Preparation method of high heat-resistant antibacterial toy paint

A technology with high heat resistance and toys, applied in the direction of antifouling/underwater coatings, coatings, paints containing biocides, etc., can solve the problems of poor antibacterial performance, poor heat resistance, poor adhesion, etc., to achieve improved Adhesive effect, improvement of antibacterial performance, and effect of improving the degree of decomposition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

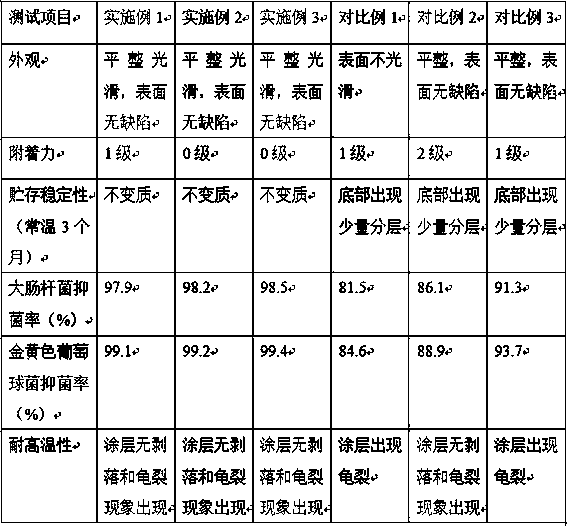

Examples

Embodiment 1

[0031] Preparation of solid-liquid mixture:

[0032] Put aloe vera leaves and rice leaves into an oven at a mass ratio of 1:3, dry for 2 hours at a temperature of 90°C, and put them into a planetary ball mill after drying at a speed of 80r / min and a ball-to-material ratio of 5:1. Grinding for 3 hours to obtain the grinding product, put the grinding product and hydrochloric acid with a mass fraction of 10% into a beaker at a mass ratio of 1:10, and let stand at room temperature for 2 hours to obtain a solid-liquid mixture.

[0033] Preparation of the reaction mixture:

[0034] Place the above beaker in an ultrasonic oscillator, vibrate for 3 hours at a frequency of 36 kHz to obtain an oscillation product, filter the oscillation product to obtain a filter residue, wash the filter residue with distilled water for 3 times, and put the filter residue and distilled water into the reaction at a mass ratio of 1:5 In the still, the closed reaction kettle was filled with nitrogen into ...

Embodiment 2

[0044] Preparation of solid-liquid mixture:

[0045] Put aloe vera leaves and rice leaves into an oven at a mass ratio of 1:3, dry for 2 hours at a temperature of 95°C, and put them into a planetary ball mill after drying at a speed of 90r / min and a ball-to-material ratio of 5:1. Grinding for 3 hours to obtain the grinding product, put the grinding product and hydrochloric acid with a mass fraction of 11% into a beaker at a mass ratio of 1:10, and let stand at room temperature for 2 hours to obtain a solid-liquid mixture.

[0046] Preparation of the reaction mixture:

[0047] Place the above beaker in an ultrasonic oscillator, vibrate for 3 hours at a frequency of 38 kHz to obtain an oscillation product, filter the oscillation product to obtain a filter residue, wash the filter residue with distilled water 4 times, and put the filter residue and distilled water into the reaction at a mass ratio of 1:5 In the still, the closed reaction kettle was filled with nitrogen into the ...

Embodiment 3

[0057] Preparation of solid-liquid mixture:

[0058] Put aloe leaves and rice leaves into an oven at a mass ratio of 1:3, dry for 3 hours at a temperature of 100°C, and put them into a planetary ball mill after drying at a speed of 100r / min and a ball-to-material ratio of 5:1. Grind for 4 hours to obtain a grinding product, put the grinding product and 12% hydrochloric acid in a mass ratio of 1:10 into a beaker, and let stand at room temperature for 3 hours to obtain a solid-liquid mixture.

[0059] Preparation of the reaction mixture:

[0060] Place the above beaker in an ultrasonic oscillator, vibrate for 4 hours at a frequency of 40 kHz to obtain an oscillation product, filter the oscillation product to obtain a filter residue, wash the filter residue with distilled water for 5 times, and put the filter residue and distilled water into the reaction at a mass ratio of 1:5 In the still, the closed reaction kettle was filled with nitrogen into the reaction kettle, the pressur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com