Acrylic protective film for aluminum-plastic film manufacturing process and preparation method of acrylic protective film

A technology of acrylic and aluminum-plastic film, applied in the direction of film/sheet adhesive, adhesive type, coating, etc., to achieve the effect of reducing the degree of crosslinking, stable viscosity, and high wettability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

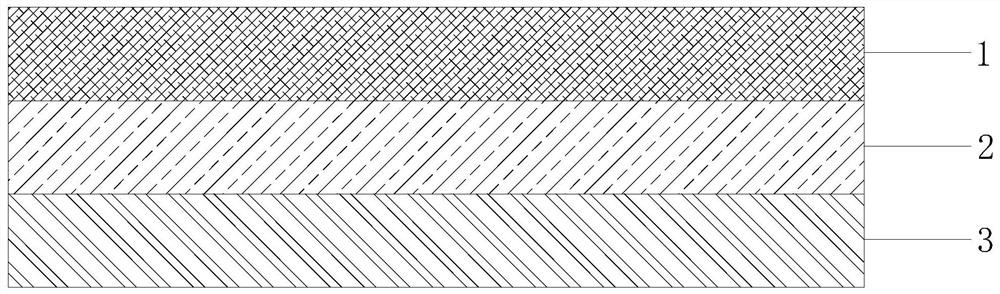

[0026] An acrylic protective film for aluminum-plastic film manufacturing process, comprising an antistatic layer 1, a substrate layer 2 and an adhesive layer 3, the antistatic layer 1 and the adhesive layer 3 are respectively coated on both sides of the substrate layer 2, The antistatic layer 1 is obtained by coating an antistatic agent on the substrate layer 2 and drying it. The antistatic agent adopts a polythiophene system with an impedance of 10 4 ~10 10 Ω, with a thickness of 0.5 μm, the substrate layer 2 is made of PET material, with a thickness of 36 μm;

[0027] The adhesive layer 3 is obtained by coating the substrate layer 2 with an acid-free acrylic adhesive and drying it. The acid-free acrylic adhesive includes the following components in parts by weight:

[0028] Acid-free acrylic resin: 100 parts;

[0029] Toluene diisocyanate curing agent: 1.0 parts;

[0030] Isooctyl myristate: 2 parts;

[0031] Fluorine additive: 0.3 parts;

[0032] Add ethyl acetate sol...

Embodiment 2

[0039] An acrylic protective film for aluminum-plastic film manufacturing process, comprising an antistatic layer 1, a substrate layer 2 and an adhesive layer 3, the antistatic layer 1 and the adhesive layer 3 are respectively coated on both sides of the substrate layer 2, The antistatic layer 1 is obtained by coating an antistatic agent on the substrate layer 2 and drying it. The antistatic agent adopts a polythiophene system with an impedance of 10 4 ~10 10 Ω, with a thickness of 0.5 μm, the substrate layer 2 is made of PET material, with a thickness of 45 μm;

[0040] The adhesive layer 3 is obtained by coating the substrate layer 2 with an acid-free acrylic adhesive and drying it. The acid-free acrylic adhesive includes the following components in parts by weight:

[0041] Acid-free acrylic resin: 100 parts;

[0042] Toluene diisocyanate curing agent: 1.2 parts;

[0043] Isooctyl myristate: 2 parts;

[0044] Fluorine additive: 0.3 parts;

[0045] Add ethyl acetate sol...

Embodiment 3

[0052] An acrylic protective film for aluminum-plastic film manufacturing process, comprising an antistatic layer 1, a substrate layer 2 and an adhesive layer 3, the antistatic layer 1 and the adhesive layer 3 are respectively coated on both sides of the substrate layer 2, The antistatic layer 1 is obtained by coating an antistatic agent on the substrate layer 2 and drying it. The antistatic agent adopts a polythiophene system with an impedance of 10 4 ~10 10 Ω, with a thickness of 0.6 μm, the substrate layer 2 is made of PET material, with a thickness of 25 μm;

[0053] The adhesive layer 3 is obtained by coating the substrate layer 2 with an acid-free acrylic adhesive and drying it. The acid-free acrylic adhesive includes the following components in parts by weight:

[0054] Acid-free acrylic resin: 100 parts;

[0055] Toluene diisocyanate curing agent: 1.0 parts;

[0056] Isooctyl myristate: 2 parts;

[0057] Silicone leveling agent: 0.2 parts;

[0058] Add ethyl aceta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| impedance | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com