center, stable hydrophobic association hydrogel is formed through induction, and the viscosity of the adhesive system is stabilized. The wood adhesive provided by the invention solves the problems of poor water resistance and weaker viscosity of the current common wood adhesive.

Owner:广州国色生物科技有限公司

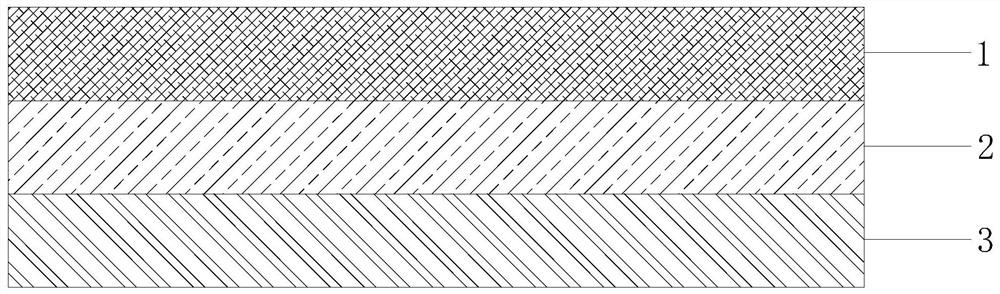

Online lamination protection film of light guide plate and preparation process of online lamination protection film

ActiveCN106142787AImprove fitRelatively difficult to shiftSynthetic resin layered productsLaminationElastomerTectorial membrane

The invention discloses an online lamination protection film of a light guide plate and a preparation process of the online lamination protection film. The online lamination protection film of the light guide plate comprises a base material surface layer, a core layer and an elastomer layer, wherein the core layer is arranged between the base material surface layer and the elastomer layer, and the base material surface layer, the core layer and the elastomer layer are integrally formed by virtue of a co-extrusion process. The protection film is stable in viscosity, good in light guiding property, excellent in high-temperature high-humidity aging resistance, and free from scratching a protected surface; and the viscosity of the protection film is not changed along with the temperature rising / lowering, can be repeatedly laminated and can avoid the adhesive residue phenomenon. Therefore, the protection film is very suitable for being used as the protection film of the light guide plate.

Owner:SHENZHEN FENGZHAO NEW MATERIAL CO LTD

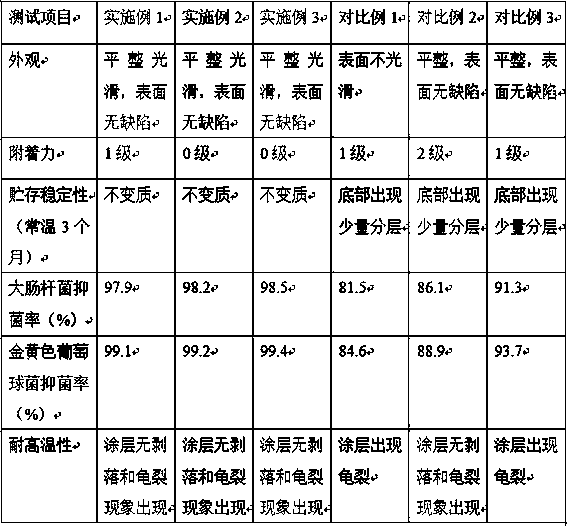

Preparation method of high heat-resistant antibacterial toy paint

InactiveCN109777169AImprove adhesionHigh degree of decompositionAntifouling/underwater paintsPaints with biocidesFiberTree root

The invention relates to a preparation method of high heat-resistant antibacterial toy paint, and belongs to the technical field of paint preparation. The preparation method comprises the following steps: using aloe leaves and rice leaves as raw materials to prepare a reaction mixture, then mixing the reaction mixture with ginkgo leaves and ginkgo tree roots and fermenting, adding aluminum chloride to obtain a reaction filtrate, and finally mixing the reaction filtrate with an organic solvent and other auxiliary agents and stirring to obtain the high heat-resistant antibacterial toy paint. Byextracting nutrients from the aloe leaves and generating organo-functional groups such as carboxyl groups, hydroxyl groups, phenolic hydroxyl groups on the surface, the adhesion between various molecules inside the paint is enhanced, and the adhesion between the paint and the toy material is improved. Meanwhile, the ginkgo tree grows a large amount of ginkgo biloba endophytic bacteria during the fermentation process, which helps to improve the antibacterial property. By introducing aluminium ions into the aloe nutrients and various fiber components, aluminium oxide grows on the surface of fiber and then toughness of the fiber is enhanced. Meanwhile, the toy paint has good heat resistance and has a wide application prospect.

Owner:常州环际商贸有限公司

Adhensive rotary printer

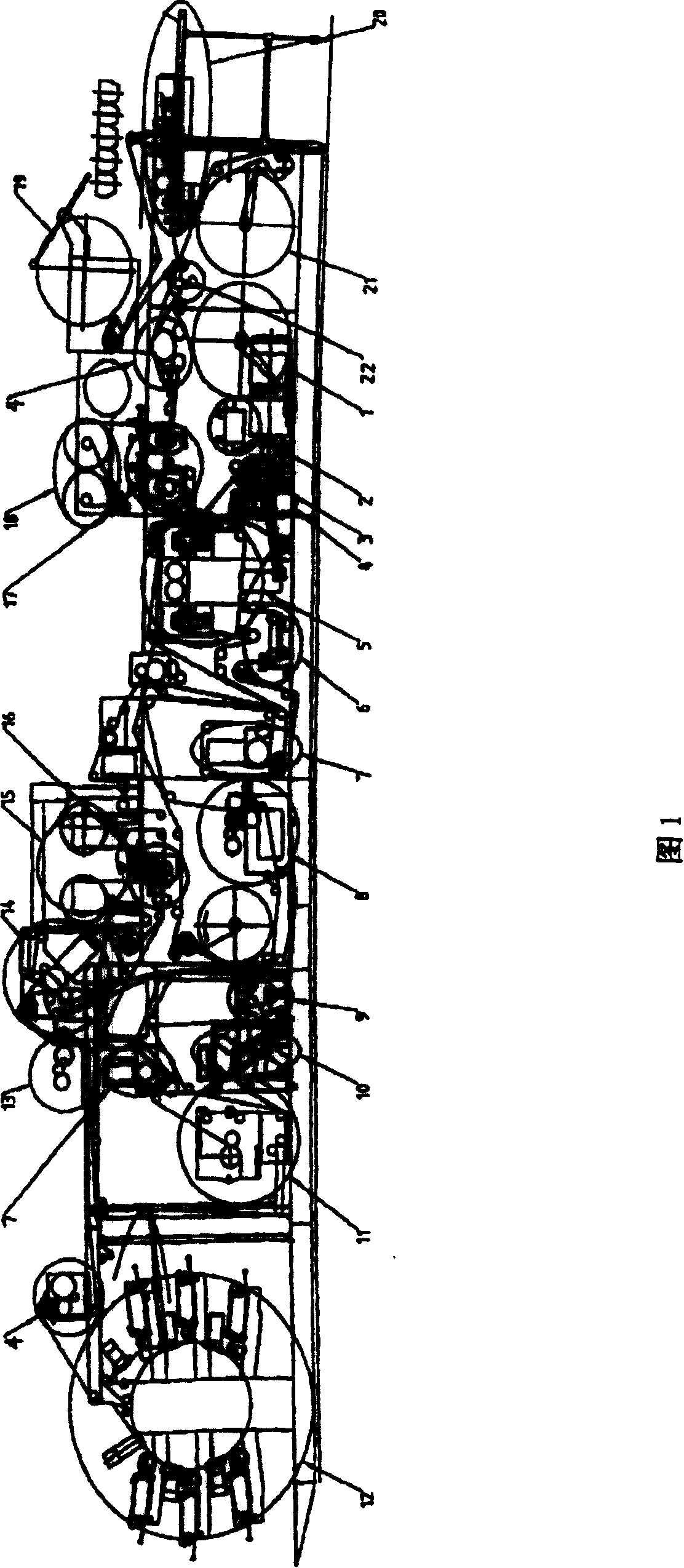

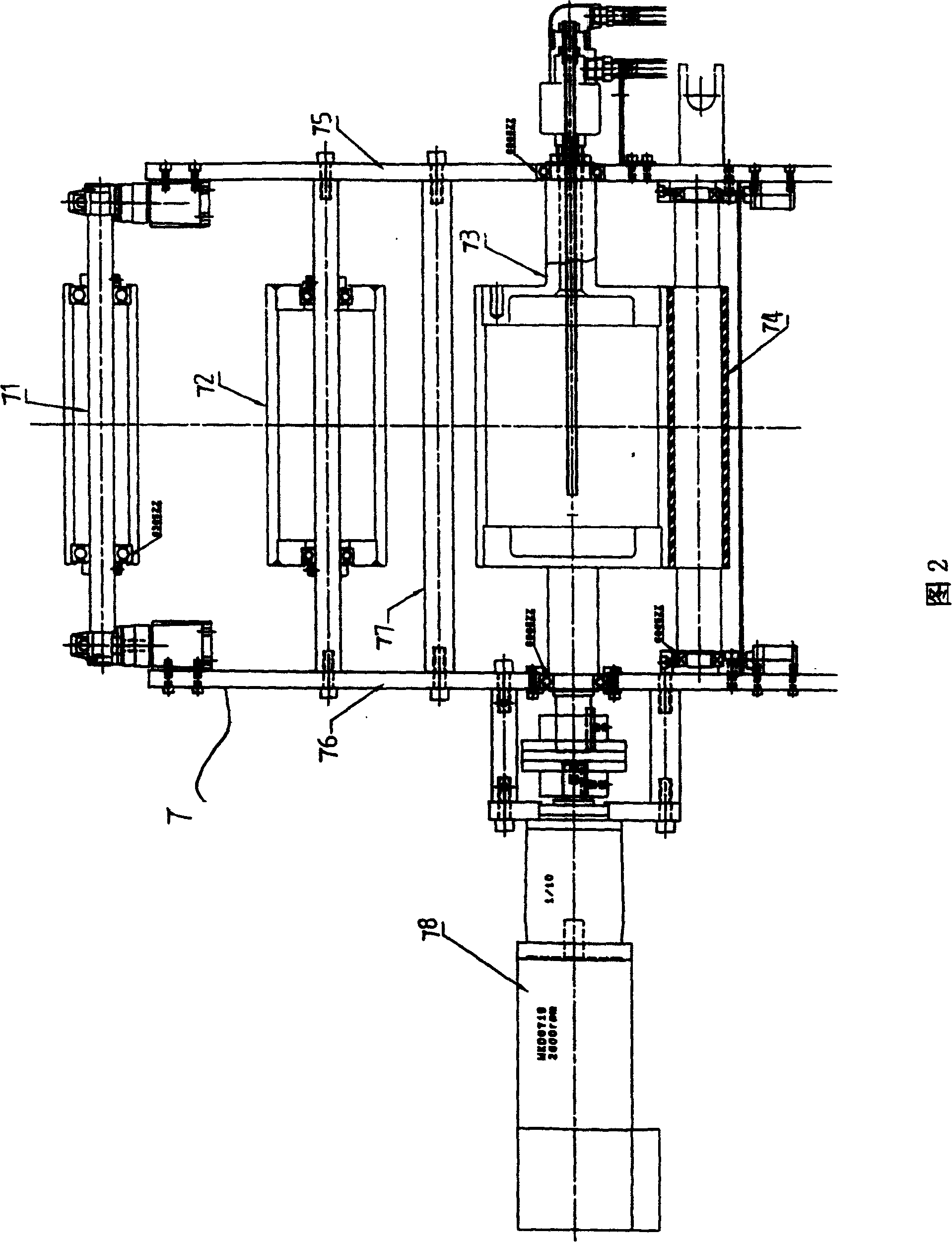

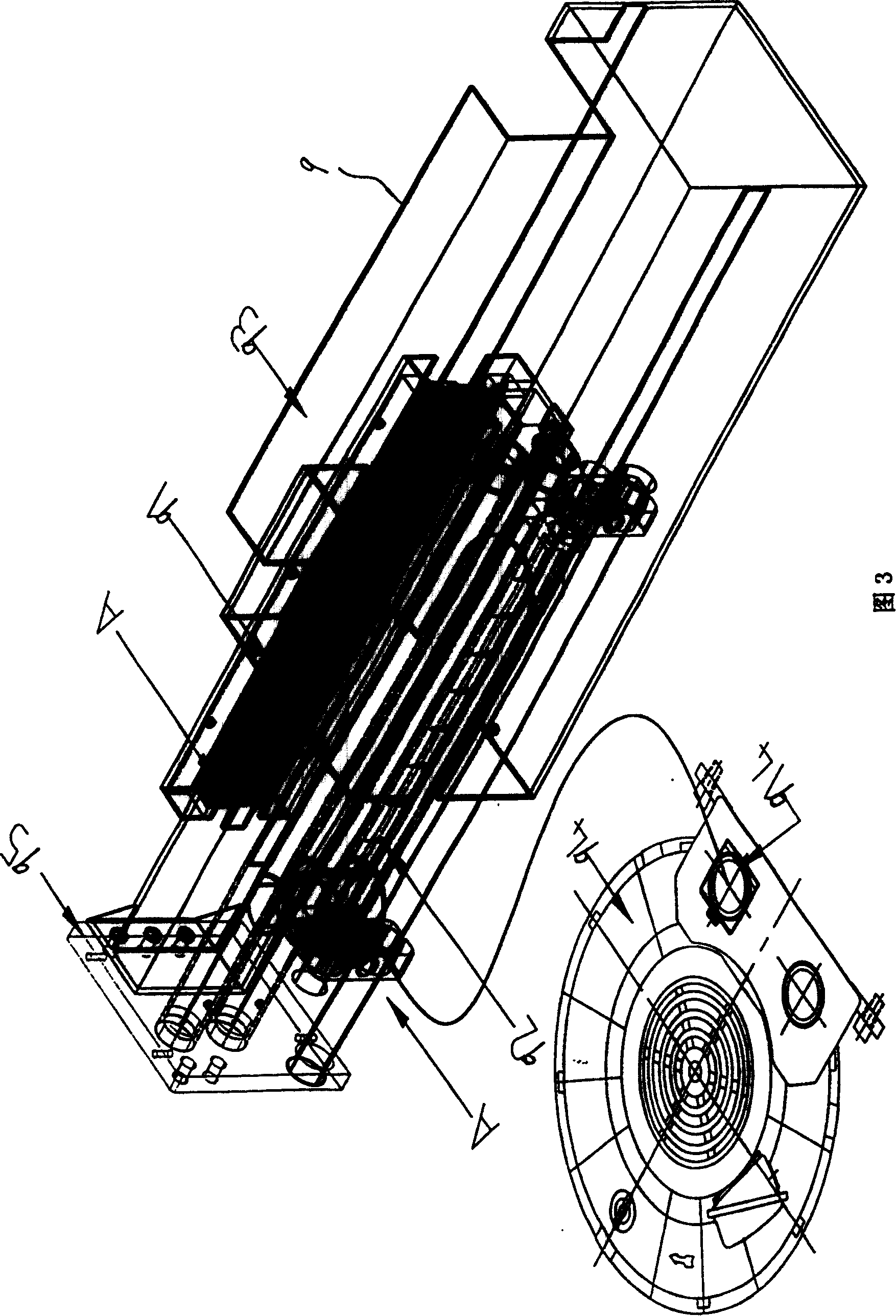

InactiveCN100382963CViscous stabilitySticky and flexibleRotary pressesScreen printingSmall footprint

A rotary press for printing on non-drying adhesive matter is composed of paper feeder, paper receiver, speed reducer, AC servo tension control and tract unit, platen unit, skew corrector, servo motor cooling and driving unit, flexible plate printing unit, paper chip and static electricity remover, corona unit, silk screen printing unit, satellite relief printing unit, gilded film sticking-UV baking-cooling driver, golden foil feeder, reel, gilded film cutting unit, etc.

Owner:SHANGHAI XINMIN TAIYO KIKAI

A method for improving the stability of silicone pressure-sensitive adhesives for protective films

ActiveCN105441017BStable temperature resistanceImprove storage performanceAdhesivesCarboxylic acidKetone

The invention relates to a method for improving stability of an organosilicone pressure-sensitive adhesive for a protective film. The method comprises steps as follows: step 1), removal of water and hydroxyl: a water and hydroxyl removal agent containing organic acyloxy silane compounds is added to a reaction system to reduce water left in the adhesive and hydroxyl left on an adhesive structure; step 2), thorough inactivation of a catalyst: a) when primary amine or secondary amine is used as a condensation polymerization catalyst, an adhesive reaction system is kept at the temperature of about 70 DEG C at the nitrogen reaction atmosphere, primary amine or secondary amine and aldehydes, ketones or low-level carboxylic acid react to generate Schiff base, generated unstable Schiff base reacts with diethyl malonate, and Schiff base becomes beta-amino acid without catalytic activity; b), when secondary amine or tertiary amine is used as a condensation polymerization catalyst, acidic compounds which can react with secondary amine or tertiary amine to generate a stable compound are added to the reaction system; step 3), residual small molecular substances are removed in the vacuum state; step 4), neutralization of residual acidic compounds: sodium alcoholate is added to neutralize residual acidic compounds in the adhesive.

Owner:ANHUI MINGXUN NEW MATERIAL TECH

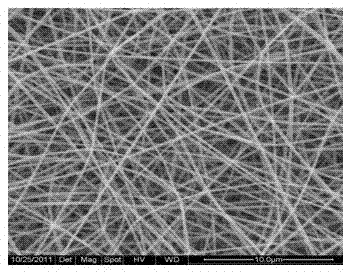

Safe rope-free mask

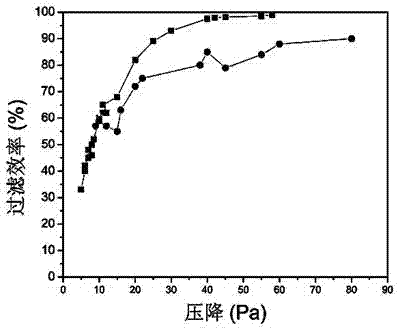

InactiveCN105433472AImprove filtration efficiencyImprove filtering effectProtective garmentSpecial outerwear garmentsFiberEngineering

The invention discloses a safe rope-free mask. The problems that an existing mask is inconvenient to wear and low in air pollutant filtering efficiency are solved. The safe rope-free mask comprises mask cloth, a mask nose clamp and a mask rubber ring. The mask cloth is used for covering the face contour of the human body and purifying air and comprises a primary filtering supporting layer, a nanofiltration layer and a protection layer which are sequentially overlapped together from outside to inside. The nanofiltration layer is of an interlayer structure and comprises two layers of nonfiber nets and micron fiber felt which is clamped between the two layers of nonfiber nets and manufactured by a chitosan solution through an electrostatic spinning process. The mask nose clamp is arranged at the upper end of the mask cloth. The mask rubber ring is arranged on the edge of the protection layer. The safe rope-free mask is convenient to wear, comfortable and safe, multi-layer structural design is adopted, then the characteristics of a chitosan material and the electrostatic spinning process are ingeniously combined, and therefore the filter effect of the mask on air pollutants is greatly optimized, and the effect of purifying the air is enhanced.

Owner:MATERIAL INST OF CHINA ACADEMY OF ENG PHYSICS

Method for preparing gel adhesives for PP brush wires

ActiveCN103788896AHigh strengthImprove rigidityAdhesivesLow-density polyethyleneLinear low-density polyethylene

The invention discloses a method for preparing gel adhesives for PP brush wires. The gel adhesives are composed of the raw materials, by weight, 35-50 parts of polypropylene wiredrawing powder, 20-25 parts of linear low density polyethylene, 20-25 parts of linear low density polyethylene first-class reworked materials and 10-15 chlorinated polypropylene. The method comprises the steps that the polypropylene wiredrawing powder, the linear low density polyethylene, the linear low density polyethylene first-class reworked materials and the chlorinated polypropylene are put into a high-speed mixing machine with the rotating speed of 100 rpm, are mixed for five minutes, and then are added to a double-screw extruder, the temperature of a first area is 175 DEG C, the temperature of a second area is 185 DEG C, the temperature of a third area is 190 DEG C, the temperature of a die head is 195 DEG C, and the gel adhesives are obtained through fusion. The gel adhesives are good in tenacity and weather fastness.

Owner:安徽环美刷业股份有限公司

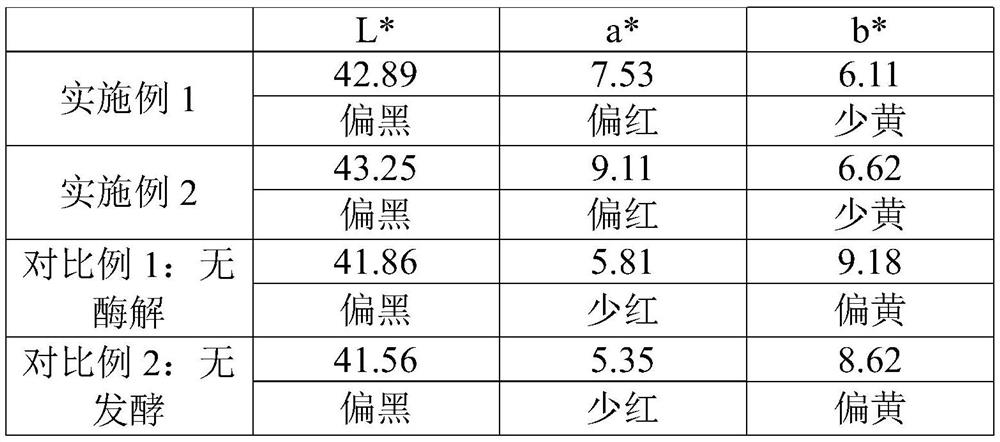

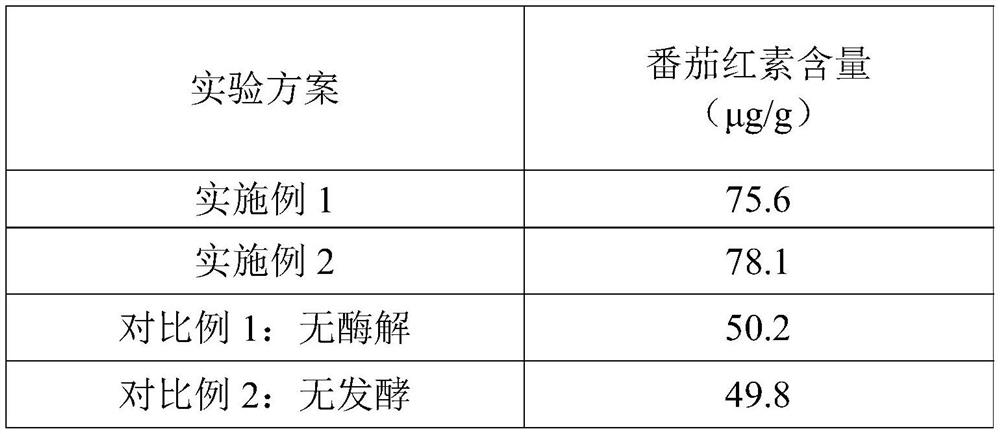

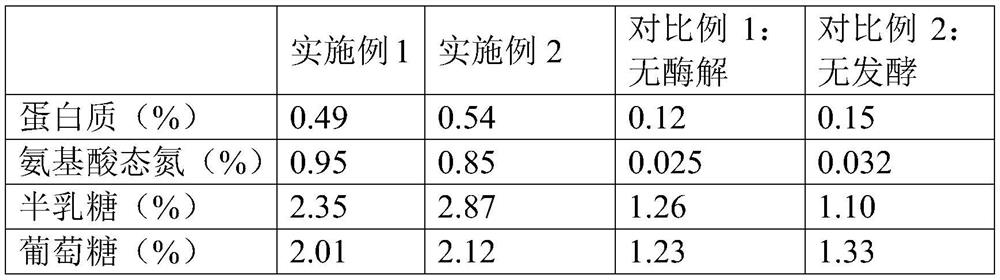

Tomato fermented product and preparation method thereof

The invention discloses a tomato fermented product and a preparation method thereof. The preparation method comprises the following steps: (1) screening raw materials by using a color selector; (2) cleaning and preparing the raw materials; (3) performing vacuum homogeneous emulsification; (4) performing vacuum low-temperature concentration; (5) performing anaerobic biological enzymolysis; (6) performing anaerobic fermentation; and (7) performing filling and sterilizing. According to the preparation method disclosed by the invention, the raw materials are screened by using the color selector, and green and yellow tomatoes are selected from the raw materials, so that the adverse effects of the green and yellow tomatoes on the color and flavor of the product can be removed to the greatest degree, and the color and flavor of the product are guaranteed to the greatest degree; and moreover, by using the vacuum low-temperature concentration and vacuum homogeneous emulsification method, the instability of lycopene caused by temperature and oxygen can be effectively reduced, and the lycopene content in the product is effectively improved.

Owner:四川天味食品集团股份有限公司

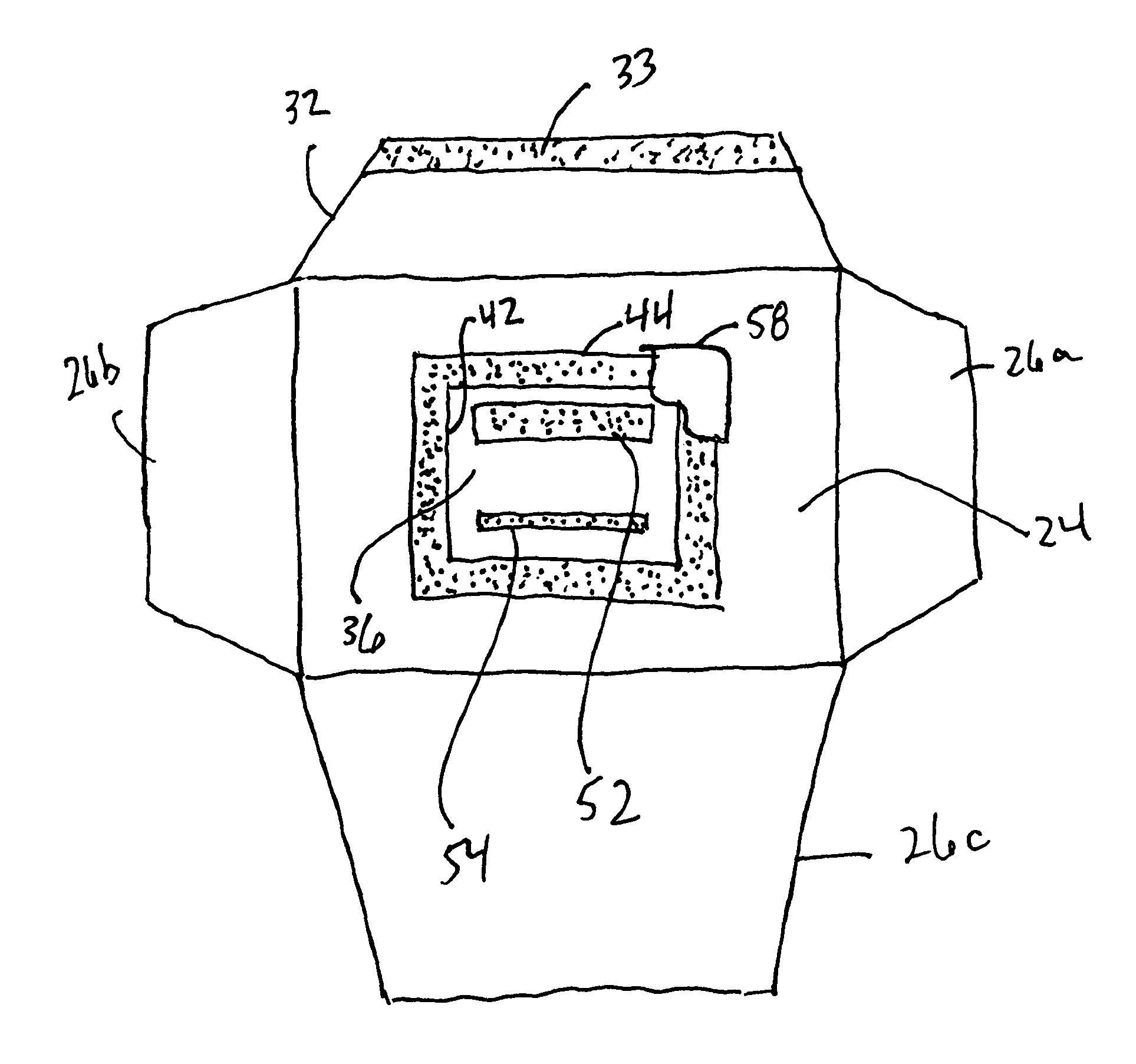

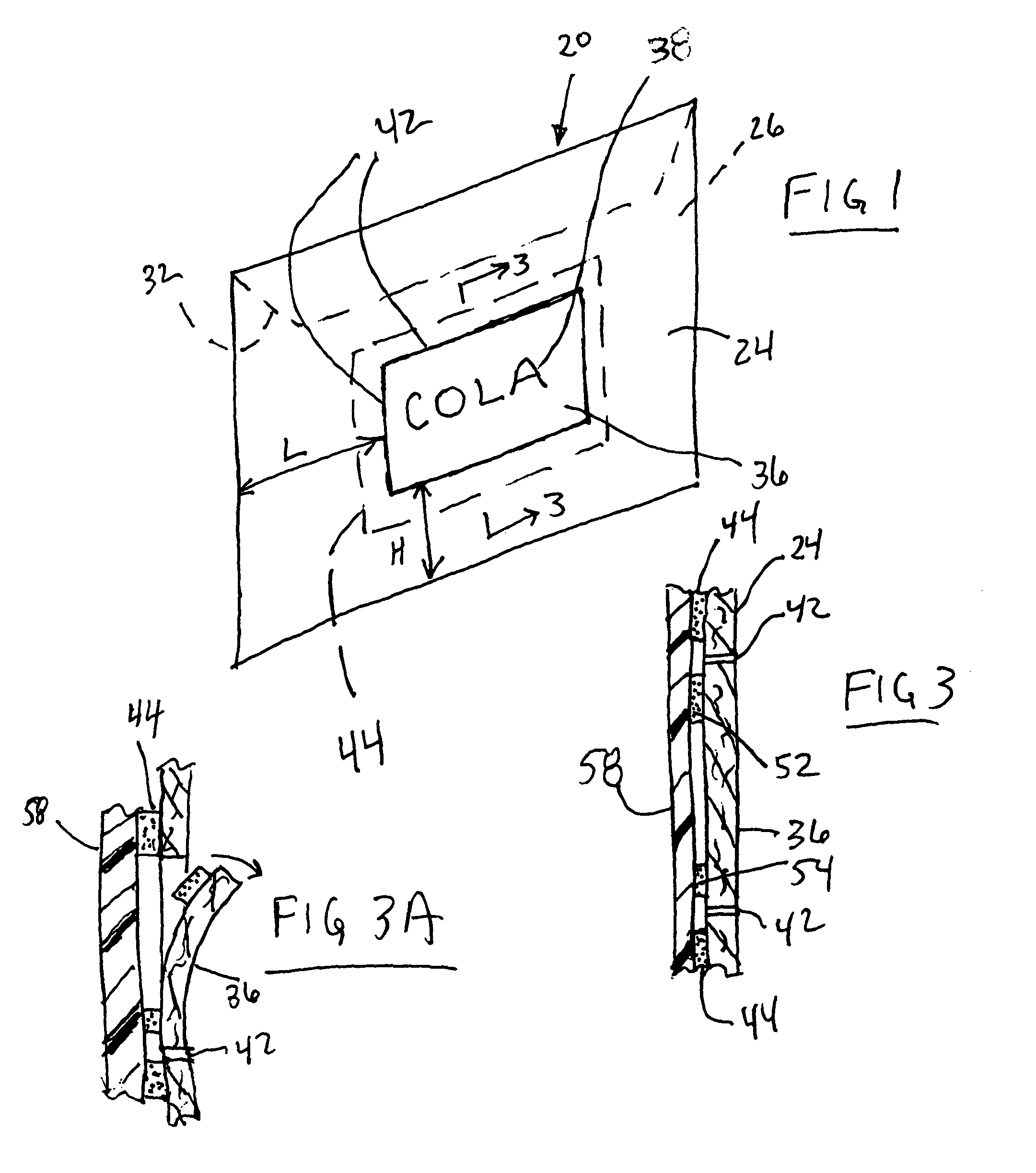

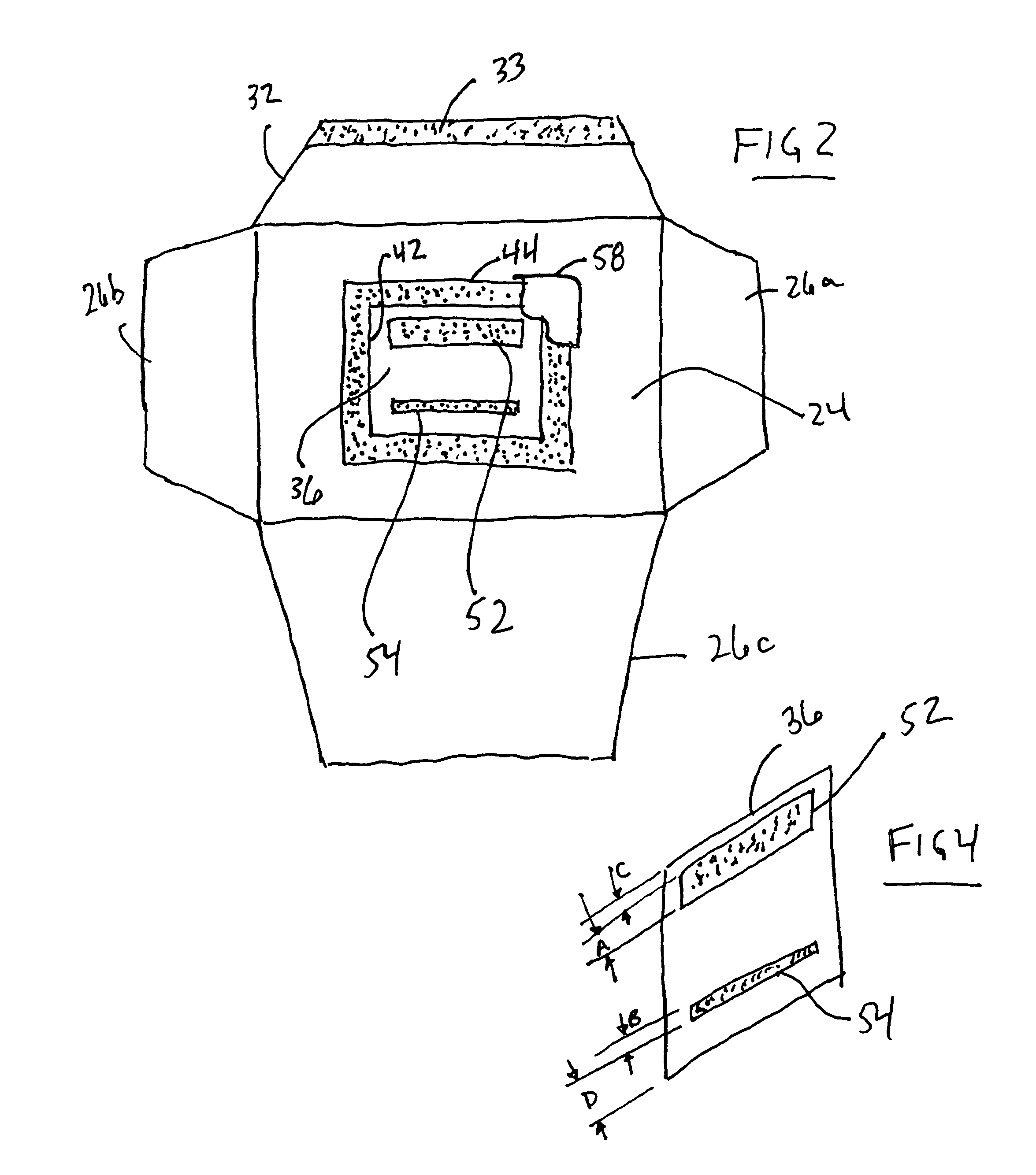

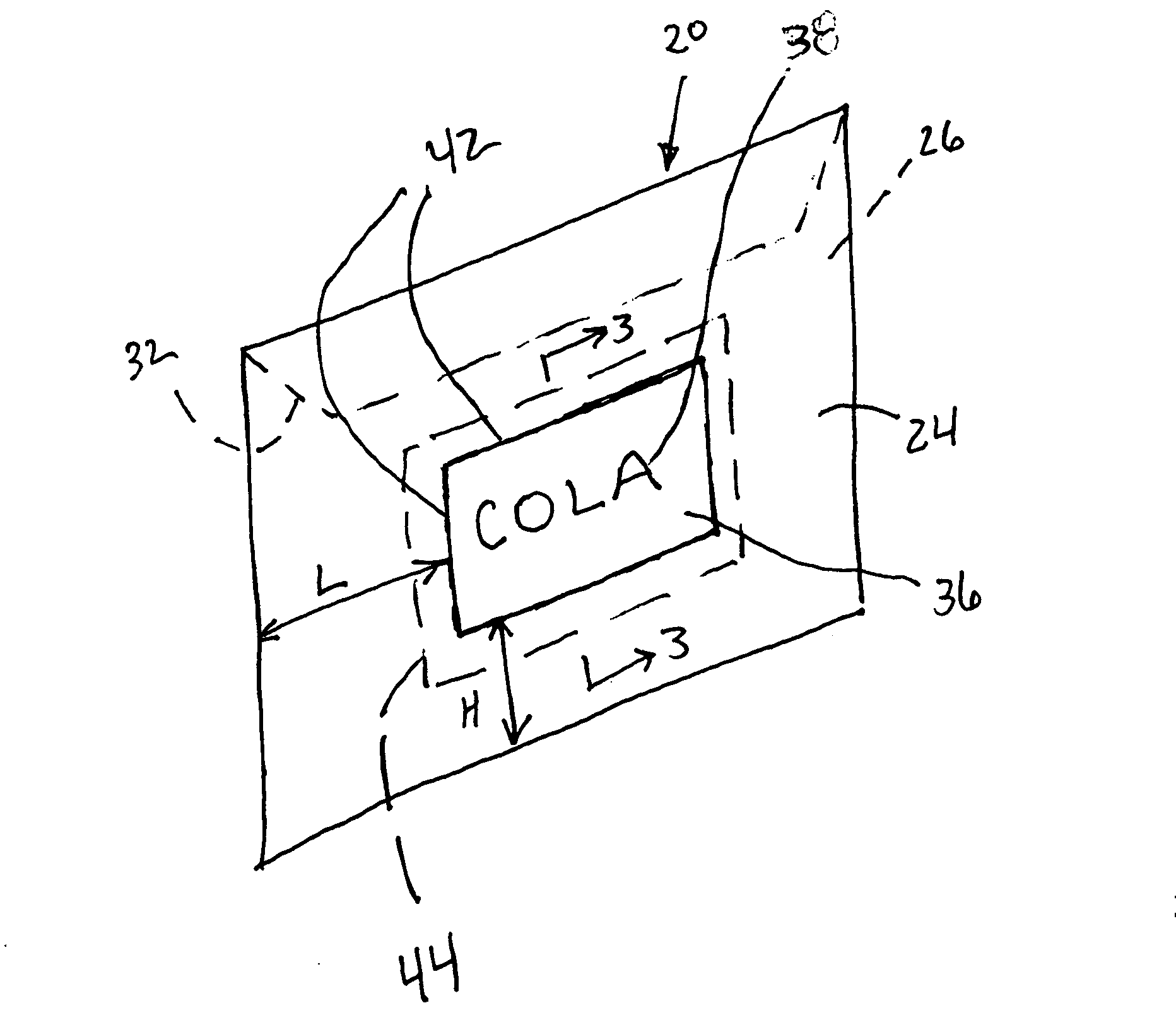

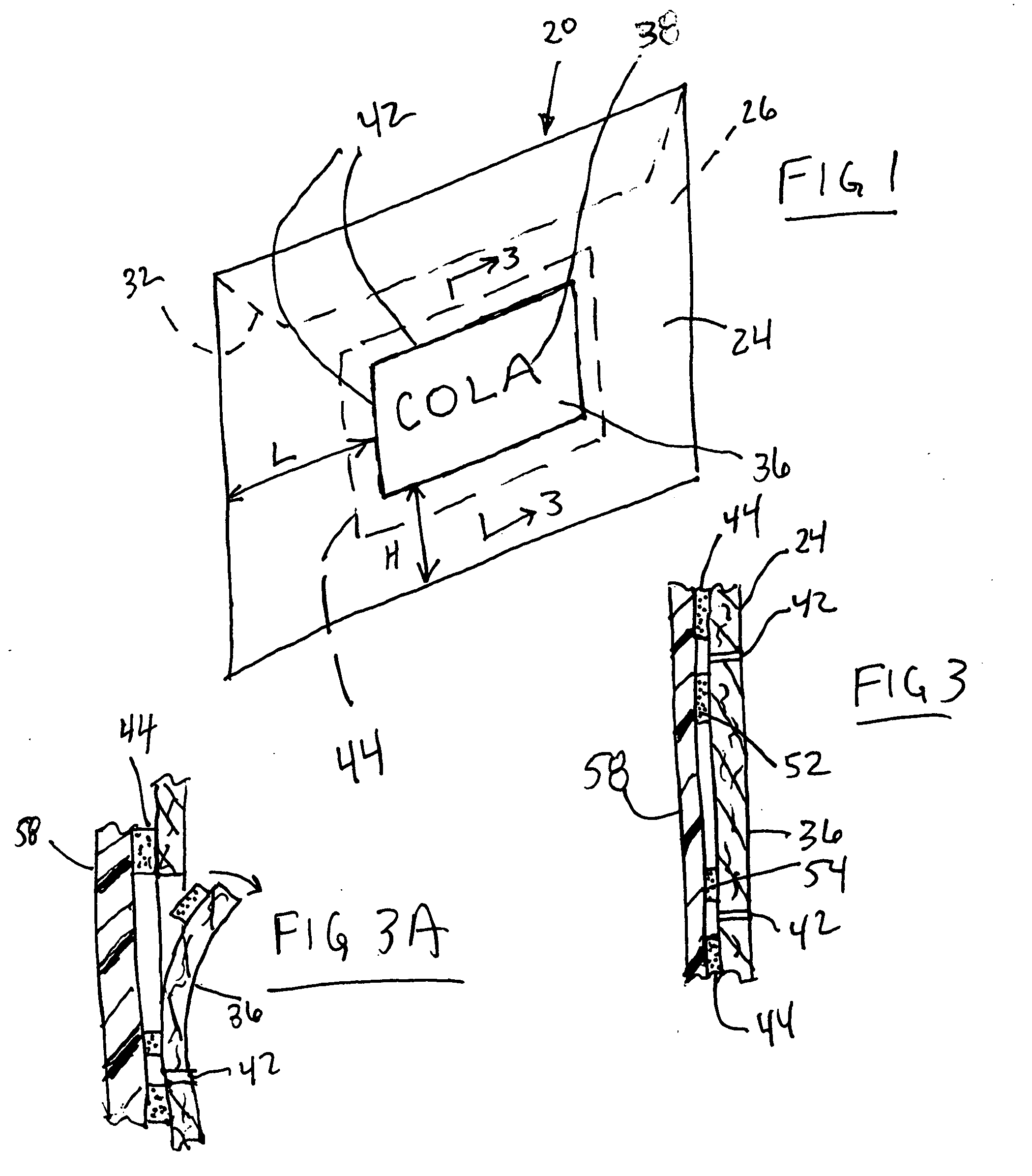

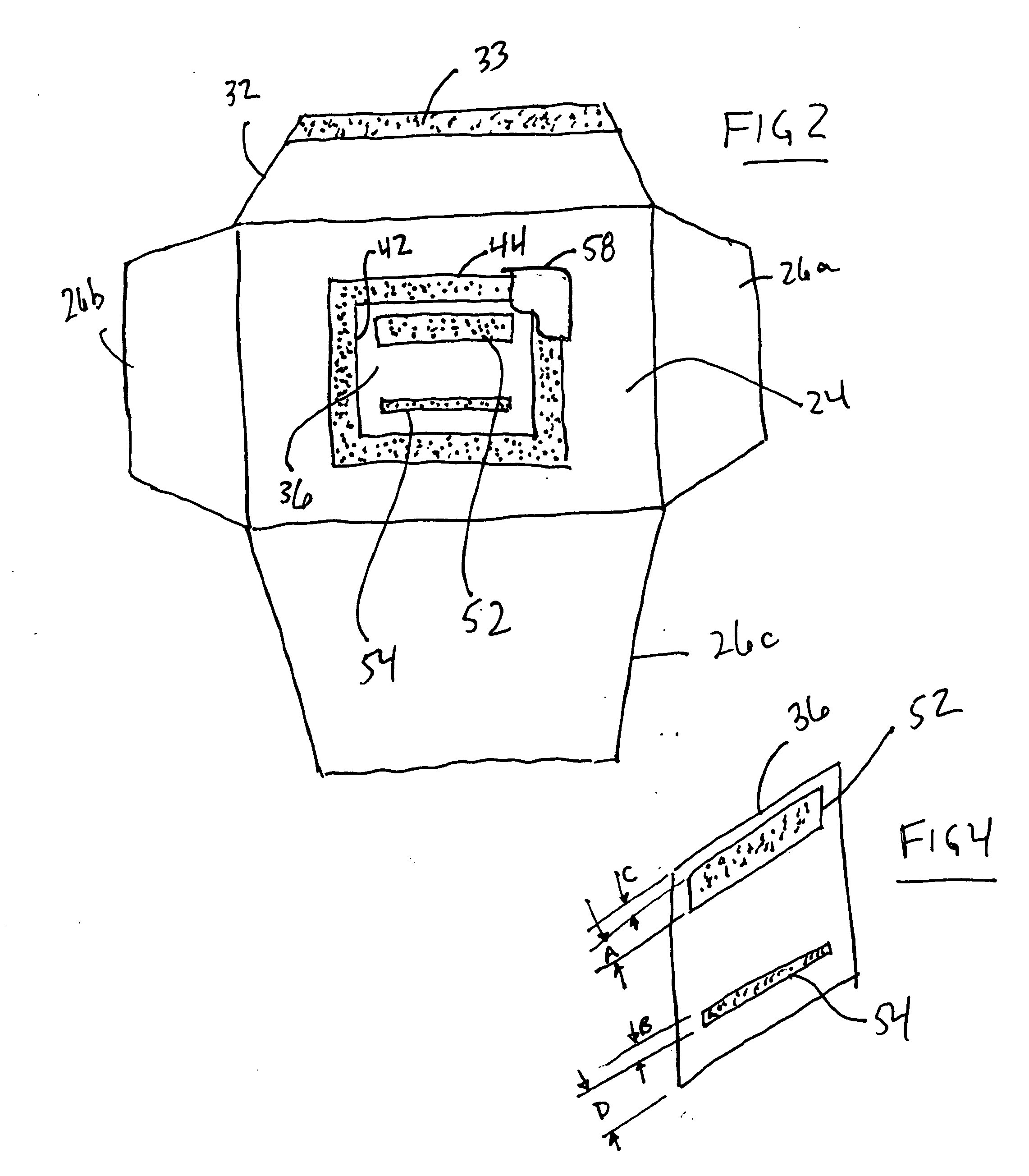

Integrated envelope and repositionable note

An envelope includes a front wall and an overlying back wall. The front wall and the back wall are connected around mutual edges to form an enclosed pouch. One of the front wall and the back wall includes a message portion separable from remaining portions of the one of the front wall and the back wall. A release sheet is secured to an inside surface of the one of the front wall and the back wall overlying the message portion. The message portion comprises areas of removable adhesive or multiple reuse adhesive and is secured to the release sheet by the multiple reuse adhesive to form a repositionable note once removed from the one of the front wall and the back wall.

Owner:MAILAGAIN

Preparation method of environment-friendly type special protecting film with high viscosity for light guide plates

InactiveCN107083203AViscous stabilityIncrease stickinessFilm/foil adhesive primer layersCoatingsPolypropyleneAntioxidant

The invention discloses a preparation method of an environment-friendly type special protecting film with high viscosity for light guide plates. The preparation method comprises the steps: proportionally mixing propylene block copolymers, ethylene vinyl acetate copolymers and polyolefine elastomers; stirring the mixture for 3-4h to obtain an intermediate layer; coating a substrate layer with the intermediate layer, and baking at 115-120DEG C for 1.5-2min; and uniformly stirring polypropylene, metallocene polyethylene and an antioxidant of a self-adhering layer at 65-70DEG C, coating the intermediate layer with the self-adhering layer, baking at 100-110DEG C for 2-3min, and conducting curing by ultraviolet light, wherein the energy of the ultraviolet light is 60-65J / cm<2>, to obtain the protecting film.

Owner:CHENGDU HUIJIA ADHESIVE PROD CO LTD

PVC protective film and preparation method thereof

PendingCN112574681AResolve shrinkageAvoid diversionFilm/foil adhesive primer layersEster polymer adhesivesPolymer scienceWafer

The invention relates to the technical field of protective films, in particular to a PVC protective film and a preparation method thereof; one surface of the PVC protective film is a smooth surface, and the other surface of the PVC protective film is a matte surface; a non-silicon release layer is arranged on the smooth surface of the PVC protective film; the matt surface of the PVC protective film is coated with an isolation coating; an acrylate adhesive layer is arranged on the surface, far away from the PVC protective film, of the isolation coating. According to the protective film and thepreparation method thereof, the cleanliness of the surface of the wafer is improved, the use performance of the wafer is ensured, and the PVC film is more uniform and smooth in thickness and stable inviscosity.

Owner:镝普材料(深圳)有限公司

A method for extending the stability of silicone pressure-sensitive adhesives

The invention provides a method for expanding stability of an organosilicone pressure-sensitive adhesive. The method comprises the following steps: (1) removing water; (2) removing hydroxyl, namely adding a silicon hydroxyl remover containing a trialkyl silicon carboxylate compound to a reaction system to reduce residual oxhydryl in an adhesive molecular structure; (3) thoroughly inactivating a catalyst, wherein the step is performed according to the following two conditions: when primary amine or secondary amine is utilized as a polycondensation catalyst, enabling the primary amine or the secondary amine to react with aldehydes or ketones and low-level carboxylic acid to generate a schiff base in a nitrogen reaction atmosphere, enabling the generated instable schiff base to react with diethyl malonate, and changing the schiff base into beta-amino acid free of catalytic activity; and when secondary amine or tertiary amine is utilized as the polycondensation catalyst, adding an acid substance which can react with the secondary amine or the tertiary amine to form a stable compound to the reaction system; (4) removing residual small molecular substances in vacuum; and (5) neutralizing the residual acid substance.

Owner:ANHUI MINGXUN NEW MATERIAL TECH

Carrier tape for 5G chip PVD process and manufacturing method thereof

PendingCN113980596AEasy accessNot easy to residue glueNon-macromolecular adhesive additivesFilm/foil adhesivesPolyethylene glycolPhysical chemistry

The invention relates to the technical field of chip accessories, in particular to a carrier tape for a 5G chip PVD process and a manufacturing method thereof. The carrier tape comprises the following components in parts by weight: 30-70 parts of pyromellitic dianhydride, 20-60 parts of dimethyl acetyl, 5-15 parts of composite nanoparticles, 40-90 parts of organic sol, 30-40 parts of p-phenylenediamine, 20-25 parts of polyethylene glycol, 20-25 parts of ethanol, 30-45 parts of an antistatic liquid and 20-30 parts of a composite acrylic acid glue solution. According to the invention, the problems that the existing carrier tape is unstable in viscidity, easy to fall off, easy to remain glue when being taken down, and low in process yield can be effectively solved.

Owner:SHENZHEN HORAE TECH

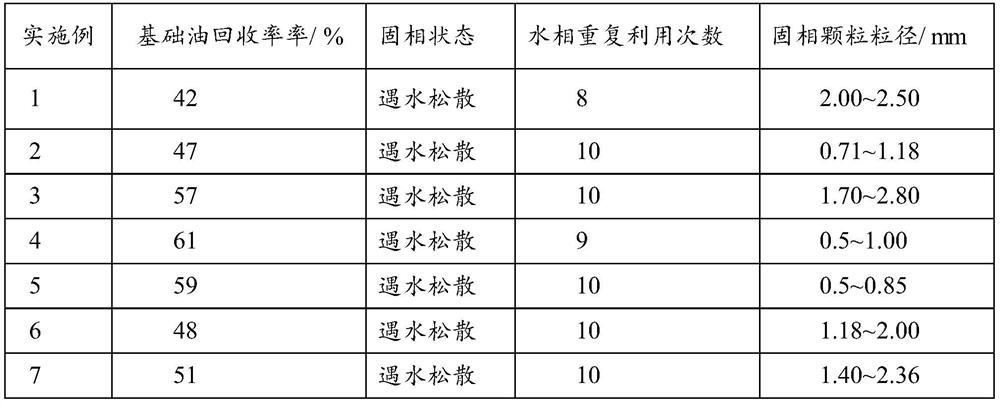

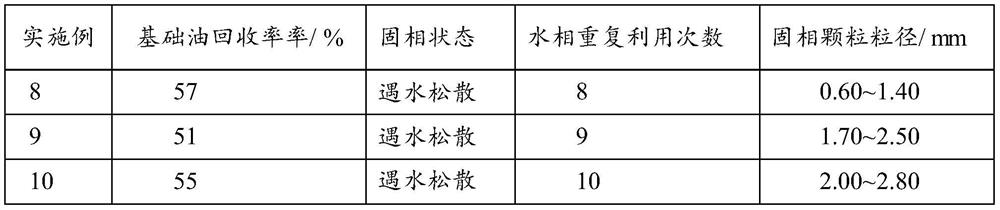

A kind of oil-based drilling cuttings breaking stabilizer and preparation method thereof

ActiveCN107510915BViscous stabilityAchieve separationDewatering/demulsification with chemical meansHydrocarbon oils treatmentOrganic acidFlocculation

The invention provides an oil base drilling cutting destabilizing agent. The oil base drilling cutting destabilizing agent is prepared and obtained through materials including an alkali compound, organic matter and water. The organic matter includes an amide compound and / or polyatomic organic acid. The mass ratio of the alkali compound to the organic matter to the water is (13-20):(14-20):(60-73). According to the oil base drilling cutting destabilizing agent, through the synergistic effect of charge neutrality and flocculation, viscosity stability of an oil base drilling cutting system is destroyed, separation of a basic oil phase, a water phase and a solid phase in oil base drilling cuttings can be achieved through only one step, and the treated solid phase is in a loose flocculent shape. According to the oil base drilling cutting destabilizing agent, separation of the oil phase, the water phase and the solid phase is facilitated, the destabilizing effect on the solid phase is good, and high-quality basic oil in the oil base drilling cuttings can be recycled and obtained. The invention further provides a preparation method of the oil base drilling cutting destabilizing agent.

Owner:中石化石油工程技术服务有限公司 +1

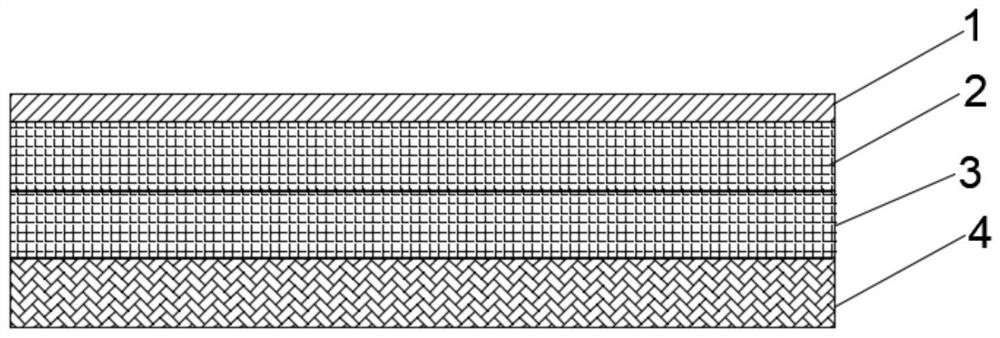

Transfer paper

PendingCN112571900AViscous stabilityHigh light transmittanceSynthetic resin layered productsRubber layered productsPolymer scienceSilica gel

The invention discloses transfer paper which comprises a PET silica gel layer, a first adhesive layer, a second adhesive layer and a white PET layer which are sequentially stacked from bottom to top.The thickness of the PET silica gel layer is 0.065 mm, the thickness of the white PET layer is 0.05 mm, the thickness of the first adhesive layer is 0.05 mm, and the thickness of the second adhesive layer is 0.05 mm. According to the transfer paper disclosed by the invention, the two adhesive layers are arranged between the PET silica gel layer and the white PET layer, so that the viscosity of thetransfer paper is stable under the action of the first adhesive layer and the second adhesive layer; and meanwhile, under the synergistic effect of the PET silica gel layer, the first adhesive layer,the second adhesive layer and the white PET layer, the transfer paper has excellent light transmittance, high temperature resistance, exhaust performance and tensile strength, and is stable in mechanical performance, long in transfer frequency and stable in adsorbability.

Owner:上海仰璞实业有限公司

Preparation method of gel-like adhesive for pp brush filaments

ActiveCN103788896BHigh strengthImprove rigidityAdhesivesLow-density polyethyleneLinear low-density polyethylene

The invention discloses a method for preparing gel adhesives for PP brush wires. The gel adhesives are composed of the raw materials, by weight, 35-50 parts of polypropylene wiredrawing powder, 20-25 parts of linear low density polyethylene, 20-25 parts of linear low density polyethylene first-class reworked materials and 10-15 chlorinated polypropylene. The method comprises the steps that the polypropylene wiredrawing powder, the linear low density polyethylene, the linear low density polyethylene first-class reworked materials and the chlorinated polypropylene are put into a high-speed mixing machine with the rotating speed of 100 rpm, are mixed for five minutes, and then are added to a double-screw extruder, the temperature of a first area is 175 DEG C, the temperature of a second area is 185 DEG C, the temperature of a third area is 190 DEG C, the temperature of a die head is 195 DEG C, and the gel adhesives are obtained through fusion. The gel adhesives are good in tenacity and weather fastness.

Owner:安徽环美刷业股份有限公司

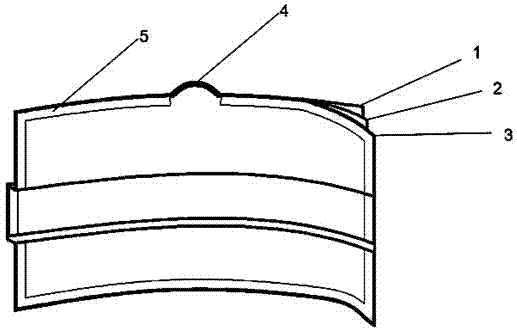

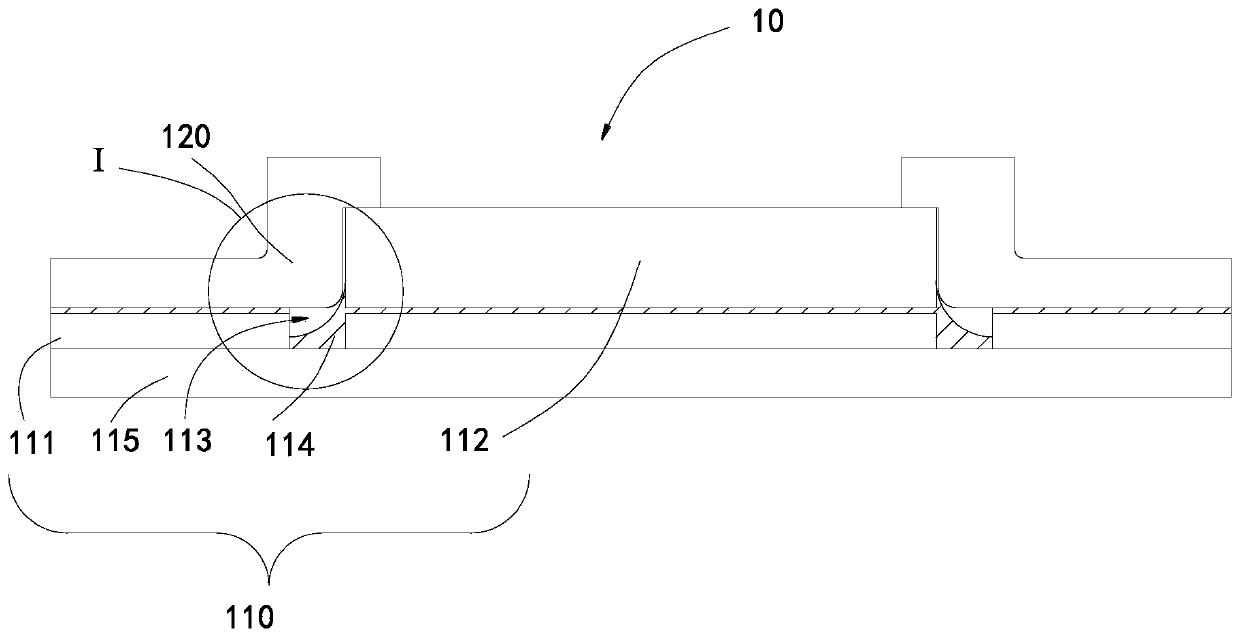

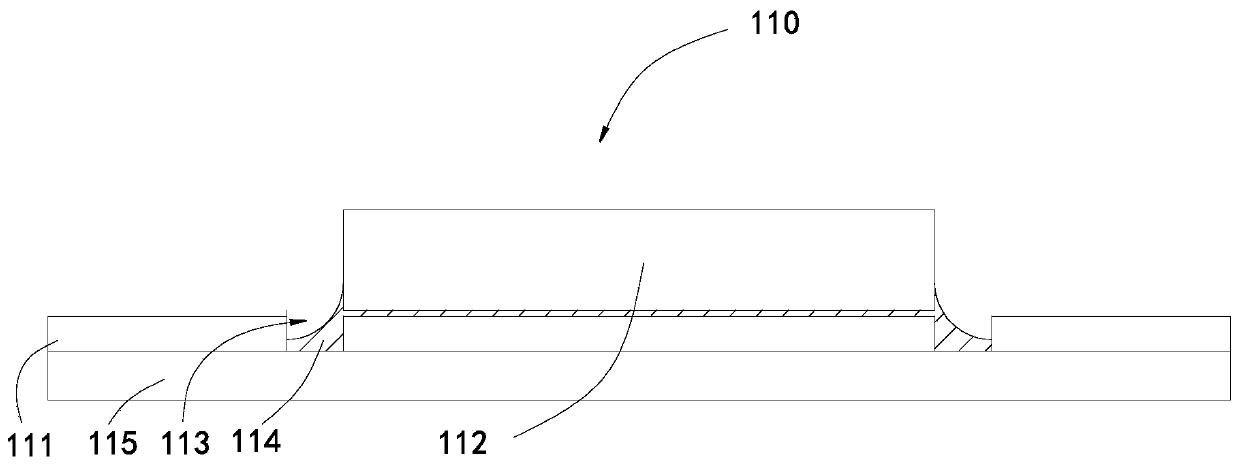

Circuit board, electronic device and packaging method

ActiveCN107613644BViscous stabilityReduce volumePrinted circuit non-printed electric components associationSemiconductor packageElectronic component

The embodiment of the invention provides a circuit board, electronic equipment and a package method, belongs to the field of semiconductor package. The circuit board comprises a substrate, wherein aninstallation surface of the substrate comprises an installation region, an electronic component is arranged on the installation region, a groove is formed in boundary of the installation region and isfilled with filling glue, a part of filling glue is arranged in the groove, and the other part of filling glue is exposed out of the installation surface and is in contact with the electronic component. A cover body of the electronic equipment is arranged at an opening of the groove, and the bending radius of a bending part is smaller than the width of the groove. A part of filling glue is arranged in the groove, the other part of filling glue is exposed out of the installation surface, the volume of the filling glue arranged on a surface of the substrate also can be reduced, thus, the volumeof the cover body can be further reduced, and the volume of the electronic equipment is reduced; and moreover, the bending part of the cover body is arranged at the opening of the groove, the volumeof the bending part of the cover body can be not too small, and insufficient strength of the bending part caused by excessively small volume of the bending part is prevented.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

Environmental-friendly protection film for automobile

ActiveCN101928527BImprove bindingChemically resistantFilm/foil adhesivesSynthetic resin layered productsUltravioletEngineering

The invention provides an environmental-friendly protection film for an automobile. The environmental-friendly protection film is produced by co-extruding and casting an external layer, a middle layer and a bonding layer according to a certain thickness proportion to obtain a white protection film with the thickness of 40 to 100 micron. The environmental-friendly protection film mainly has the functions of dust prevention, mechanical damage prevention, ultraviolet prevention, bird dung pollution prevention, scraping prevention, oil pollution prevention, acid and alkali corrosion resistance, solvent corrosion resistance and the like.

Owner:安徽双津实业有限公司

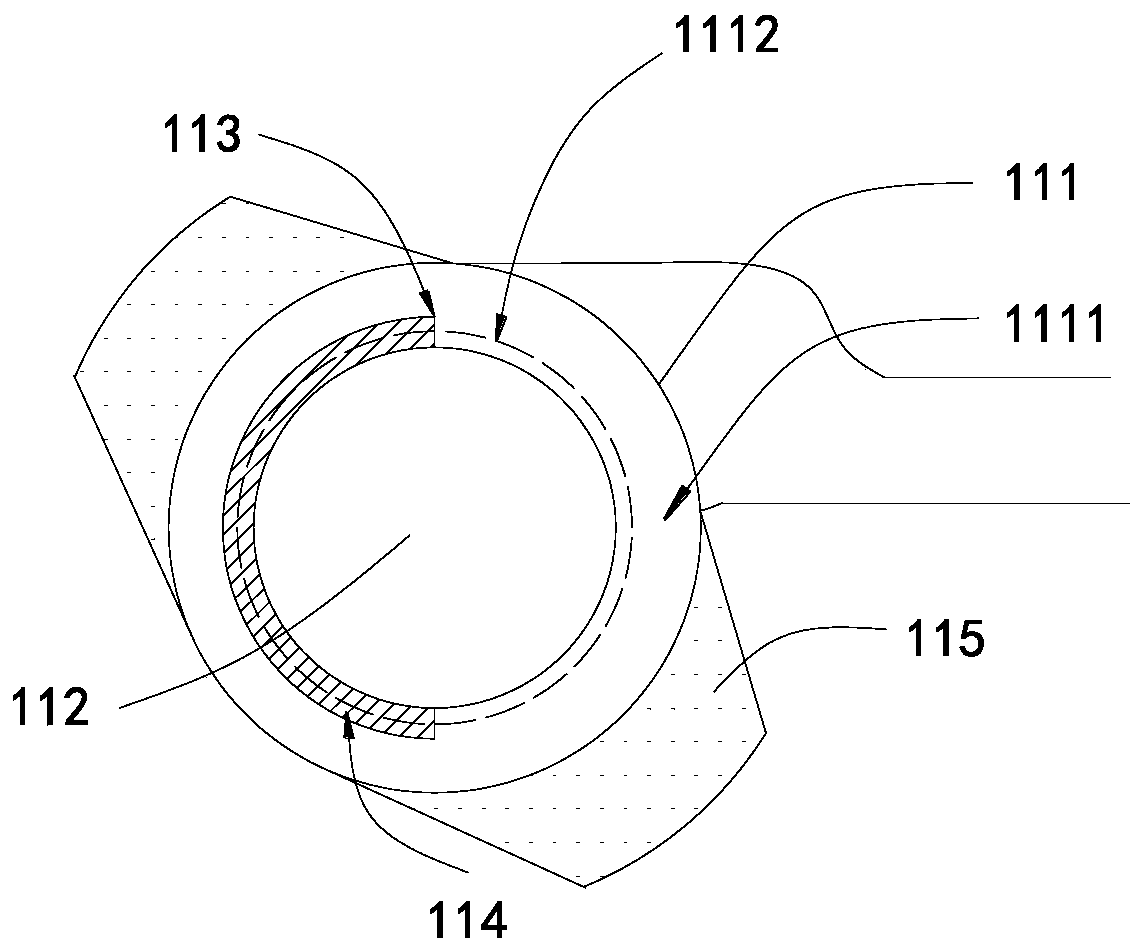

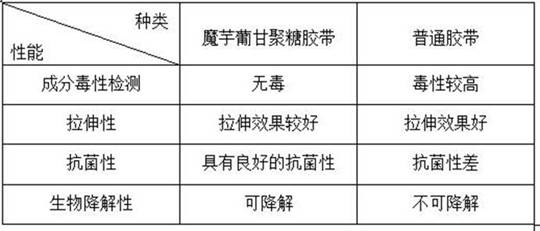

A kind of food-grade konjac glucomannan adhesive tape and preparation method thereof

ActiveCN108893069BHigh transparencyBiodegradableFilm/foil adhesivesPolysaccharide adhesivesPolymer scienceFood grade

The invention relates to a food grade konjac glucomannan adhesive tape and a preparation method thereof. The food grade konjac glucomannan adhesive tape contains an adhesive tape base material and glue sol. The preparation method comprises the following steps: preparing dissolved corn protein, dissolved nano-cellulose and mixed sol, preparing base material layer sol and the adhesive tape base material, preparing the glue sol, and preparing the food grade konjac glucomannan adhesive tape. The food grade konjac glucomannan adhesive tape has the functions of common glue and further has the characteristics that the transparency is high, the adhesive tape can be in direct contact with foods and can be degraded, and the like. Meanwhile, the change of the adhesion strength along the changes of the temperature and the time is relatively small, the adhesive tape has relatively good adhesion stability and does not have adhesive residue. The adhesive tape further has a certain waterproof functionand still has relatively good adhesive property under a relatively high humidity.

Owner:FUJIAN AGRI & FORESTRY UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com