UV viscosity-reducing adhesive film applied to PVC substrate and used for film reversion of semiconductor chip, and preparation method thereof

A semiconductor and adhesive film technology, which is applied in the field of PVC substrate UV adhesive film and its preparation, can solve the problems of residual adhesive in UV film, influence of UV adhesive stability, unstable product viscosity, etc., to achieve stable viscosity, The effect of high crosslink density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

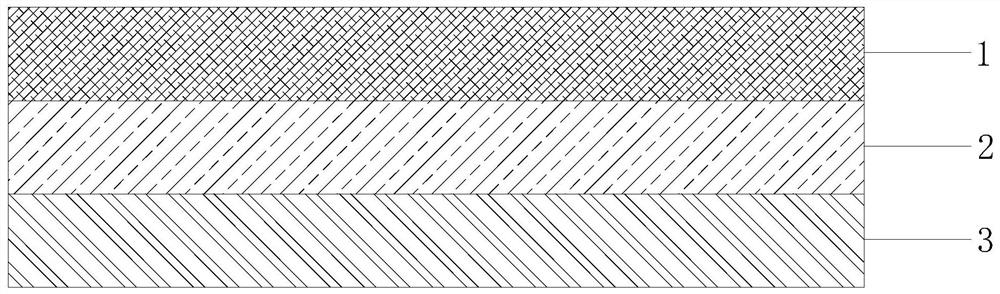

[0031] Embodiment 1: as figure 1 Shown, a kind of PVC base material UV viscous-reducing adhesive film that is used for semiconductor chip inverted film, comprises base material layer 1, adhesive layer 2 and release film layer 3, and described adhesive layer 2 is positioned at base material layer 1 and release type Between layers 3, the substrate layer 1 is preferably a 70 μm PVC film, the release film layer 3 is a PET monosilicon release film with a thickness of 36 μm, and a release force of 15g / 25mm. Cloth is prepared by drying on the substrate layer 1, and the UV visbreaking glue includes the following components in parts by weight:

[0032] Acrylic glue 70 parts, UV monomer or oligomer 30 parts, curing agent 1.5 parts, photoinitiator 1.2 parts, plasticizer: 5 parts;

[0033] Wherein acrylic glue comprises following components by weight:

[0034] 80 parts of butyl acrylate, 10 parts of vinyl acetate, 6 parts of acrylic acid, 0.2 part of hydroxyethyl methacrylate, 0.5 part ...

Embodiment 2

[0043] like figure 1 Shown, a kind of PVC base material UV viscous-reducing adhesive film that is used for semiconductor chip inverted film, comprises base material layer 1, adhesive layer 2 and release film layer 3, and described adhesive layer 2 is positioned at base material layer 1 and release type Between layers 3, the substrate layer 1 is preferably a 70 μm PVC film, the release film layer 3 is a PET monosilicon release film with a thickness of 36 μm, and a release force of 20g / 25mm, and the adhesive layer 2 is UV viscous-reducing glue Coated on the substrate layer 1 and dried, the UV visbreaking glue includes the following components in parts by weight:

[0044] 60 parts of acrylic glue, 25 parts of UV monomer or oligomer, 0.9 parts of curing agent, 1.4 parts of photoinitiator, and 2 parts of plasticizer;

[0045] Wherein acrylic glue comprises following components by weight:

[0046] 70 parts of butyl acrylate, 5 parts of vinyl acetate, 3 parts of acrylic acid, 1 par...

Embodiment 3

[0055] like figure 1 Shown, a kind of PVC base material UV viscous-reducing adhesive film that is used for semiconductor chip inverted film, comprises base material layer 1, adhesive layer 2 and release film layer 3, and described adhesive layer 2 is positioned at base material layer 1 and release type Between layers 3, the substrate layer 1 is preferably a 70 μm PVC film, the release film layer 3 is a PET monosilicon release film with a thickness of 36 μm, and a release force of 10g / 25mm, and the adhesive layer 2 is UV viscous-reducing glue Coated on the substrate layer 1 and dried, the UV visbreaking glue includes the following components in parts by weight:

[0056] 70 parts of acrylic glue, 20 parts of UV monomer or oligomer, 2 parts of curing agent, 0.5 part of photoinitiator, and 10 parts of plasticizer;

[0057] Wherein acrylic glue comprises following components by weight:

[0058] 60 parts of butyl acrylate, 2 parts of vinyl acetate, 1 part of acrylic acid, 2 parts ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com